Linearized optical signal transmission system of electronic transformer

An electronic transformer and transmission system technology, applied in electromagnetic wave transmission system, transmission system, optical fiber transmission, etc., can solve the problems of increasing DC reference signal compensation amount, heavy workload, and high difficulty in implementation, and achieve the goal of offsetting LED luminous characteristics Change, strong engineering practicability, simple circuit to achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

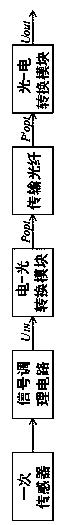

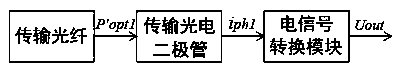

[0032] Such as figure 1 As shown, a linearized optical signal transmission system of an electronic transformer includes a primary sensor, a signal conditioning circuit, an electro-optical conversion module, a transmission optical fiber and a photoelectric conversion module. The primary sensor is connected to the input end of the signal conditioning circuit, the output end of the signal conditioning circuit is connected to the input end of the electro-optic conversion module, the output end of the electro-optical conversion module is connected to the input end of the transmission fiber (the transmission fiber is located at the connection end of the high-voltage side), the transmission fiber The output end (the connection end of the transmission fiber at the low-voltage side) is connected to the input end of the photoelectric conversion module, and the output end of the photoelectric conversion module outputs the signal.

[0033] After the primary sensor collects the electrical...

Embodiment 2

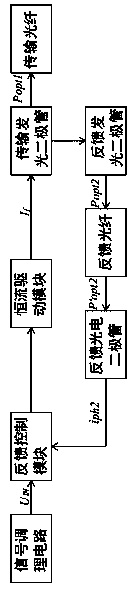

[0049] The difference between this embodiment and Embodiment 1 is that in this embodiment, the difference between the voltage signals at both ends of the input feedback control module is used to realize the voltage signal U IN and transmit the luminous power of the LED P opt1 There is a linear relationship between the two.

[0050] Such as Figure 5 As shown, an electrical signal conversion module is set in the feedback loop, and the electrical signal conversion module is located between the feedback photodiode and the feedback control module. The feedback photodiode generates a current signal after being excited by the light signal, and the current signal passes through the electrical signal on the high voltage side. The conversion module converts the feedback voltage into the other input terminal of the feedback control module.

[0051] The specific working process and working principle are as follows:

[0052] It can be seen from the description of the embodiment that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com