Patents

Literature

54results about How to "Control current size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

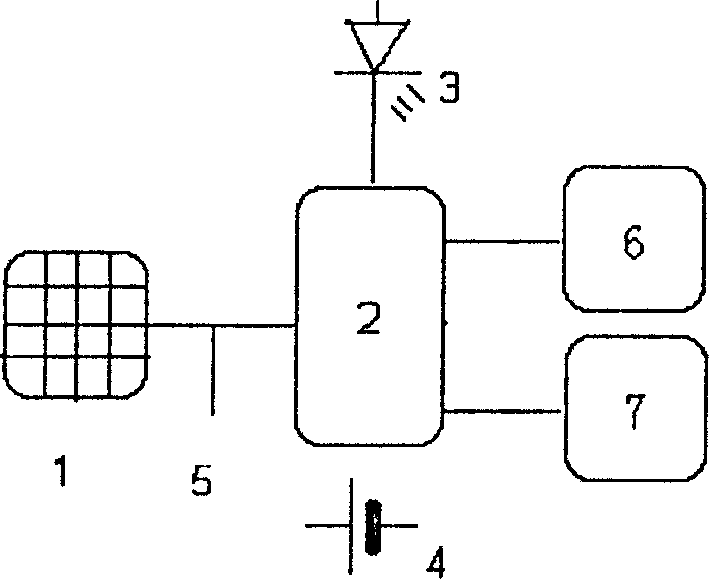

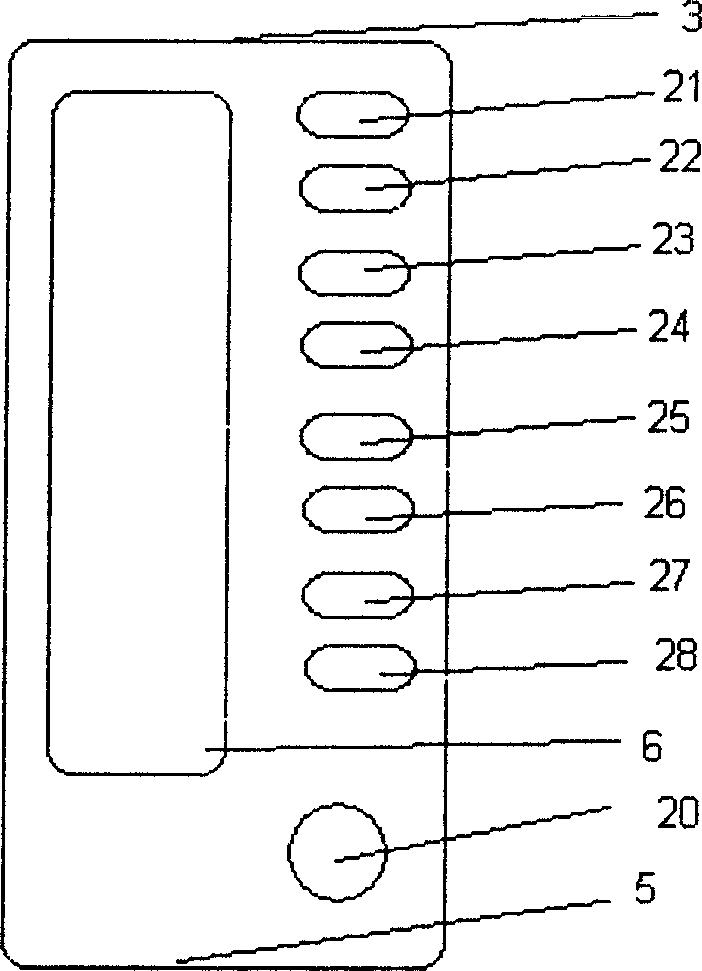

Remote control method of LED decorative illuminating light

InactiveCN1909008ARealize digital controlReduce volumeNon-electrical signal transmission systemsElectric light circuit arrangementInfraredControl manner

The related control method for LED used as decorative lighting lamp comprises: applying IR technology to remote control the LED, using MCU or ASIC to code or random control signal, arranging an external analog electric signal input interface and pre-set remote control coding data memory, using embedded-MPU to receive signal and generate digital PWC signal to control RGB current of every LED. This invention is benefit to build individual dynamic lighting atmosphere.

Owner:NANJING HANDSON SCI & TECH CORP

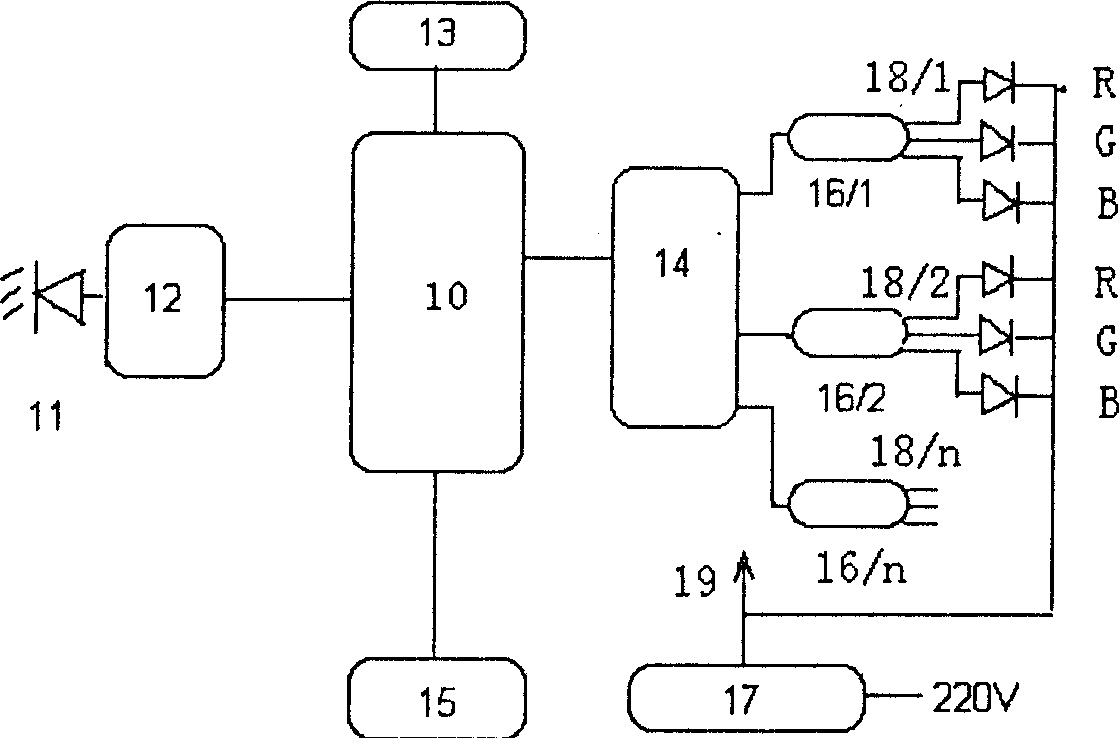

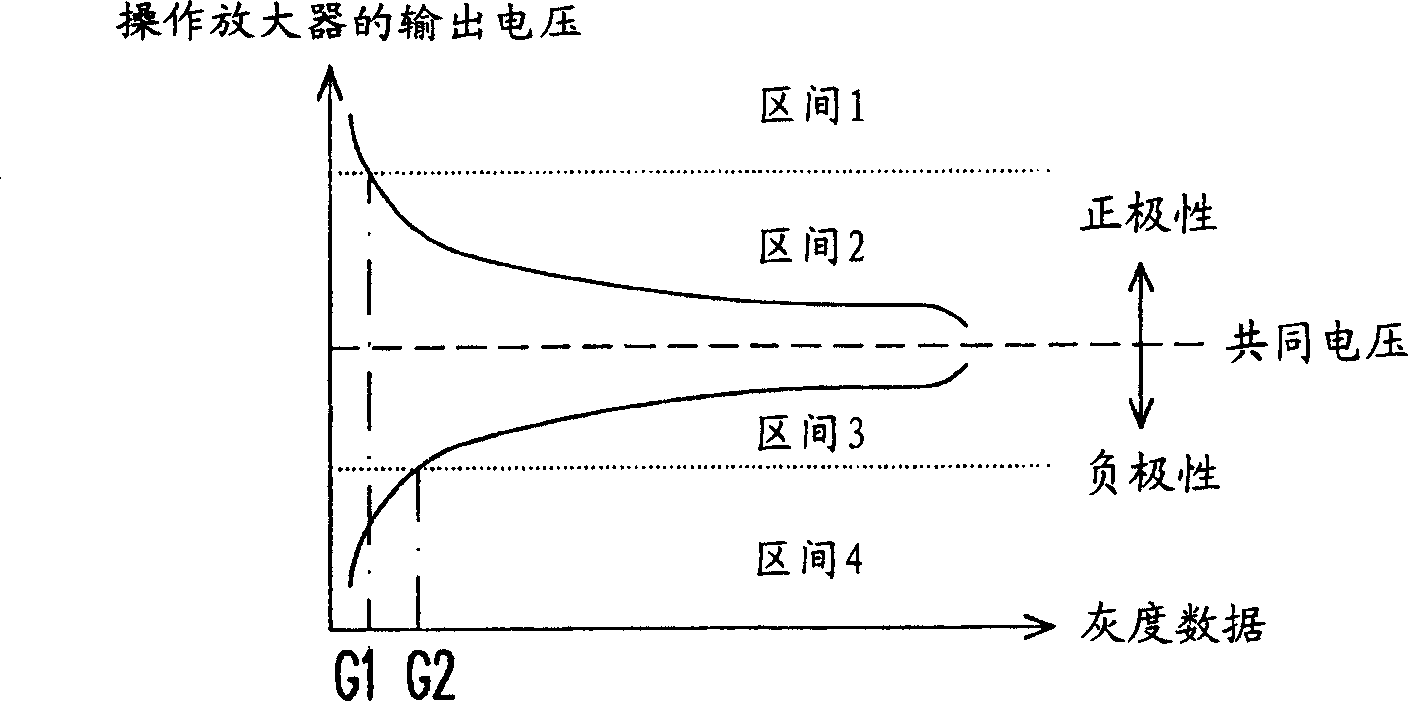

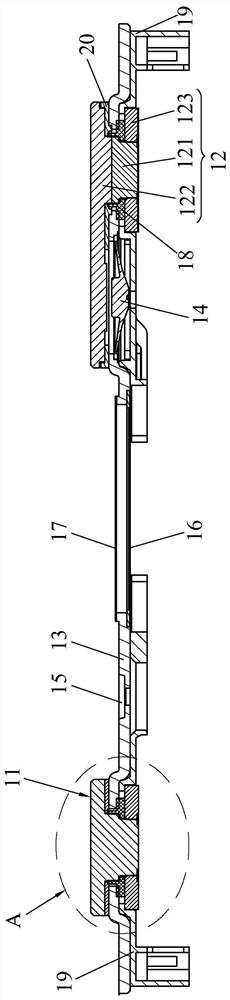

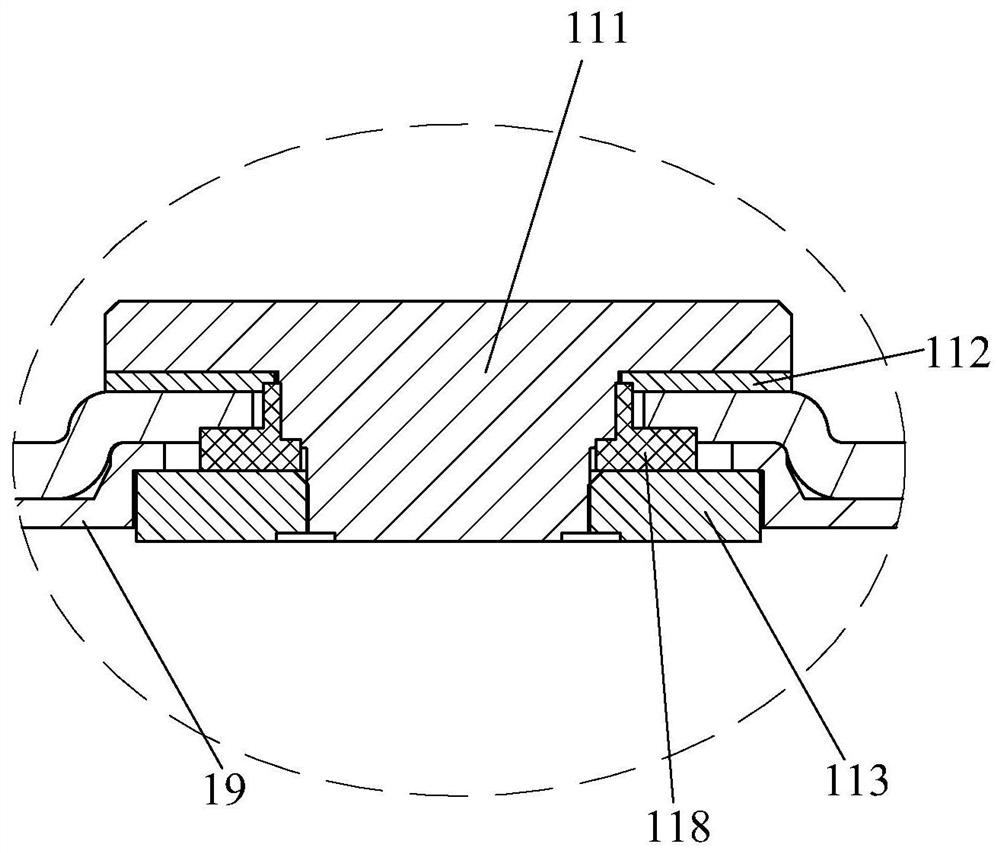

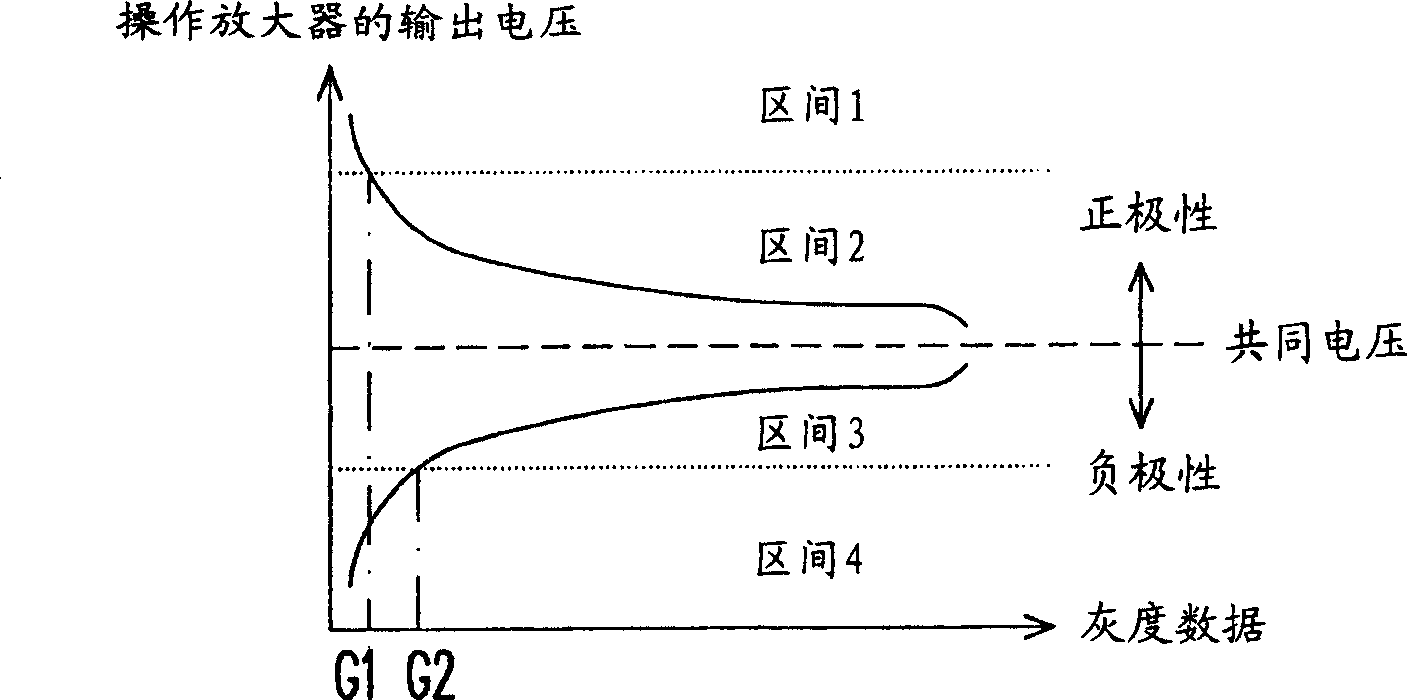

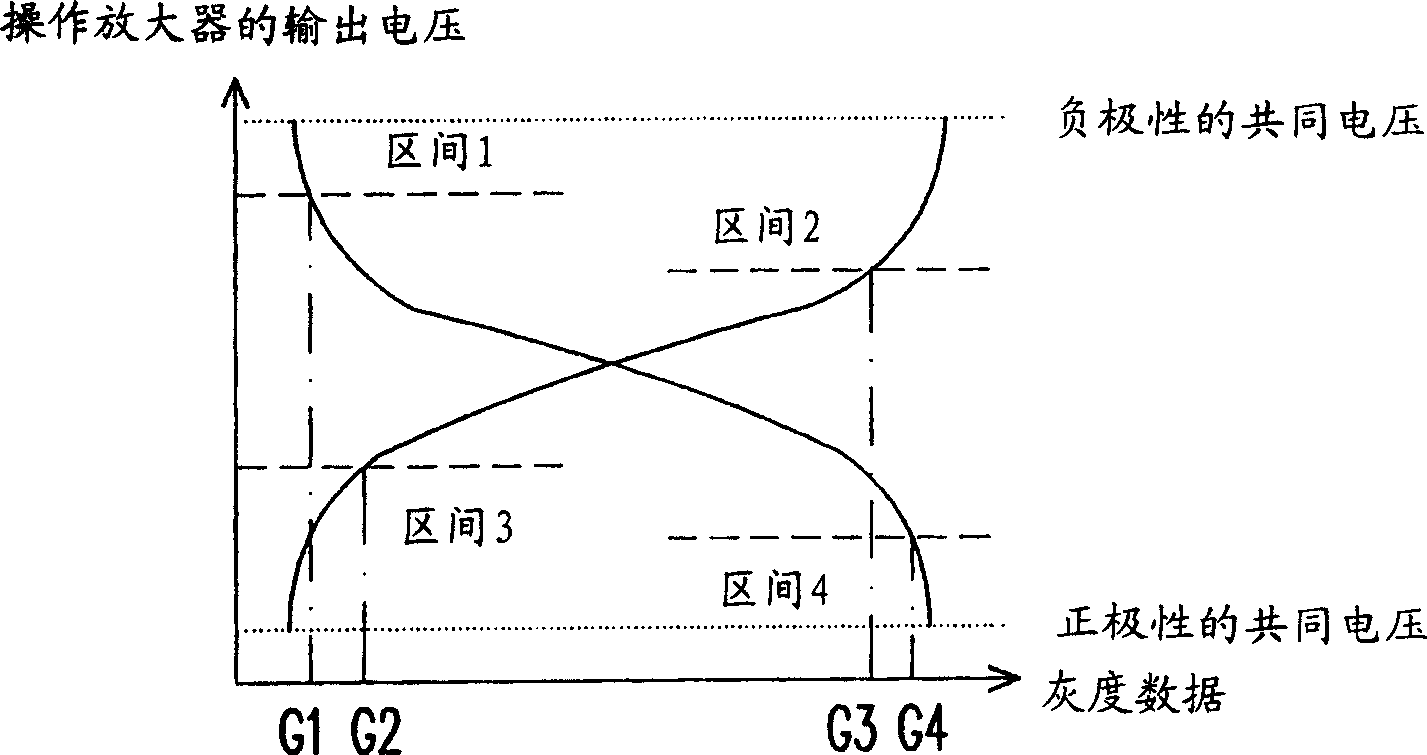

Driving device and driving method thereof

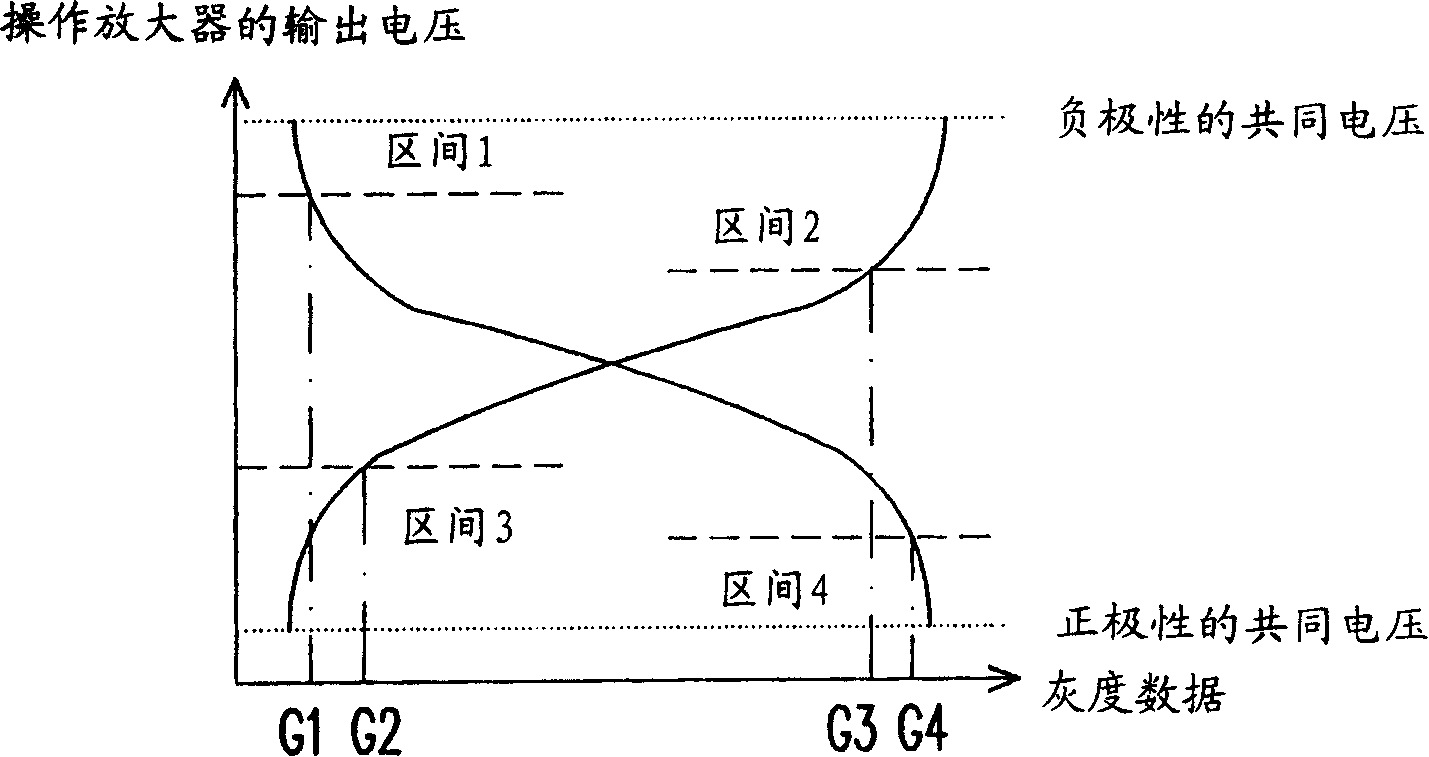

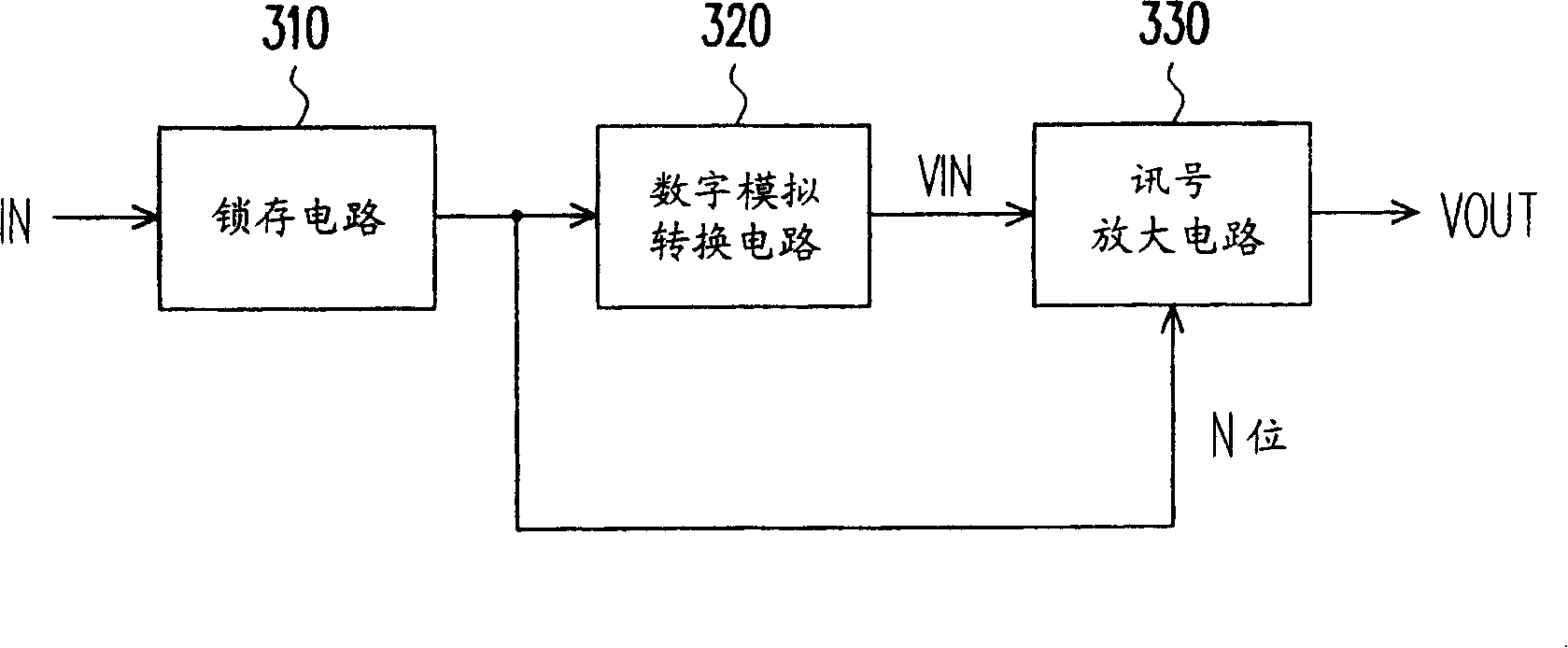

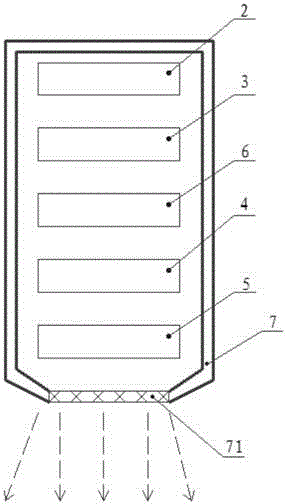

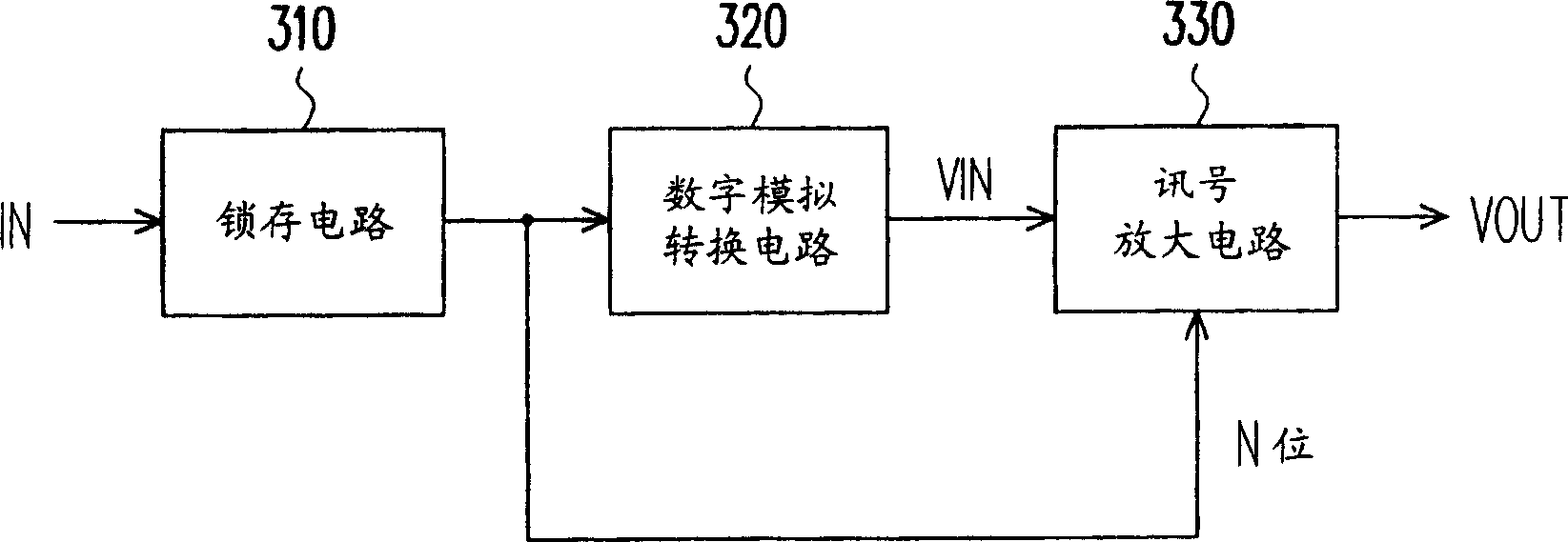

ActiveCN101221714AShorten the stabilization timeControl current sizeCathode-ray tube indicatorsDifferential amplifiersDigital dataDigital analog

The invention provides a driving device and a driving method thereof. The driving device comprises a digital-analog conversion circuit and a signal amplifying circuit, wherein, the digital-analog conversion circuit is used to receive digital data and converts the digital data into an analog signal; the signal amplifying circuit is coupled with the digital-analog conversion circuit for receiving the analog signal to generate a driving signal and dynamically changing the driving capability of the driving signal according to at least one bit in the digital data.

Owner:NOVATEK MICROELECTRONICS CORP

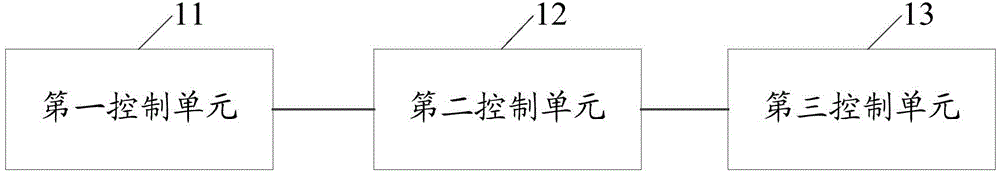

Control circuit for vehicle welcome light and vehicle welcome light

InactiveCN104981059AImprove the display effectControl glow colorElectric light circuit arrangementEngineeringControl circuit

The present invention discloses a control circuit for a vehicle welcome light and the vehicle welcome light. The control circuit comprises a first control unit used for receiving a first pulse width modulated signal sent by a controller and controlling the size of a first current input into the R end of a three-color LED light source by regulating the duty cycle of the first pulse width modulated signal, a second control unit used for receiving a second pulse width modulated signal sent by the controller and controlling the size of a second current input into the G end of the three-color LED light source by regulating the duty cycle of the second pulse width modulated signal and a third control unit used for receiving a third pulse width modulated signal sent by the controller and controlling the size of a third current input into the B end of the three-color LED light source by regulating the duty cycle of the third pulse width modulated signal. According to the control circuit and the vehicle welcome light disclosed by the invention, the display effect of the vehicle welcome light is greatly enhanced.

Owner:KOSTAL SHANGHAI MANAGEMENT

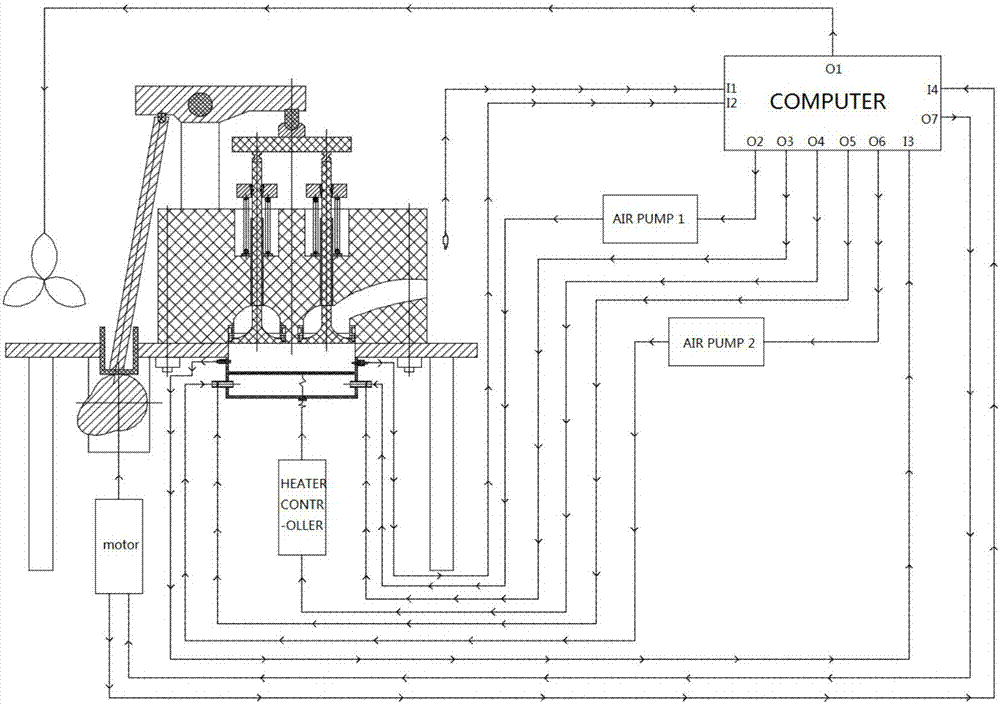

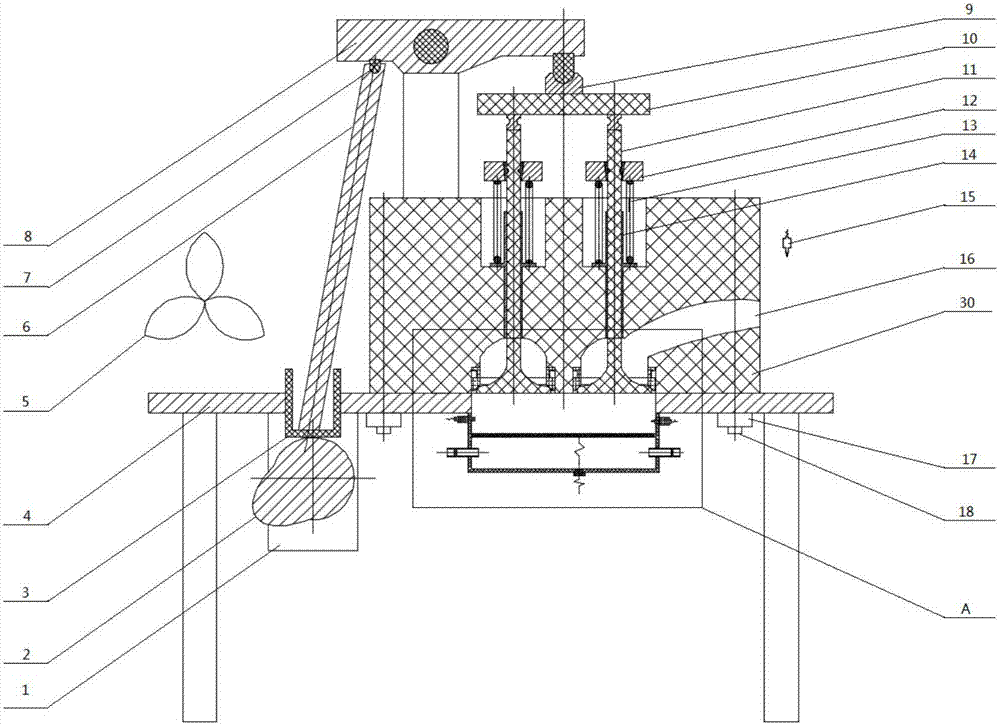

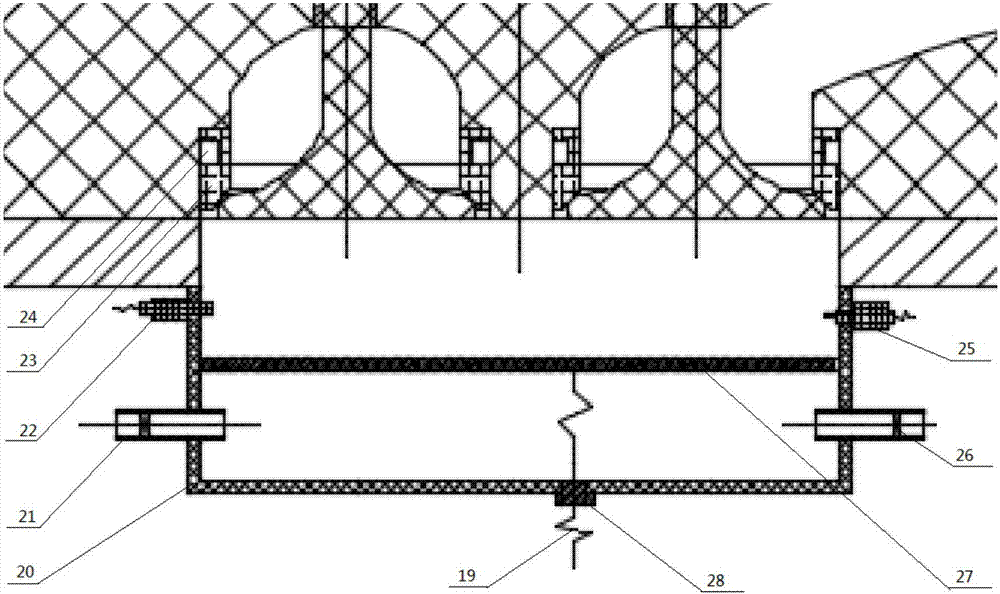

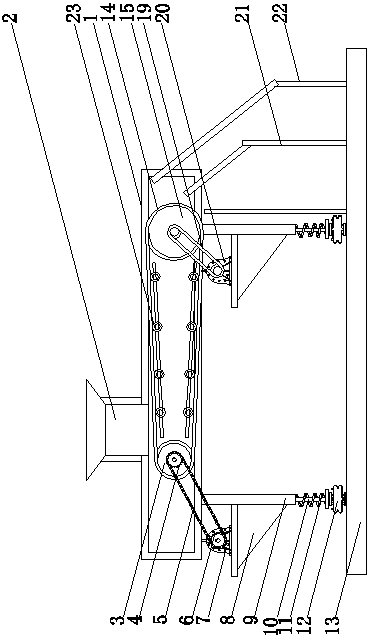

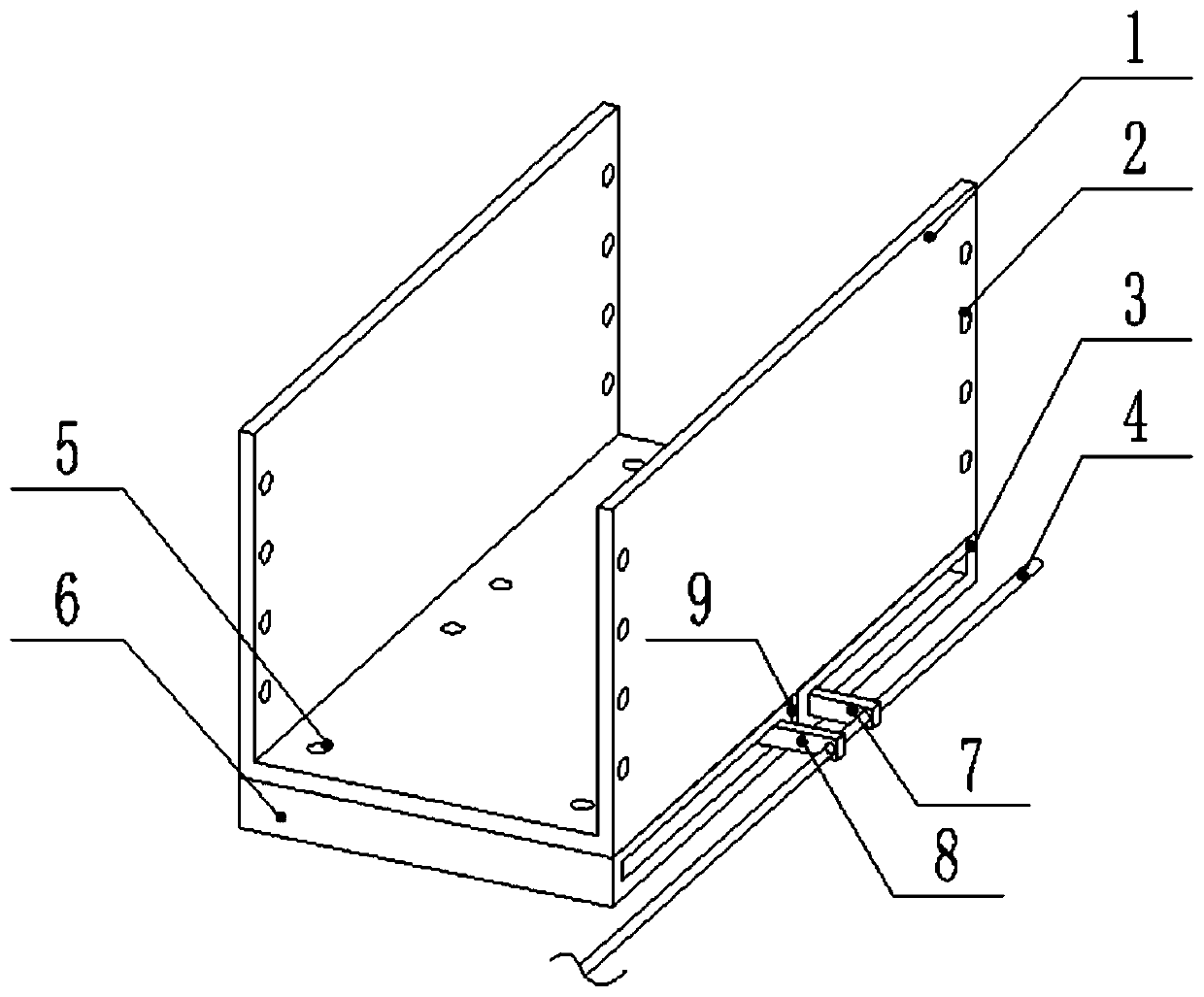

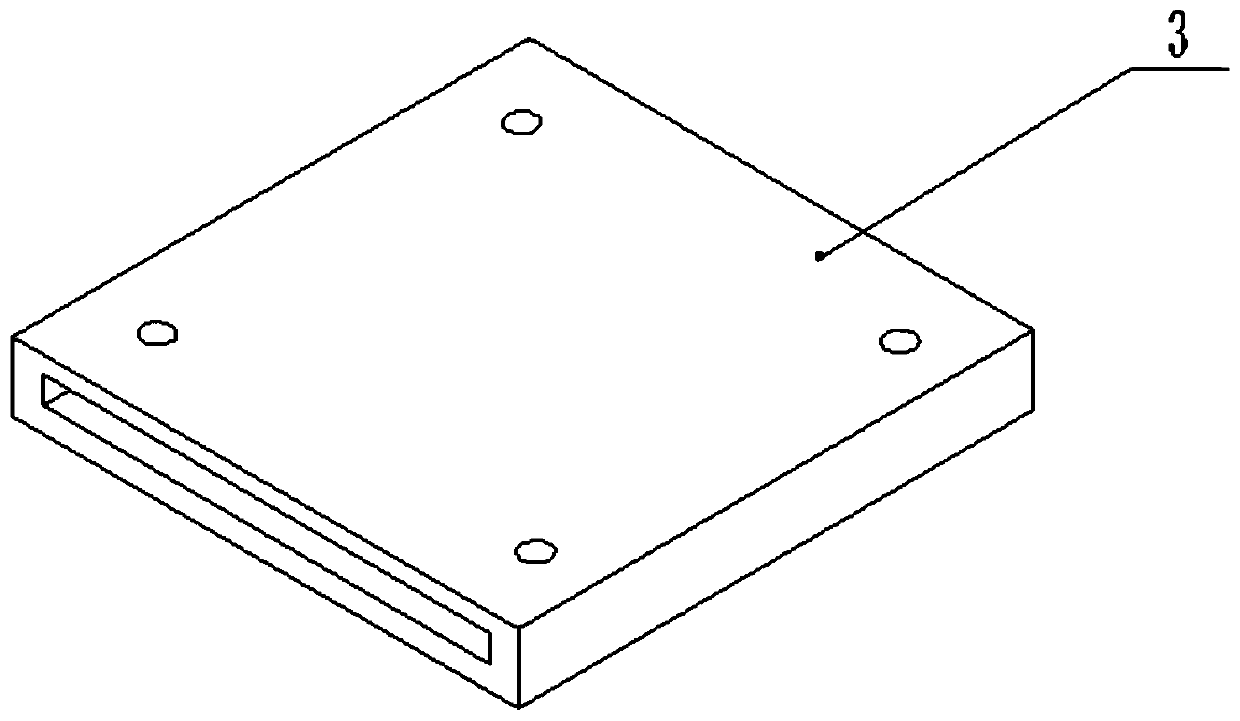

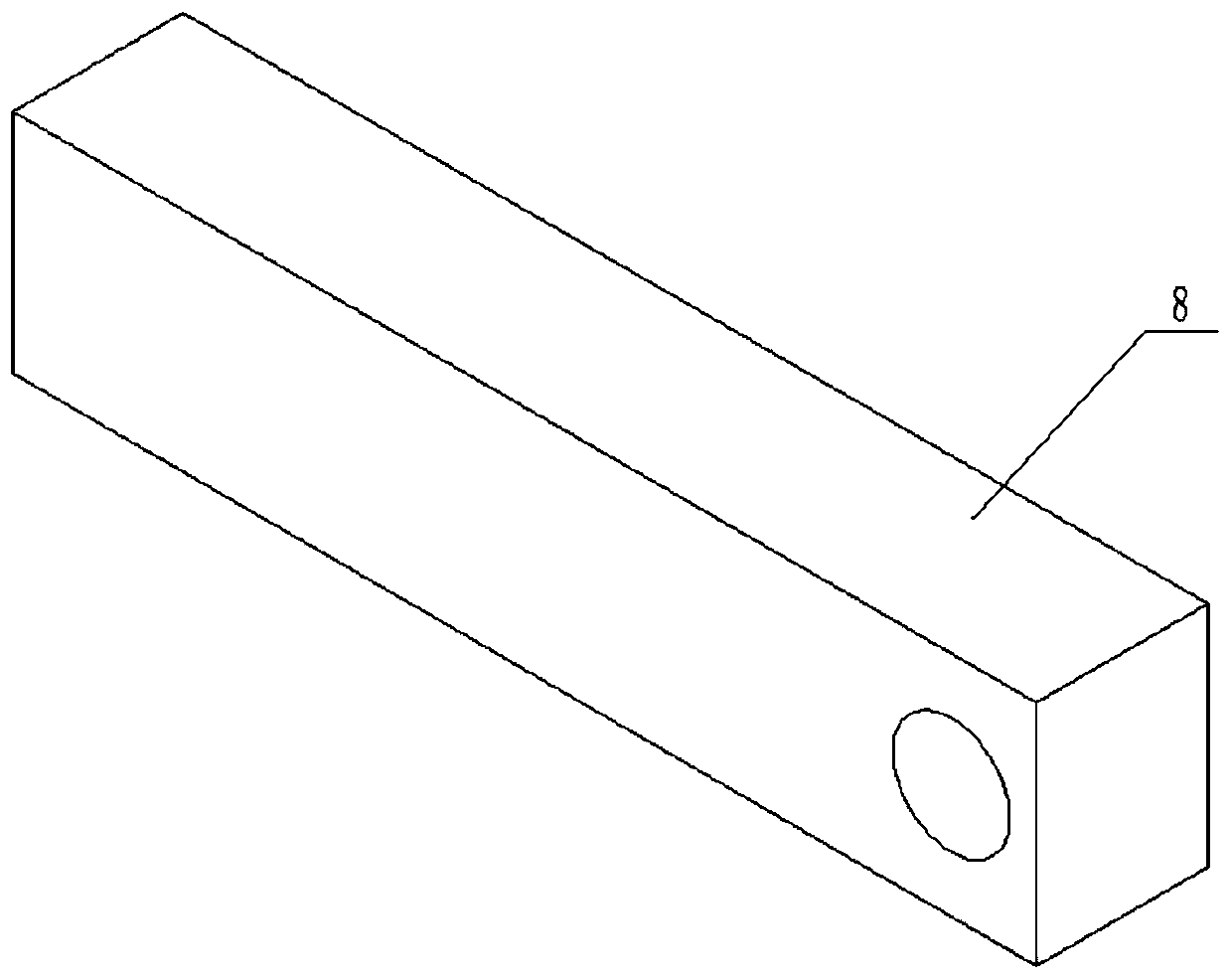

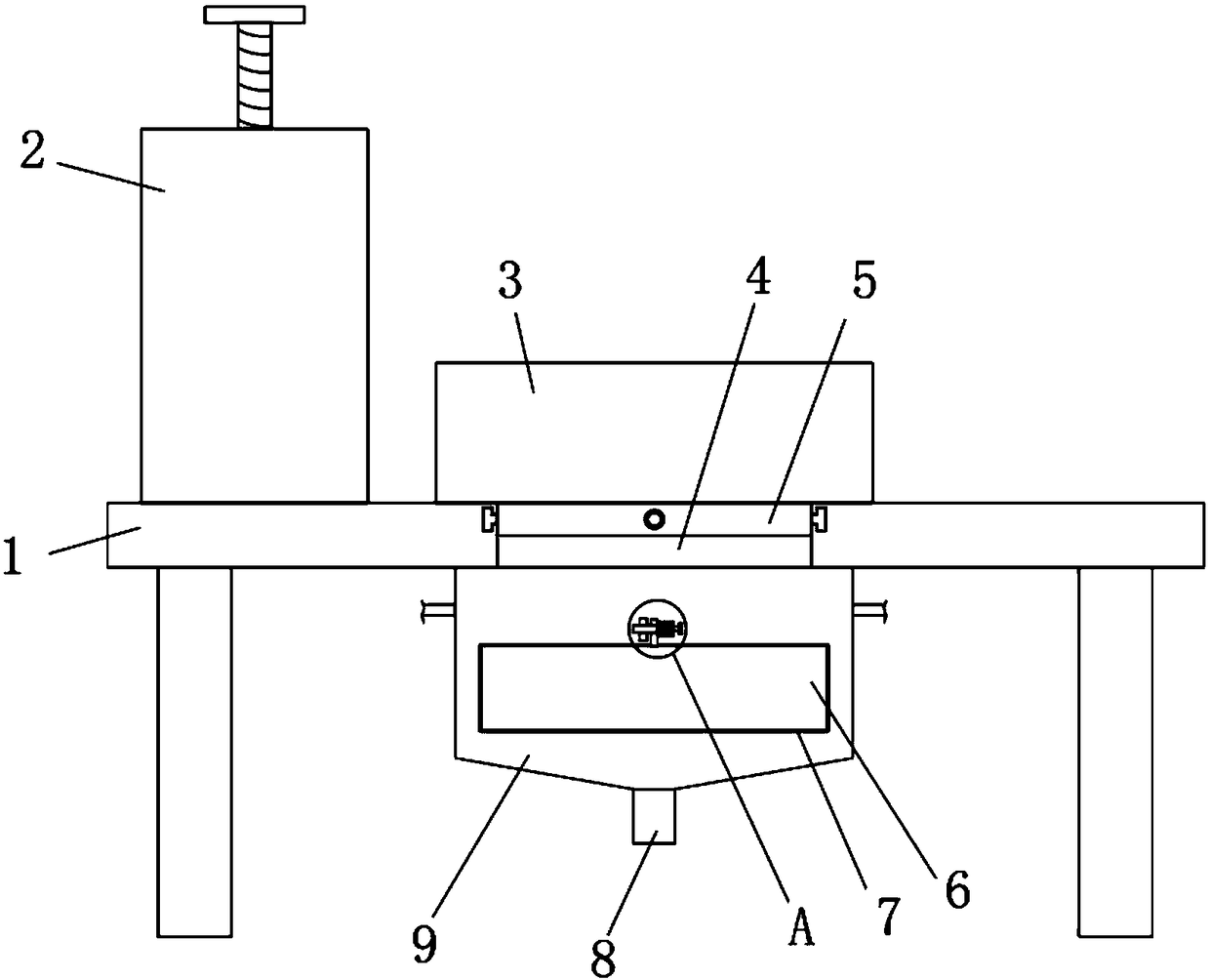

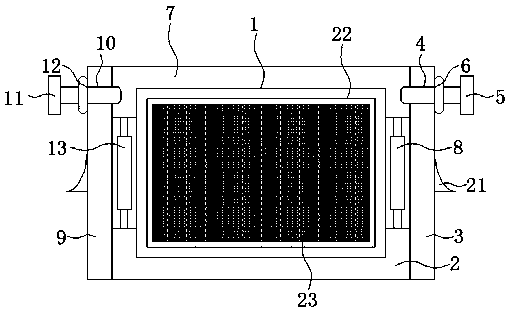

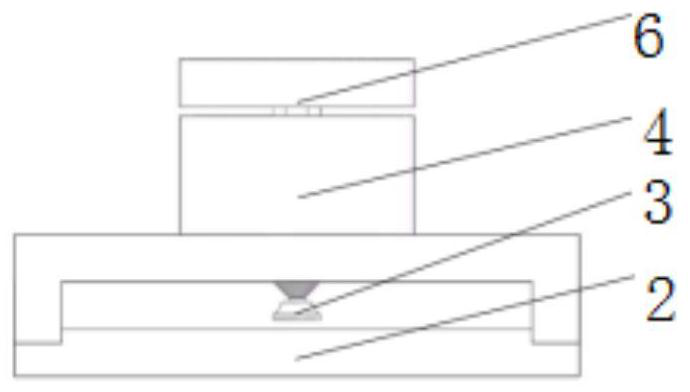

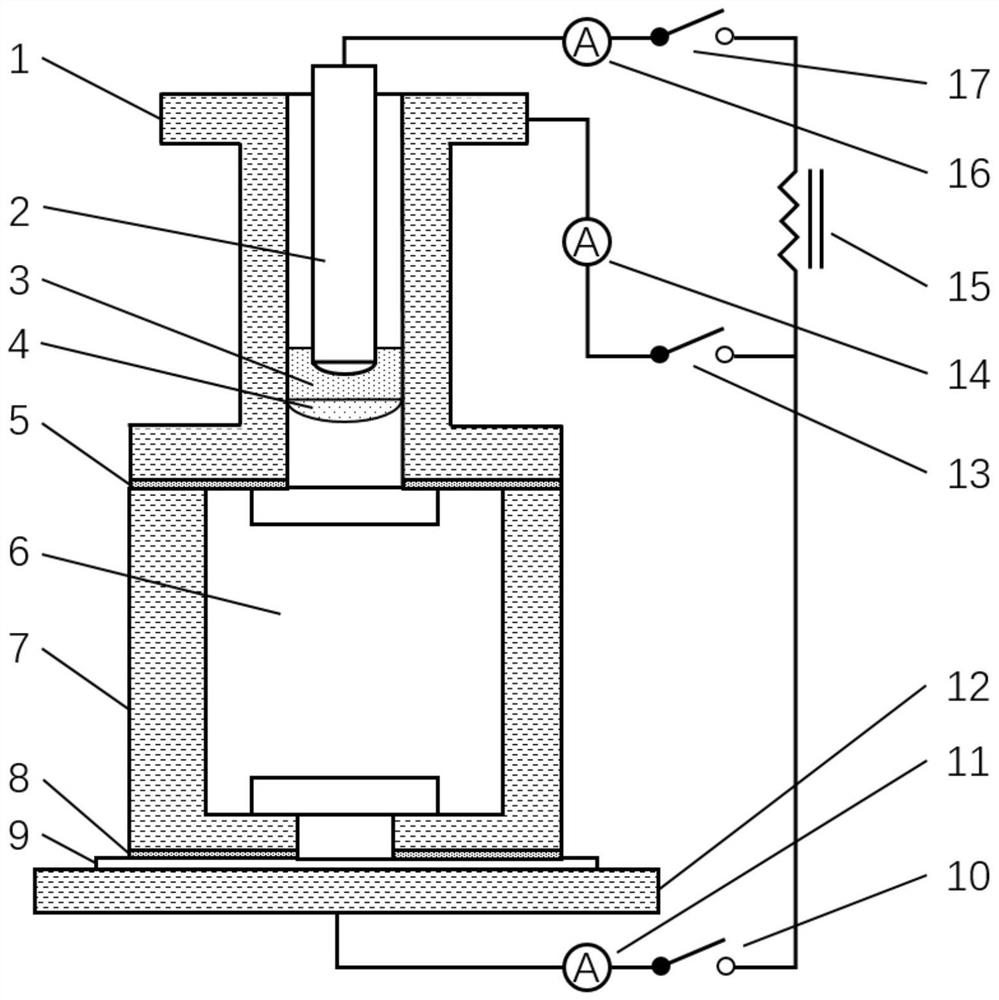

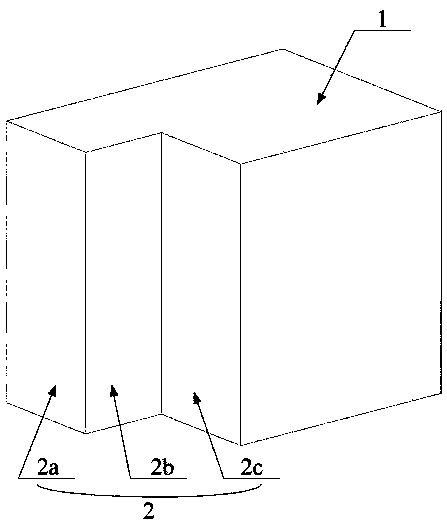

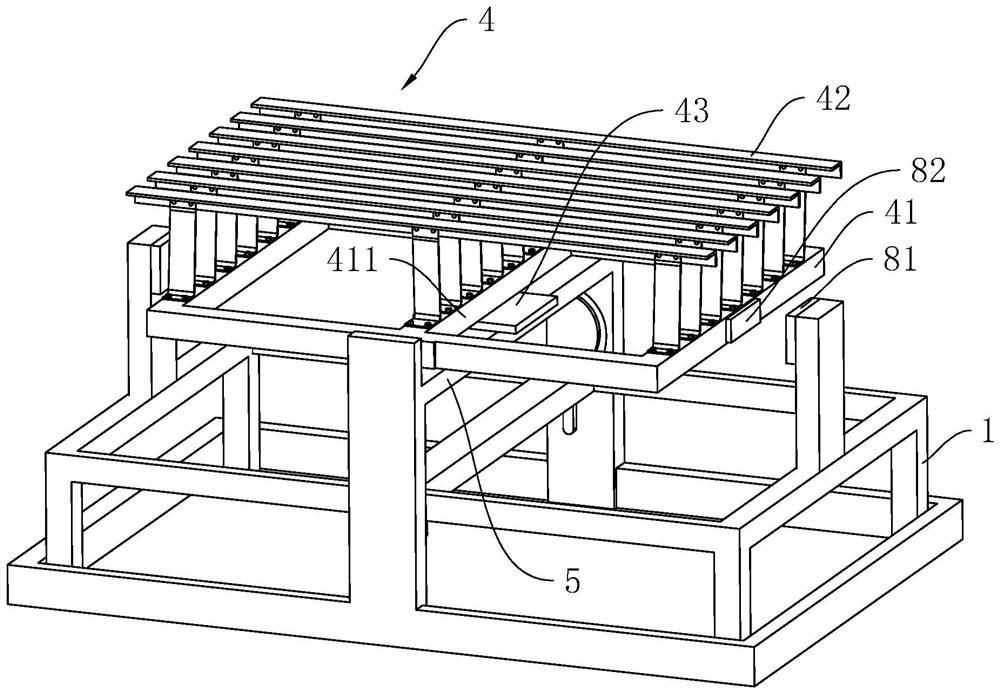

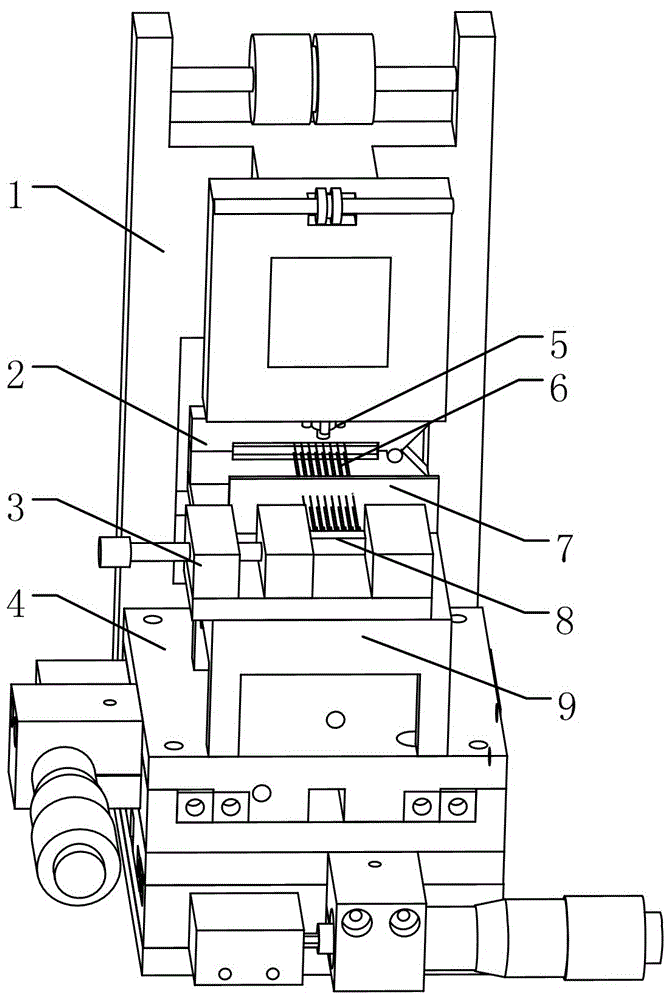

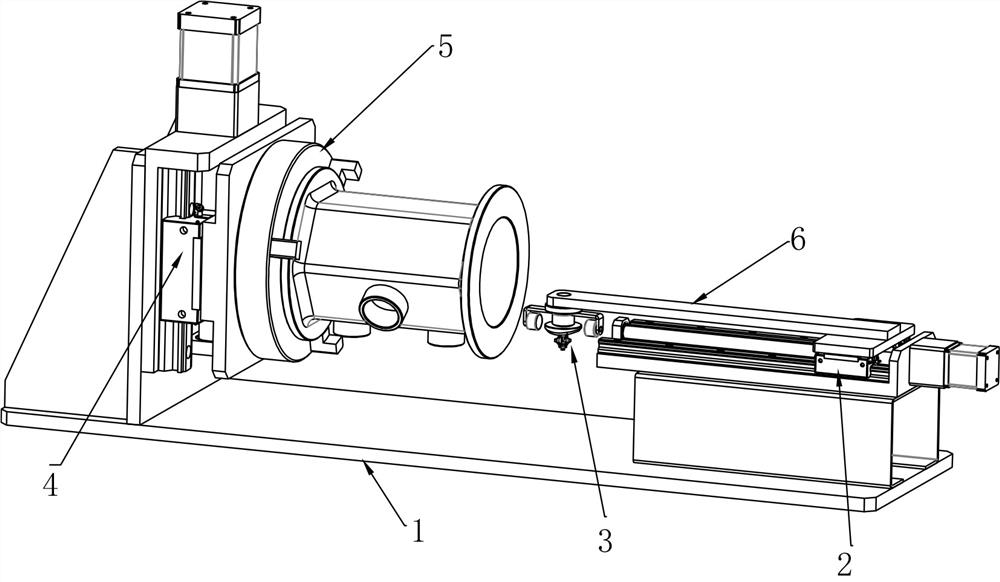

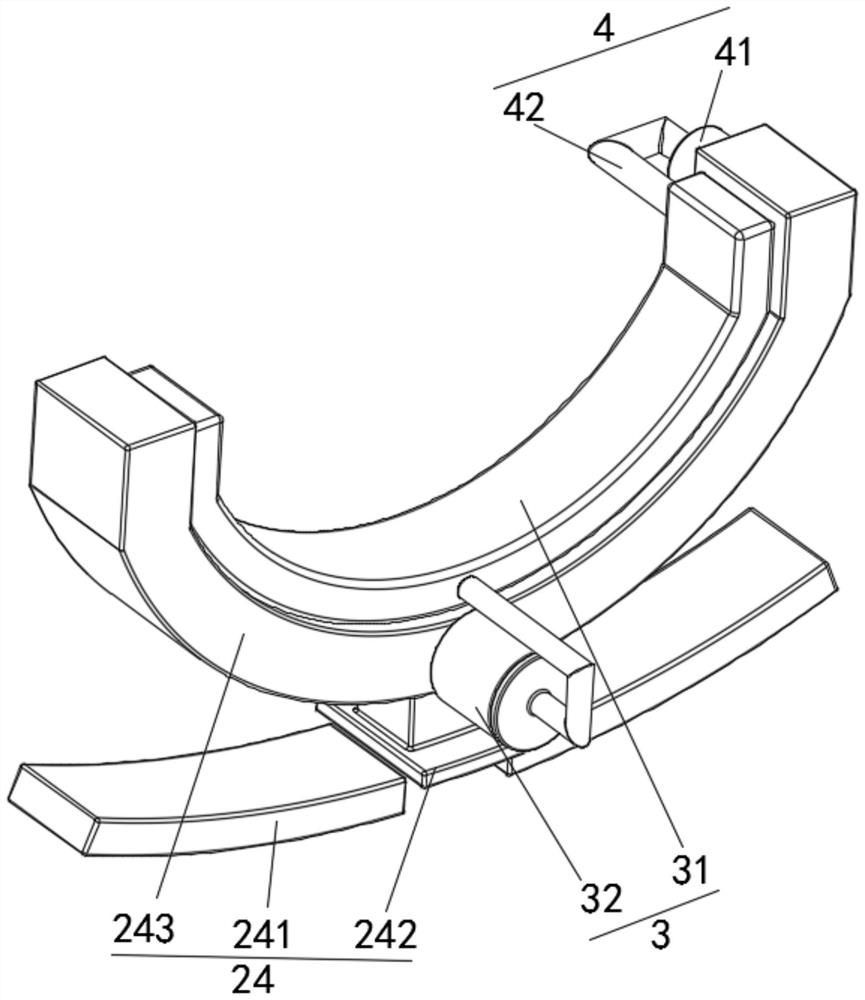

Double exhaust valve-valve retainer wearing testing apparatus and method thereof

PendingCN106918523ASave manpower, material and financial resourcesControl current sizeInvestigating abrasion/wear resistanceExhaust valveWear testing

The invention discloses a double exhaust valve- valve retainer wearing testing apparatus and a method thereof, which solve the problems that the current testing apparatus is complex and is not accorded with the practical condition of an exhaust valve, and the testing apparatus has the advantages of simple structure, convenient dismounting, energy saving and environmental protection. The double exhaust valve-valve retainer wearing testing apparatus comprises a cylinder cover arranged on a testing stand, a double exhaust valve channel is arranged in the cylinder cover, an exhaust valve retainer is arranged at the bottom of the exhaust valve channel, a cam action execution mechanism is arranged at the top of the exhaust valve to drive the action of the exhaust valve; a cylinder body of the cylinder is simulated, the cylinder body is support by the testing stand, the top of the cylinder body and the bottom of the cylinder cover are communicated, an air intake is arranged at the cylinder body, and is connected with an inflation mechanism; a heating mechanism is arranged on the internal surface or external surface of the cylinder body, the cylinder body and the gas in the cylinder body are heated to the set temperature, the operation process of the cylinder is simulated, after multitime tests, the wearing of exhaust valve-valve retainer can be observed through naked eyes or a scanning electron microscope.

Owner:SHANDONG UNIV

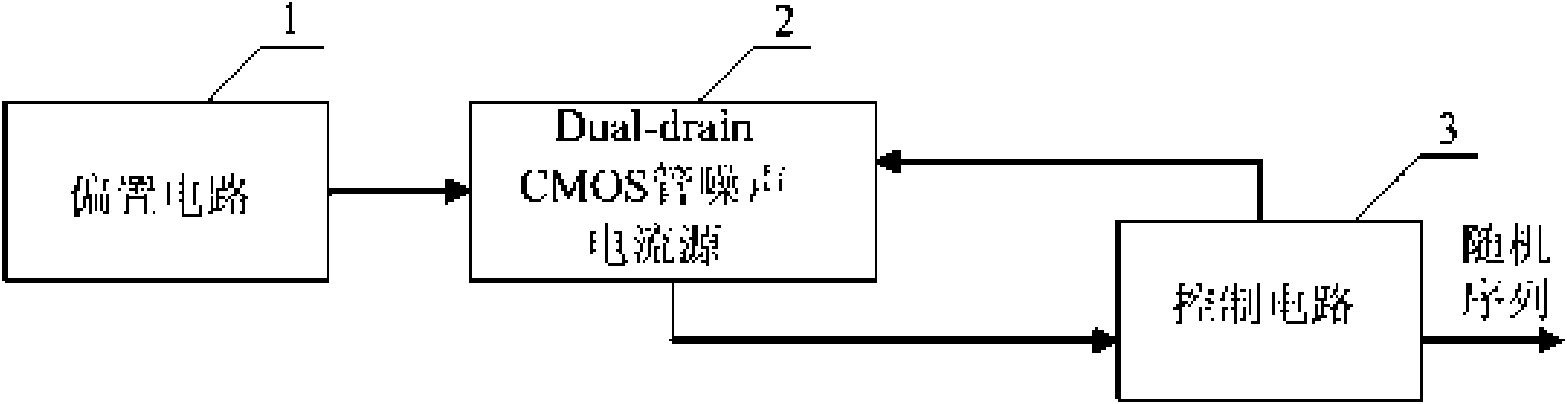

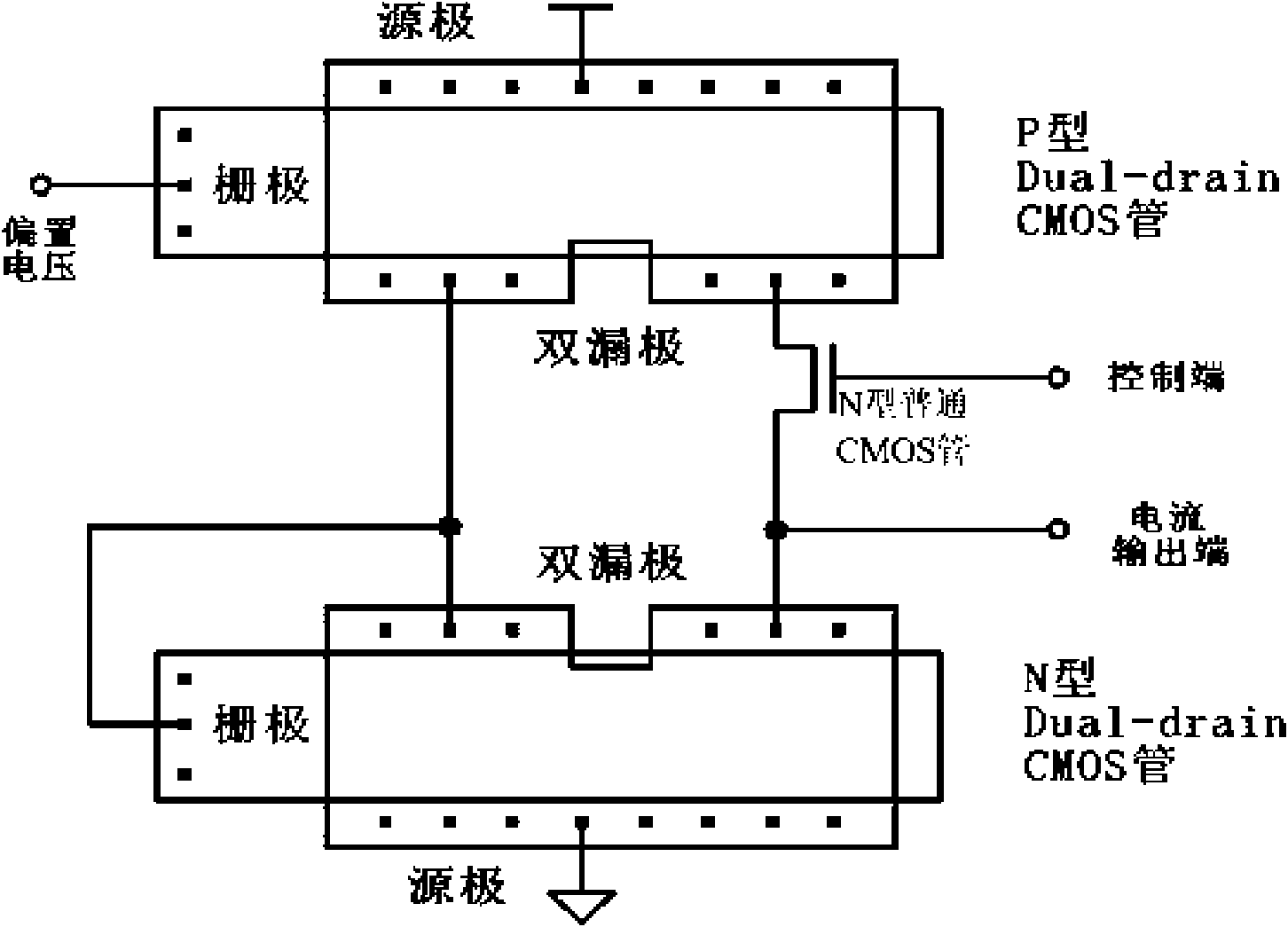

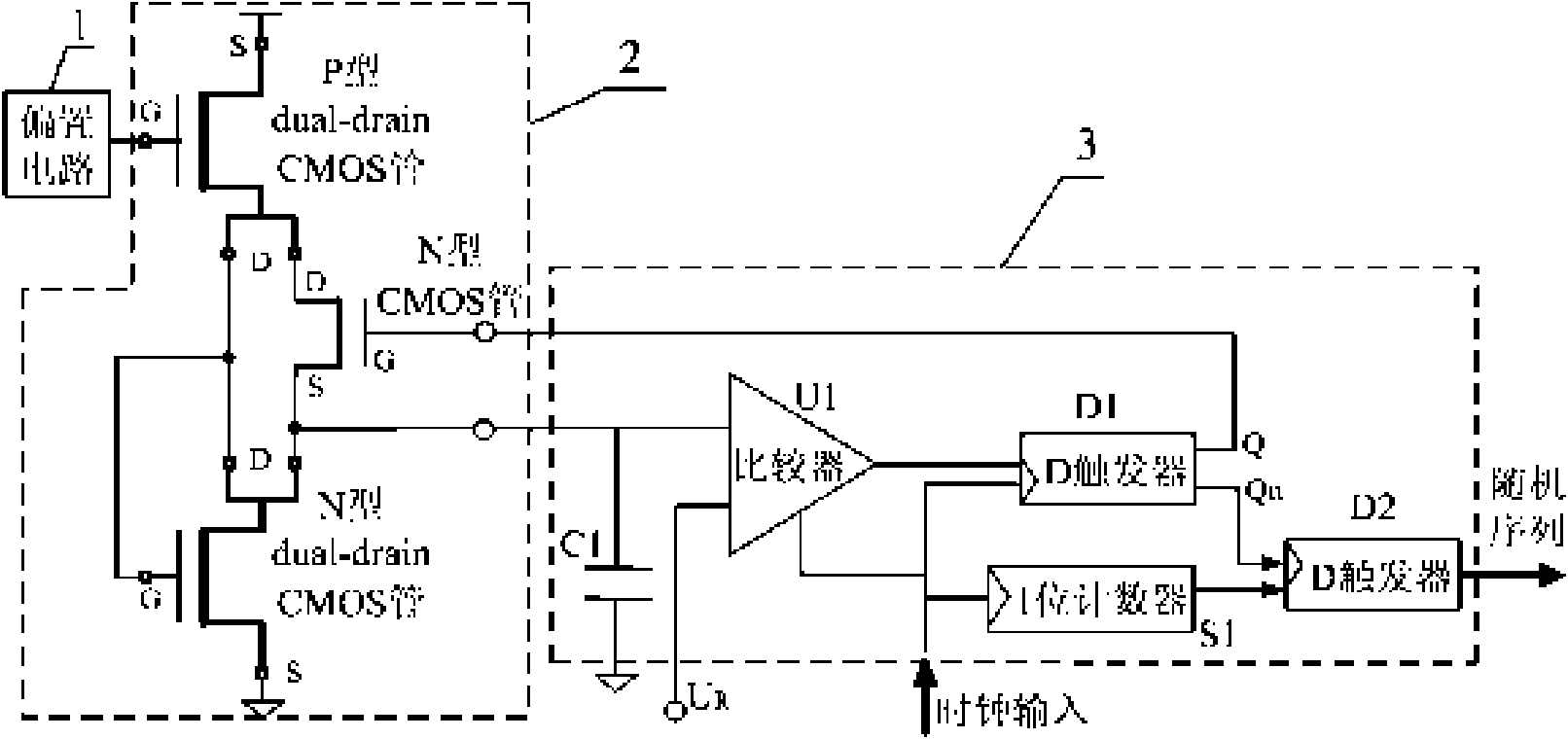

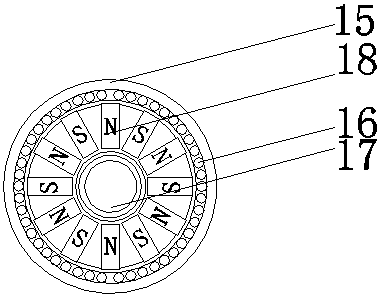

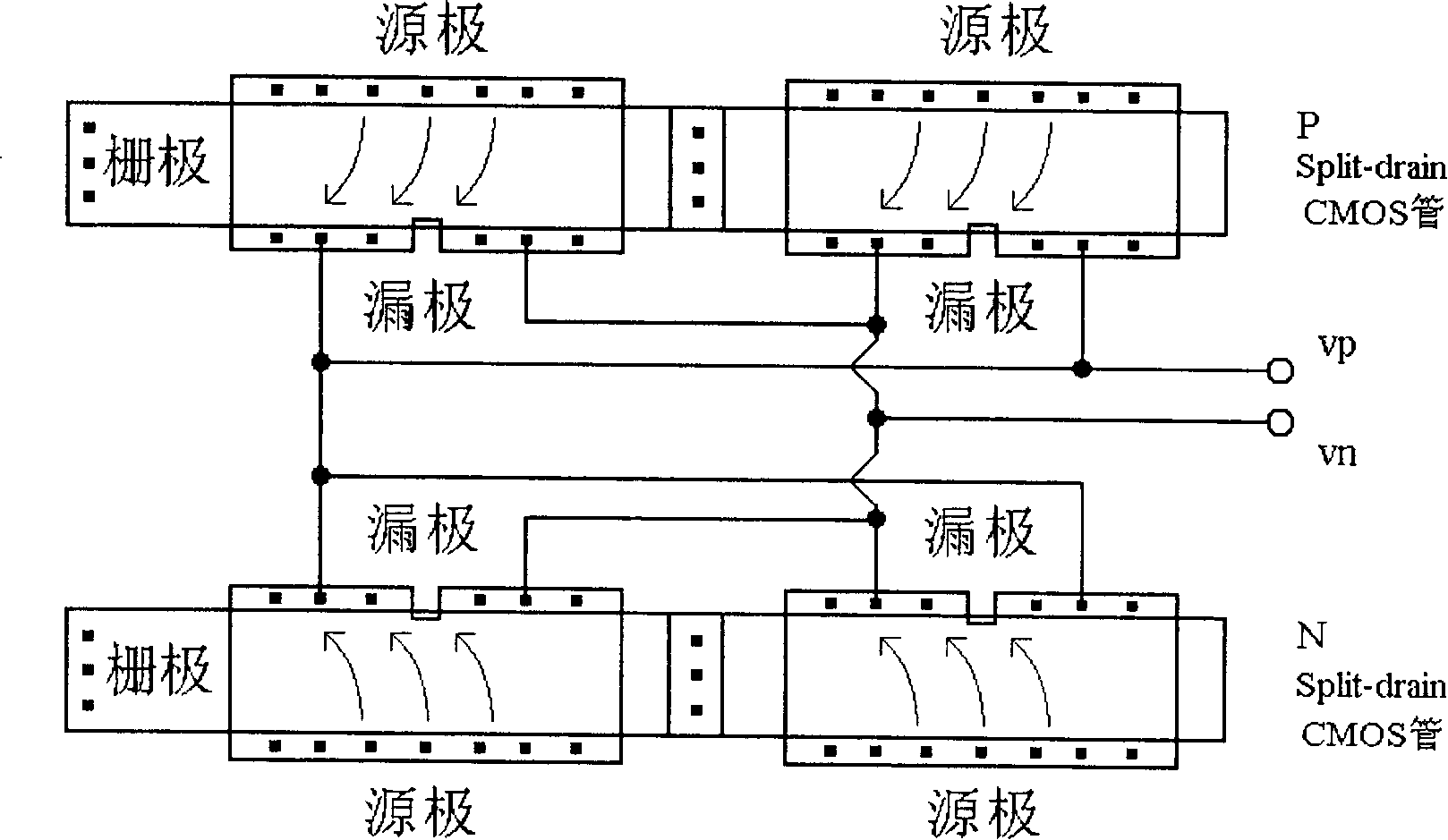

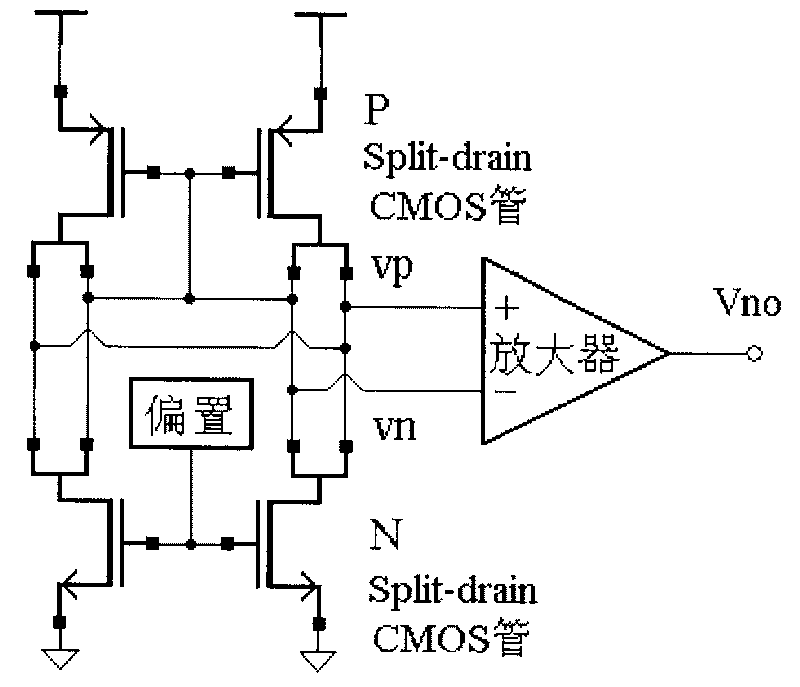

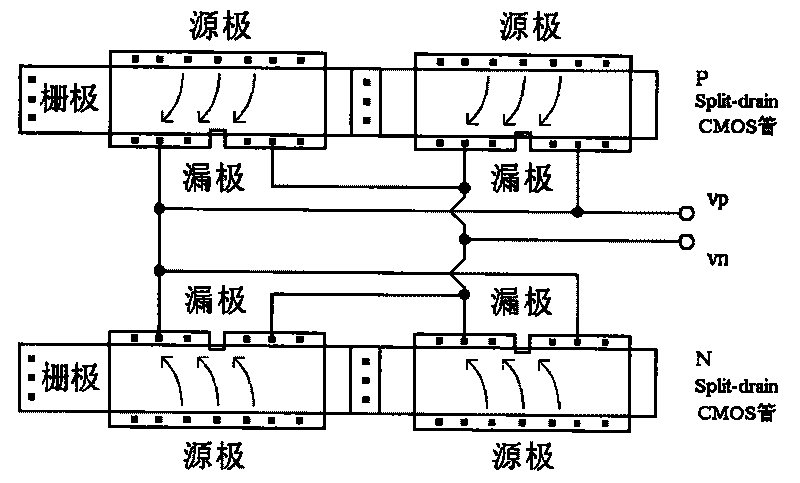

CMOS (Complementary Metal Oxide Semiconductor) random number generator

ActiveCN101833434AReduce power consumptionMeet high power requirementsRandom number generatorsEngineeringNumber generator

The invention discloses a CMOS (Complementary Metal Oxide Semiconductor) random number generator with low power consumption, which comprises an offset circuit, a double-drain CMOS noise current source and a control circuit, wherein the offset circuit is used for providing a direct current working point for the double-drain CMOS noise current source; the double-drain CMOS noise current source generates a noise current signal by utilizing a double-drain CMOS; and the control circuit is used for converting the noise current signal output by the double-drain CMOS noise current source into a random sequence to be output, detecting the noise current signal and controlling the output of the double-drain CMOS noise current source or stopping outputting the noise current signal according to a detection result. The invention greatly lowers the power consumption of a random number generator by utilizing the characteristic of large noise of the double-drain CMOS, and is suitable for a radio frequency identification label chip.

Owner:NATIONZ TECH INC

Environmentally-friendly non-ferrous metal separator for garbage treatment

PendingCN108325741ASolve the problem that it is not convenient to adjust the current sizeIncrease speedNon-rotating vibration suppressionMagnetic separationElectric machineDrive motor

The invention discloses an environmentally-friendly non-ferrous metal separator for garbage treatment. The non-ferrous metal separator comprises a support; a feed port is formed in the top end of thesupport; a main rotating shaft is connected to the inner wall of the support in a rotating mode; a main gear disc fixedly sleeves the surface of the main rotating shaft; the surface of the main gear disc is in transmission connection with an auxiliary gear disc through a chain; and the axis of the auxiliary gear disc is fixedly connected to the output end of a driving motor. According to the non-ferrous metal separator, an auxiliary rotating shaft, a bearing, a rotating roller and electromagnets are arranged, the electromagnets are driven by the rotating roller to rotate in the auxiliary rotating shaft together with the auxiliary rotating shaft through the bearing, so that the rotating roller and the auxiliary rotating shaft rotate relatively, current is generated, the rotating speed can be adjusted conveniently, the magnitude of the current can be controlled, the rotating roller and the auxiliary rotating shaft rotate at the same axis, the installation and maintenance are convenient,other screening devices do not need to be additionally arranged, the floor area can be saved, and therefore the problem that the magnitude of the current is inconvenient to adjust when an existing non-ferrous metal separator is used can be solved.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

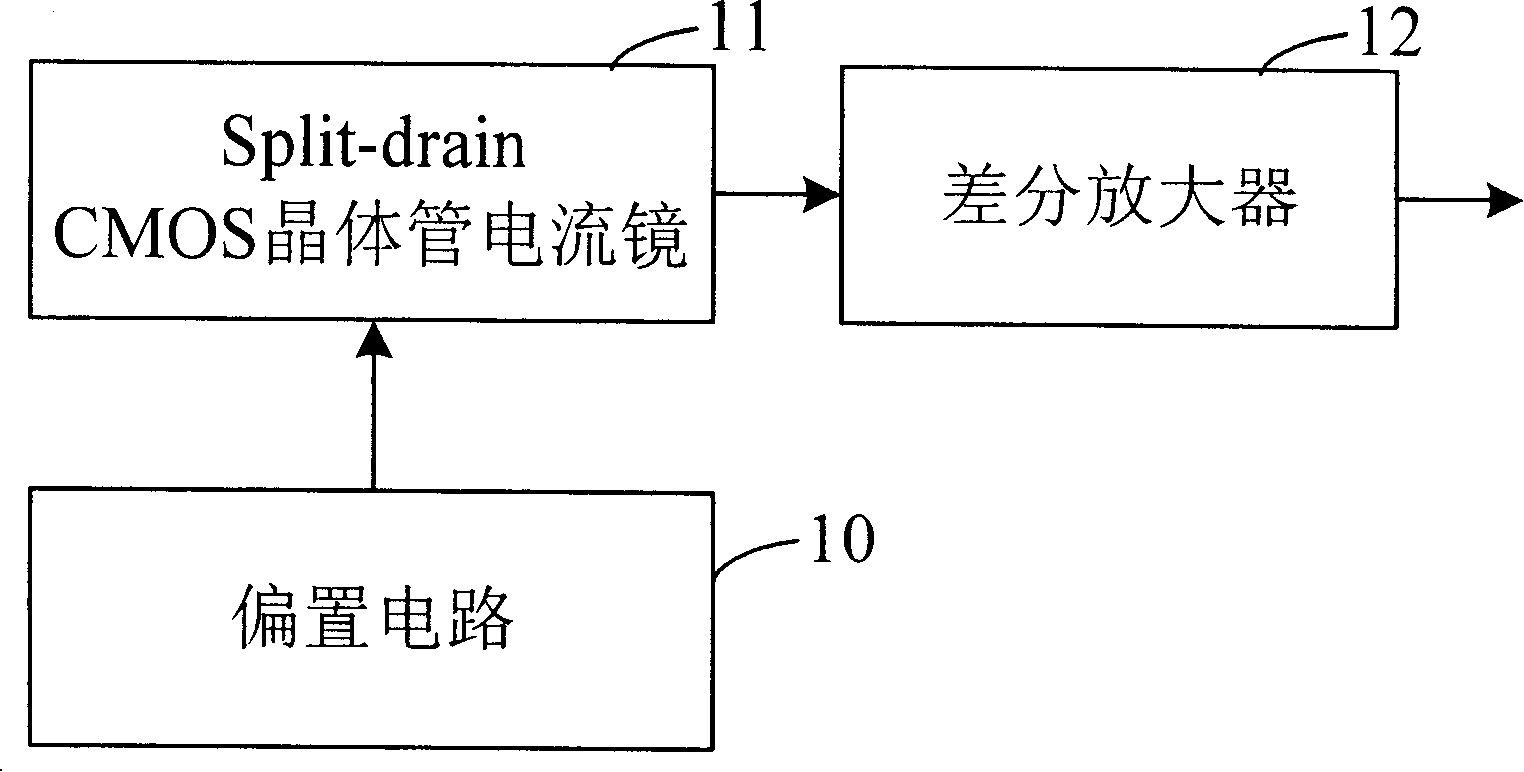

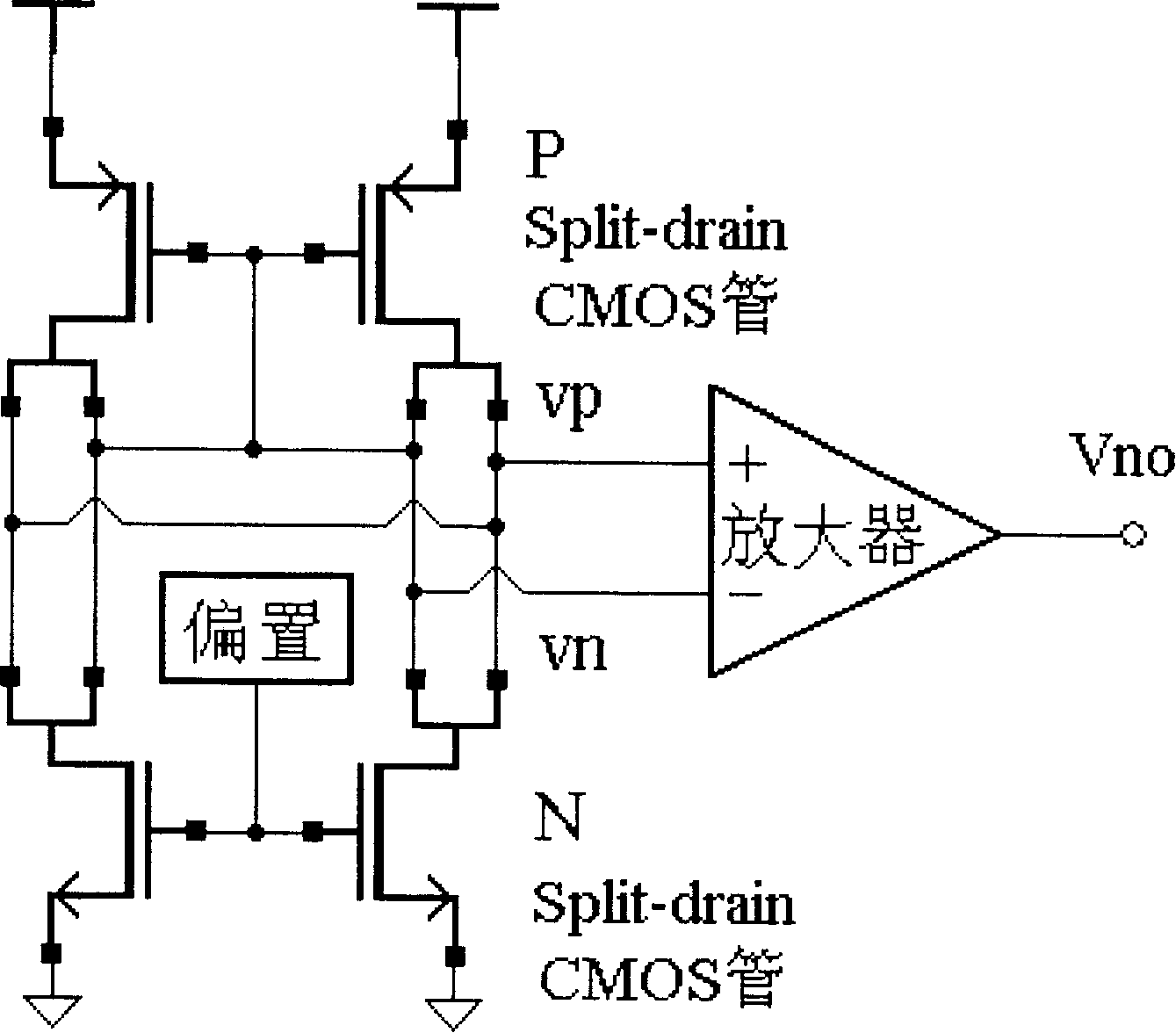

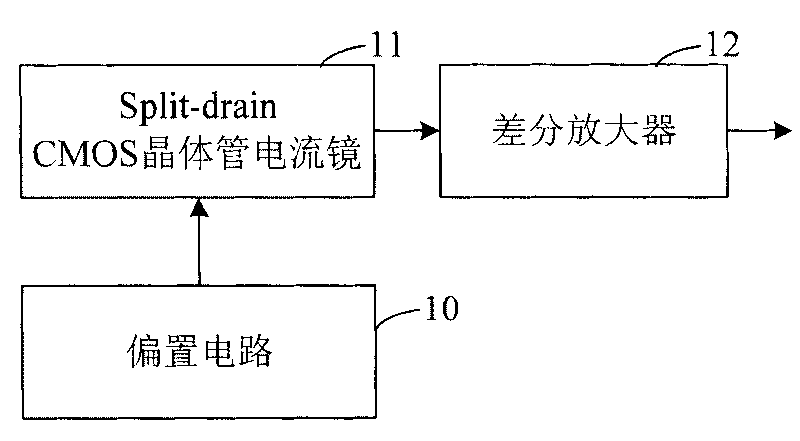

Complementary type metal oxidizing layer semiconductor noise generator

ActiveCN101202532AReduce power consumptionSolve the problem of working distanceNoise generationDifferential amplifiersDifferential amplifierSemiconductor

The invention relates to the noise generator technical field. The invention discloses a complementary metal oxide semiconductor noise generator, comprising a bias circuit which is used for providing DC working points for a dual-drain complementary metallic oxide semiconductor transistor current mirror and a differential amplifier; the dual-drain complementary metallic oxide semiconductor transistor current mirror is used for converting slight noise current signals into amplified or larger differential voltage signals which are then output to the differential amplifier; the invention also comprises the differential amplifier which is used for converting differential both-terminal signals input by the dual-drain complementary metallic oxide semiconductor transistor current mirror into single-terminal signals and amplifies and outputs the single-terminal signals. By adopting the CMOS process which is widely applied, the invention greatly reduces the power loss of noise generator and well solves the problem that reactive label working distance is shortened even the power loss is only a plurality of MuW.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

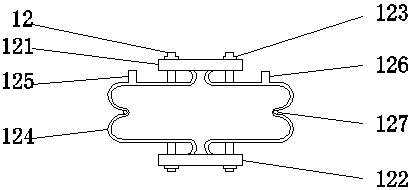

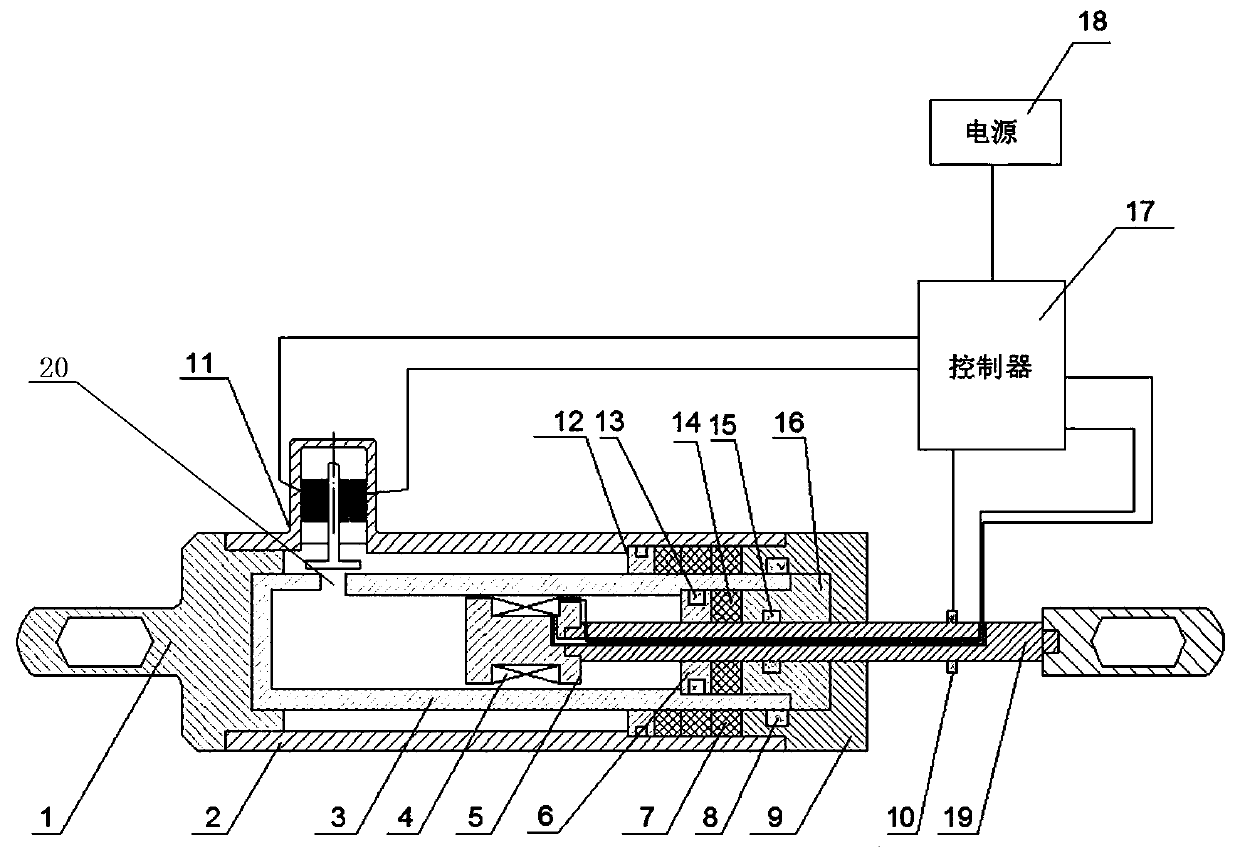

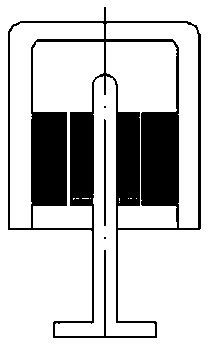

Stroke varying type double-cylinder active magneto-rheological shock absorber based on shearing mode

ActiveCN110056599AControl current sizeControl the degree of opening and closingSpringsNon-rotating vibration suppressionMagnetic currentMetal rubber

The invention discloses a stroke varying type double-cylinder active magneto-rheological shock absorber based on a shearing mode. The stroke varying type double-cylinder active magneto-rheological shock absorber based on the shearing mode is composed of a bottom cover, an outer cylinder barrel, an inner cylinder barrel, an electromagnetic valve, a piston rod, a floating piston, a piston surroundedby a coil, metal rubber, a fuzzy controller, a sensor and the like, the electromagnetic piston is located in the inner cylinder barrel, the piston rod is connected with the electromagnetic piston, the inner cylinder barrel and the outer cylinder barrel are fixed on the same base, the inner cylinder barrel and the outer cylinder barrel are connected through a through hole in the side wall of the inner cylinder barrel, the electromagnetic valve is arranged on the portion, corresponding to the through hole of the side wall of the inner cylinder barrel, of the side wall of the outer cylinder barrel, the metal rubber and the floating piston structure are arranged on the inner side of the outer cylinder barrel. When the vibration absorber works, a central controller of a vibration damping system can control the current on the electromagnetic coil and opening of the electromagnetic valve so as to control the output force of the shock absorber according to an acceleration signal transmitted by an acceleration sensor installed on the shock absorber; and the central control system of the shock absorber can control the opening and closing degree of the electromagnetic valve according to thesize of the road excitation, and the buffer stroke is controlled.

Owner:ZHONGBEI UNIV

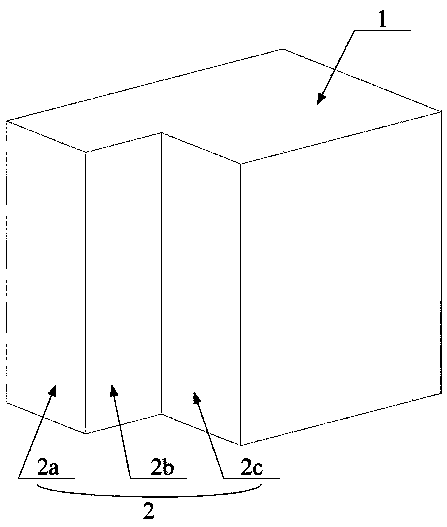

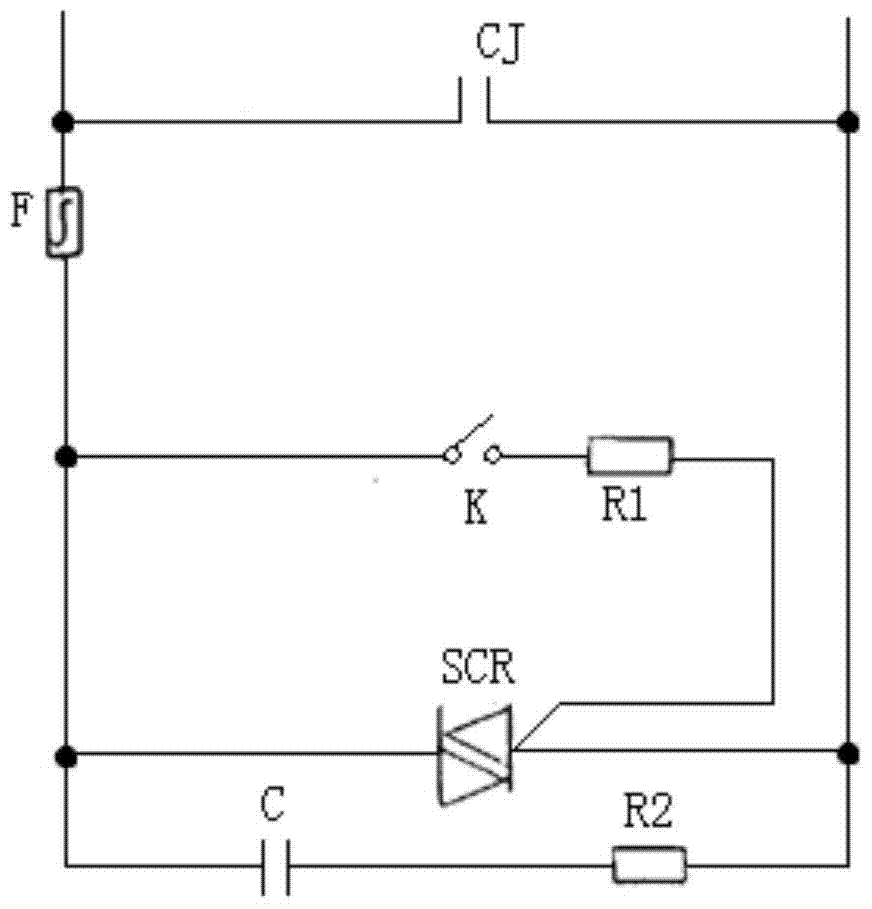

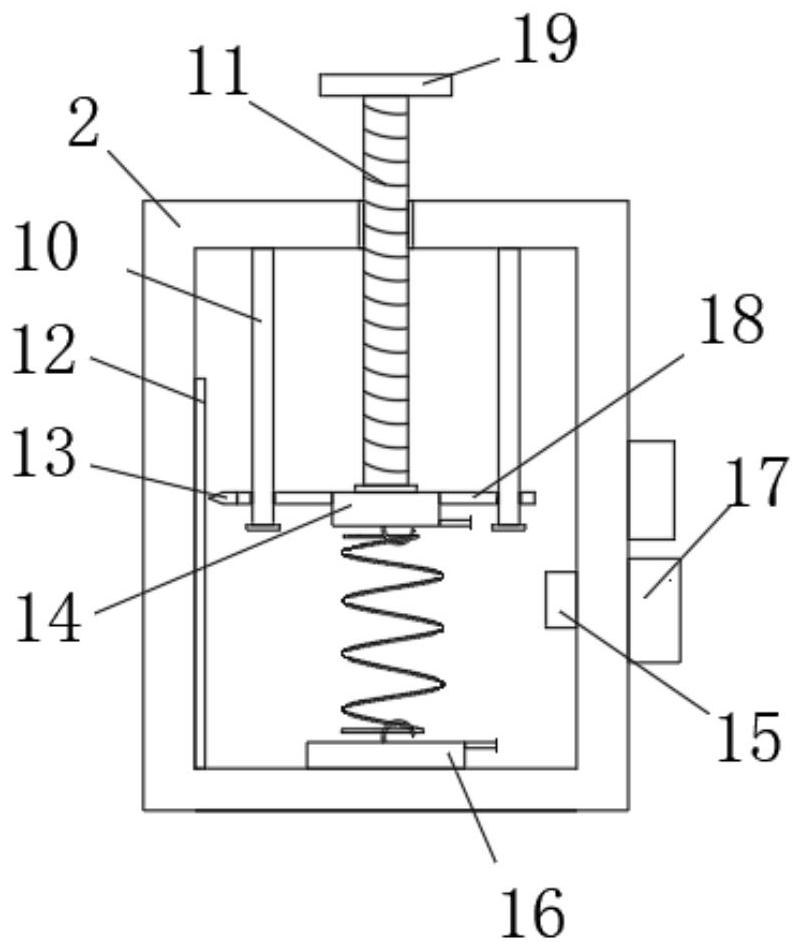

Proton exchange membrane fuel cell low-temperature cold start box capable of realizing uniform heating and control method thereof

ActiveCN111129540AGood heating effectReduced cold start timeFuel cell heat exchangeEngineeringElectrical and Electronics engineering

The invention provides a proton exchange membrane fuel cell low-temperature cold start box capable of realizing uniform heating and a control method of the proton exchange membrane fuel cell low-temperature cold start box. The proton exchange membrane fuel cell low-temperature cold start box structurally comprises: a proton exchange membrane fuel cell stack supporting box body, two ends of which need to be provided with end plates for fixing and bearing cells; two resistance plates arranged at the bottom of the supporting box body, wherein sliding grooves are formed in one ends of the two resistance plates and used for electrifying and heating the fuel cell stack; a movable electrode with a threaded hole, wherein one end of the movable electrode is supported in the sliding groove of the resistance plate, and the movable electrode is used for being connected with a power supply and can move; and a threaded rod, wherein one end of the threaded rod is connected with the motor, and the threaded rod is rotatable and can move the electrode matched with the threaded rod. The end, close to the pile end cover, of the resistance plate and the electrodes are connected with the two electrodesof the power source respectively to form a loop, and due to the fact that the electrodes are movable, a heating area can be changed. The method has the advantages that the temperature uniformity of the galvanic pile can be realized during cold start of the galvanic pile, and the energy consumption for heating is low.

Owner:JIANGSU UNIV

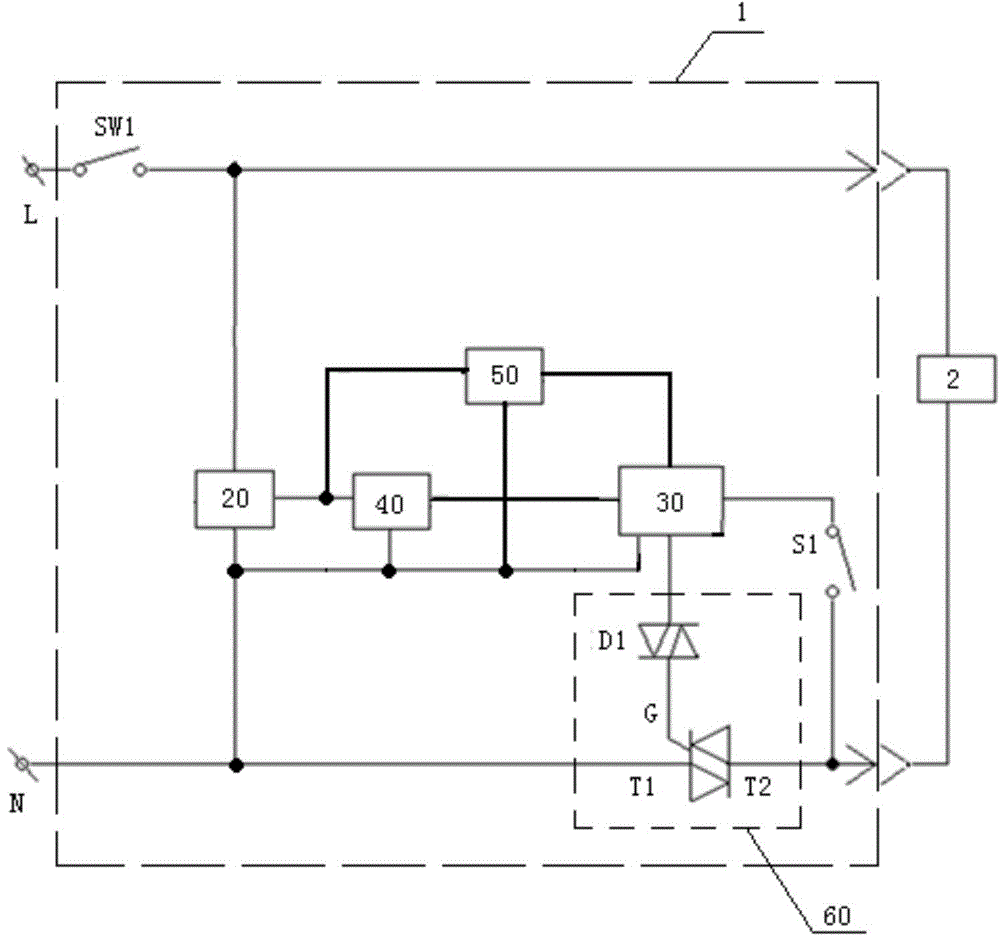

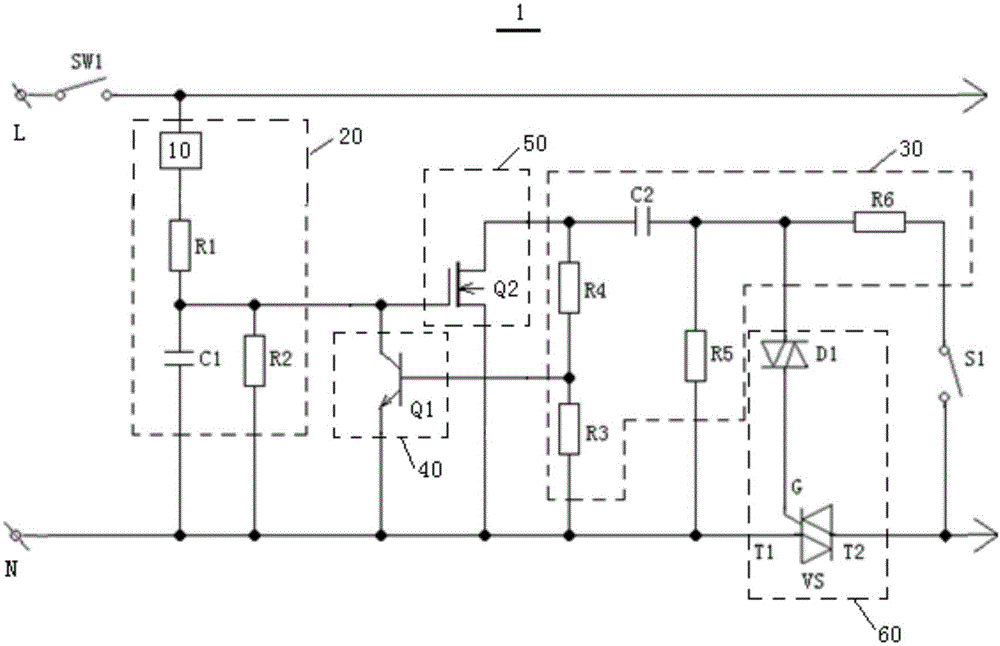

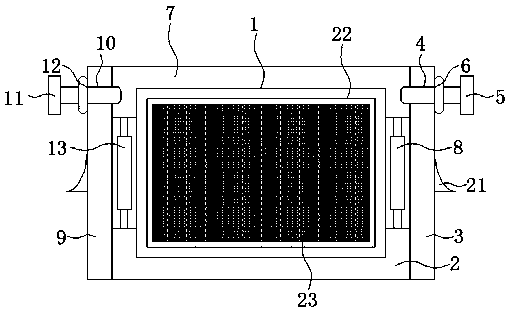

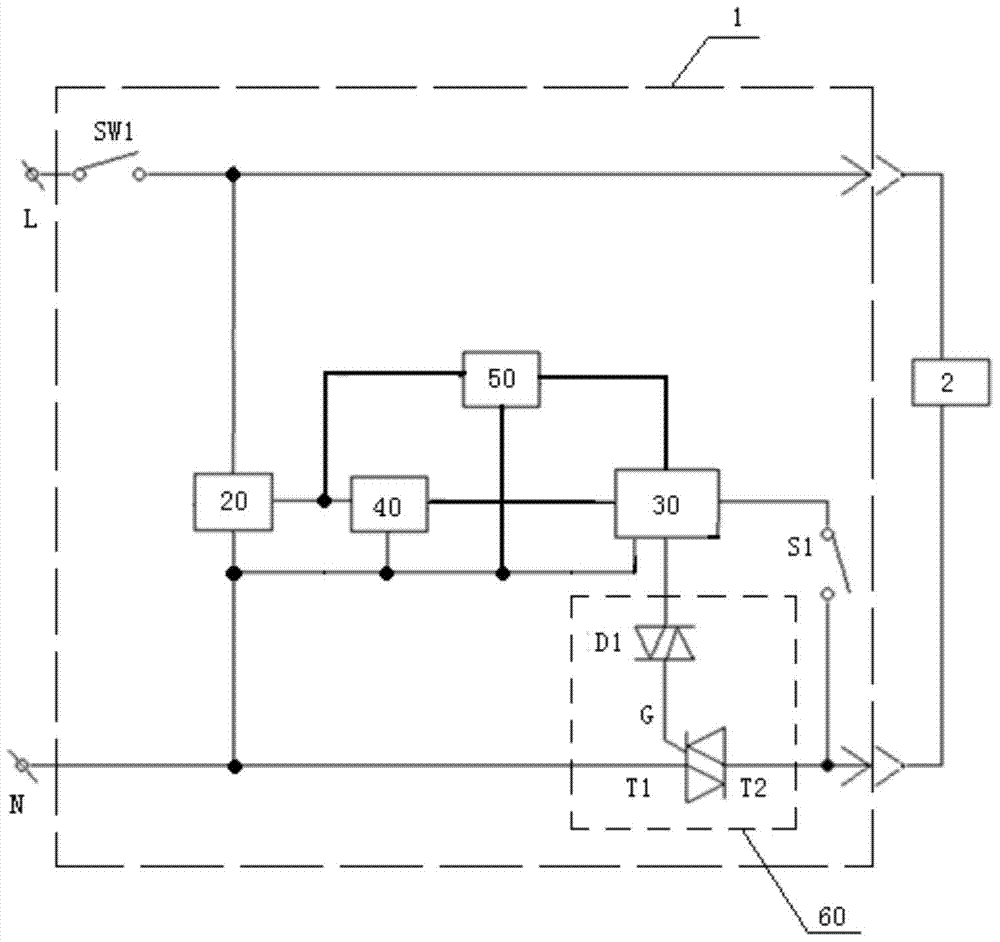

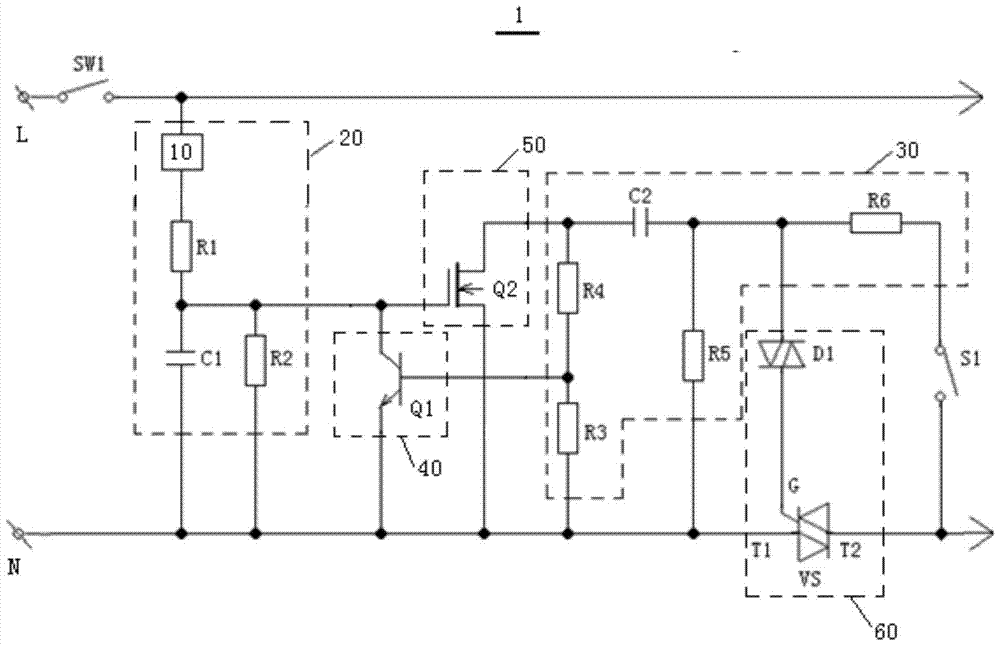

Non-arc power-off protection switch control circuit

ActiveCN104811169AProtective contactExtended service lifeElectronic switchingTime delaysElectric arc

The invention discloses a non-arc power-off protection switch control circuit. The control circuit comprises a first switch, a second switch, a first time delay circuit, a first controllable switch, a second controllable switch, a second time delay circuit and a thyristor circuit, wherein one end of the first switch is connected to a live wire of a power supply, and the other end of the first switch is connected with a load; the first time delay circuit is used for rectifying output of the power supply and controlling on and off of the second controllable switch; the second time delay circuit is used for controlling on and off of the first controllable switch; the time constant of the second time delay circuit is smaller than the time constant of the first time delay circuit; the second switch is connected between a second input end of the second time delay circuit and a null wire; the thyristor circuit is in circuit connection between the live wire of the power supply and the load. The non-arc power-off protection switch control circuit has the characteristics of long life, simple structure and low cost.

Owner:KEDU ELECTRIC CO LTD

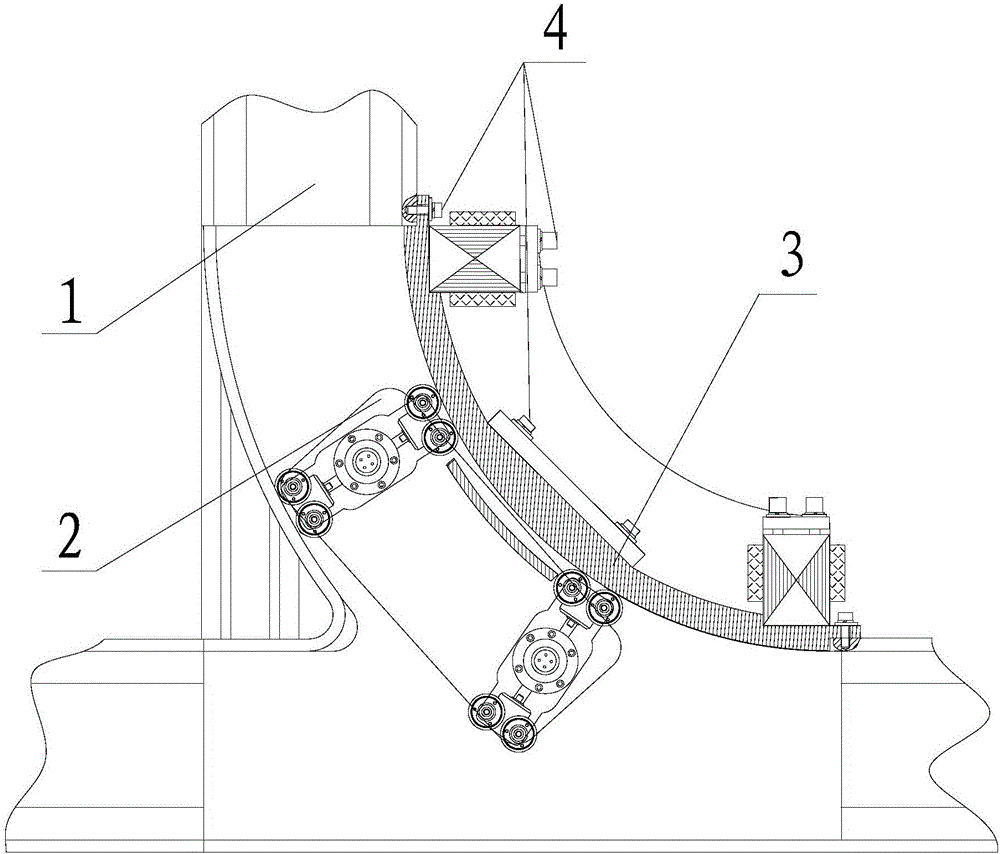

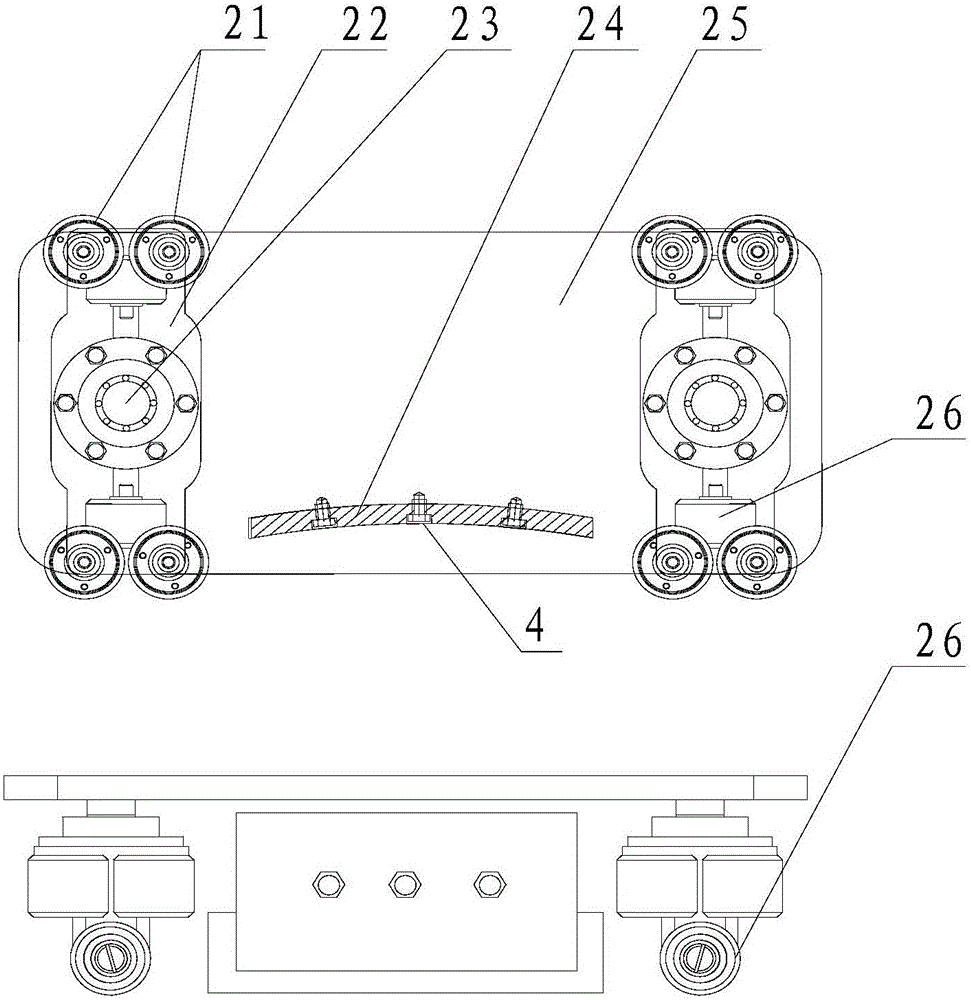

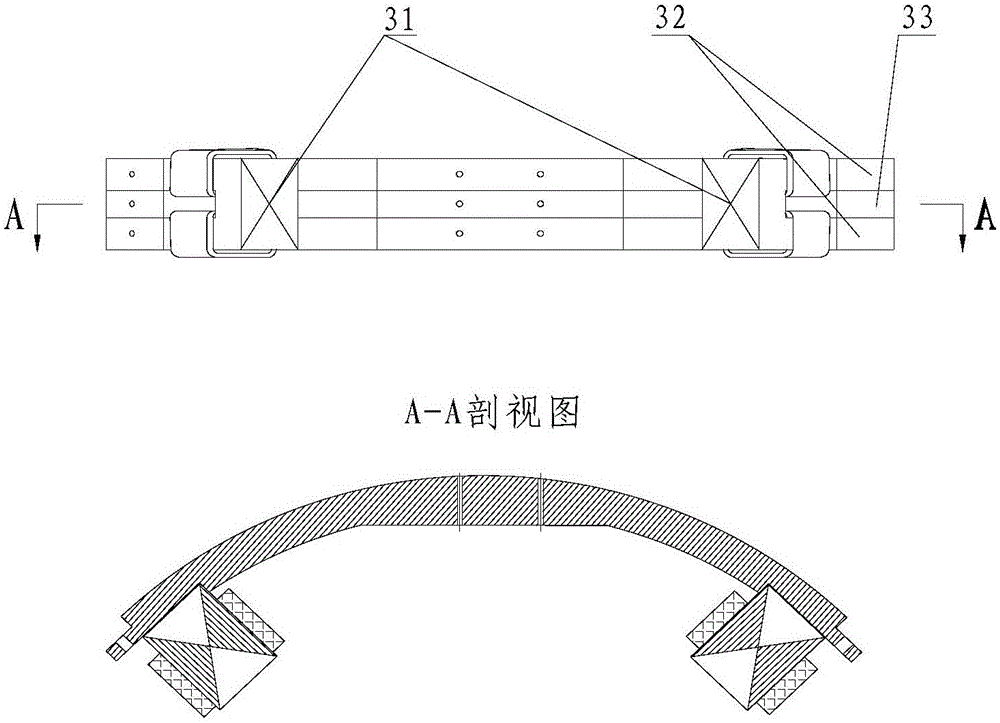

Double-closed-magnetic-circuit bend electromagnetic track transfer guide device and method

ActiveCN105818819ARealize full guidanceControl current sizeRailway componentsRailway tracksEngineeringElectromagnet

The invention relates to a double-closed-magnetic-circuit bend electromagnetic track transfer guide device which comprises a guide motion part and an electromagnetic excitation source part. The electromagnetic excitation source part is composed of two electromagnets, an upper bend magnetic conductive track, a lower bend magnetic conductive track and a middle spacer ring. The upper bend magnetic conductive track and the lower bend magnetic conductive track are in a vertical installation structure form and are bonded to the middle spacer ring to form a whole through epoxy glue and fastened to the end face on one side of an outer track through screws, and therefore the upper bend magnetic conductive track and the lower bend magnetic conductive track become a part of the outer track. By the adoption of the device, track transfer of a locomotive when running on a bend is achieved, and guidance is stable and controllable.

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

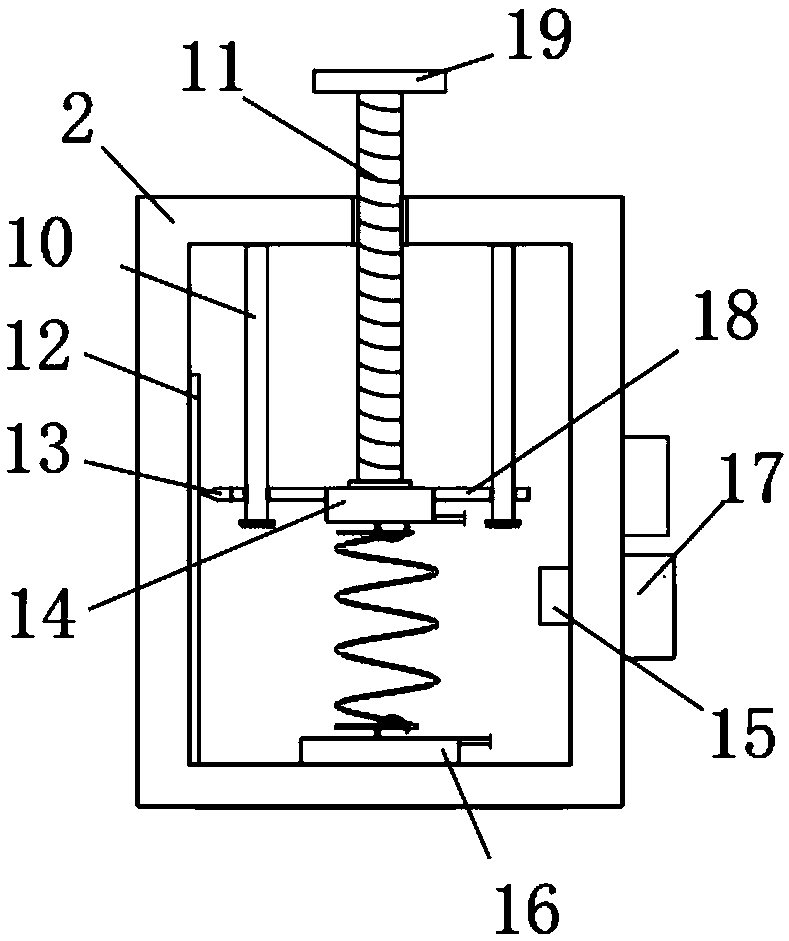

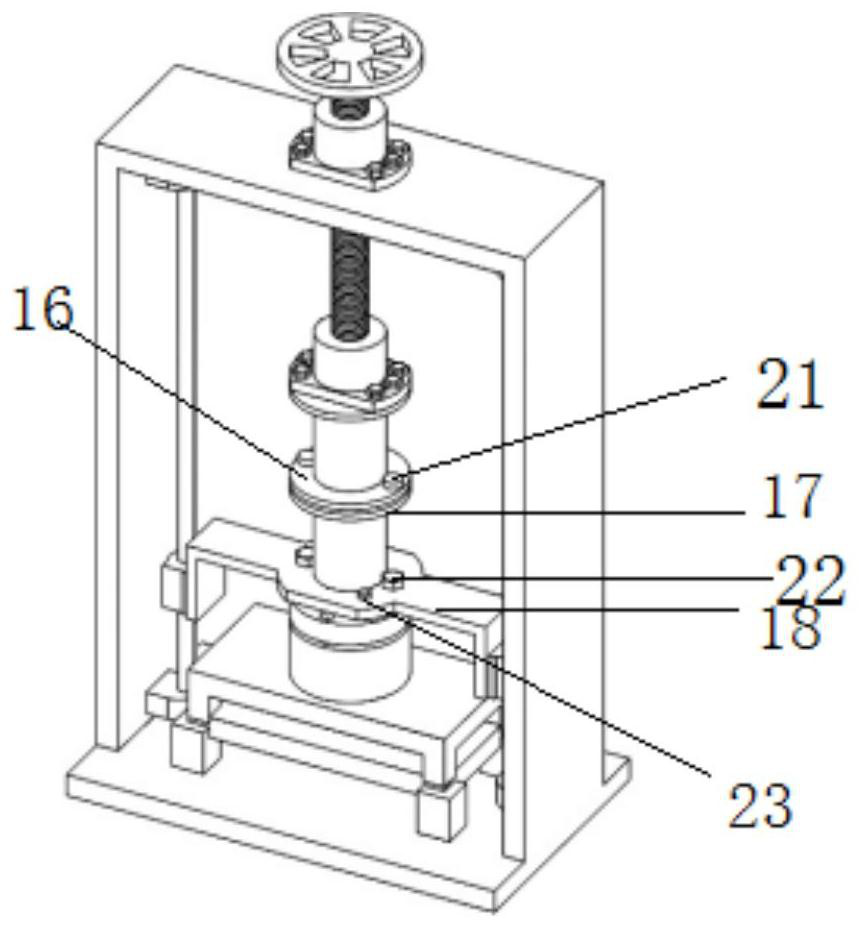

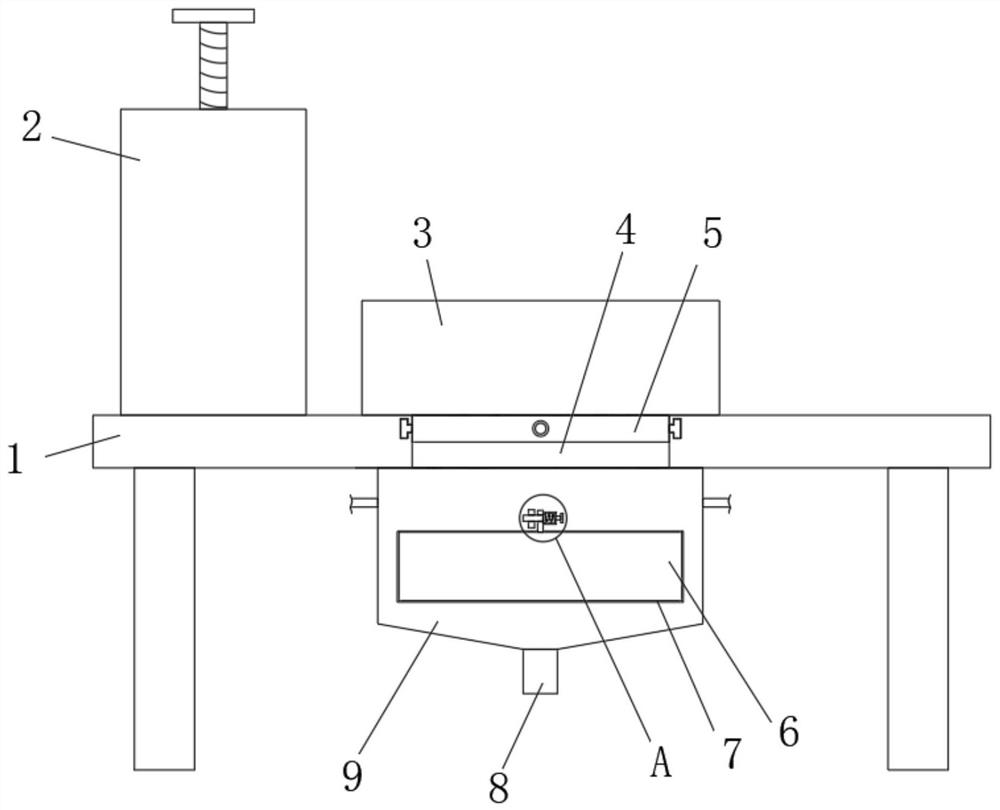

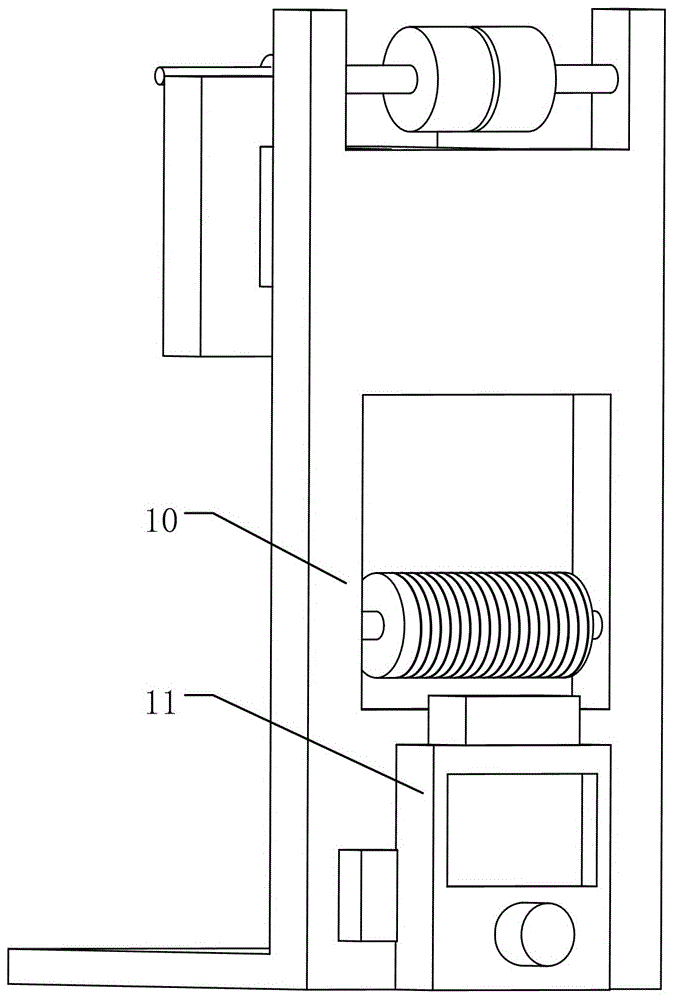

Spring stretching and correcting device

ActiveCN108856605AControl heating temperatureControl current sizeWire springsDrain tubeComputer engineering

The invention discloses a spring stretching and correcting device. The spring stretching and correcting device comprises an operation table, wherein the upper end of the operation table is successively fixedly connected with a fixing vertical frame and a fixing cross frame from left to right; a correcting mechanism is arranged on the inner side of the fixing vertical frame; a detecting mechanism is arranged on the inner side of the fixing cross frame; a dropping groove of which the position corresponds to the fixing cross frame is formed in the operation table in a penetrating manner; a baffleis arranged in the dropping groove and is slidably connected with the inner wall of the dropping groove; the lower end of the operation table is fixedly connected with a cleaning box of which the position corresponds to that of the dropping groove; the lower end of the cleaning box is fixedly connected with a liquid draining tube; a cleaning mechanism is arranged in the cleaning box; a drawing groove is formed in a side wall of the cleaning box in a penetrating manner; and the inside of the drawing groove is slidably connected with a collecting net frame. A spring can be rapidly stretched andcorrected, stretching while heating is realized, the correcting effect is good, after the spring is corrected, the performance of the spring can be tested, and the spring can be cleaned.

Owner:CHONGQING LIYING INTELLIGENT TECH RES INST CO LTD

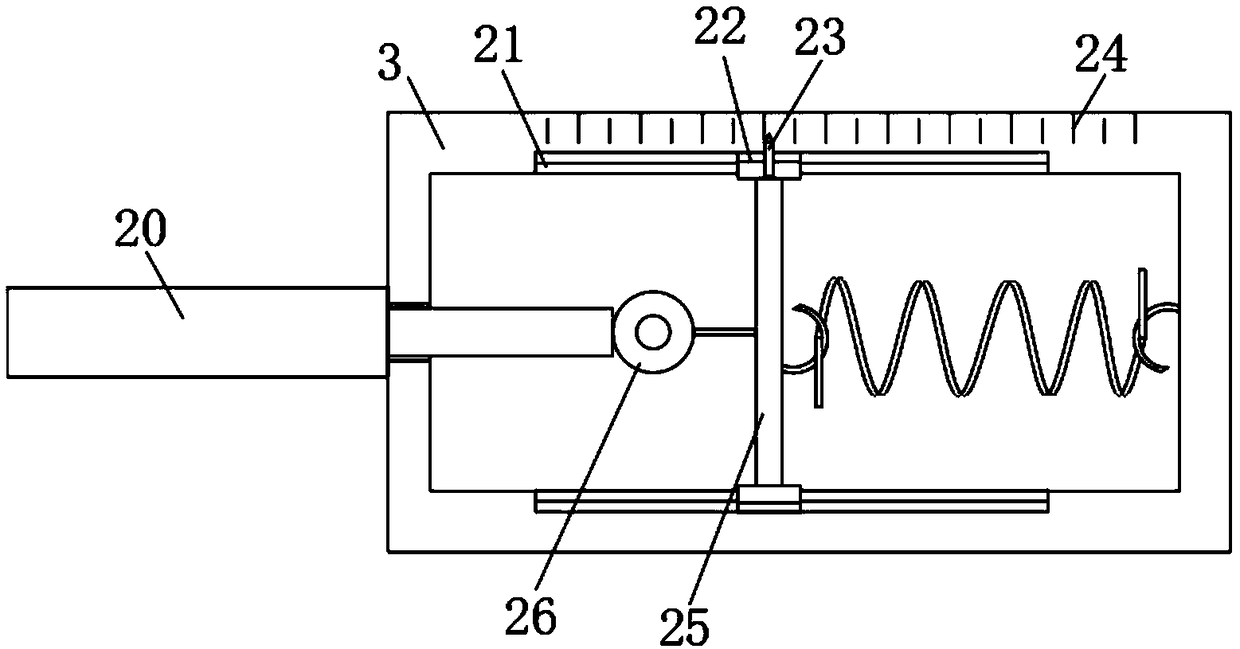

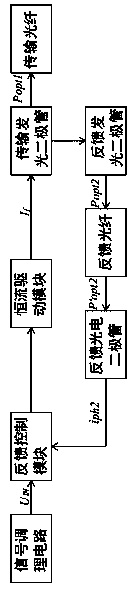

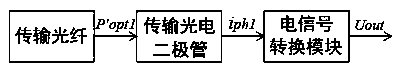

Linearized optical signal transmission system of electronic transformer

ActiveCN111211839AImprove reliabilityReduce complexityFibre transmissionInformation technology support systemDriving currentTransformer

The invention discloses a linearized optical signal transmission system of an electronic transformer, and belongs to the technical field of electrical engineering measurement. The high-voltage side and the low-voltage side are connected through a transmission optical fiber, and the system is characterized in that an electro-optical conversion module comprises a feedback control module; the feedback control module controls a transmission light-emitting diode and a feedback light-emitting diode to flow through driving currents with the same magnitude, and an optical signal emitted by the transmission light-emitting diode is connected with an interface, located on the high-voltage side, of the transmission optical fiber; a feedback loop is further arranged on the high-voltage side, optical signals emitted by the feedback light-emitting diode are converted into feedback voltage through the feedback loop, and the feedback voltage is connected with the other input end of the feedback controlmodule. According to the linearized optical signal transmission system of the electronic transformer, the feedback control module and the feedback loop connected with the feedback control module arearranged, so the size to be measured on the high-voltage side is linearly expressed through the luminous intensity of the light emitting diode, the complexity of the system is reduced, and the reliability is higher.

Owner:SHANDONG UNIV OF TECH

Electromagnetic adsorption device for packaging box

ActiveCN109178600AAvoid leaningPrevent movementBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesElectricityPower flow

The invention discloses an electromagnetic adsorption device for a packaging box. The electromagnetic adsorption device comprises a power supply, a switch, an electromagnetic coil, a piezoelectric power generation device, a controller and a signal receiver. The electromagnetic coil is connected to the power supply through the switch. The controller is connected to the power supply and the signal receiver. The electromagnetic coil is provided with an iron core. The piezoelectric power generation device comprises a piezoelectric crystal, a rectifying circuit, a current detection device and a signal emitter. The piezoelectric crystal is connected to a rechargeable battery through the rectifying current. The current detection device is arranged between the rectifying circuit and the rechargeable battery for detecting the amplitude of the current generated by the piezoelectric power generation device. The signal emitter is connected to the current detection device for emitting a current signal detected by the current detection device.

Owner:苏州聚鑫机器人有限公司

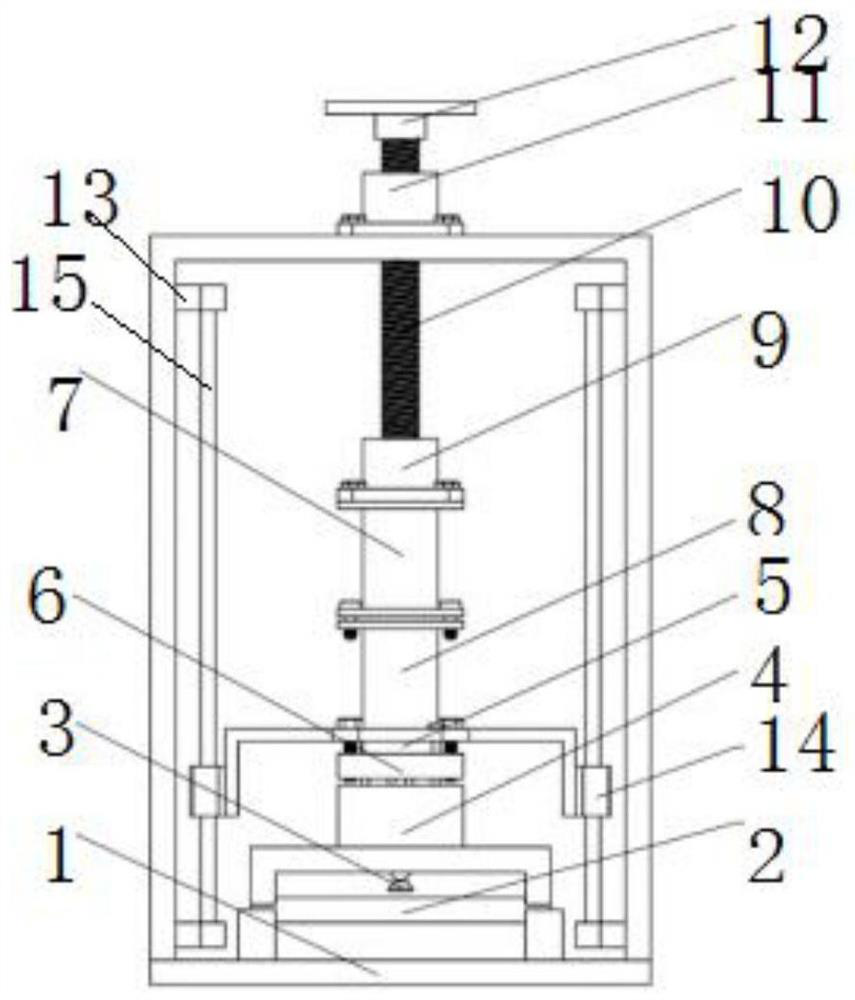

Hot pressing sintering clamp for chip packaging and chip packaging method

ActiveCN112786523AGuaranteed verticalityGuaranteed uniformityFinal product manufactureSolid-state devicesPlate pressureThrust bearing

The invention discloses a hot pressing sintering clamp for chip packaging and a chip packaging method. The hot pressing sintering clamp comprises a rack, a lower heating plate, a pressing head, an upper matching cover plate, a pressure sensor, a pressure transmission guide rod, a pressurizing mechanism, a thrust bearing, a lead screw, a lead screw nut and a rotating handle, and the lower heating plate and the upper matching cover plate are precisely matched at the four corners; the parallelism between the upper plate and the lower plate is ensured; and the pressure is controlled by the current in the two mutually exclusive electromagnets. And a spherical hinge structure is arranged between the pressure head and the pressure transmission guide rod, so that the upper surface of the chip can be uniformly pressed when the upper surface of the chip is not parallel to the lower surface of the substrate. The pressure transmission guide rod is precisely matched with the vertical through hole of the upper matching cover plate, so that the perpendicularity between the pressure transmission guide rod and the upper surface of the lower heating plate during pressurization is ensured, and the uniformity of the thickness of the welding flux of the sintering layer can be ensured in the pressurization process; in the heating process, the current of the electromagnet is controlled through pressure feedback, and pressure constant control is achieved.

Owner:BEIHANG UNIV

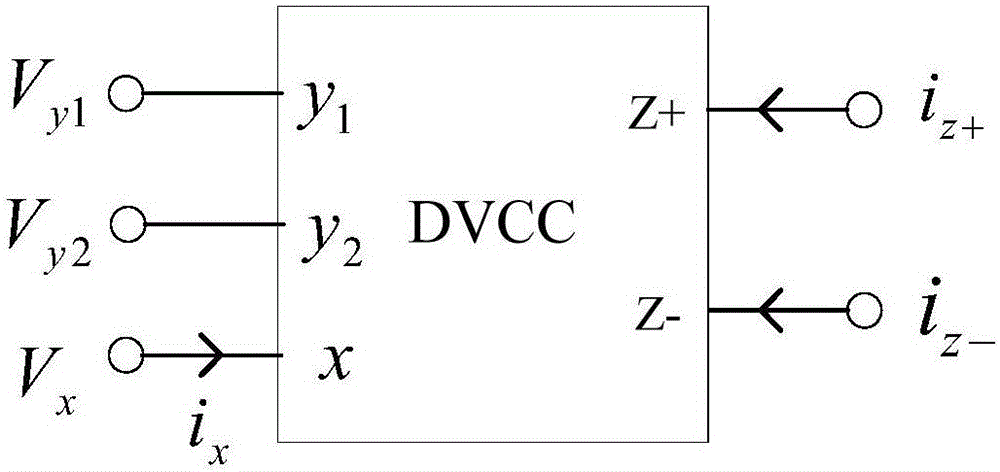

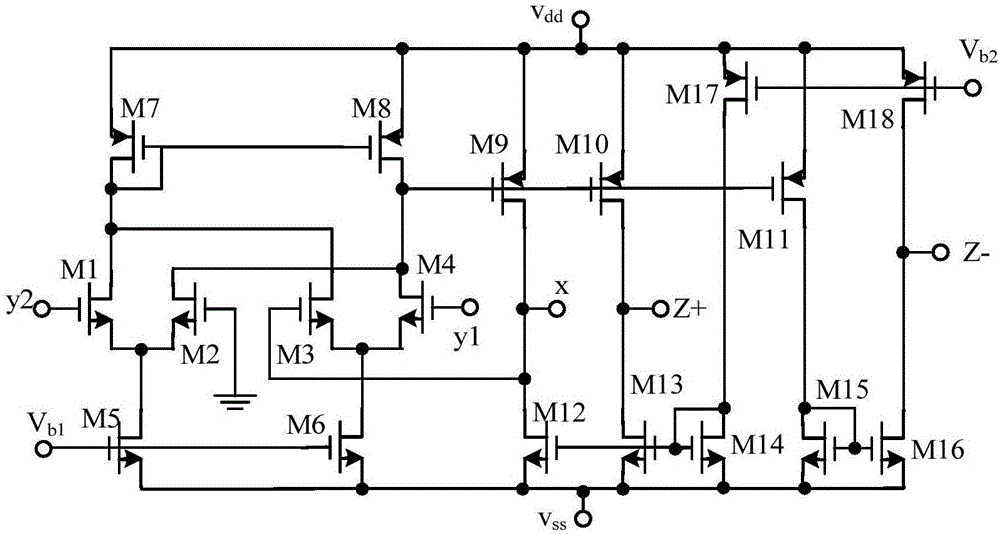

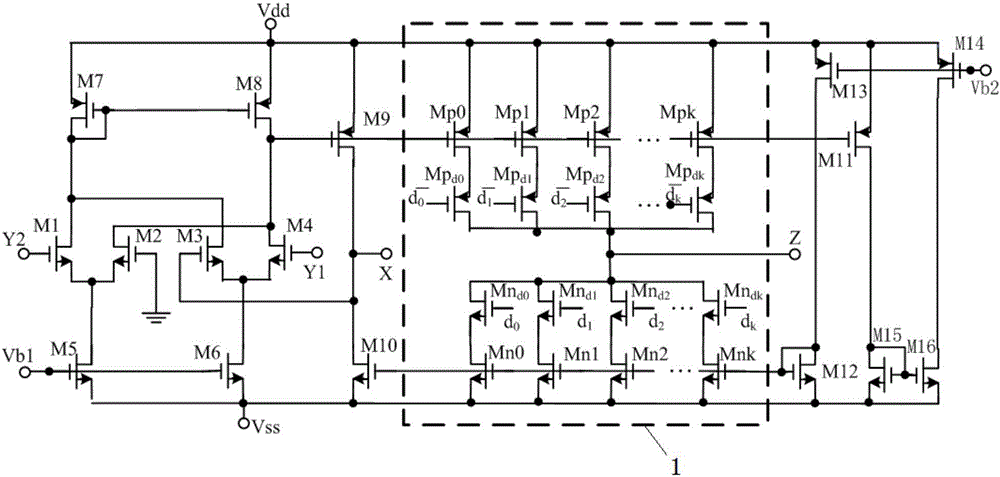

Differential voltage type current conveyor and biquad filter circuit

ActiveCN106130504AControl current sizeSimple structureFrequency selective two-port networksEngineeringControl circuit

The invention discloses a differential voltage type current conveyor, comprising a switch control circuit, and first to sixteenth MOS transistors. The switch control circuit is a switch array controlled by a digital signal. The switch control circuit comprises 2M PMOS transistors and 2M NMOS transistors. The differential voltage type current conveyor provided by the invention comprises the switch control circuit. The switch control circuit comprises the PMOS transistors and the NMOS transistors of the same quantity. The PMOS transistors and the NMOS transistors form the switch array controlled by the digital signal. Therefore, the current of the Z output end of the differential voltage type current conveyor is controlled. The differential voltage type current conveyor has digital controllable current gain, a differential voltage input characteristic of a current conveyor and an electric tuning characteristic, and has the advantages of simple structure and wide application range. The invention also discloses a biquad filter circuit comprising the differential voltage type current conveyor.

Owner:湖南纽帕科技有限公司

Method for controlling quality of water turbine guide vane casting through double-loop conductive crystallizer electroslag remelting

PendingCN114350970AUniform temperature distributionGood solidification quality and surface qualityCasting safety devicesFoundry mouldsSlagDual loop

The invention discloses a method for controlling the quality of a water turbine guide vane casting through electroslag remelting of a double-loop conductive crystallizer. The method comprises the specific steps that (1) slag materials are baked; 2) determining the slag quantity and the filling ratio of the upper crystallizer and the lower crystallizer; a bottom pad and a lower crystallizer are placed, and an arcing material is bound to an electrode end; (3) switching on a power supply, starting to add slag, and arcing to melt slag; (4) after all the slag materials are melted down, the remelting current and voltage are adjusted and set, and electroslag remelting in the lower crystallizer is carried out; (5) after the electroslag in the lower crystallizer is remelted, an upper conductive crystallizer is installed, electrodes are replaced, the remelting current and voltage are adjusted and set again, and electroslag remelting is conducted through a double loop of a power source, a consumable electrode, slag charge, a metal molten pool, a casting, a bottom water tank, a power source and a double loop of the power source, the consumable electrode, the slag charge, the upper conductive crystallizer and the power source; and (6) in the later stage of remelting, after feeding operation of the electroslag remelting point is stopped, power is cut off, and a remelted water turbine guide vane casting is obtained through cooling. By adopting the method, the water turbine guide vane casting with good surface and internal quality can be obtained.

Owner:SHENYANG RES INST OF FOUNDRY

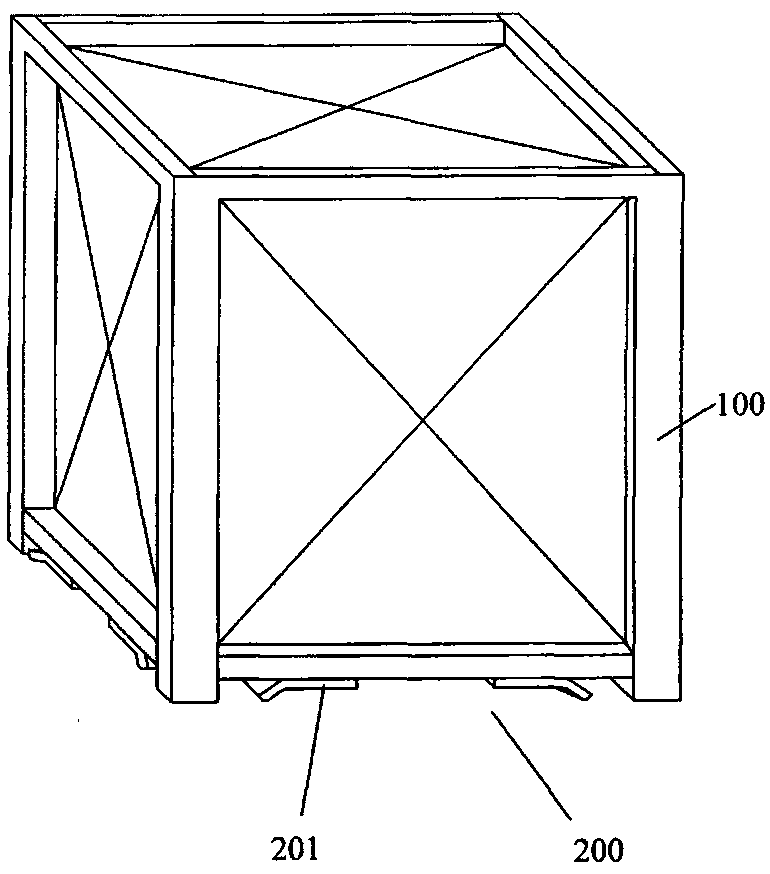

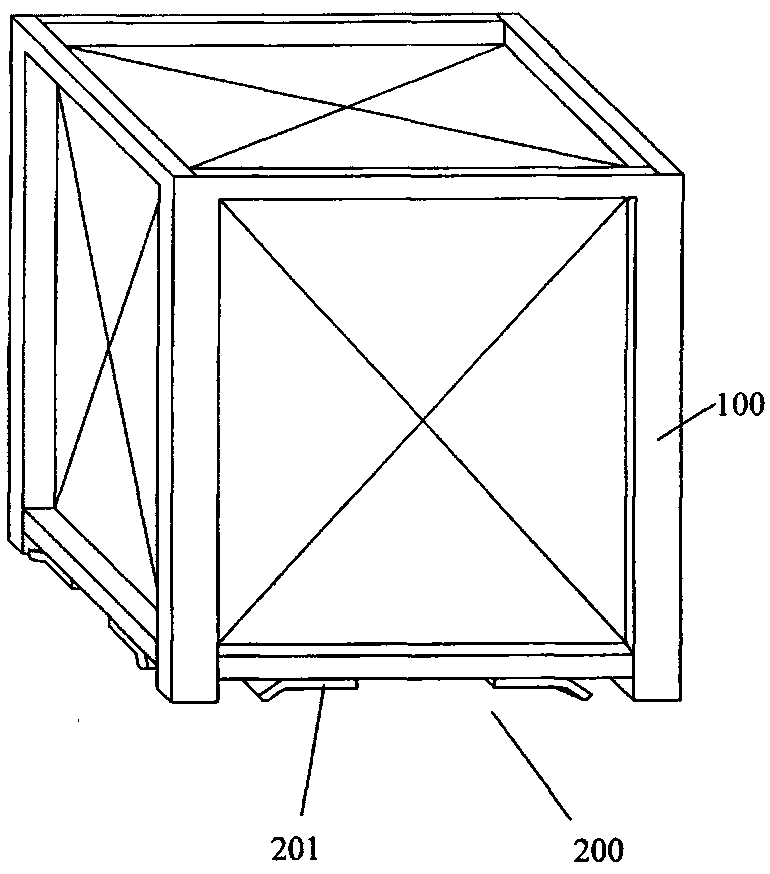

Electromagnetic adsorption type packaging box for long-distance transportation

InactiveCN109178601APlace stableSo as not to damageClosure with auxillary devicesContainers to prevent mechanical damageEngineeringChassis

The invention discloses an electromagnetic adsorption type packaging box for long-distance transportation. The packaging box comprises a packaging box body, a fixed chassis, a baffle plate and an airpressure rod. The bottom of the packaging box body is fixedly connected to the fixed chassis, one side of the outer surface of the fixed chassis is fixedly connected to the baffle plate, and a first hole is formed in the upper surface of the baffle plate. According to the electromagnetic adsorption type packaging box for long-distance transportation, the fixed chassis is arranged at the bottom ofthe packaging box body, the packaging box body can be placed stably. The baffle plate is arranged out of the fixed chassis, so that the packaging box body is not impacted by an external force, and thecondition that the packaging box bodies collide to damage as the packaging box bodies swing in the long-distance transportation is avoided. A protecting cover is arranged on the top of the packagingbox body, and the air pressure rod is arranged between the protecting cover and the fixed chassis, so that the packaging box body is protected fully. An electromagnetic adsorption device is arranged to enhance fixation of the packaging box body, so that the safety of the packaging box body is enhanced effectively.

Owner:ZHENGZHOU YUNQI IND EQUIP TECH CO LTD

A non-arc power failure protection switch control circuit

Owner:KEDU ELECTRIC CO LTD

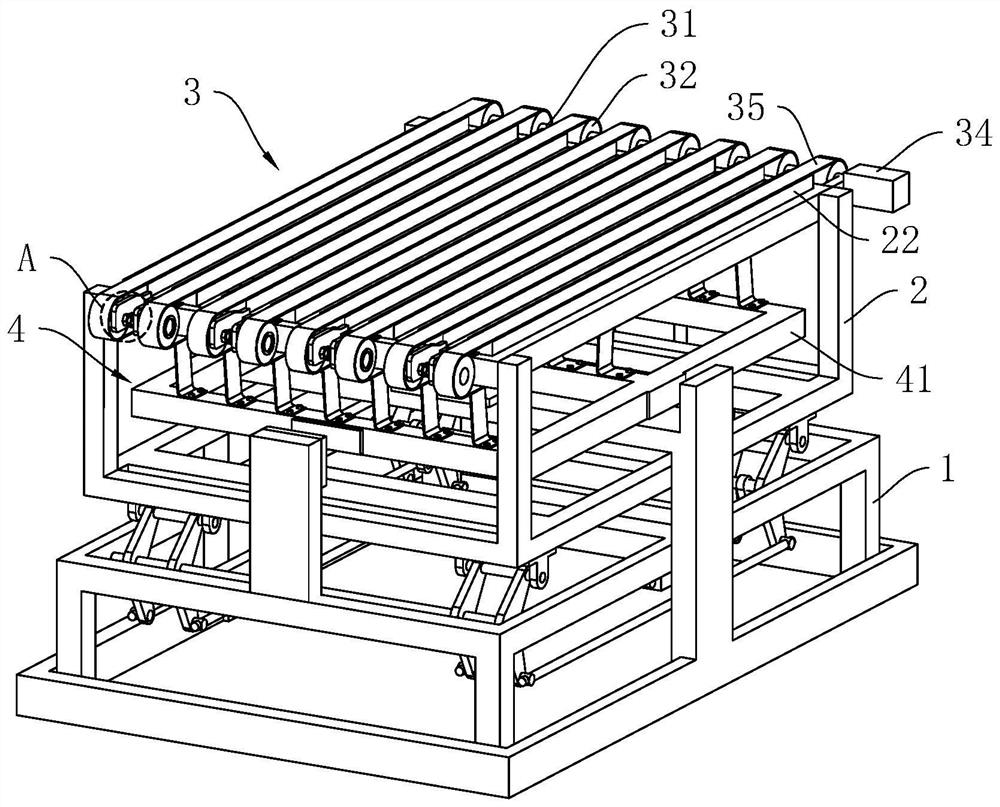

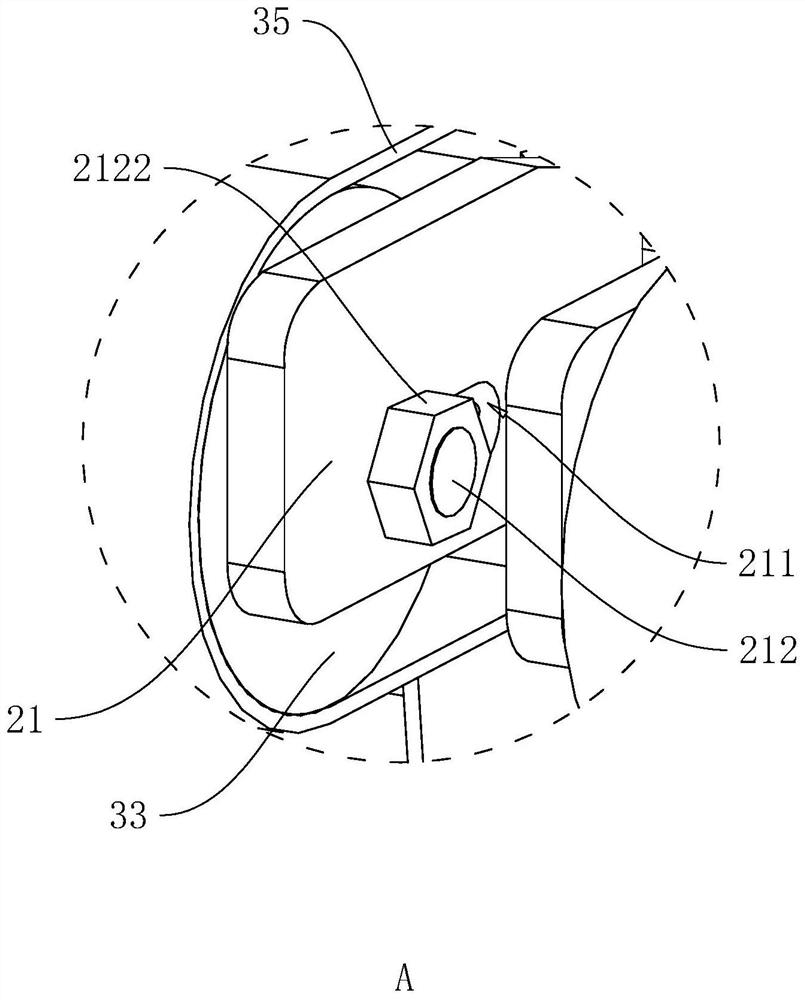

Material transportation and weighing integrated inspection system

ActiveCN113155261AEasy to operateSave human effortConveyorsControl devices for conveyorsStructural engineeringMaterial transport

The invention relates to a material transportation and weighing integrated inspection system, which relates to the technical field of material production equipment, and comprises a frame body, a mounting frame, a transportation mechanism and a weighing mechanism, the weighing mechanism comprises a bearing frame arranged on the frame body, a supporting rod arranged on the bearing frame, a weighing device arranged at the bottom of the bearing frame and a lifting assembly used for driving the mounting frame to ascend and descend, the weighing device is fixedly connected with the frame body, a gap allowing the supporting rod to stretch out is formed in the mounting frame, and when the mounting frame descends, materials are arranged on the supporting rod. When the materials are discharged, the materials are weighed firstly, the lifting assembly is used for controlling the mounting frame to descend, the supporting rod supports the materials, after the materials are completely separated from the mounting frame, the weighing device is used for weighing the materials, the mounting frame is controlled to ascend after weighing is completed, and then the conveying mechanism is used for conveying the materials. The whole blanking operation is very convenient, manpower is saved, and the production efficiency is improved.

Owner:浙江致盛包装科技有限公司

A spring stretch correction device

ActiveCN108856605BControl heating temperatureControl current sizeWire springsDraining tubeEngineering

The invention discloses a spring stretching and correcting device. The spring stretching and correcting device comprises an operation table, wherein the upper end of the operation table is successively fixedly connected with a fixing vertical frame and a fixing cross frame from left to right; a correcting mechanism is arranged on the inner side of the fixing vertical frame; a detecting mechanism is arranged on the inner side of the fixing cross frame; a dropping groove of which the position corresponds to the fixing cross frame is formed in the operation table in a penetrating manner; a baffleis arranged in the dropping groove and is slidably connected with the inner wall of the dropping groove; the lower end of the operation table is fixedly connected with a cleaning box of which the position corresponds to that of the dropping groove; the lower end of the cleaning box is fixedly connected with a liquid draining tube; a cleaning mechanism is arranged in the cleaning box; a drawing groove is formed in a side wall of the cleaning box in a penetrating manner; and the inside of the drawing groove is slidably connected with a collecting net frame. A spring can be rapidly stretched andcorrected, stretching while heating is realized, the correcting effect is good, after the spring is corrected, the performance of the spring can be tested, and the spring can be cleaned.

Owner:CHONGQING LIYING INTELLIGENT TECH RES INST CO LTD

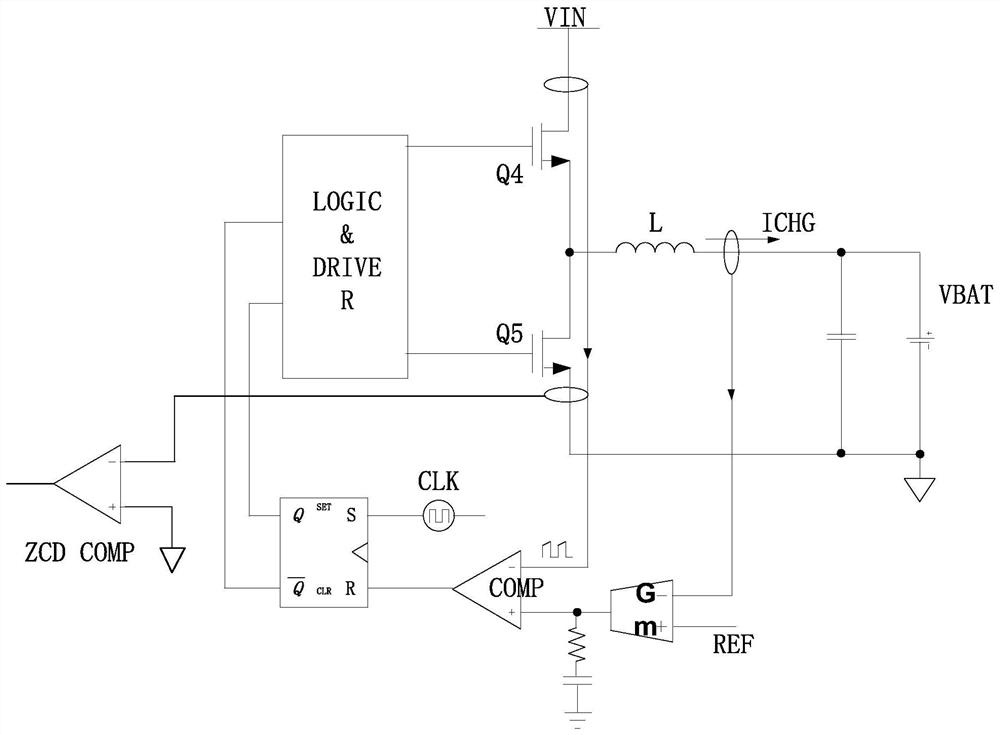

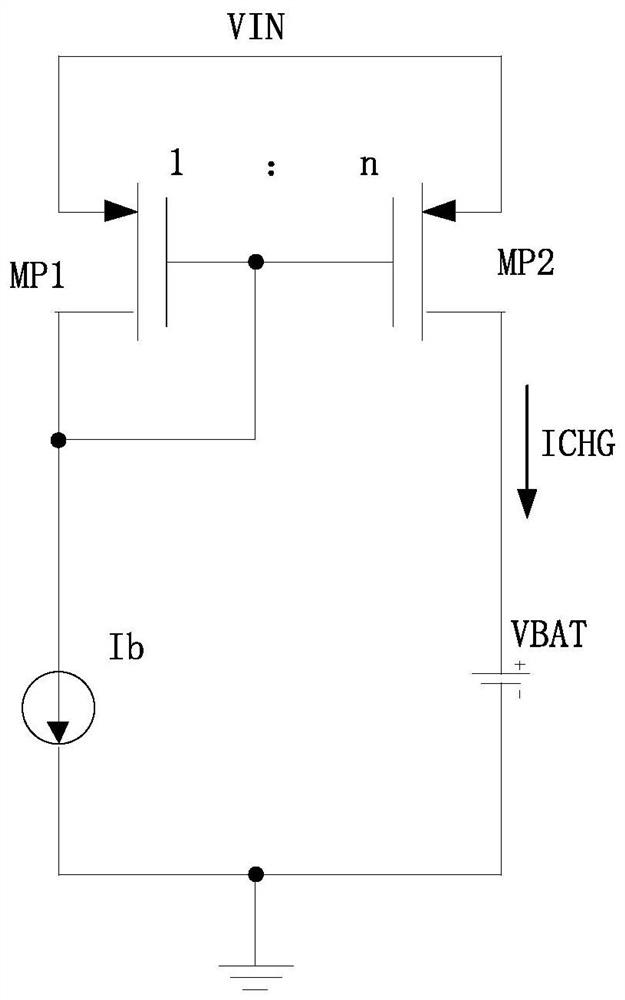

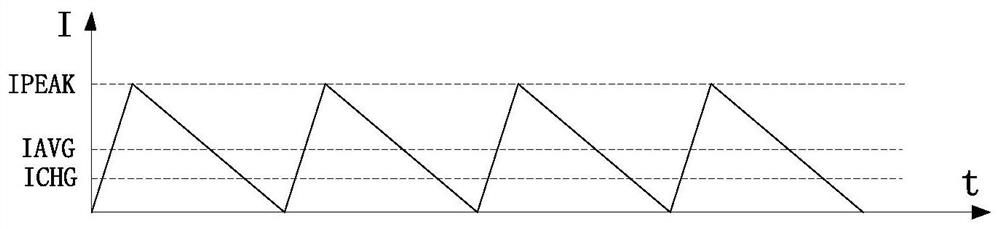

A circuit and method for implementing trickle charging in a switch mode charger

ActiveCN110601309BExtended service lifeControl current sizeBatteries circuit arrangementsSecondary cells charging/dischargingMOSFETCharge current

The invention discloses a circuit and method for realizing trickle charging in a switch mode charger, which mainly solves the problem that the trickle charging scheme of the existing switch mode charger cannot accurately control and adjust the size of the trickle charging current ICHG, so that Its application scenarios are limited. Use the time when the inductor current appears for time-sharing timing, introduce a pause time between two consecutive times when the inductor current appears, and use the comparator and RS flip-flop to realize the control of the average value of the charging current in the switch mode charger, so that It can achieve neither adding an additional MOSFET nor causing heat, and can also accurately control the current size of the trickle charging, which not only saves the cost but also effectively prolongs the service life of the charger. Therefore, it has high use value and promotion value.

Owner:SOUTHCHIP SEMICON TECH SHANGHAI CO LTD

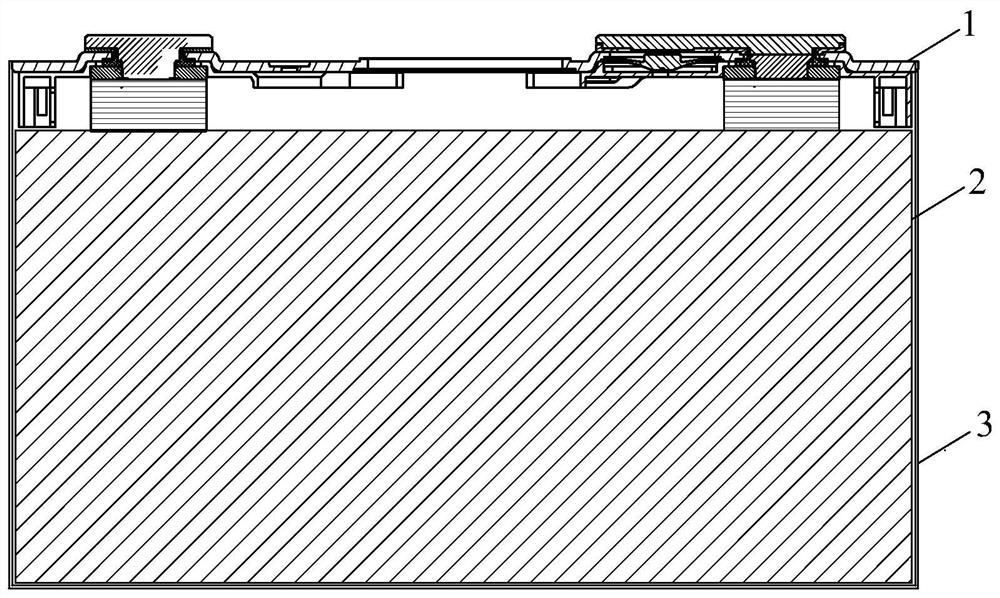

Secondary battery top cover and secondary battery

ActiveCN108110159BImprove high temperature resistanceIncrease contact resistanceSecondary cellsCell lids/coversElectrical batteryElectrical connection

The invention provides a secondary battery top cover, comprising: a top cover sheet and a first electrode unit, a second electrode unit and a flipping sheet arranged on the top cover sheet, the first electrode unit includes a first pole and a resistor arranged on the first pole, the first pole is electrically connected to the top cover sheet through the resistor, the second electrode unit includes a second pole and a conductive sheet electrically connected to the second pole, the second pole is connected to the second pole The top cover is insulated and assembled, the overturning piece is electrically connected to the top cover, the conductive piece is located above the overturning piece, and the resistor has conductive filler and adhesive. When an accident happens to the battery, the first electrode unit and the second electrode unit are electrically connected to form an external short circuit due to the action of the flipping sheet and the electrical connection of the resistance to the first electrode and the top cover sheet, because the conductive filler and adhesive are used. Resistance, the resistance of the resistance is stable, and the contact resistance is small, which can well control the magnitude of the current, thereby improving the safety performance of the battery.

Owner:江西百思利新能源科技股份有限公司

Driving device

ActiveCN101221714BControl current sizeShorten the stabilization timeCathode-ray tube indicatorsDifferential amplifiersDigital dataAnalog signal

The invention provides a driving device and a driving method thereof. The driving device comprises a digital-analog conversion circuit and a signal amplifying circuit, wherein, the digital-analog conversion circuit is used to receive digital data and converts the digital data into an analog signal; the signal amplifying circuit is coupled with the digital-analog conversion circuit for receiving the analog signal to generate a driving signal and dynamically changing the driving capability of the driving signal according to at least one bit in the digital data.

Owner:NOVATEK MICROELECTRONICS CORP

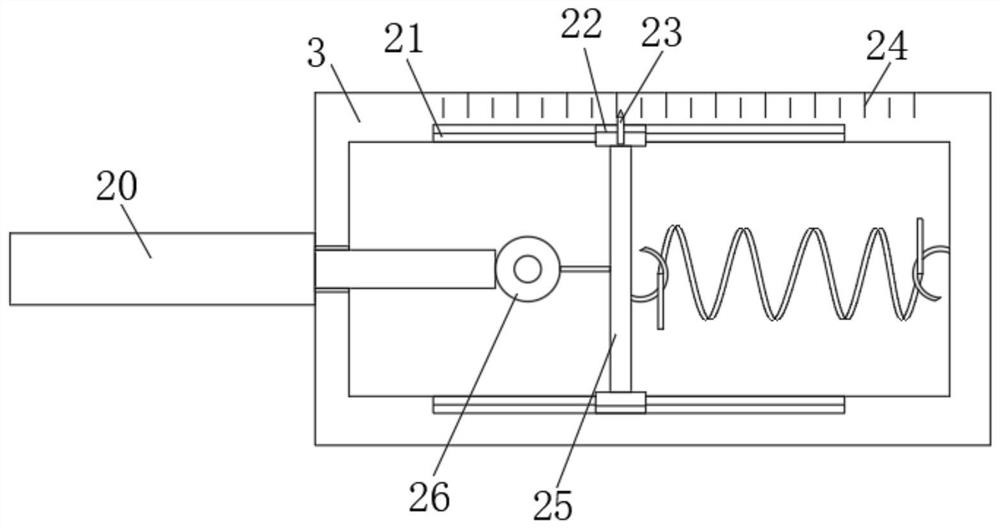

Micro-wire electrode processing device

InactiveCN106623697AAvoid burnsControl current sizeOther manufacturing equipments/toolsInsulation layerPower flow

The invention relates to a micro-wire electrode processing device which can be used for welding electrode wires to electrode pins. The micro-wire electrode processing device includes: a work platform; an electrode clamp which is arranged on the work platform and is configured to fix the electrode pins; an array hole plate which is arranged on a workbench, each electrode wire can successively pass through corresponding hole of the array hole plate so as to allow a plurality of electrode wires to form an electrode wire array; an electrode wire clamp which is arranged on the work platform, and is configured to clamp the electrode wires; and a wire cutting device which includes a controller and a wire cutting machine, and is configured to allow the controller to control the current of the wire cutting machine, wherein the wire cutting machine can cut off the electrode wires under the control of the controller. The work platform is fixed on an upper surface of a two-dimensional movement module, and the two-dimensional movement module is configured to adjust the position of the work platform. The beneficial effects of the invention are that the controller can control the current during cutting so as to prevent the electrode wire from being burned; and a laser device can remove surface insulation layer of the electrode wires.

Owner:科斗(苏州)脑机科技有限公司

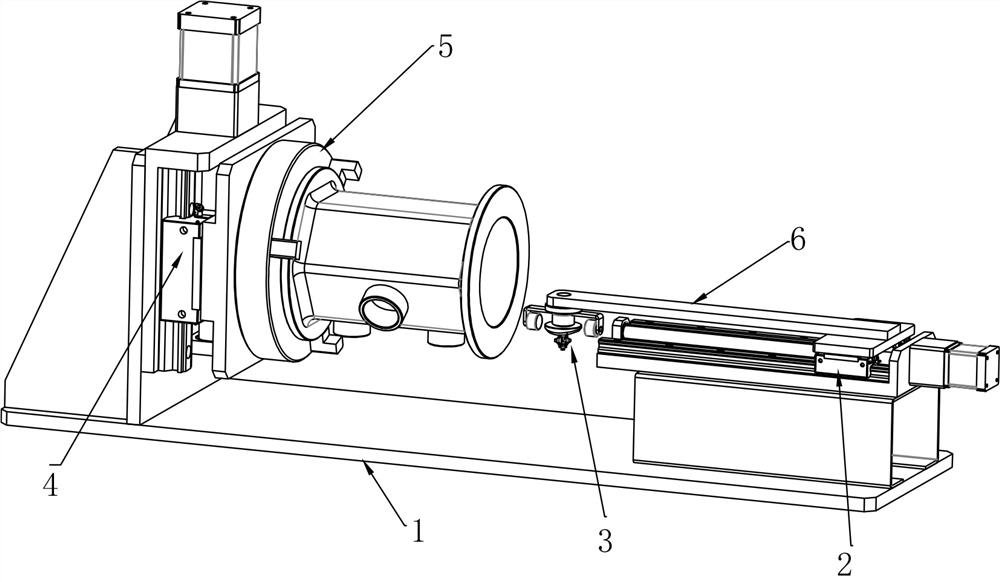

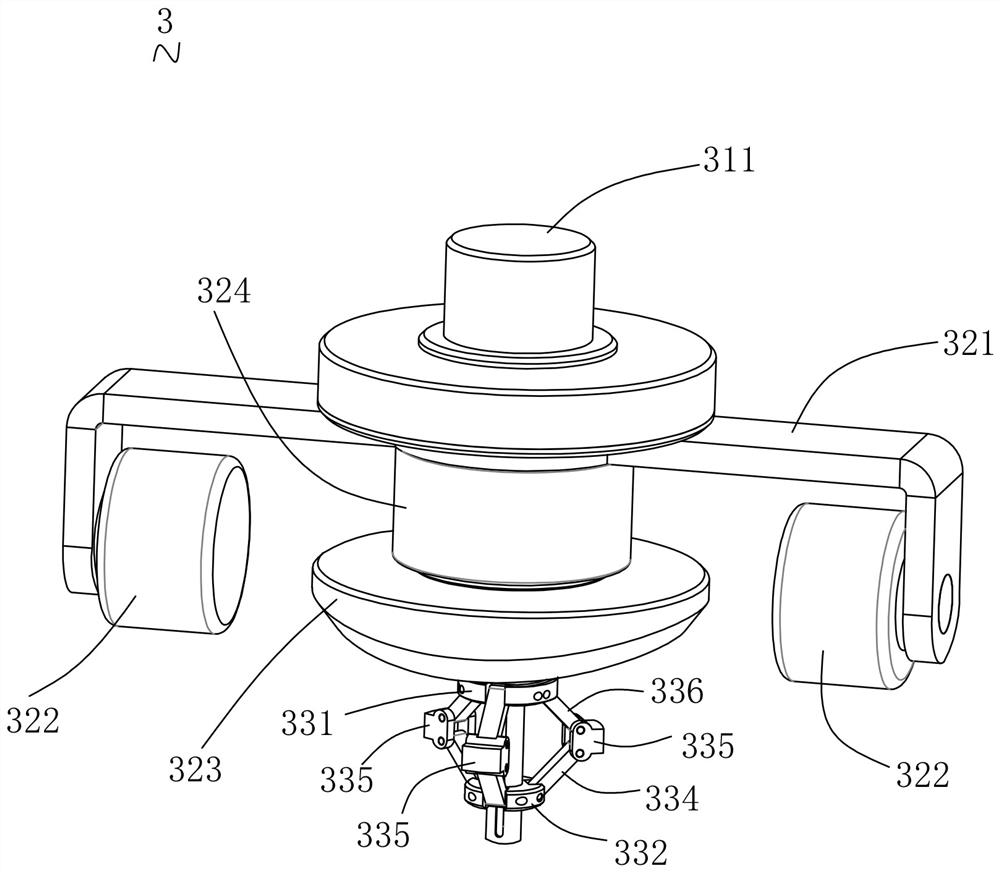

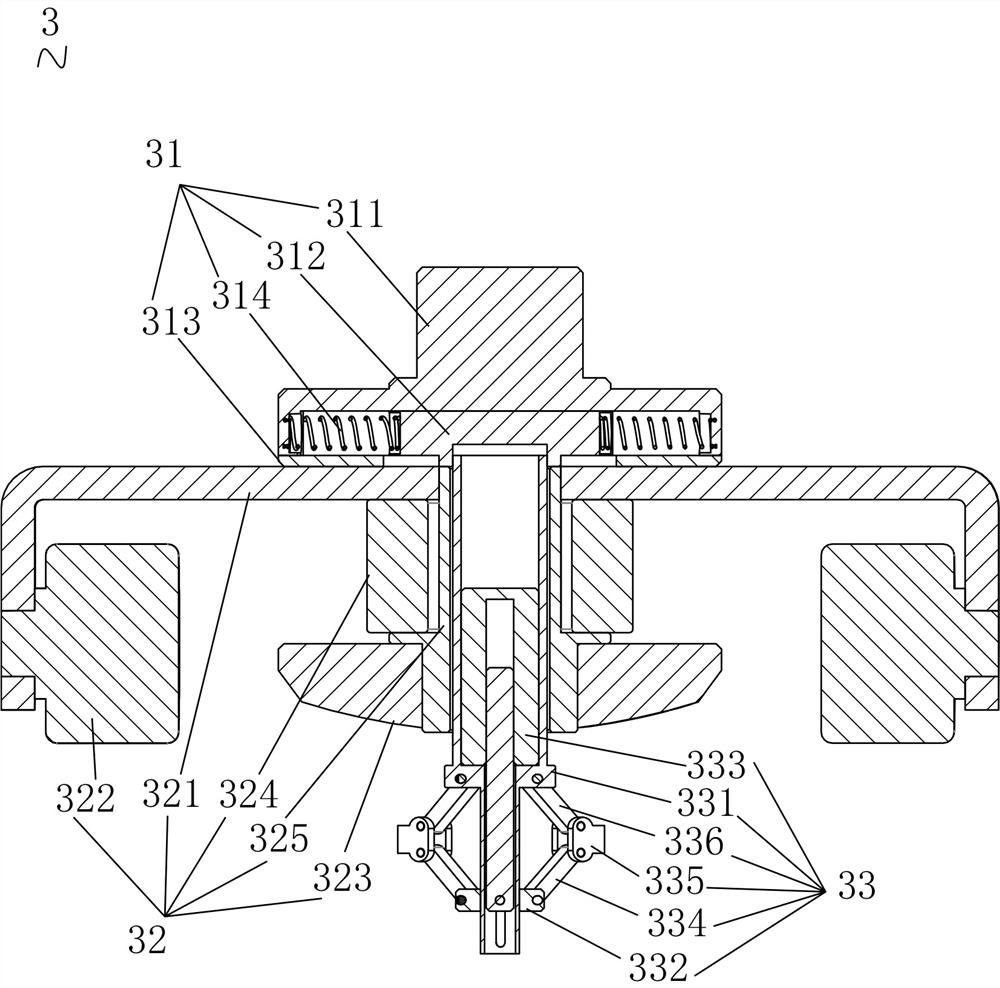

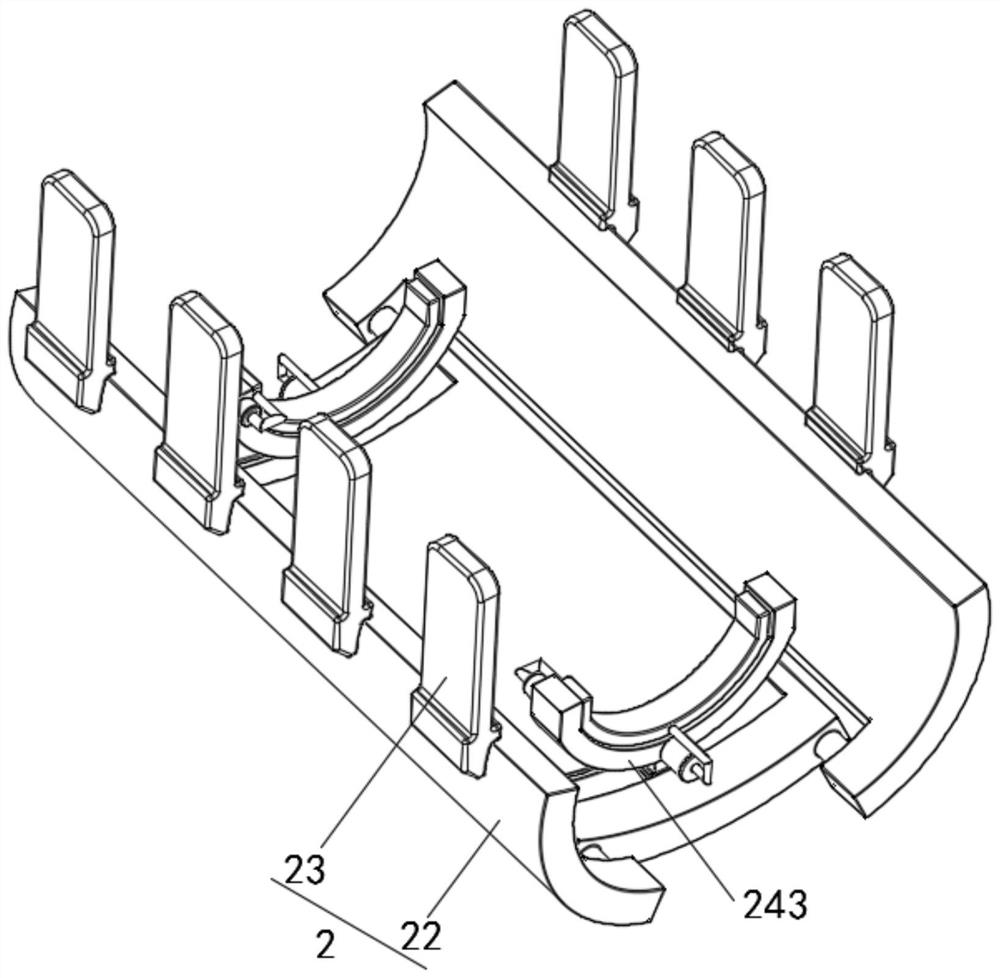

High-precision electric arc type self-adaptive grinding shaping device

InactiveCN112388485APassing resistance is smallReduce labor intensityGrinding carriagesGrinding machinesGrindingElectric arc

The invention discloses a high-precision electric arc type self-adaptive grinding shaping device. The device comprises a rack, a horizontal displacement mechanism, a self-adaptive grinding shaping mechanism, a vertical displacement mechanism and a rotary clamping mechanism; the horizontal displacement mechanism is installed at one end of the rack, the self-adaptive grinding shaping mechanism is connected with the output end of the horizontal displacement mechanism through a cantilever, the vertical displacement mechanism is installed at the other end of the rack, and the rotary clamping mechanism is fixed to the output end of the vertical displacement mechanism; and the self-adaptive grinding shaping mechanism comprises an elastic deflection compensation component, a self-orientation electrode component and a self-centering tensioning component, the elastic deflection compensation component is fixed on the cantilever, the self-centering tensioning component is connected with the deflection output end of the elastic deflection compensation component, and the self-orientation electrode component is movably connected to the self-centering tensioning component in a sleeving mode, and can rotate relative to the self-centering tensioning component. According to the device, the high-precision grinding shaping operation on an valve orifice intersection line is achieved, the mechanicaloperation is achieved, the labor intensity is reduced, the efficiency is high, and a valve is not prone to being scratched.

Owner:JINGMEN YIMEI IND DESIGN CO LTD

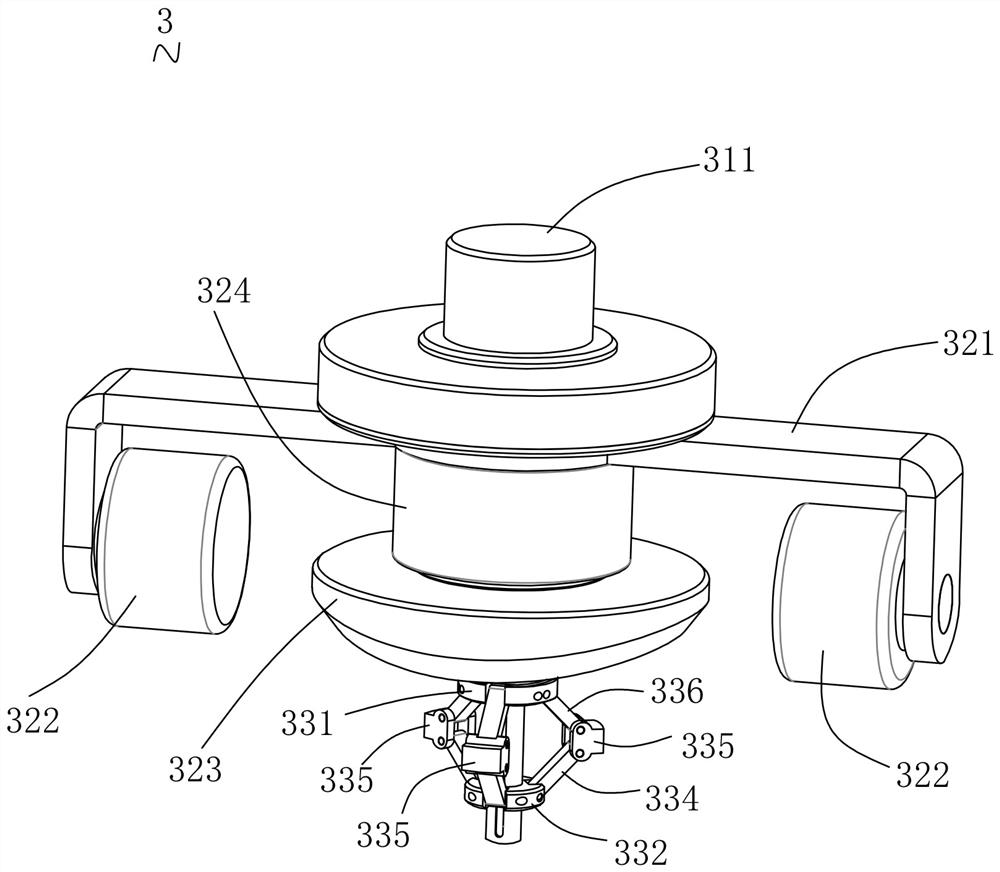

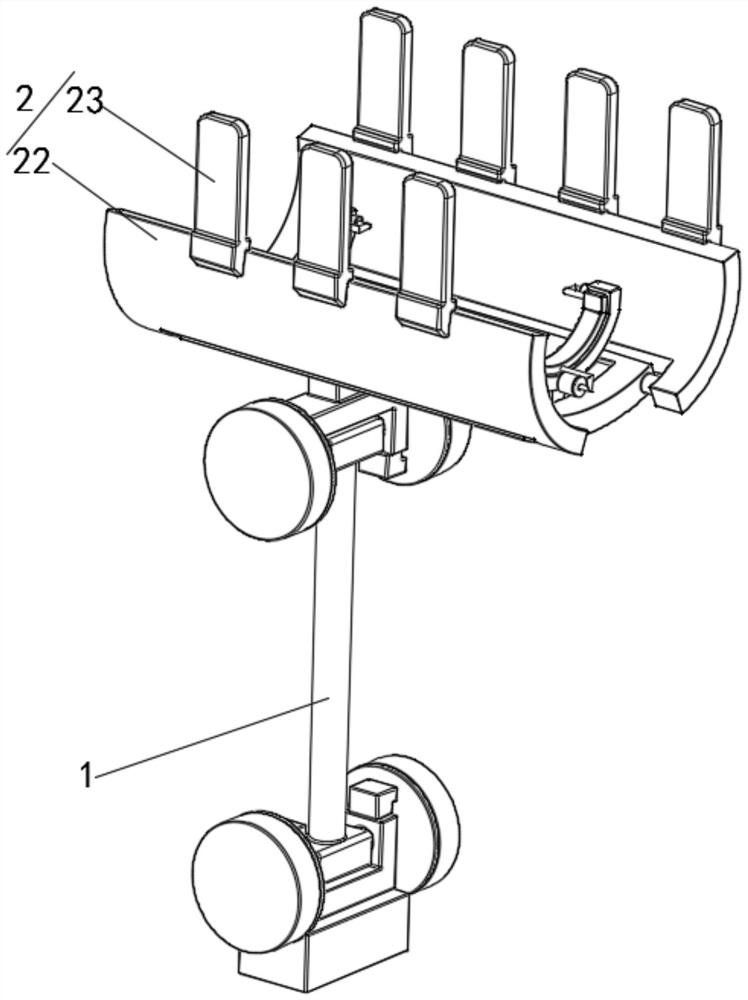

High-precision electric arc type self-adaptive grinding and shaping robot complete machine

InactiveCN112318329ANot easy to scratchPassing resistance is smallGrinding carriagesGrinding drivesEngineeringMachine

The invention discloses a high-precision electric arc type self-adaptive grinding and shaping robot complete machine. The high-precision electric arc type self-adaptive grinding and shaping robot complete machine comprises a machine tool, an electric arc type grinding robot unit, a material moving and transferring unit and a conveying unit, wherein the electric arc type grinding robot unit and theconveying unit are arranged on the machine tool at intervals, and the material moving and transferring unit is arranged on the machine tool and is located between the electric arc type grinding robotunit and the conveying unit; and the electric arc type grinding robot unit comprises a machine frame, a horizontal displacement mechanism, a self-adaptive grinding and shaping mechanism, a vertical displacement mechanism and a rotary clamping mechanism. According to the high-precision electric arc type self-adaptive grinding and shaping robot complete machine, high-precision grinding and shapingoperation at the intersection line of valve orifices is realized, mechanical operation is realized, the labor intensity is reduced, the efficiency is high, and a valve is not prone to being scratched.

Owner:JINGMEN YIMEI IND DESIGN CO LTD

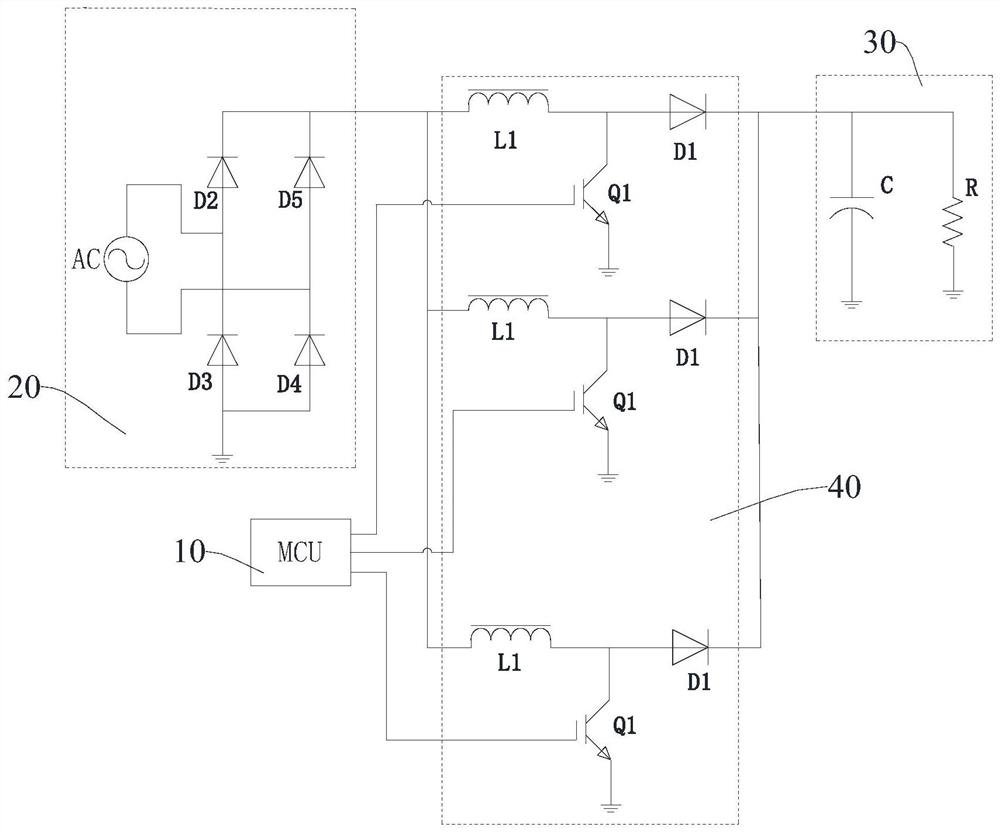

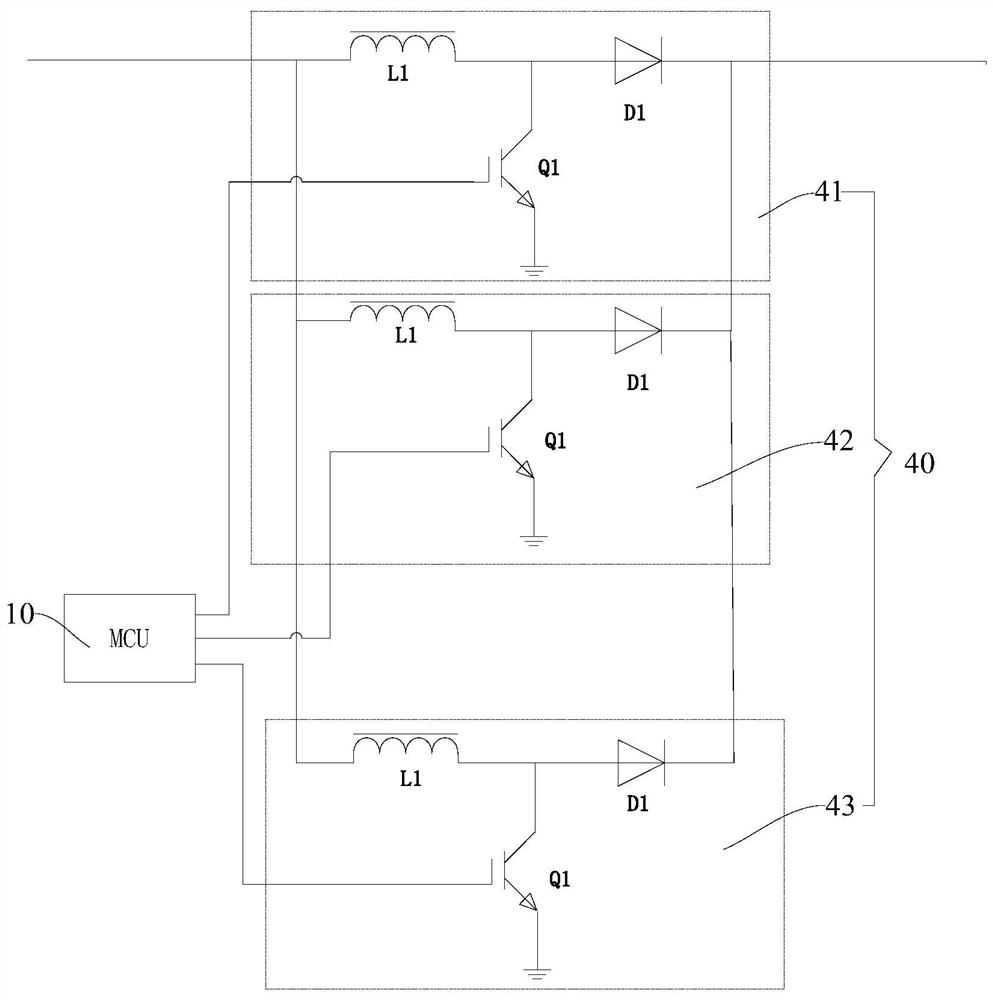

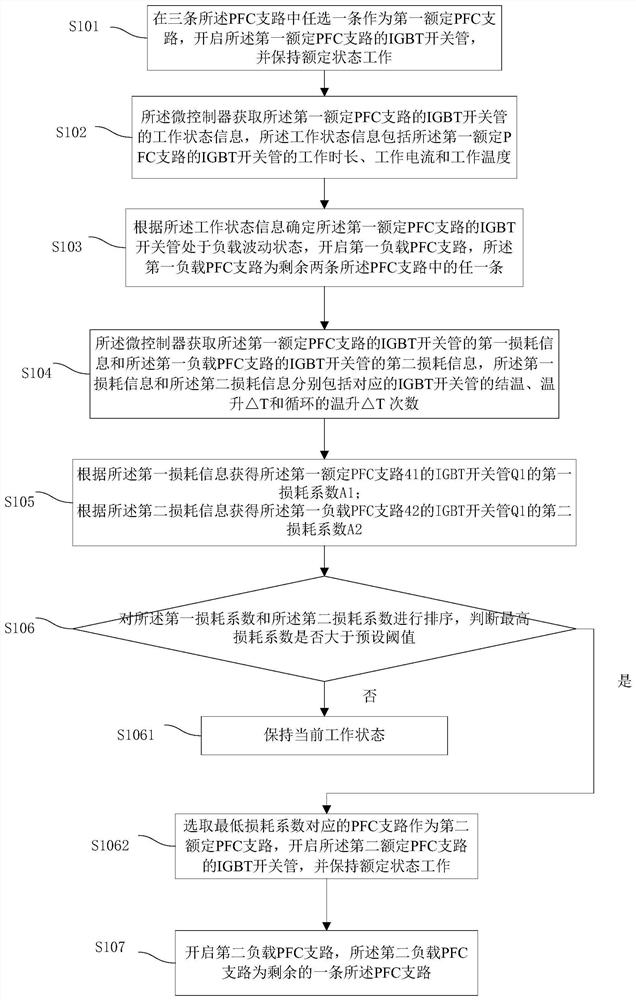

Multi-channel interleaved PFC control system and method

PendingCN111953197AControl current sizeControl feverEfficient power electronics conversionPower conversion systemsInductorLoad circuit

The invention provides a multipath interleaved PFC control system and method, the system comprises a microcontroller, a rectification circuit, a load circuit and a PFC circuit, and the PFC circuit comprises at least two PFC branches which are connected in parallel between the rectification circuit and the load circuit; each PFC branch comprises an energy storage inductor, a branch diode and an IGBT switch tube. And the microcontroller is used for switching on the IGBT switch tube of any PFC branch when the IGBT switch tube of one PFC branch is in a load fluctuation state. The method is appliedto the control system, the first rated PFC branch is ensured to work in a rated state, the IGBT switch tube of the first rated PFC branch is ensured to be in heating and heat dissipation balance to the maximum extent, the PFC function is ensured, and the first load PFC branch is started when load fluctuation occurs, so that the loss of the IGBT switch tube is reduced, and the service life of theIGBT switch tube is prolonged.

Owner:BEIJING INST OF TECH ZHUHAI CAMPUS

Distance-adjustable supporting device for laser therapeutic instrument

ActiveCN114533304ATo achieve the purpose of initial fixationTo achieve the effect of initial supportDiagnosticsSurgeryEngineeringTherapeutic effect

The invention relates to the technical field of laser therapeutic instruments, and discloses a distance-adjustable supporting device for a laser therapeutic instrument, the distance-adjustable supporting device comprises a distance adjusting rod, the upper side of the distance adjusting rod is rotatably connected with a connecting block, a fixing device comprises a bottom plate, a clamping plate, a hook-and-loop fastener and an adjusting device, the upper side of the connecting block is fixedly connected with the bottom plate, and the bottom plate is fixedly connected with the clamping plate. Clamping plates are rotationally connected to the left side and the right side of the bottom plate correspondingly, and hook-and-loop fasteners distributed at equal intervals are fixedly installed on the upper sides of the clamping plates. According to the distance-adjustable supporting device for the laser therapeutic instrument, a medical worker rotates a small arm, a shifting block is located at the center of a bottom plate to the other end of a slide rheostat, the maximum current is introduced into an electrorheological fluid solution, an electrorheological body can become a solid, and then the purpose that a distance adjusting rod, the bottom plate and a fixing block are in a fixed connection state is achieved; meanwhile, the distance adjusting rod can adjust the distance at will along with the movement of the forearm, and therefore the problem that the treatment effect is poor is solved.

Owner:XUZHOU CENT HOSPITAL

Complementary type metal oxidizing layer semiconductor noise generator

ActiveCN101202532BReduce power consumptionSolve the problem of working distanceNoise generationDifferential amplifiersDifferential amplifierSemiconductor

The invention relates to the noise generator technical field. The invention discloses a complementary metal oxide semiconductor noise generator, comprising a bias circuit which is used for providing DC working points for a dual-drain complementary metallic oxide semiconductor transistor current mirror and a differential amplifier; the dual-drain complementary metallic oxide semiconductor transistor current mirror is used for converting slight noise current signals into amplified or larger differential voltage signals which are then output to the differential amplifier; the invention also comprises the differential amplifier which is used for converting differential both-terminal signals input by the dual-drain complementary metallic oxide semiconductor transistor current mirror into single-terminal signals and amplifies and outputs the single-terminal signals. By adopting the CMOS process which is widely applied, the invention greatly reduces the power loss of noise generator and wellsolves the problem that reactive label working distance is shortened even the power loss is only a plurality of MuW.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com