High-precision electric arc type self-adaptive grinding and shaping robot complete machine

A robotic and self-adaptive technology, applied in the direction of grinding racks, grinding machine parts, grinding machines, etc., can solve problems such as scratches on the inner wall of the hole and the inner cavity of the valve, large resistance to fluid passage, unfavorable fluid flow, etc., to achieve saving The effect of labor cost, reduction of labor intensity and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

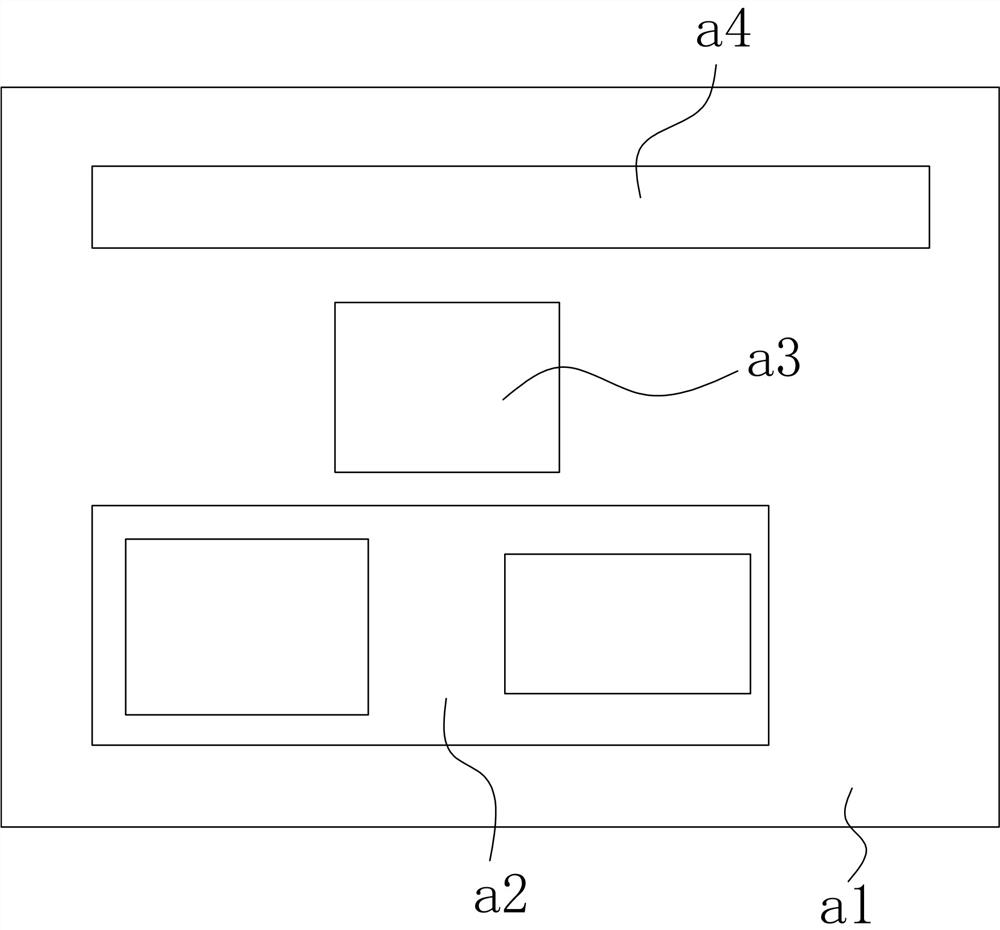

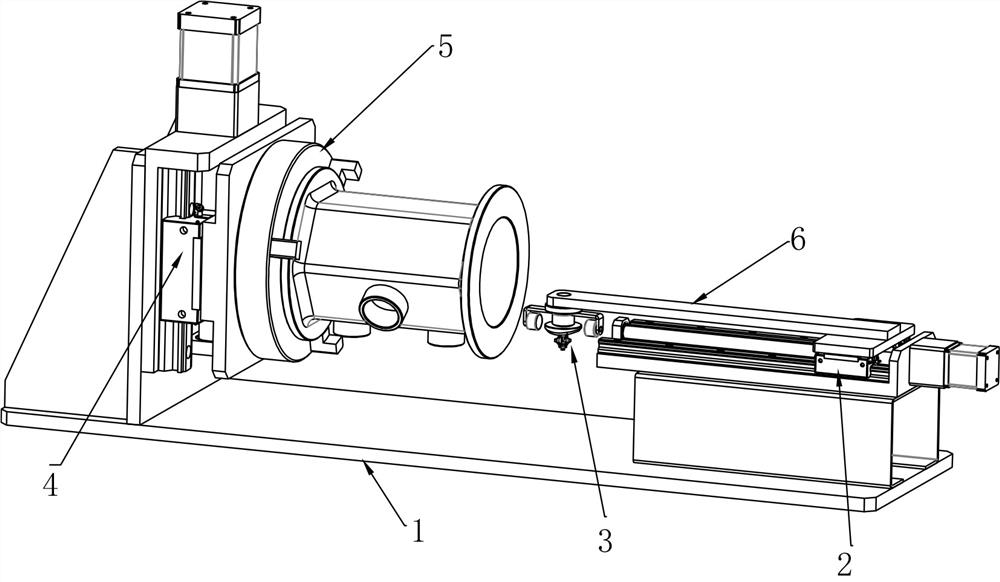

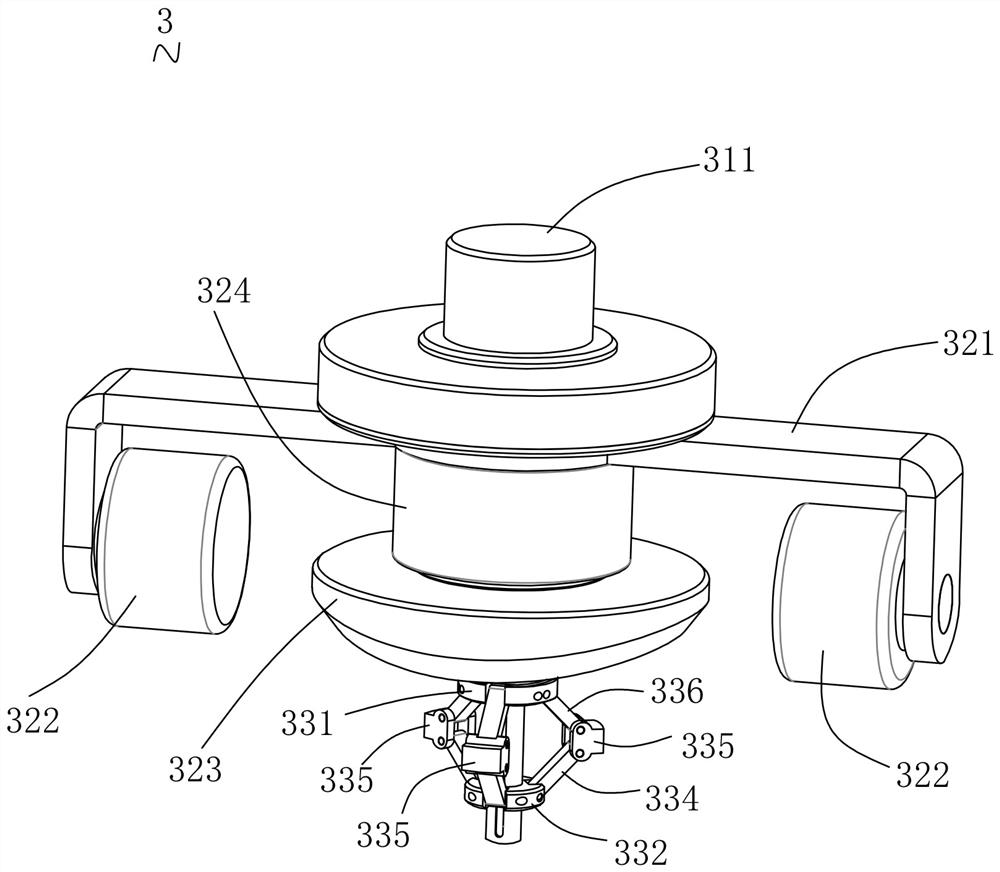

[0026] Such as Figure 1 to Figure 5 As shown, a complete high-precision arc-type adaptive grinding and shaping robot described in this embodiment includes an organic machine tool a1, an arc-type grinding robot unit a2, a material transfer unit a3, and a conveying unit a4. The robot unit a2 and the conveying unit a4 are arranged at intervals on the machine tool a1, and the material transfer unit a3 is arranged on the machine tool a1 and located between the arc grinding robot unit a2 and the conveying unit a4.

[0027] In actual use, the conveying unit a4 transports the valve to be shaped to the waiting area, and then the material transfer unit a3 transfers the valve to be shaped on the conveying unit a4 located in the waiting area to the arc grinding robot u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com