Purification method for oilfield reinjection water

A technology for oil field re-injection and refining method, which is applied in the field of oil-field re-injection water refining and oily sewage treatment. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] 1. Pretreatment of oilfield produced water

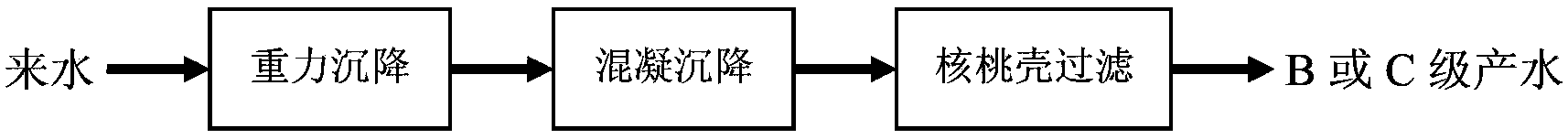

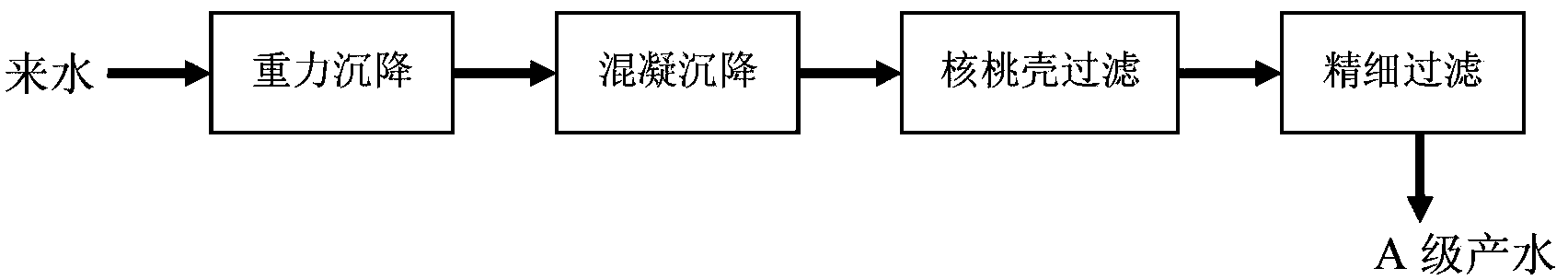

[0137] The oilfield produced water is subjected to gravity sedimentation treatment, coagulation sedimentation treatment and walnut shell filtration treatment in sequence, that is, the traditional "three sets of" treatment process is used to pretreat the oilfield produced water to remove oil and impurities to obtain pretreated water flow , the water quality of the pretreated water flow, that is, the influent water quality of the first-stage membrane filtration treatment, is shown in Table 1.

[0138] 2. Membrane filtration treatment

[0139] In the present embodiment, the main body 11 of the carrier-type carbon membrane membrane core is provided with 1480 filter channels 12 and water production channels 13 with a square cross section. The side lengths of the filter channels 12 and water production channels 13 are 2 mm, as Figure 5 , 6 , 7 shown. The main body 1 of the membrane core of the embodiment of the present inventio...

Embodiment 2

[0147] 1. Pretreatment of oilfield produced water

[0148] The oilfield produced water is subjected to gravity sedimentation treatment, coagulation sedimentation treatment and walnut shell filtration treatment in sequence, that is, the traditional "three sets of" treatment process is used to pretreat the oilfield produced water to remove oil and impurities to obtain pretreated water flow , the water quality of the pretreated water flow, that is, the influent water quality of the first-stage membrane filtration treatment, is shown in Table 2.

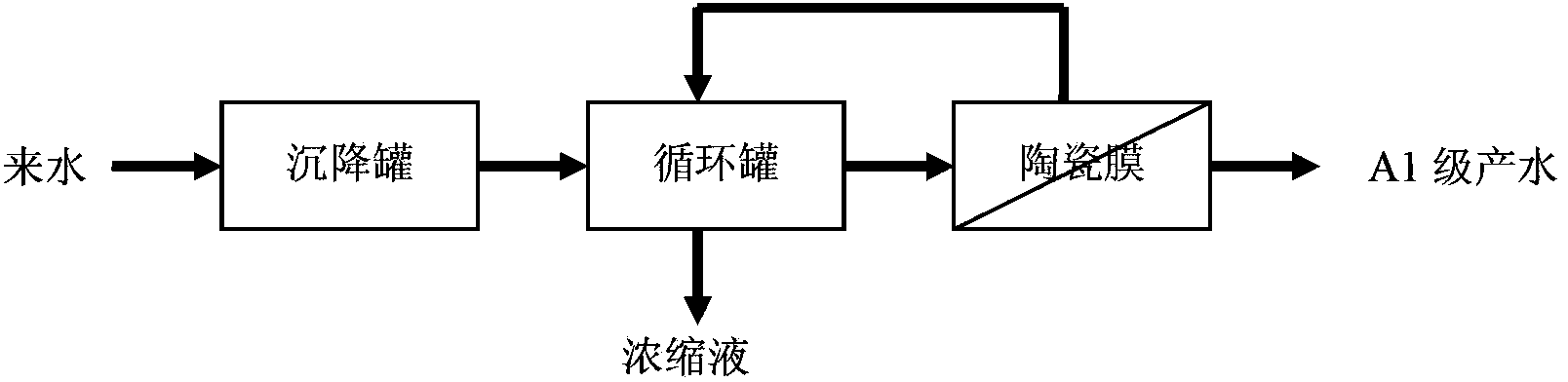

[0149] 2. Membrane filtration treatment

[0150] The pretreatment water flows into the first-stage membrane module through the water inlet pipe 5, and the first-stage membrane filtration treatment is performed in a cross-flow manner, wherein, in addition to controlling the inlet water pressure of the first-stage membrane filtration treatment to 0.4MPa, adjusting the concentration from the concentrated water outlet pipe 6 Outflow concent...

Embodiment 3

[0156] In addition to the pretreatment water quality, which is the influent water quality of the first-stage membrane filtration treatment; the first-stage filtration inlet water pressure is 0.43MPa, the concentrated water pressure is 0.35MPa, the product water pressure is 0.2MPa, and the transmembrane pressure difference is 0.19MPa; The inlet water pressure of the secondary filtration is 0.2MPa, the concentrated water pressure is 0.18MPa, the product water pressure is 0.12MPa, and the transmembrane pressure difference is 0.07MPa, and the rest are the same as in Example 2. Table 3 shows the water quality of the pretreated water and the water quality after the secondary membrane filtration treatment.

[0157] Table 3 embodiment 3 water quality analysis results

[0158] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com