Substrate bearing device and detection device

A technology for carrying devices and substrates, which is used in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., which can solve the problem of poor repeatability, difficulty in locking the manipulator, and difficulty in ensuring that the manipulator can reach the exact same measurement station. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

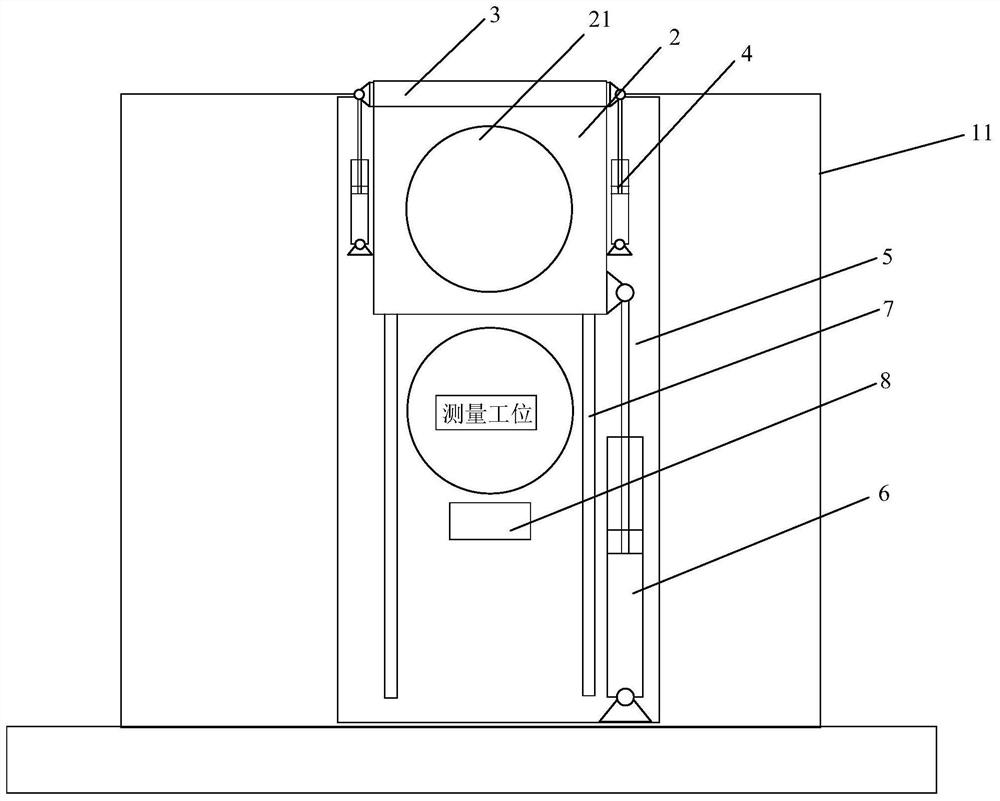

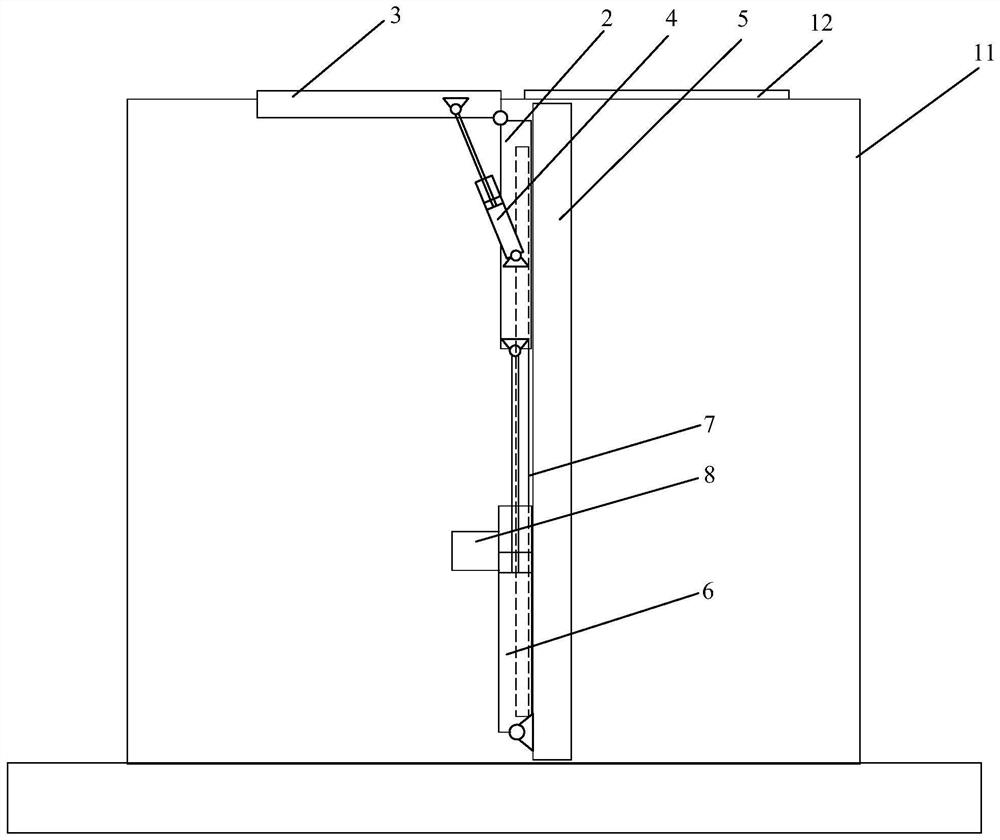

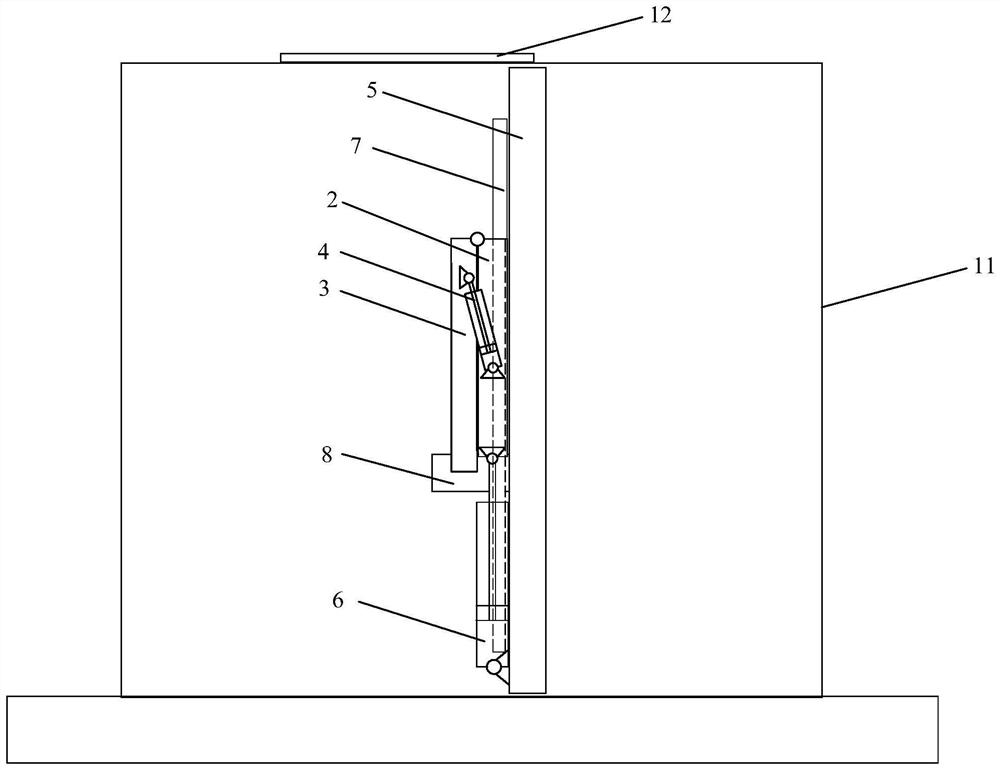

[0061] figure 1 and figure 2 It is a schematic diagram of the internal structure of the substrate carrying device under the first viewing angle and the second viewing angle when the carrier is in a horizontal posture, as shown in Figure 1-Figure 2 As shown, the substrate carrying device includes a cavity 11 , a mounting plate 2 and a stage 3 . Wherein, an opening is provided on the top of the cavity 11 , the mounting plate 2 is disposed inside the cavity 11 , the stage 3 is used to clamp the substrate 100 , and the stage 3 is rotatably matched with the mounting plate 2 . The platform 3 can be selectively turned over to a horizontal position and at least partly protrudes from the cavity 11 from the opening of the cavity 11 , or turned over to a vertical position and completely accommodated in the cavity 11 .

[0062] When the substrate carrying device of this embodiment is in use, the vacant stage 3 is turned over to a horizontal posture first, and at this time, the stage 3...

Embodiment 2

[0080] The overturning process of the stage 3 requires a certain space. If the position after the stage 3 rotates the substrate 100 to a vertical posture is the measurement station, then the measurement component cannot be set at a position closer to the measurement station. A measurement component is set near the station. In order to achieve measurement, the measurement component needs to move to other positions for avoidance before the stage 3 rotates. When the stage 3 moves to the measurement station with the substrate 100, the measurement component returns to the measurement station. Measurement near the position, that is, every time a substrate is measured, the measurement component needs to perform avoidance and return movements, which will not only lead to low measurement efficiency, but also have an adverse effect on the focusing function of the measurement component if the measurement component is an optical measurement component. In addition, in actual production, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com