Pipe fitting stamping-necking die

A technology for pipe fittings and molds, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of complex clamping structure of pipe fittings, easy deformation of pipe fittings, etc., to avoid movement, reduce the possibility of deformation, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

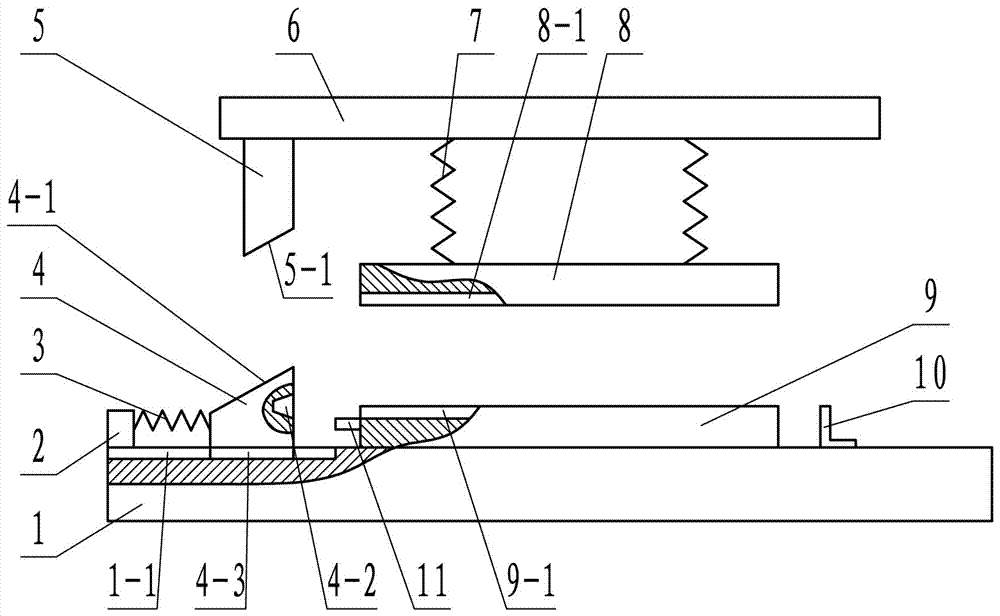

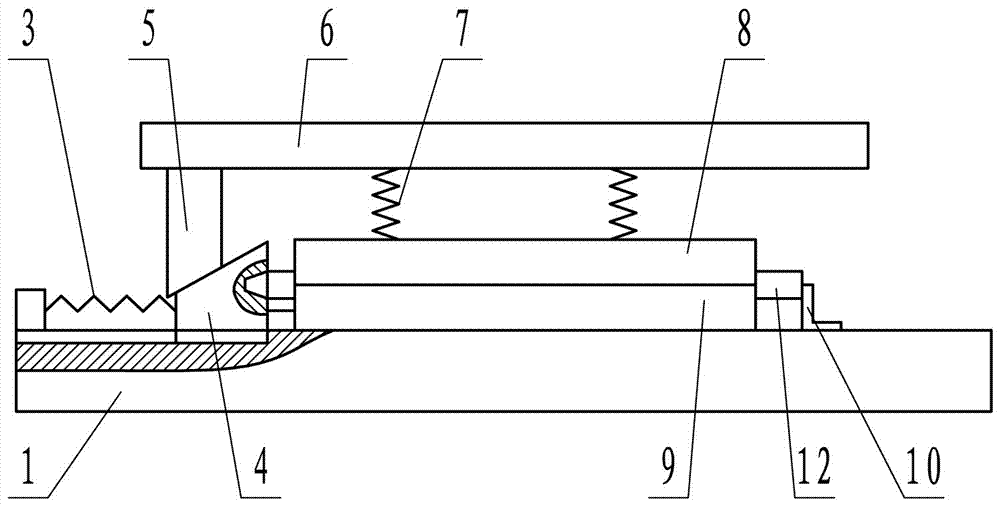

[0015] figure 1 and figure 2 The pipe fitting punching die shown mainly includes a lower die base 1, a fixed plate 2, a first spring 3, a sliding die 4, a wedge 5, an upper die 6, a second spring 7, a pressure block 8, a support block 9 and Adjust the limit plate 10. On the lower mold base 1, a fixed plate 2, a sliding die 4, a support block 9 and an adjustment limit plate 10 are sequentially arranged along the length direction, the fixed plate 1 and the support block 9 are fixed on the lower die base 1, and the sliding die 4 and The lower mold base 1 is slidingly fitted, and the adjustment limit plate 10 is connected and fixed with the lower mold base 1 by bolts. One end of the sliding die 4 is connected to the fixed plate 1 through the first spring 3, and the other end is provided with a necking cavity 4-2, and the necking cavity 4-2 is arranged f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com