Method and device for fired intermediate overheating during direct solar vapourisation in a solar thermal power station

A technology of solar energy and thermal power plants, applied in the field of solar thermal power plant equipment, can solve problems such as pressure loss and inappropriateness, and achieve the effects of high process temperature, high concentration effect, and high process maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

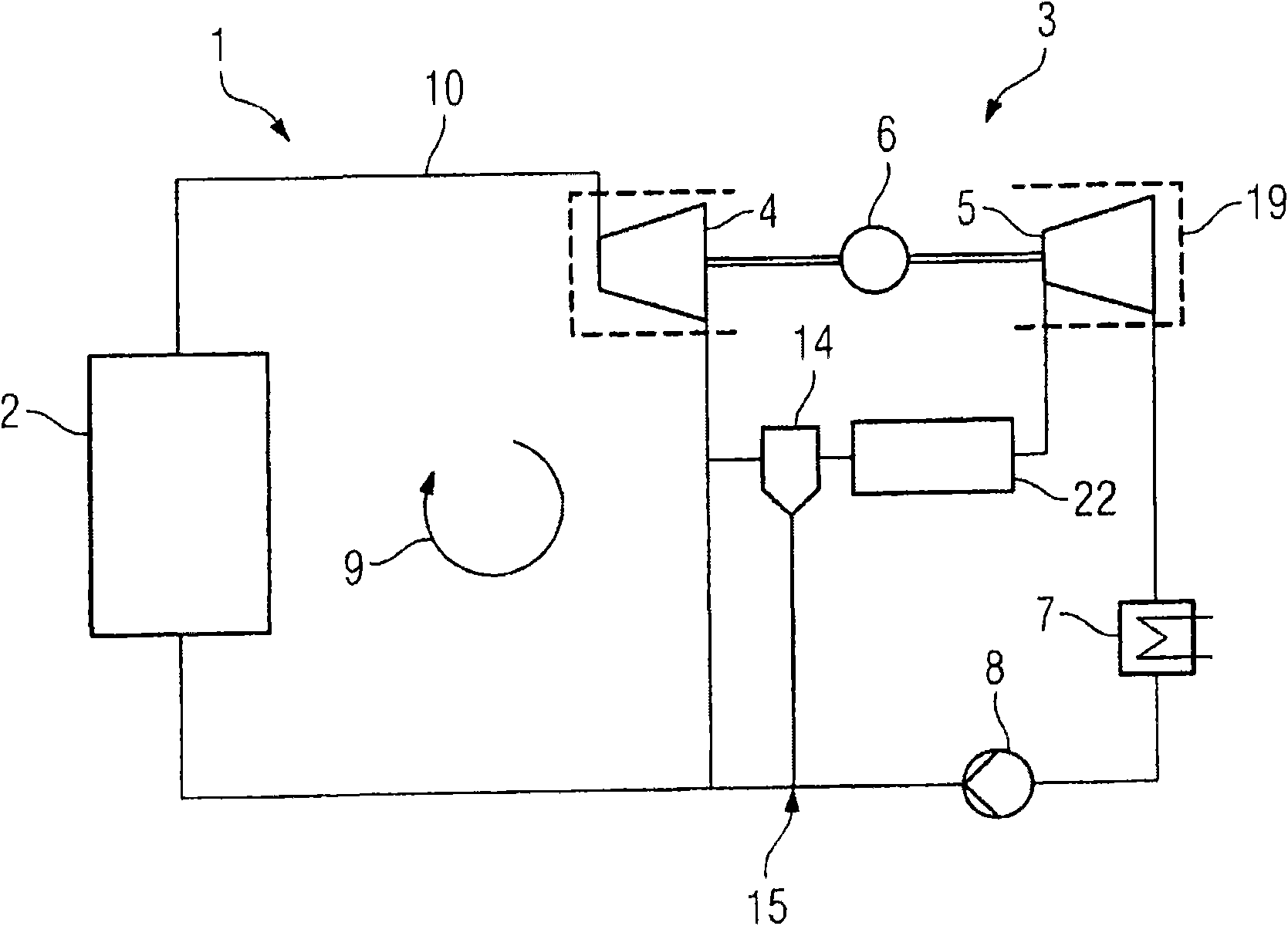

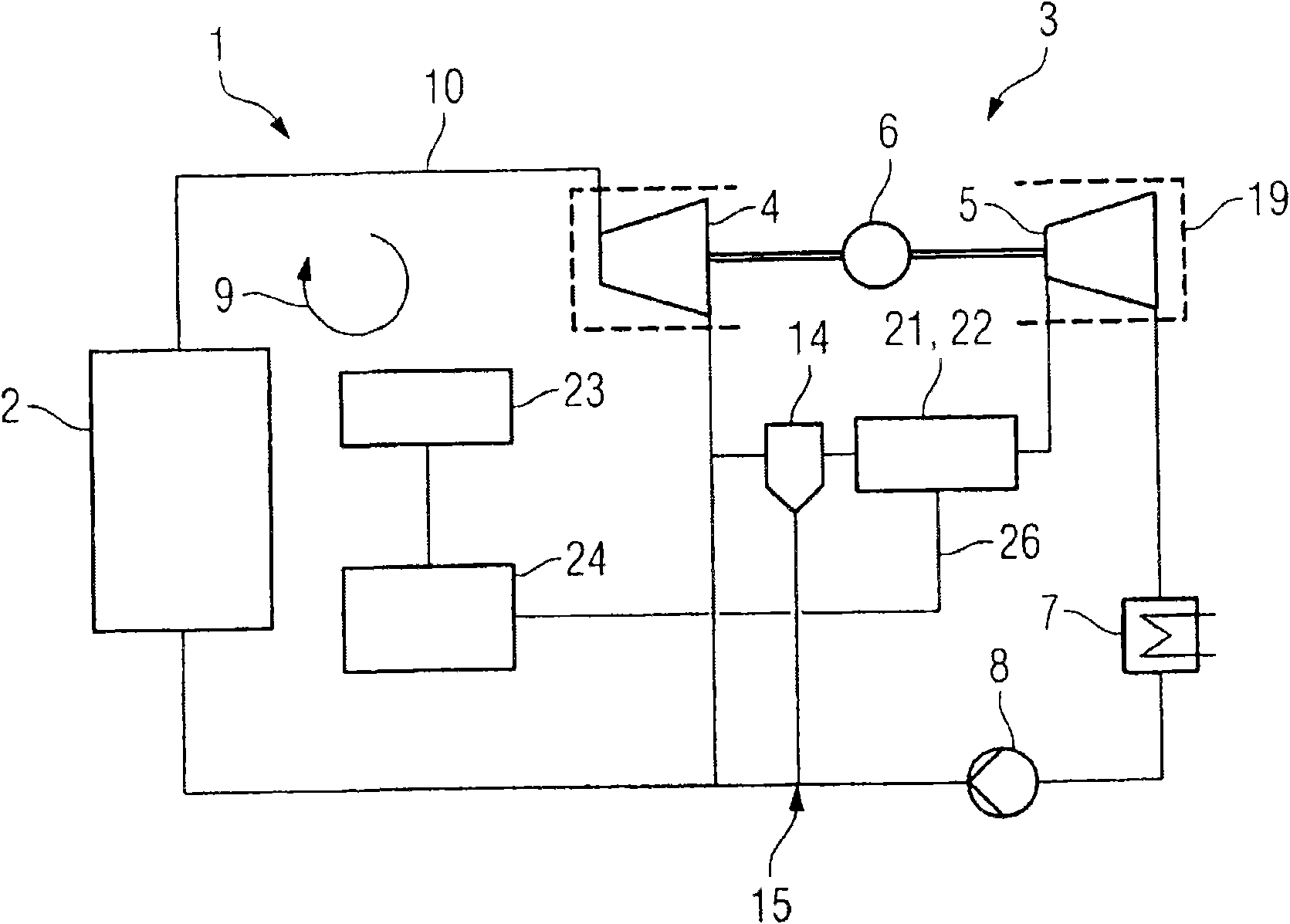

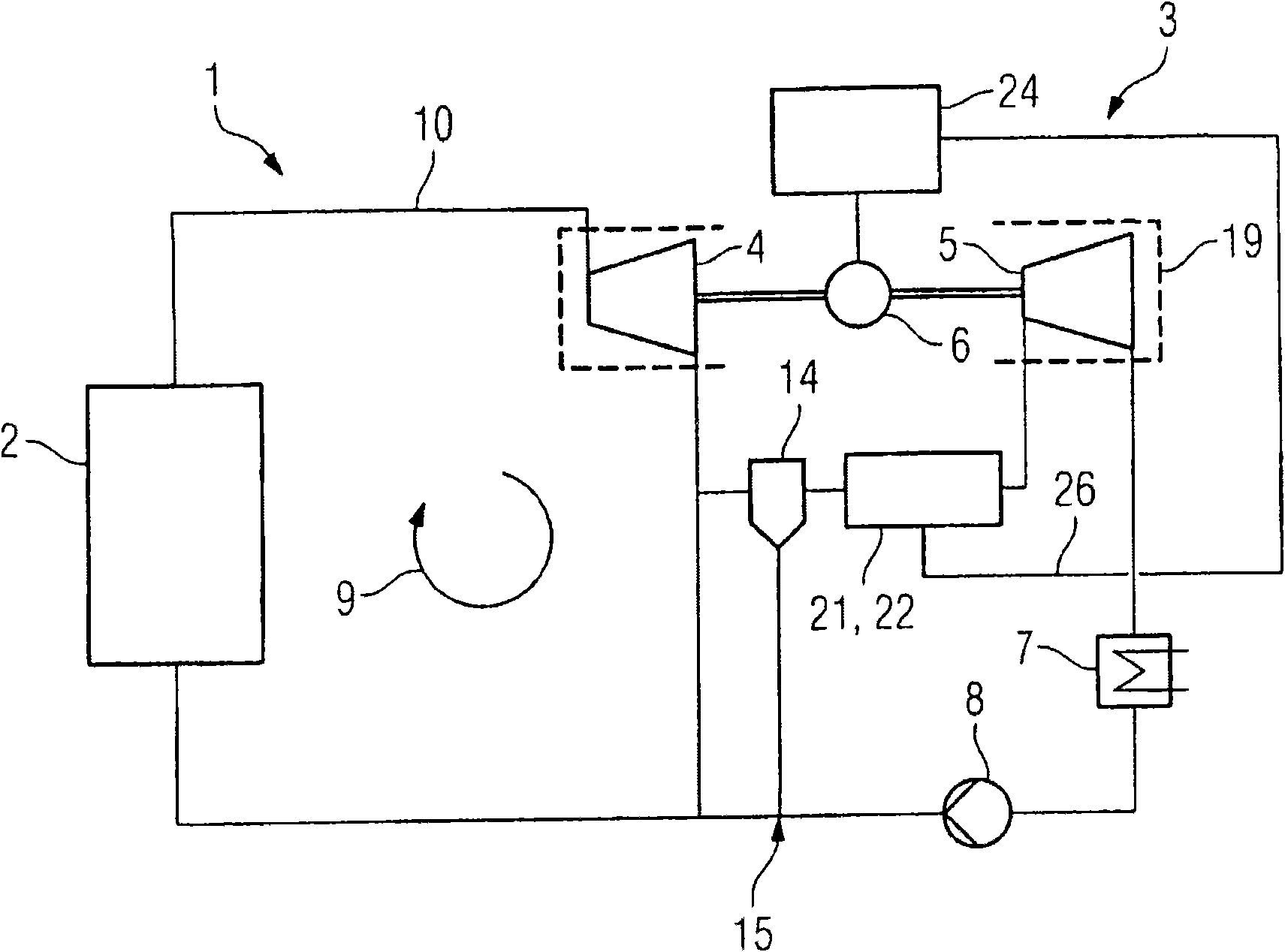

[0036] figure 1 The structure and cycle of a solar thermal power plant 1 with direct vaporization according to the invention are schematically shown. The plant 1 comprises a solar harvesting field 2 in which sunlight is collected and converted into heat energy and may for example have parabolic trough collectors, solar towers or Fresnel collectors. The collected sunlight is delivered to the heat transfer medium, which is vaporized and introduced as a working fluid through the live steam line 10 into the expansion section 19 consisting of the steam turbine 3 , for example. The steam turbine 3 includes a high-pressure turbine 4 and a low-pressure turbine 5 , which drive a generator 6 . The working fluid is expanded in the steam turbine 3 and subsequently liquefied in the condenser 7 . The feed water pump 8 pumps the liquefied heat transfer medium back to the solar collection field 2 , thus closing the heat transfer medium or working fluid circuit 9 .

[0037] according to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com