Patents

Literature

64results about How to "Protective contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

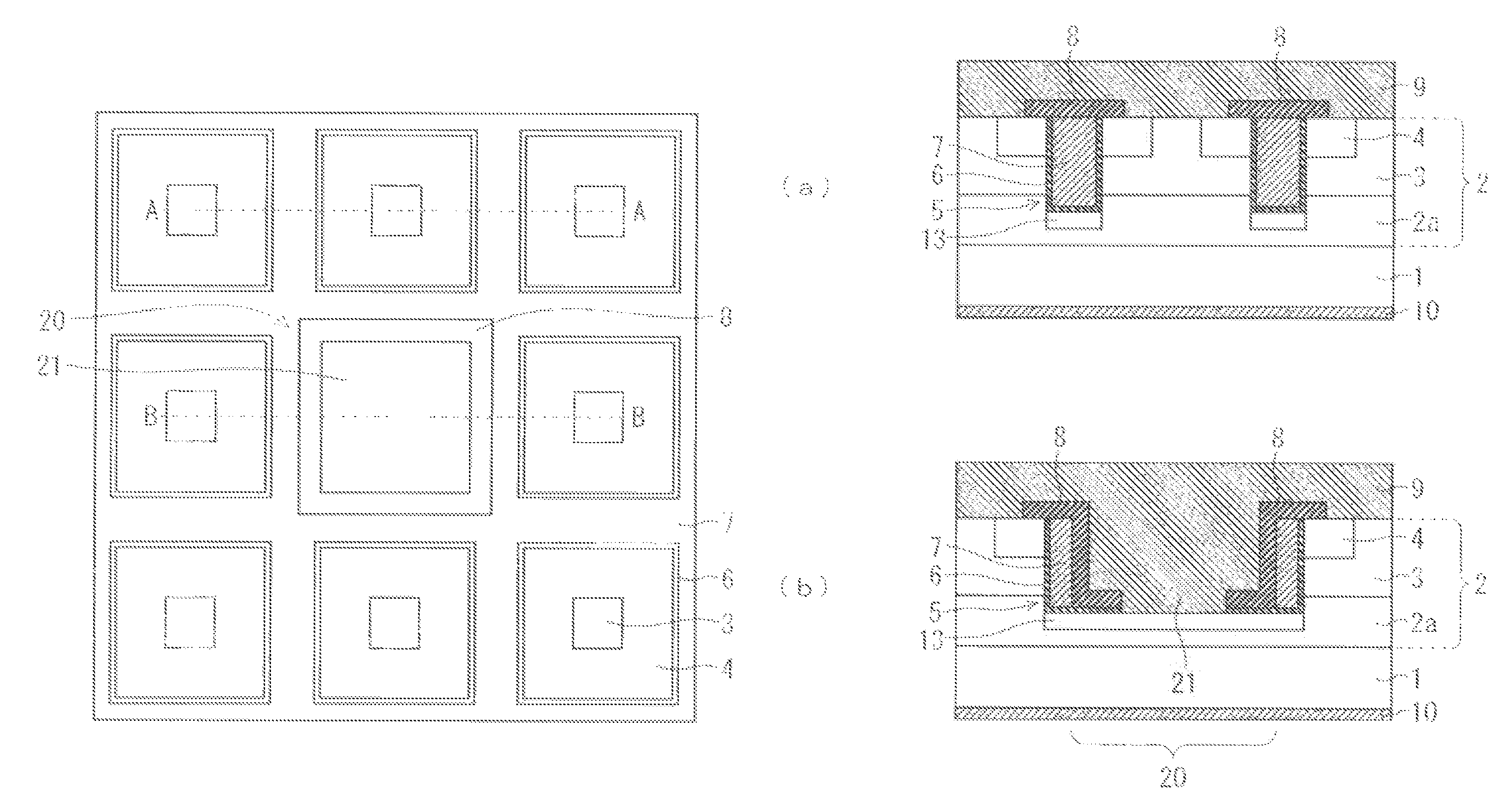

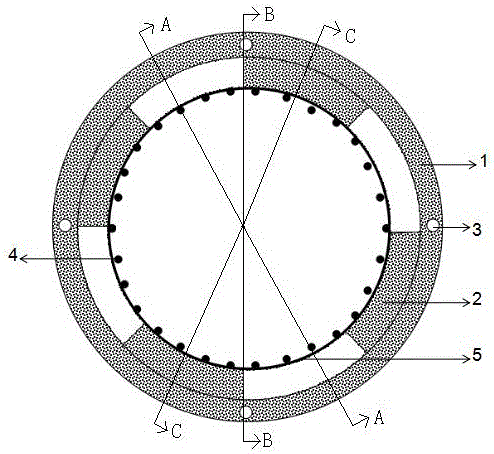

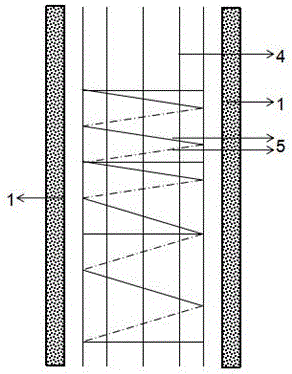

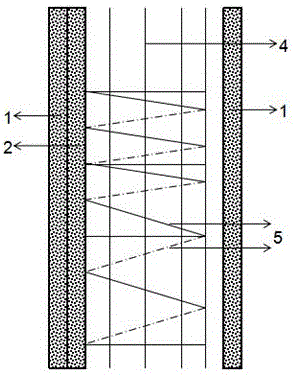

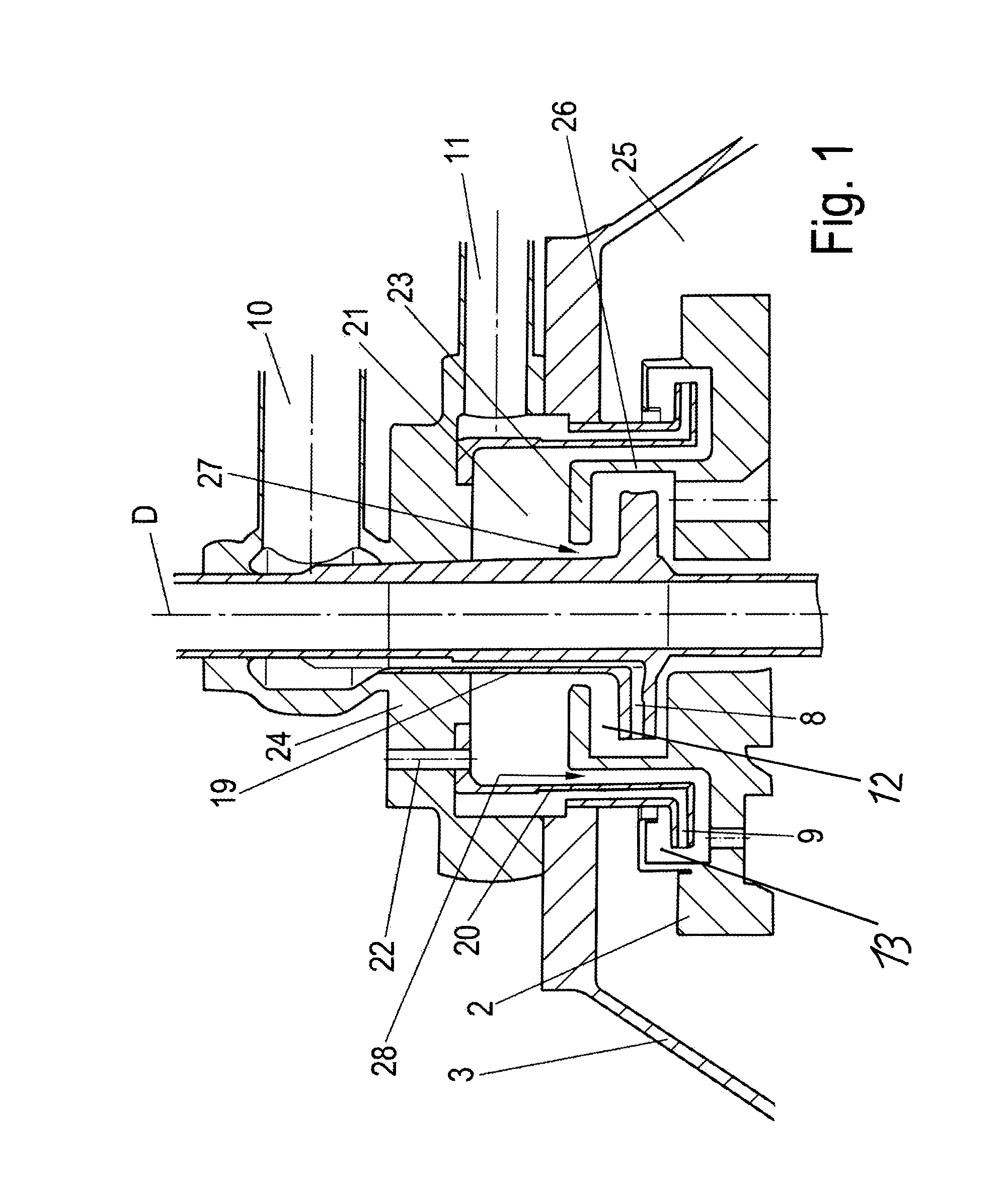

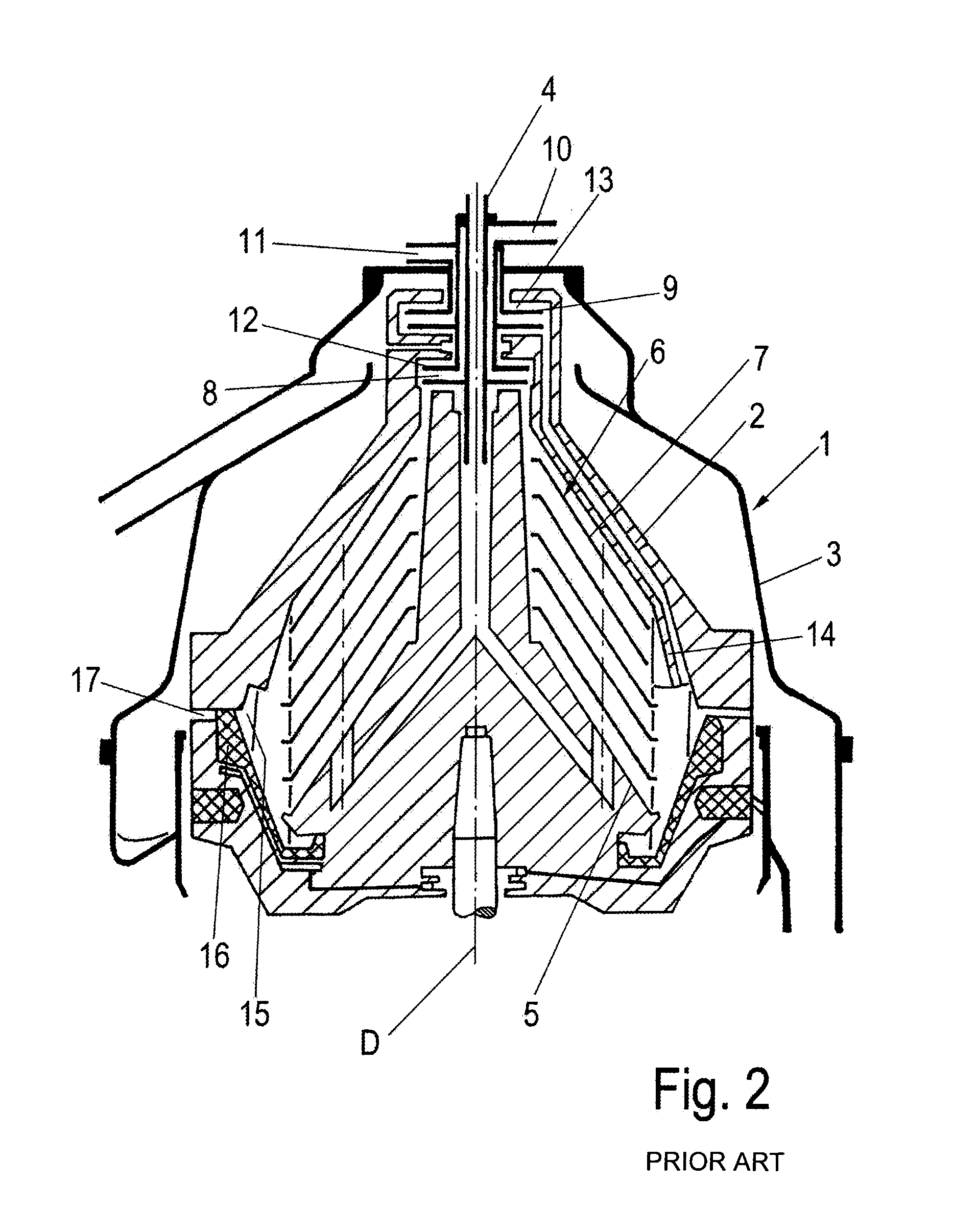

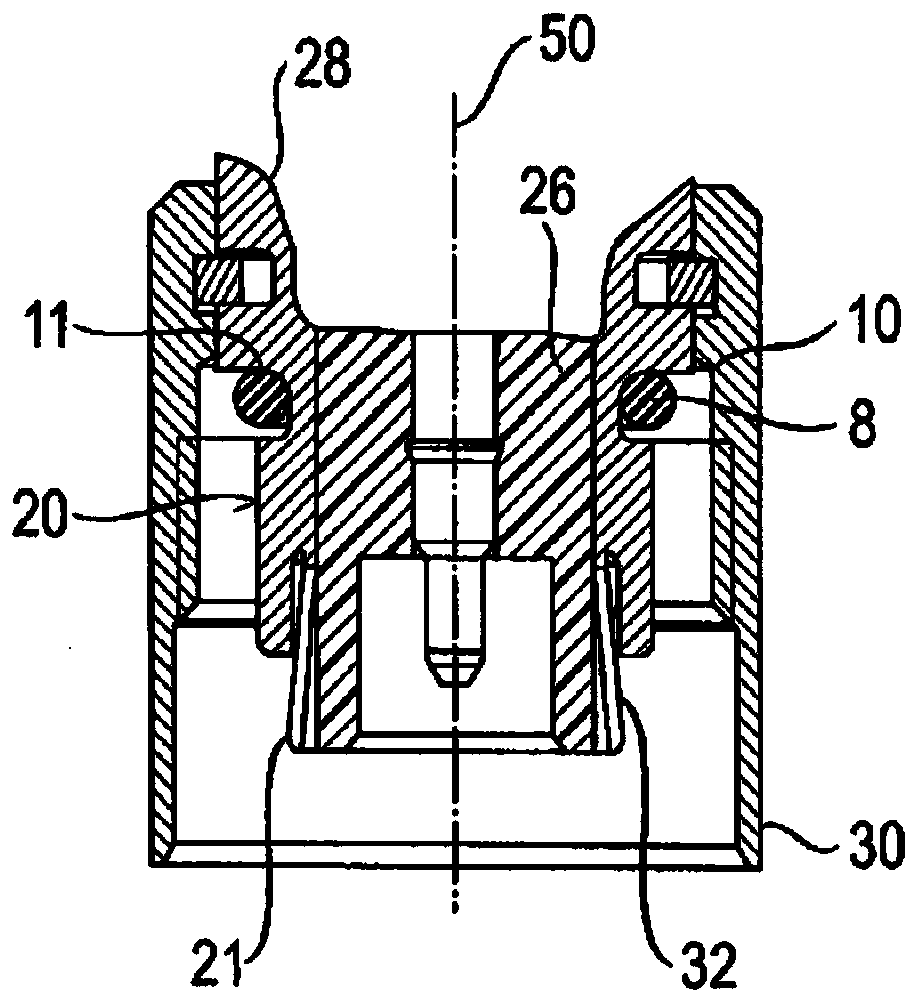

Semiconductor device and manufacturing method therefor

ActiveUS20130285140A1Avoid contactResistance valueTransistorSemiconductor/solid-state device manufacturingPower semiconductor devicePower flow

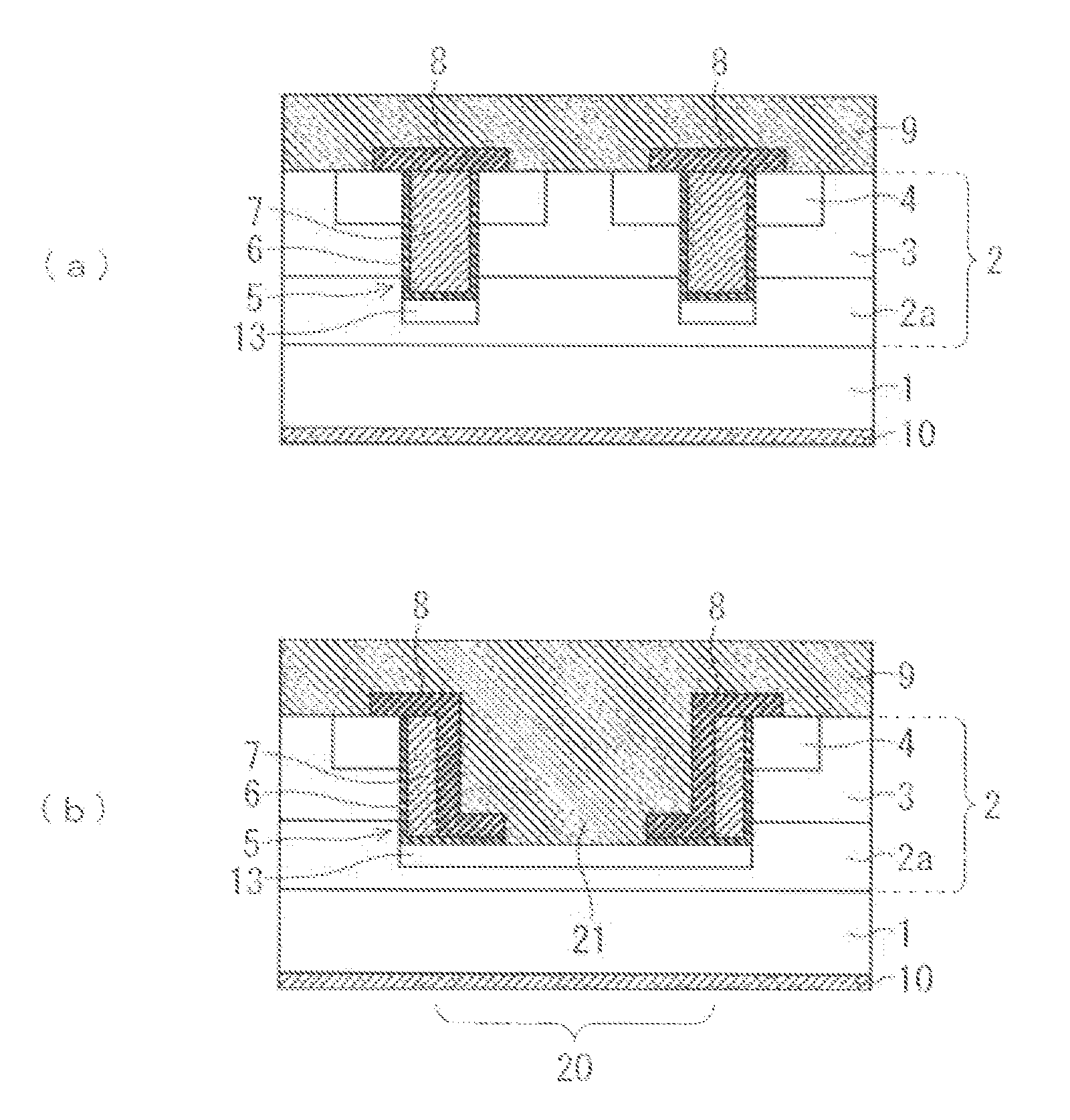

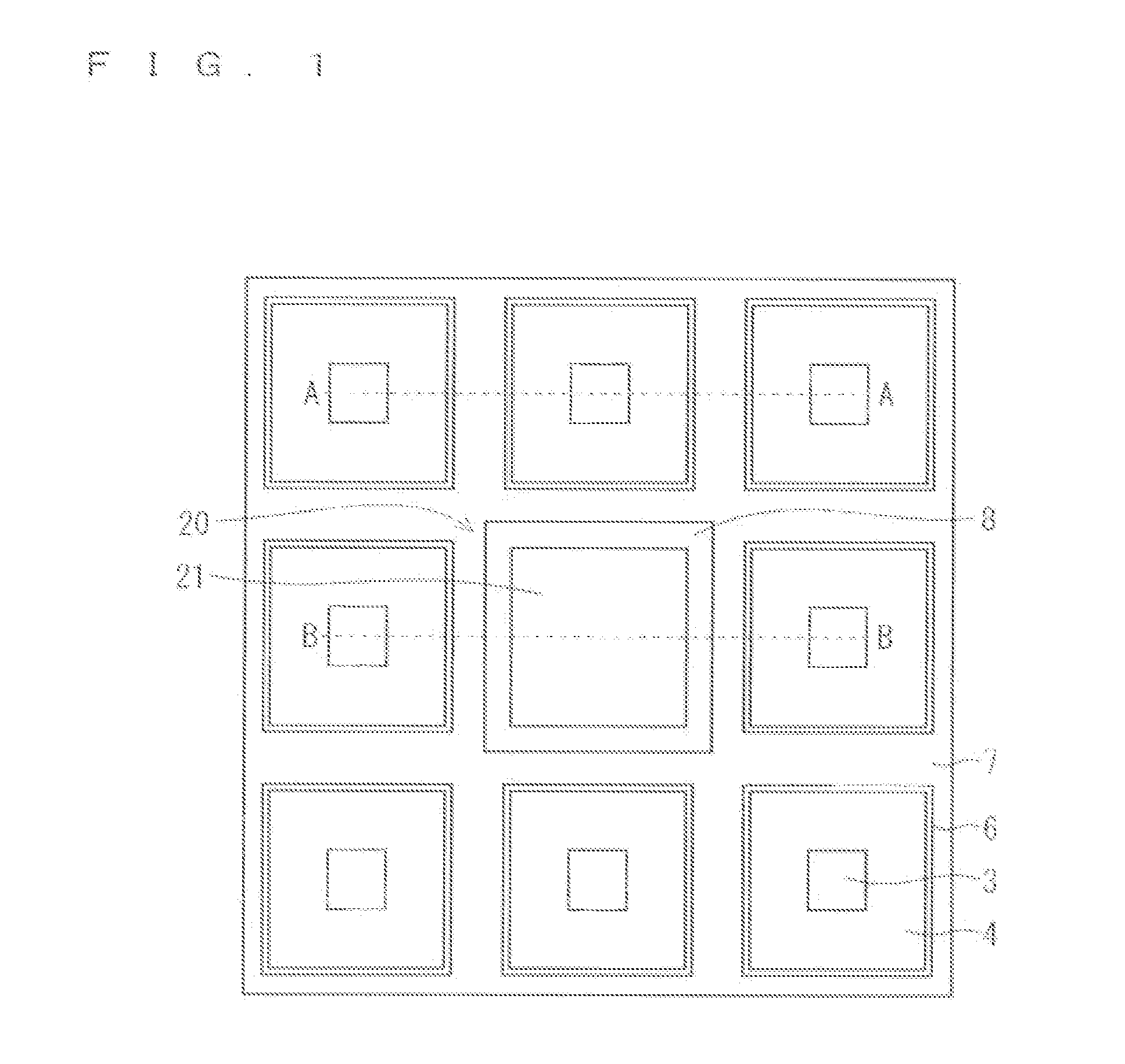

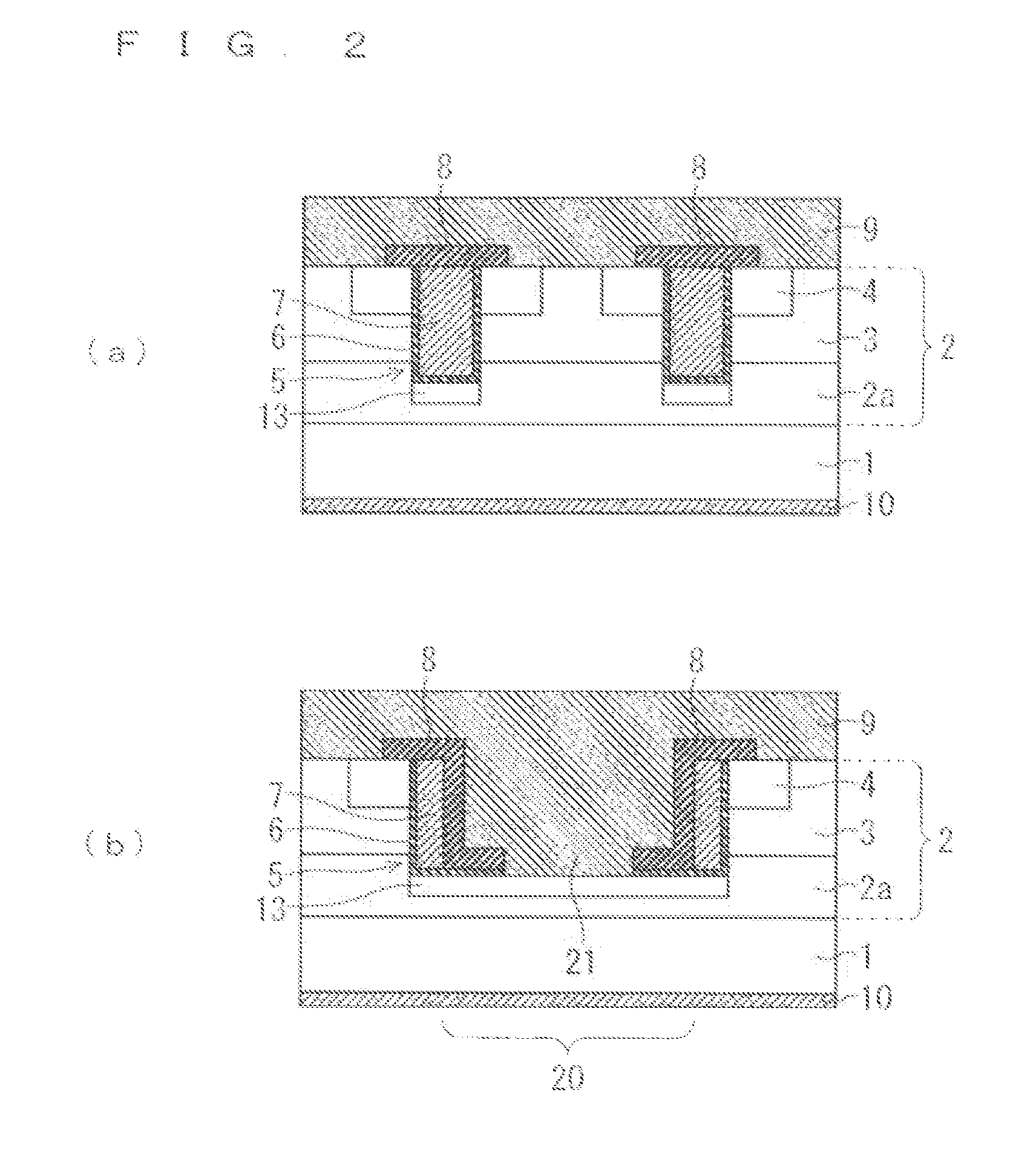

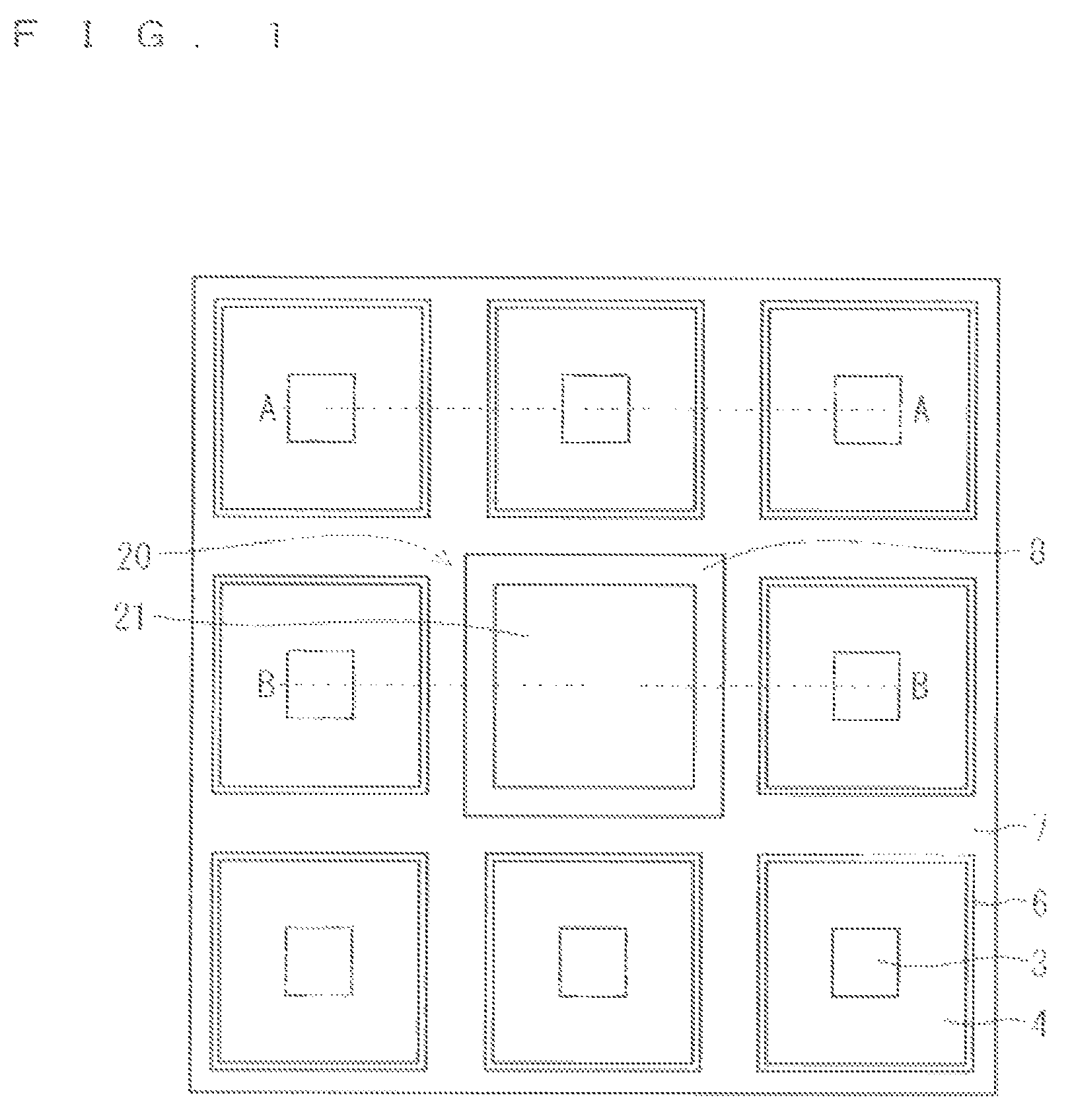

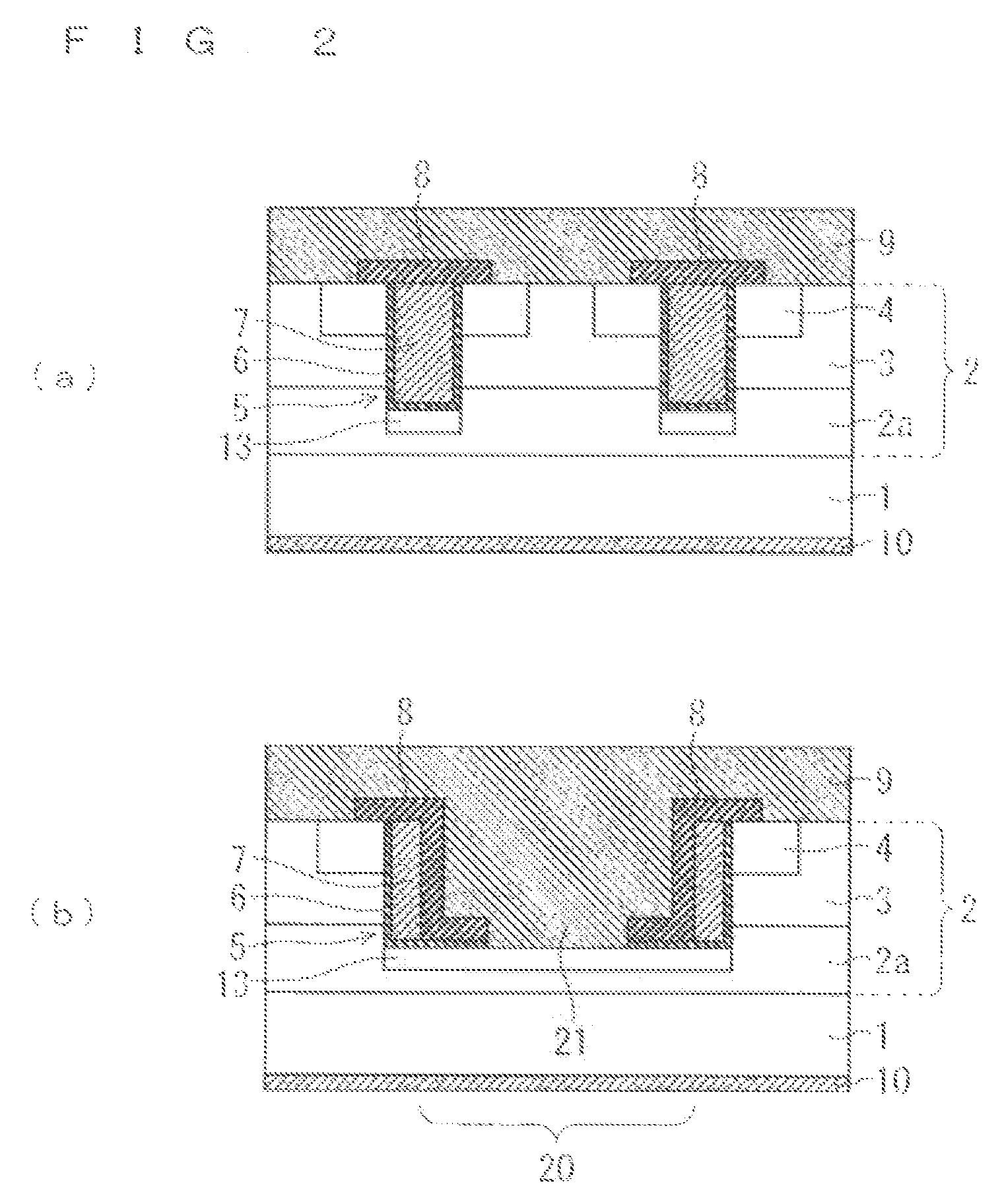

A trench-gate type semiconductor device that can prevent breakdown of a gate insulating film caused by a displacement current flowing into a protective diffusion layer at a portion of a trench underlying a gate electrode at a turn-off time and simultaneously improves a current density by narrowing a cell pitch. The semiconductor device includes a gate electrode embedded into a trench penetrating a base region. The gate electrode is disposed into a lattice shape in a planar view, and a protective diffusion layer is formed in a drift layer at the portion underlying thereof. At least one of blocks divided by the gate electrode is a protective contact region on which the trench is entirely formed. A protective contact for connecting the protective diffusion layer at a bottom portion of the trench and a source electrode is disposed on the protective contact region.

Owner:MITSUBISHI ELECTRIC CORP

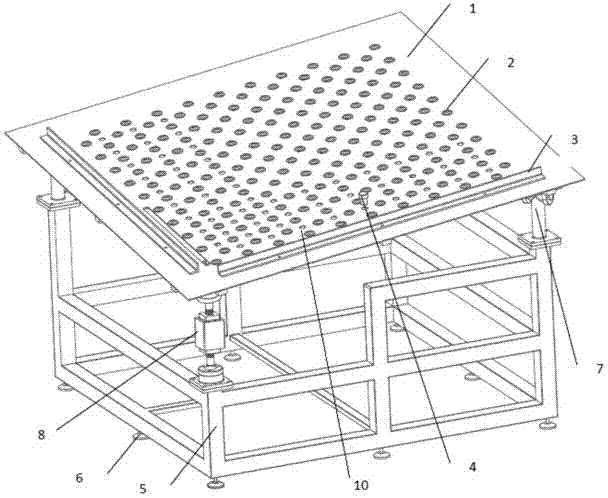

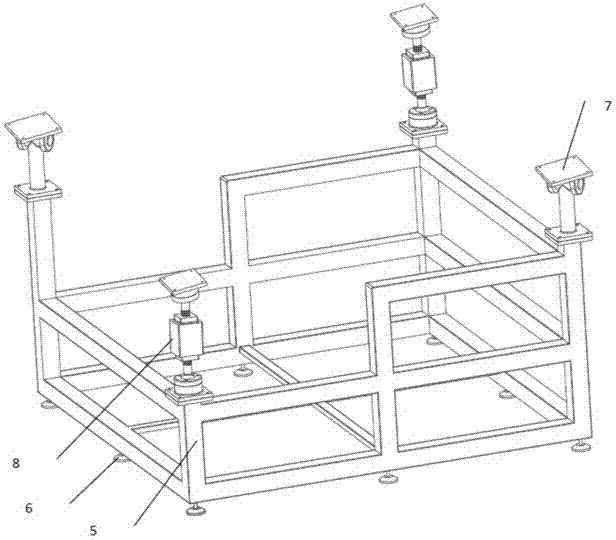

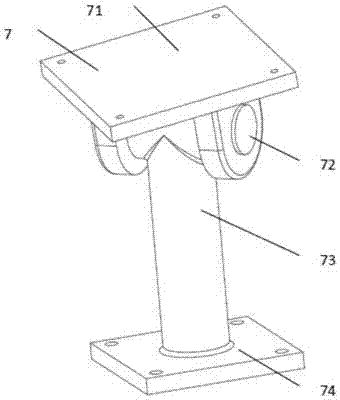

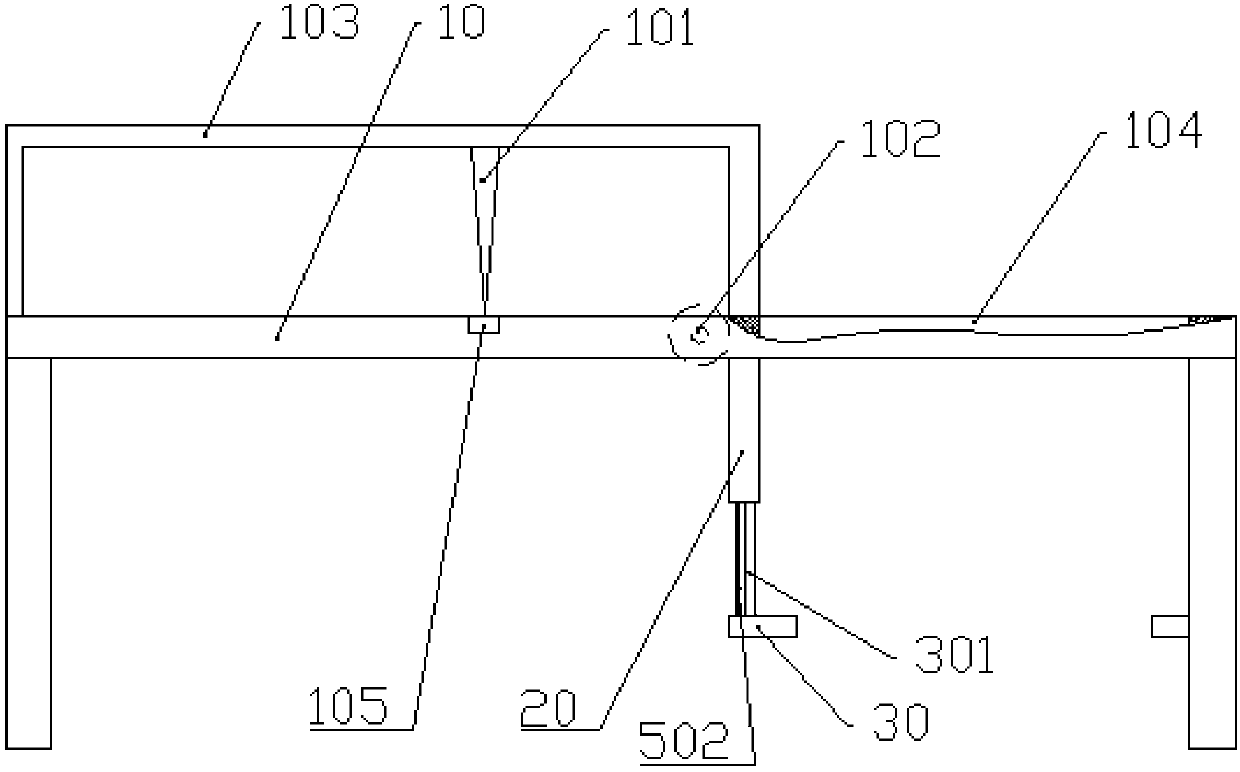

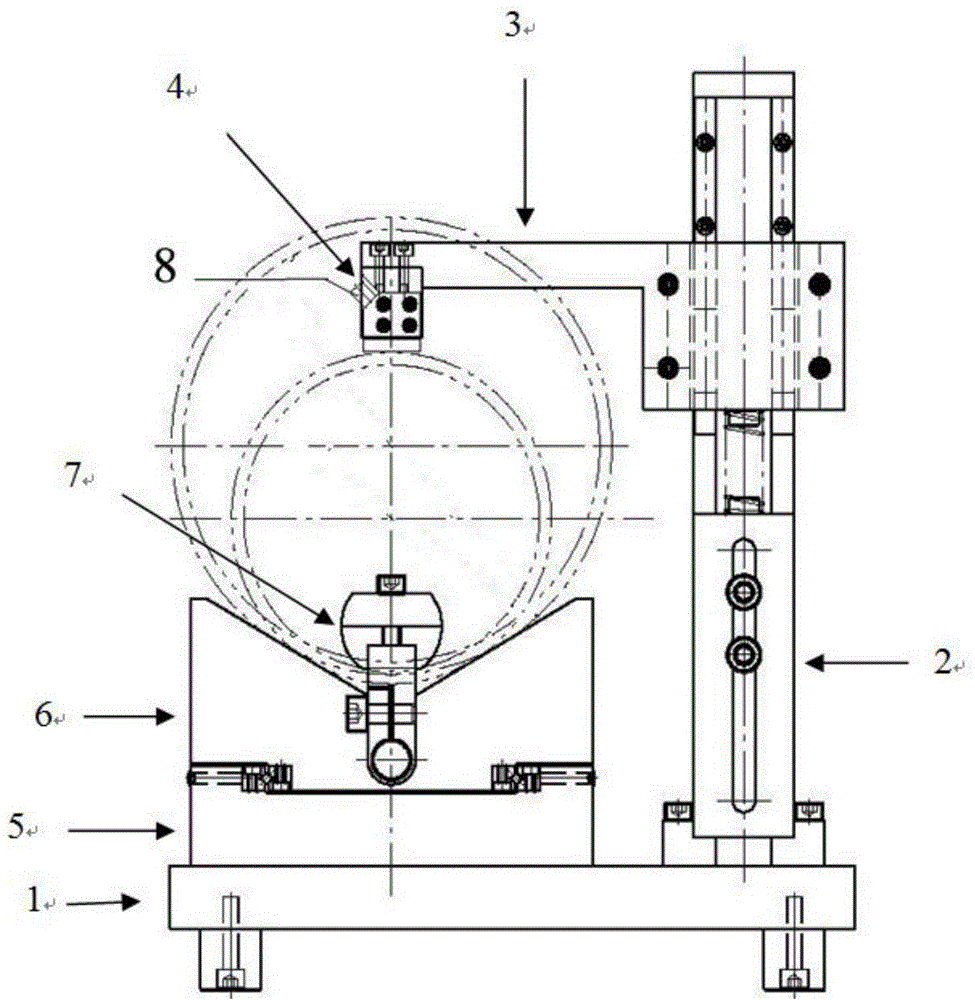

Flexible gravity centering table

ActiveCN103769488AProtective contactGuaranteed forceMetal-working feeding devicesPositioning devicesEngineeringGravitation

According to a flexible gravity centering table, a working table inclines downward in the direction from a feed station area to a discharge station area, universal wheels are arranged on the working table, and therefore workpieces are transferred to the discharge station area at the lower portion of the working table; driven-in pin type stop dogs are further arranged in the discharge station area, and therefore the layout and form of the stop dogs can be conveniently and freely adjusted in a plugging mode, and the positions of the stop dogs of the flexible gravity centering table can be randomly changed for special-shaped pieces.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

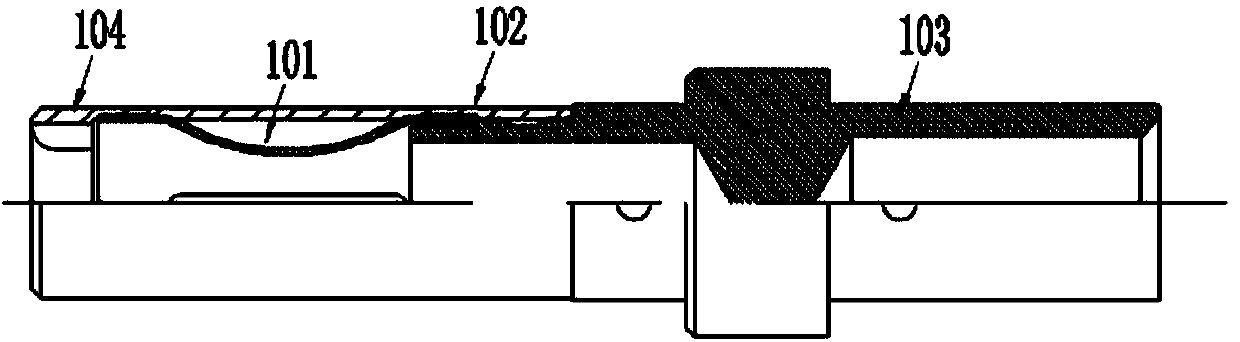

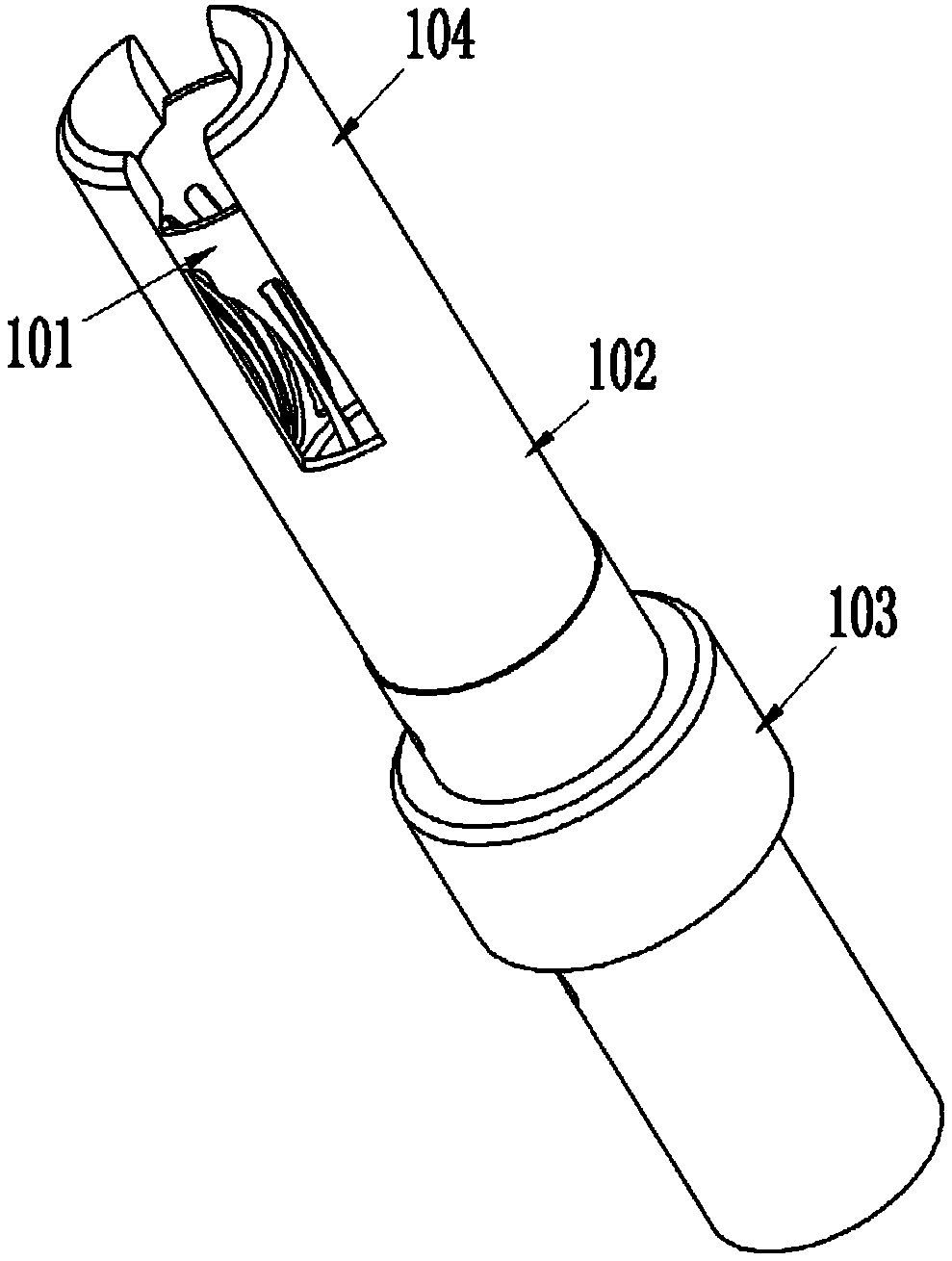

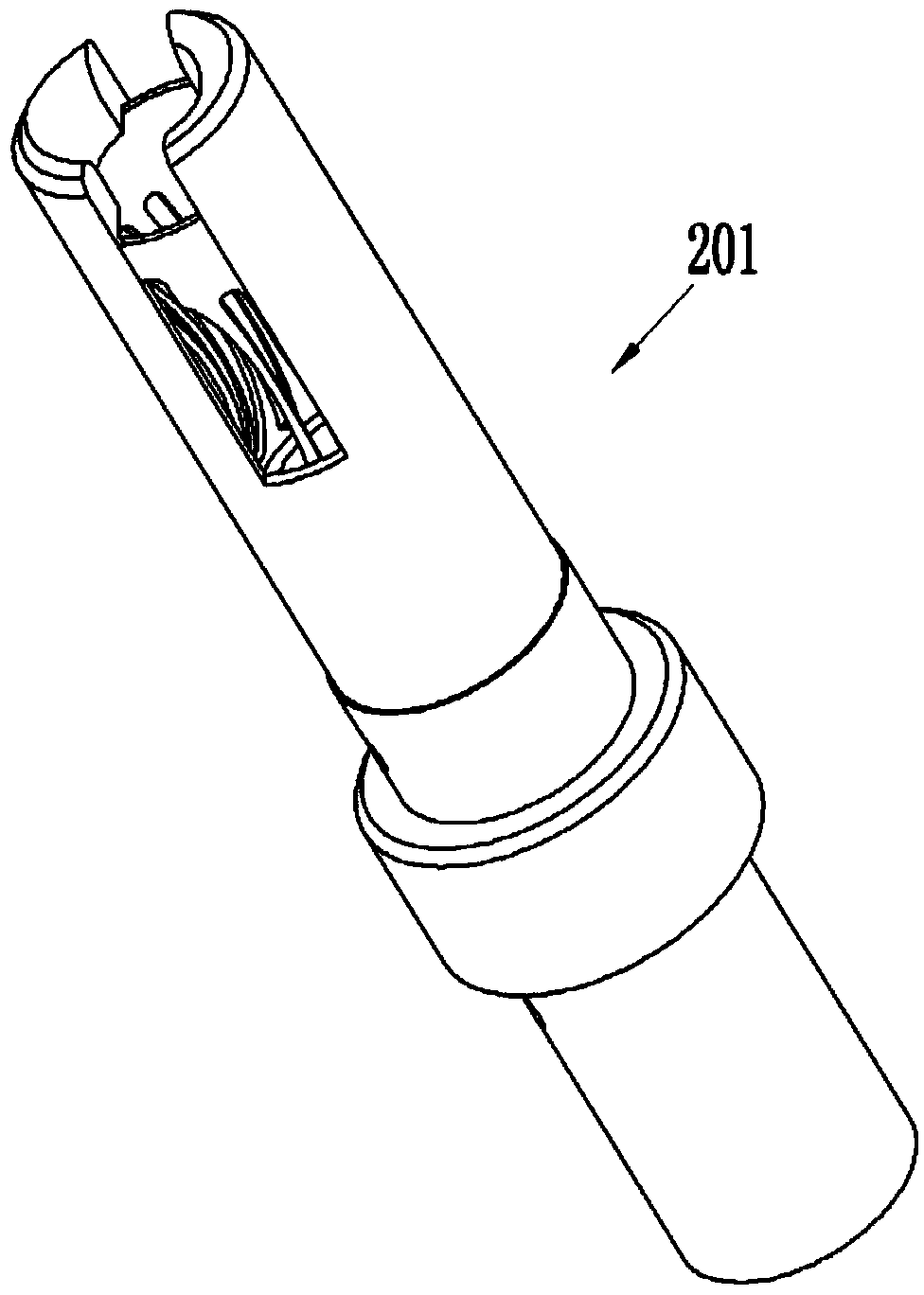

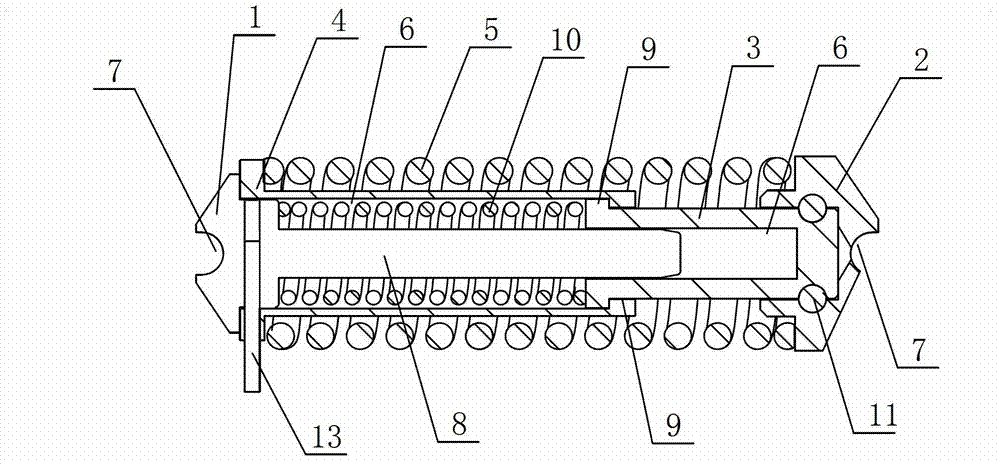

Contact member supporting hot plug and electric connector using same

InactiveCN104183943ASolve the problem of burning out the contact reedShorten discharge timeCoupling contact membersElectricityEngineering

The invention relates to electric connector field and especially to a contact member supporting hot plug and an electric connector using same. The contact member comprises a mother sleeve and a contact reed disposed in the mother sleeve. The mother sleeve comprises a front sleeve and a back sleeve fixedly connected together. The front sleeve is produced by arc extinguishing material and the front end of the front sleeve is provided with a contact structure used for electrically contacting an adaptive contact member. The contact structure is arranged in the front of the contact reed. The contact reed is fixedly connected with the back sleeve. When contact member and the adaptive contact member are plugged, the adaptive contact member firstly passes the front sleeve. The front sleeve is produced by the arc extinguishing material so as to be capable of effectively shortening discharging time and preventing the adaptive contact member and the front sleeve from being ablated. As a result, the contact performance of the contact member can be effectively protect after the contact member is subjected to hot plug, and a problem is solved that a conventional crowned hole contact member may burn out the contact reed because of hot plug.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

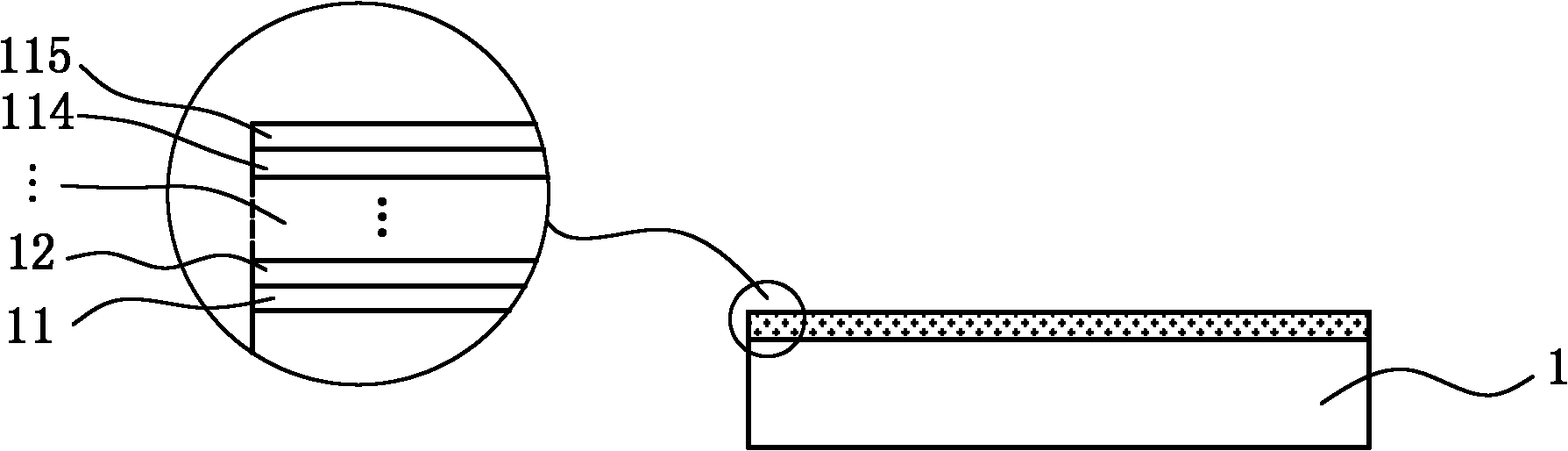

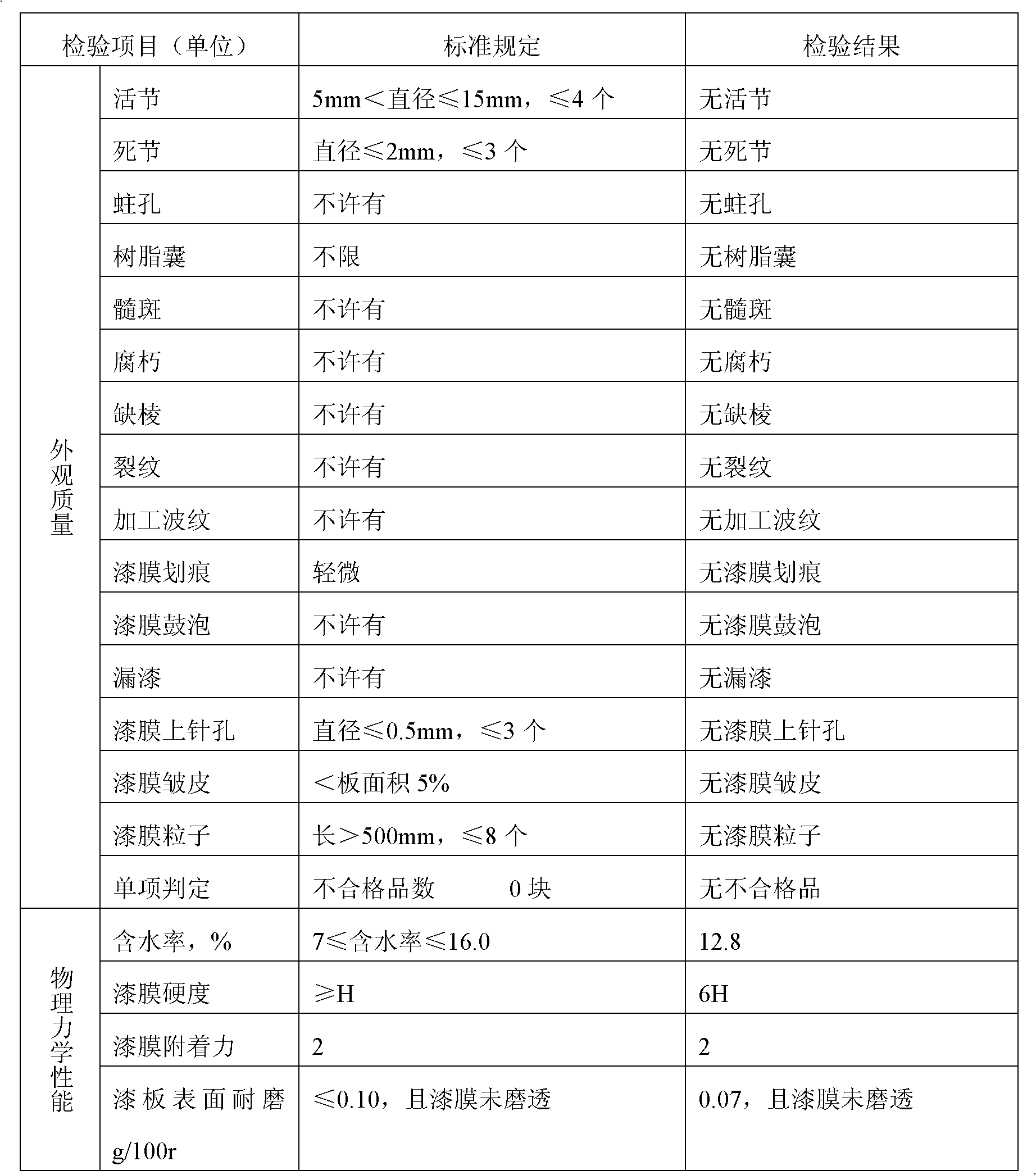

Corundum surface floor and production process thereof

ActiveCN101922227AGuaranteed aestheticsNot easy to fall offWood veneer joiningFlooringSurface finishHardness

The invention discloses a corundum surface KINGHARD floor and a production process thereof. The floor comprises a substrate (1), the surface of the substrate (1) is provided with a corundum surface finish coat layer (115), 14 coatings are also arranged below the corundum surface finish coat layer (115), and 15 varnishing processes are adopted in the process of the floor. The corundum surface floor has high surface rigidity, favorable wear resistance, coating adhesiveness and combinability of the coatings and the floor and high transparency, does not deform easily when the floor bears the pressure of heavy objects, protects the floor from contacting moisture, and avoids drastic expansion or shrinkage, prevents worm biting, and can display natural grain of woods and maintain the aesthetic feeling of the floor; the coatings do not have obvious change when the coatings are used for a long period of time, even if heavy furniture or tables and chairs are hauled on the floor, the phenomenon of scratches, whitening or falling seldom occurs to wood floors, and the coatings do not fall easily due to elongated service time.

Owner:ZHEJIANG JIAYE FLOORING CO LTD

Treatment method of wickerwork raw material wickers

ActiveCN107186846AAntioxidantThermally stableWood treatment detailsReed/straw treatmentAlkaline waterFiber

The invention relates to the technical field of wickerwork artware and discloses a treatment method of wickerwork raw material wickers. The method comprises the following steps that (1) newly-cut wickers are dewatered through natural drying, the high temper of the wickers is improved, heating treatment is conducted in alkaline water, thus peeling is facilitated, the glossiness of the wickers can be improved, and cold treatment is conducted after peeling; (2) the wickers subjected to cooling treatment are immediately steeped through a steeping solution A, the steeping solution can be rapidly adsorbed by fibers with negative charges under the effect of positive charges in the aqueous solution, a thin film is formed on the surface of each fiber, binding force among the fibers is reinforced, and shrinkage deformation of the fibers is prevented; and (3) the wickers are heated and baked in a drying oven after being steeped by the steeping solution A and then put into a steeping solution B for steeping, the steeping solution B has oxidation resistance and heat stability, connection points among the fibers are protected, and heating deformation of the fibers is prevented.

Owner:阜南县猛发工艺品有限公司

Production technology for solid wood composite floor

InactiveCN107471385AGuaranteed aestheticsGood adhesionBelt grinding machinesWood treatment detailsSolid woodWax

The invention discloses a production technology for a solid wood composite floor. The production technology comprises the step that a blank floor is produced by adopting a conventional technology and further comprises the following specific steps that (1), the surface of the blank floor is sanded with a sanding belt, and slotting and wax sealing are conducted after sanding; (2), the surface of the blank floor is colored with mixed pigments in the wood grain direction; (3), the surface of the blank floor is sanded with the sanding belt, and back paint is applied to the back face of the blank floor after sanding; (4), waterborne oil paint is applied to the surface of the blank floor; and (5), waterproof and anticorrosive formaldehyde removing glue is applied, wherein the waterproof and anticorrosive formaldehyde removing glue contains waterborne resin, an anticorrosive and mouldproof agent, an insect-repellent agent, an anti-termite agent, a formaldehyde removing agent, a film forming auxiliary agent, an anti-freezing agent and water.

Owner:陈雪珍

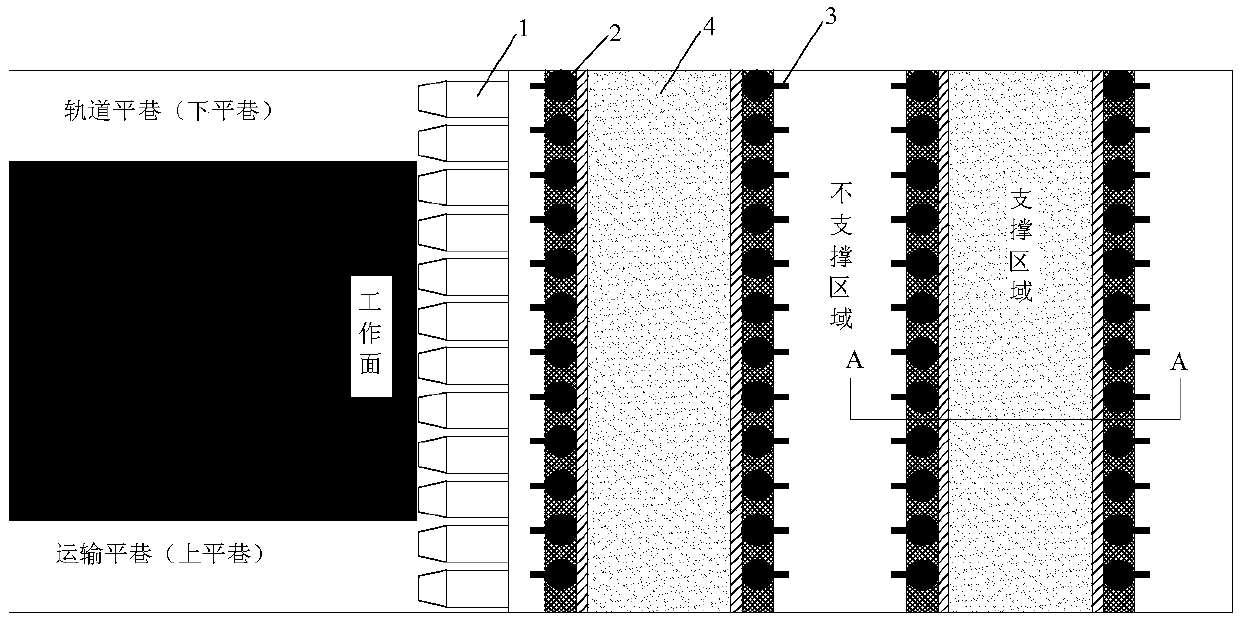

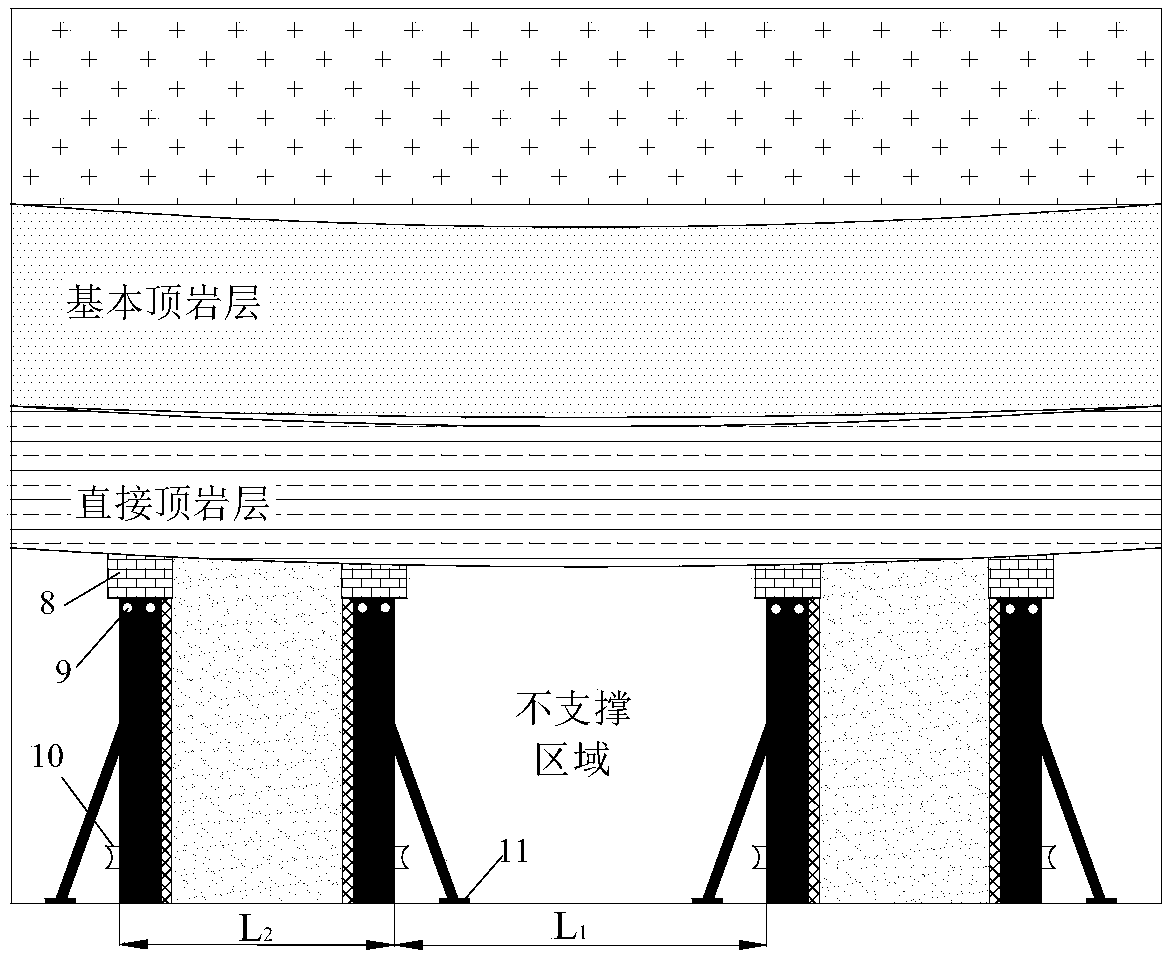

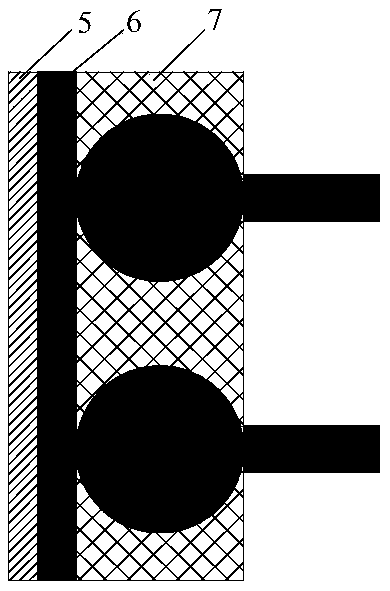

A goaf local filling supporting structure under a hard roof condition and a construction method thereof

The invention discloses a goaf local filling supporting structure body under a hard roof condition and a construction method thereof, and belongs to the technical field of rock stratum motion controlin coal mining. The supporting structure body comprises a filling body located in the goaf, lateral supporting bodies disposed on two sides of the filling body and isolation bodies. Each lateral support body comprises a concrete filled steel tube pier column, an anti-falling supporting leg and a flexible yielding component. The concrete filled steel tube pier column is a main supporting structure.The concrete-filled steel tube pier column is manufactured by pouring concrete grout into a seamless steel tube, the anti-falling supporting legs are arranged in the middle of the concrete-filled steel tube pier column, and each isolation body comprises a gangue bag wall built between the adjacent concrete-filled steel tube pier columns, a flexible side protection steel plate erected in a mannerof being tightly attached to the pier column and a waterproof plastic curtain hung on one side of the steel plate. Sufficient and long-term supporting resistance can be provided for overlying rock roofs, especially hard roofing rock stratums, in the goaf, and it is guaranteed that an elastic nuclear area exists in the center of the structure for a long time.

Owner:SHANDONG UNIV OF SCI & TECH

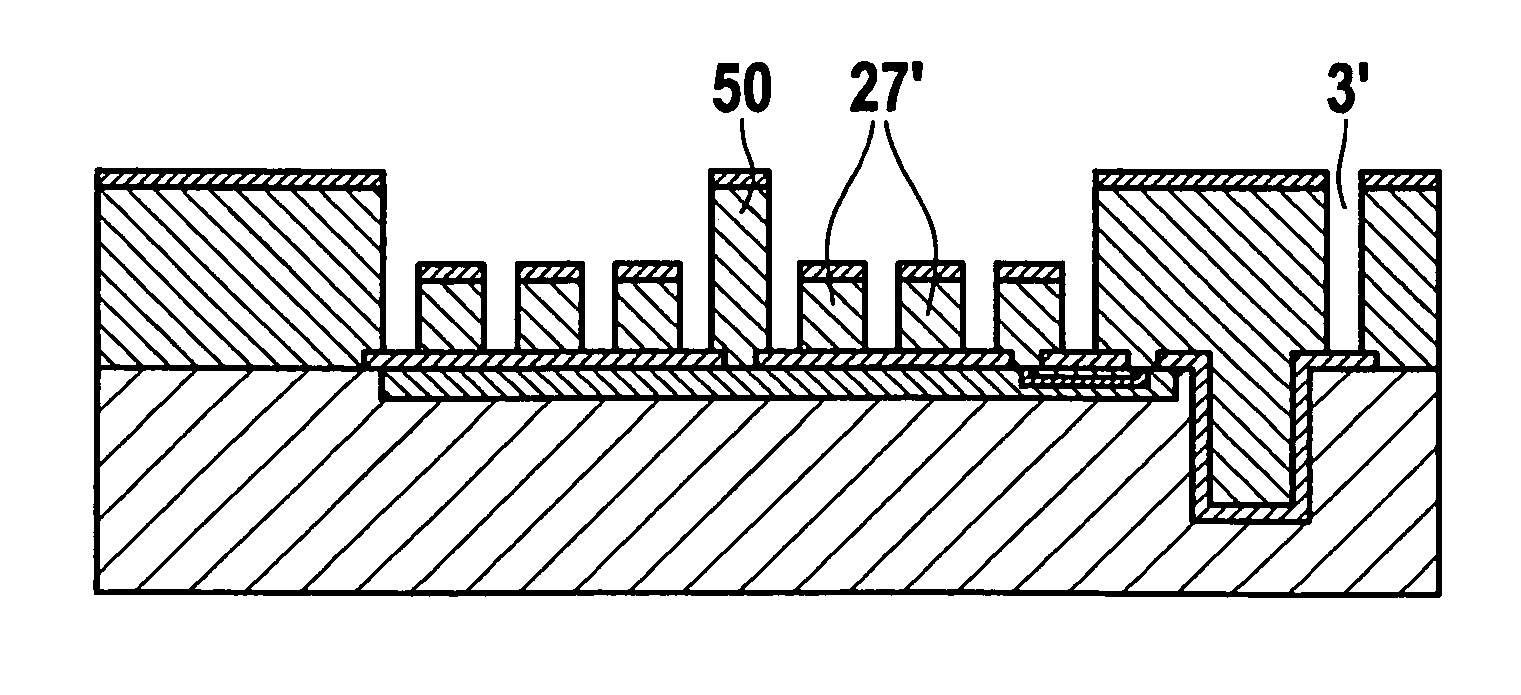

Trench-gate type semiconductor device and manufacturing method therefor

ActiveUS9224860B2Avoid contactResistance valueTransistorSemiconductor/solid-state device manufacturingTrench gateDiffusion layer

Owner:MITSUBISHI ELECTRIC CORP

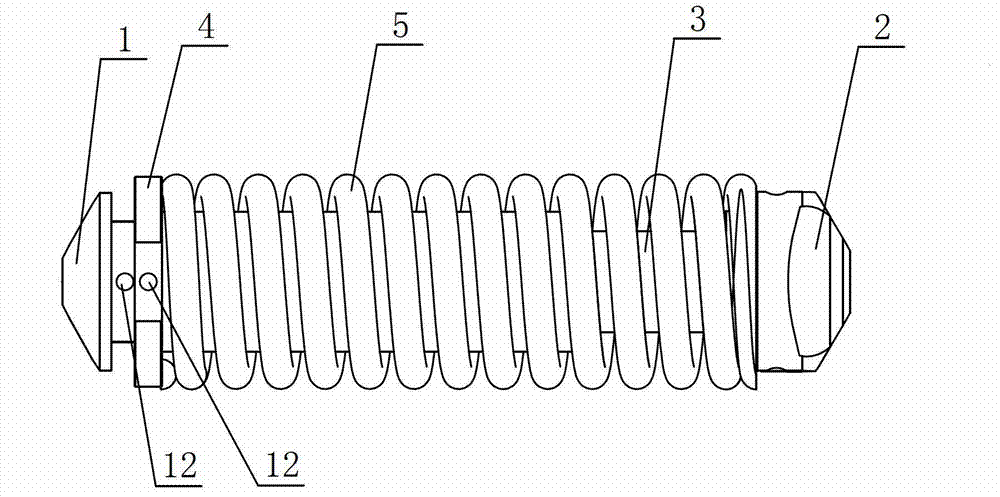

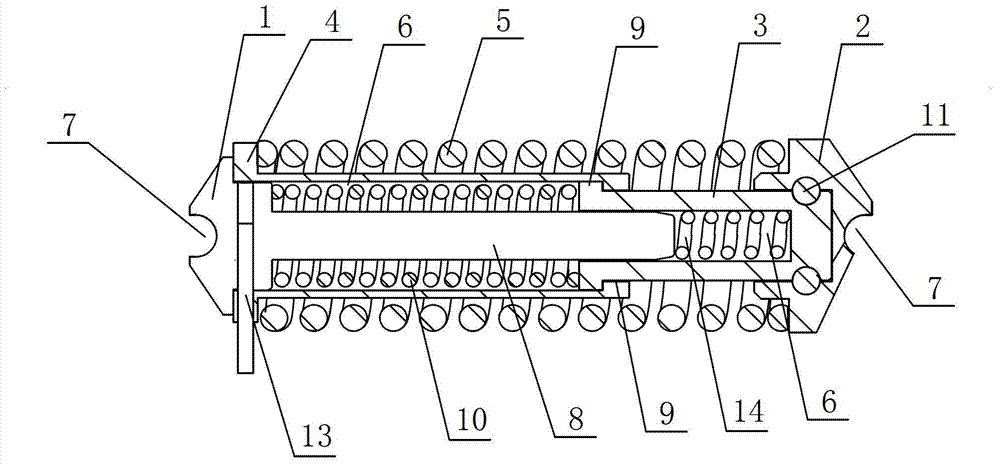

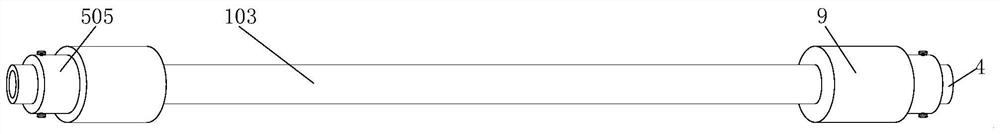

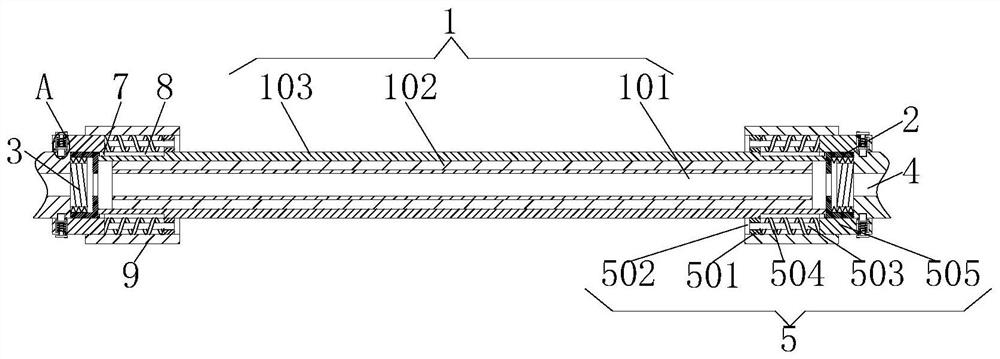

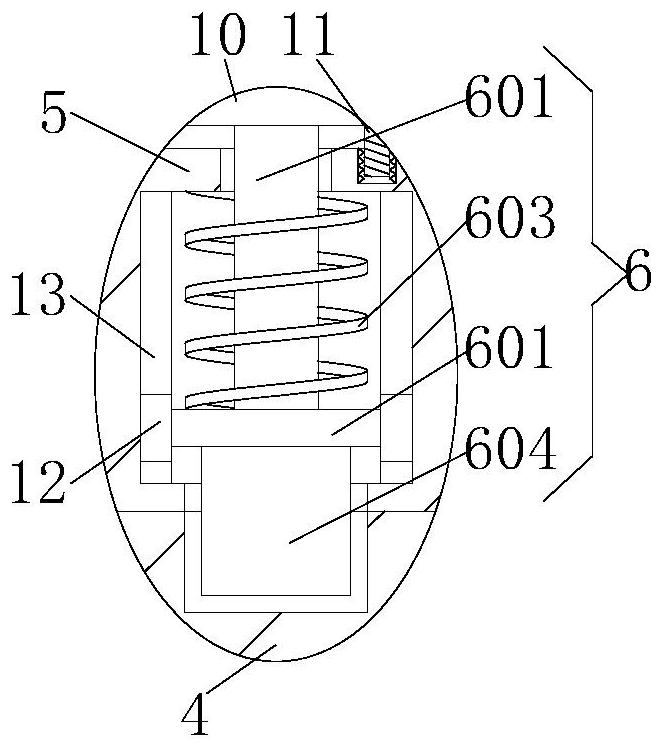

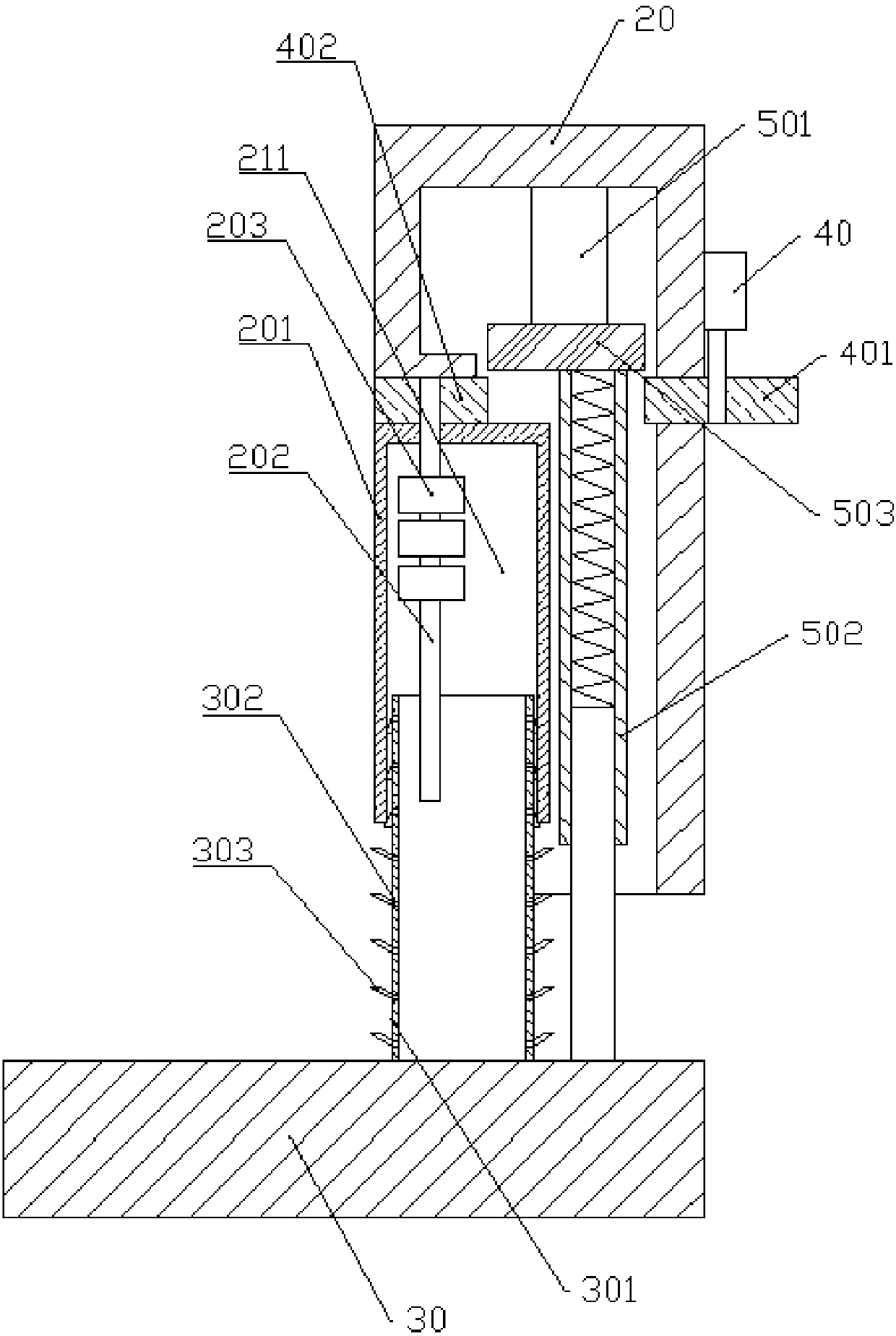

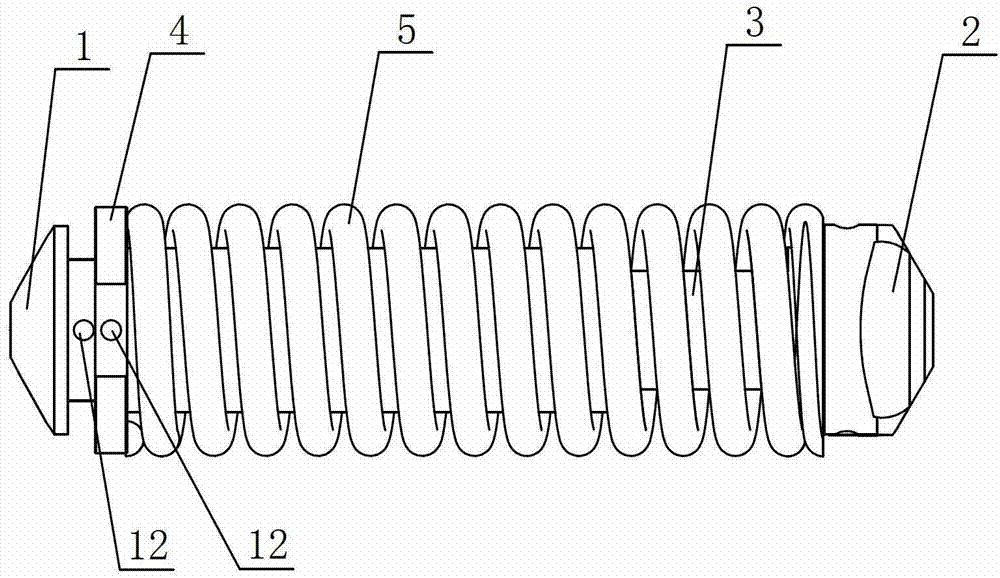

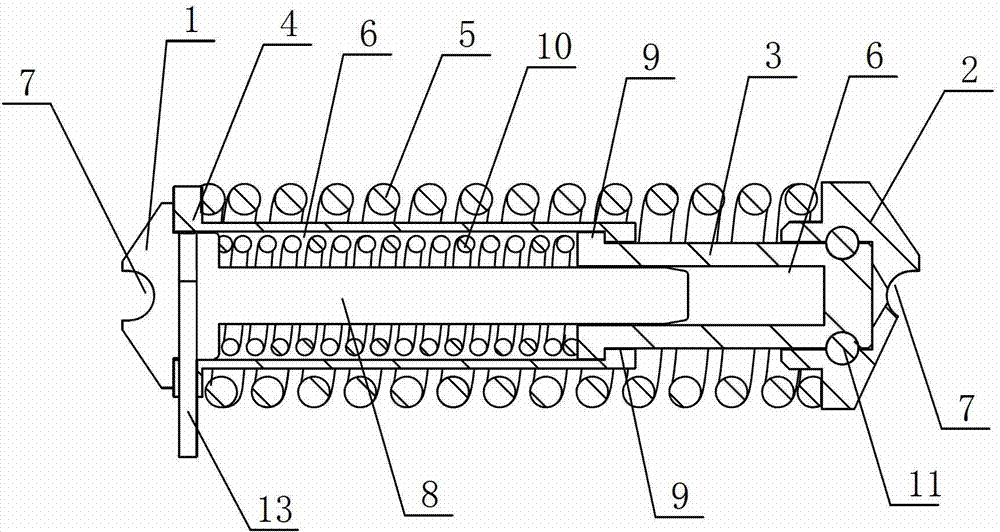

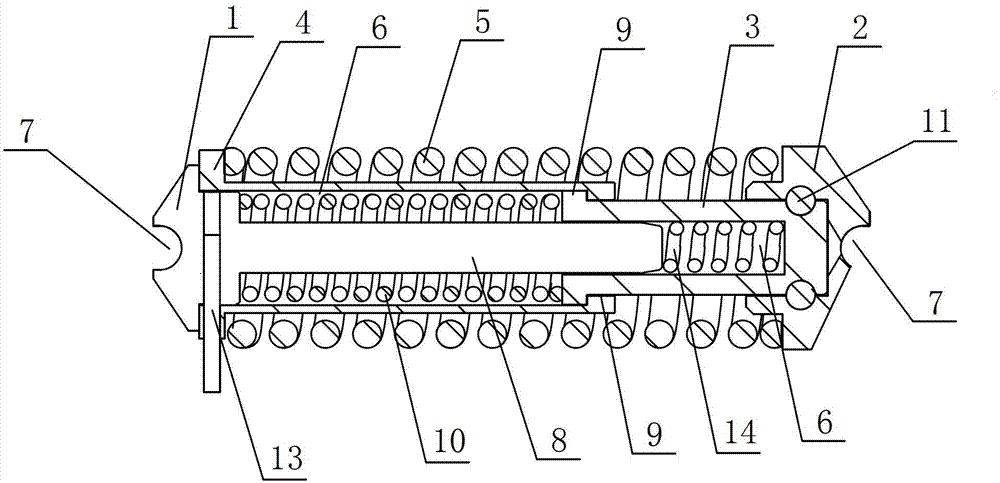

Energy storage device for electric operating mechanism

ActiveCN102779663ASimple and time-saving installationReduce volumeSwitch power arrangementsStored energyRelative Volume

The invention discloses an energy storage device for an electric operating mechanism. The energy storage device comprises a first spring chuck, a second spring chuck and a spring energy storage component which is arranged between the two spring chucks, wherein the spring energy storage component comprises an inner mounting sleeve and an outer mounting sleeve; the inner and outer mounting sleeves are provided with containing cavities capable of containing energy storage springs; one end of the inner mounting sleeve penetrates through the containing cavity of the outer mounting sleeve and is fixedly connected with the second spring chuck; the other end of the inner mounting sleeve is connected with the outer mounting sleeve through steps which are arranged corresponding to the inner and outer mounting sleeves; an outer energy storage spring is arranged between the outer mounting sleeve and the second spring chuck; an inner energy storage spring is arranged in the containing cavity of the outer mounting sleeve; and the outer ends of the first and second spring chucks are provided with mounting grooves. The energy storage device has the advantages that the device is simply mounted in a time-saving and labor-saving mode, the volume of the whole energy storage device can be effectively reduced, and the miniaturization development requirements of circuit breakers are met; and moreover, stored energy of the springs is increased in relative volume, contacts of the circuit breakers are effectively protected, and the cost is saved.

Owner:WUXI KAIXUAN MOTOR +1

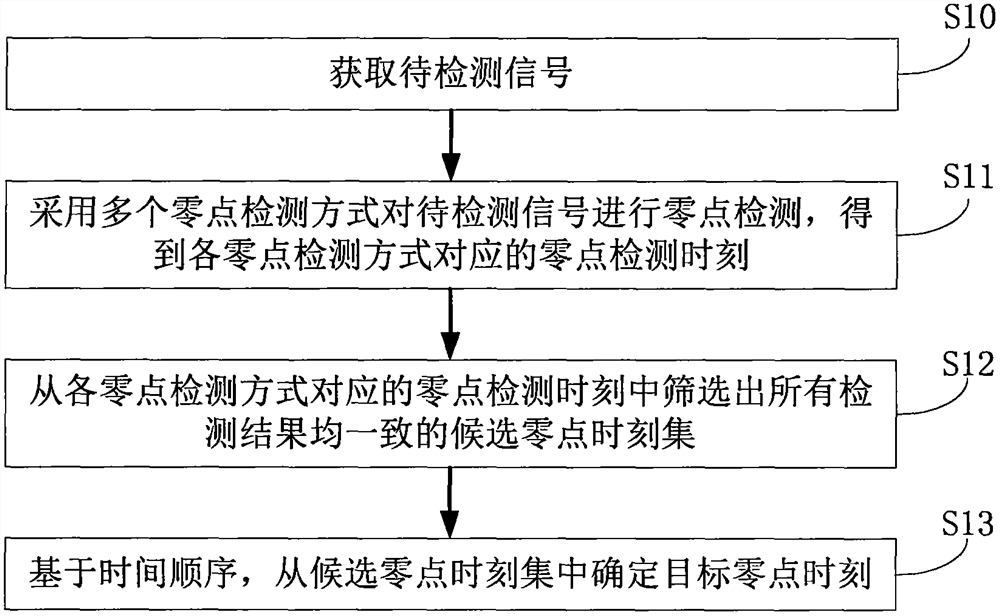

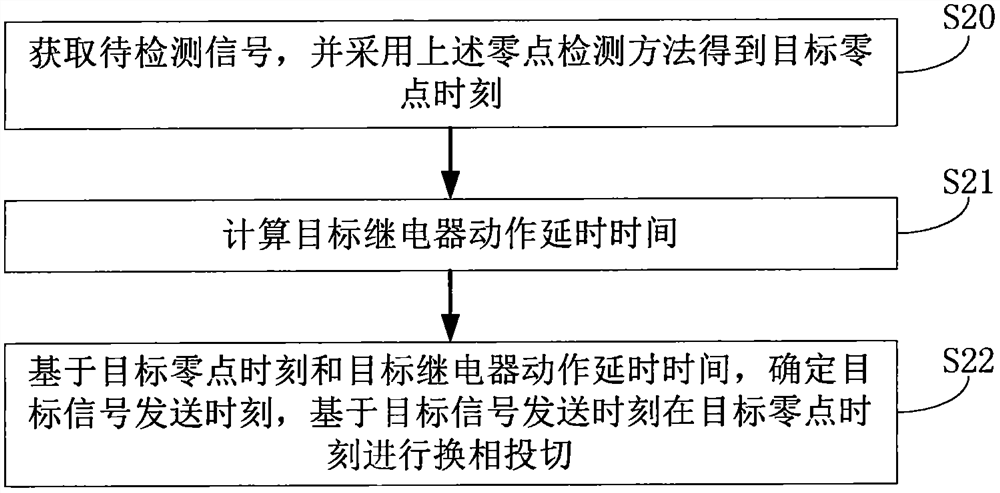

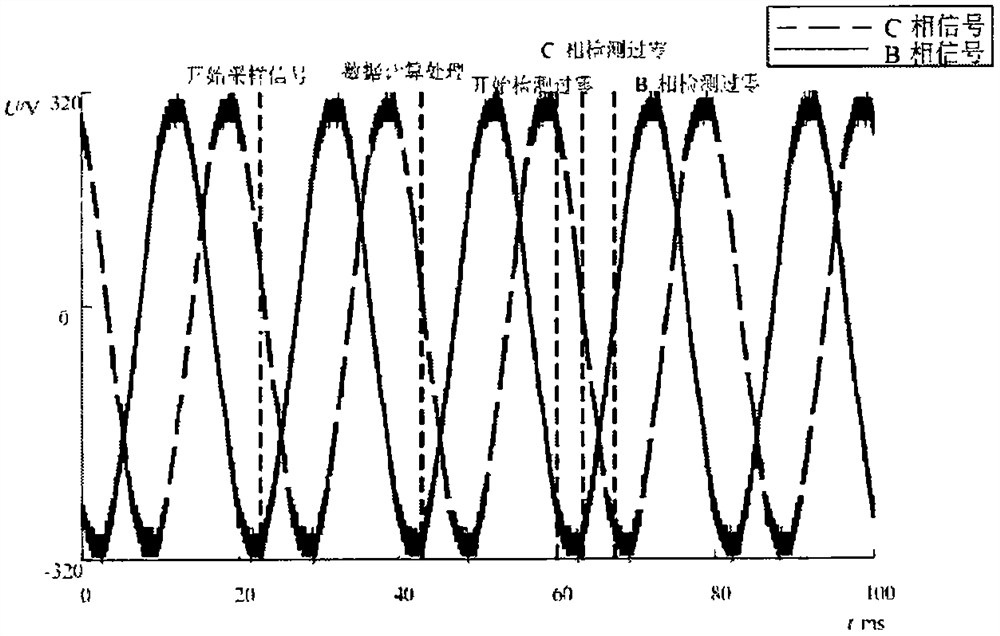

Zero point detection method, phase-change switching method, system and phase-change switching equipment

PendingCN112946352AResolve distortionSolve the requirements for precise zero-crossing identificationCurrent/voltage measurementPower network operation systems integrationControl theoryReliability engineering

The invention provides a zero point detection method, a phase-change switching method, a system and phase-change switching equipment. The zero point detection method comprises the following steps: acquiring a to-be-detected signal; performing zero point detection on the to-be-detected signal by adopting a plurality of zero point detection modes to obtain a zero point detection moment corresponding to each zero point detection mode; screening out a candidate zero point moment set with all consistent detection results from the zero point detection moments corresponding to the zero point detection modes; and determining a target zero moment from the candidate zero moment set based on the time sequence. According to the invention, the accuracy of zero-crossing identification is improved.

Owner:ZHEJIANG TENGEN ELECTRIC +2

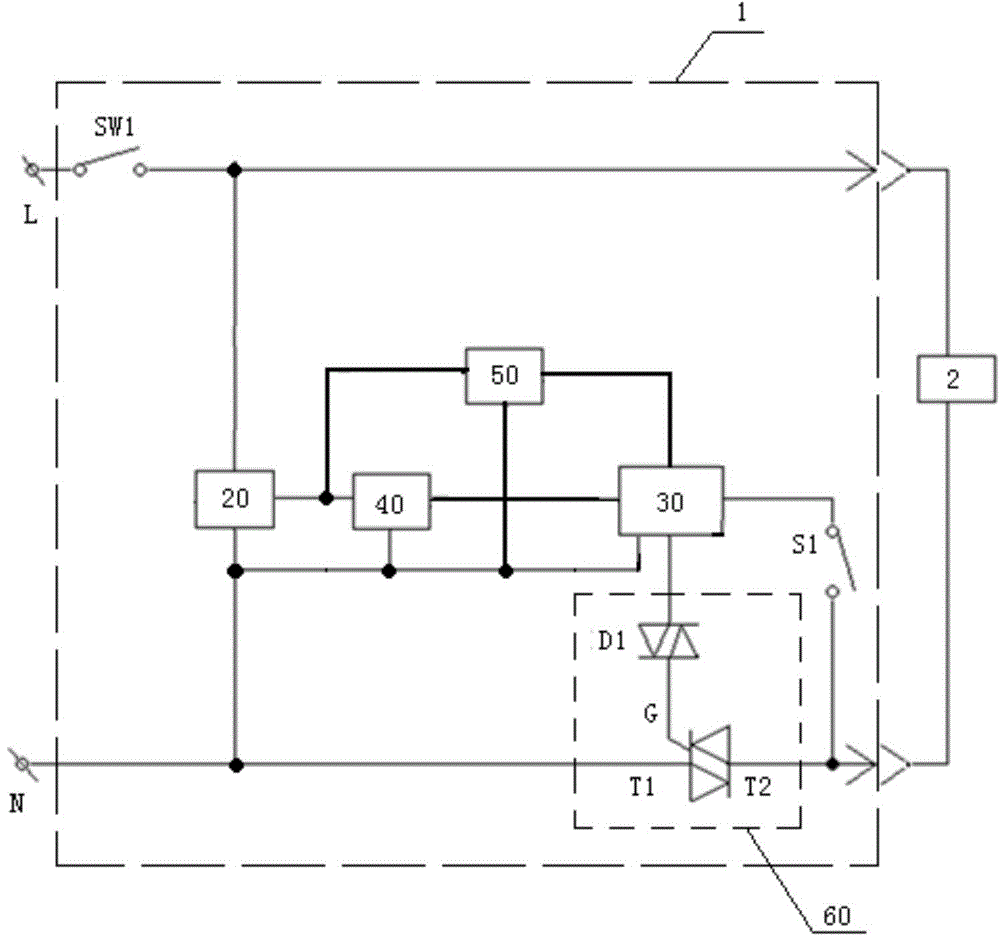

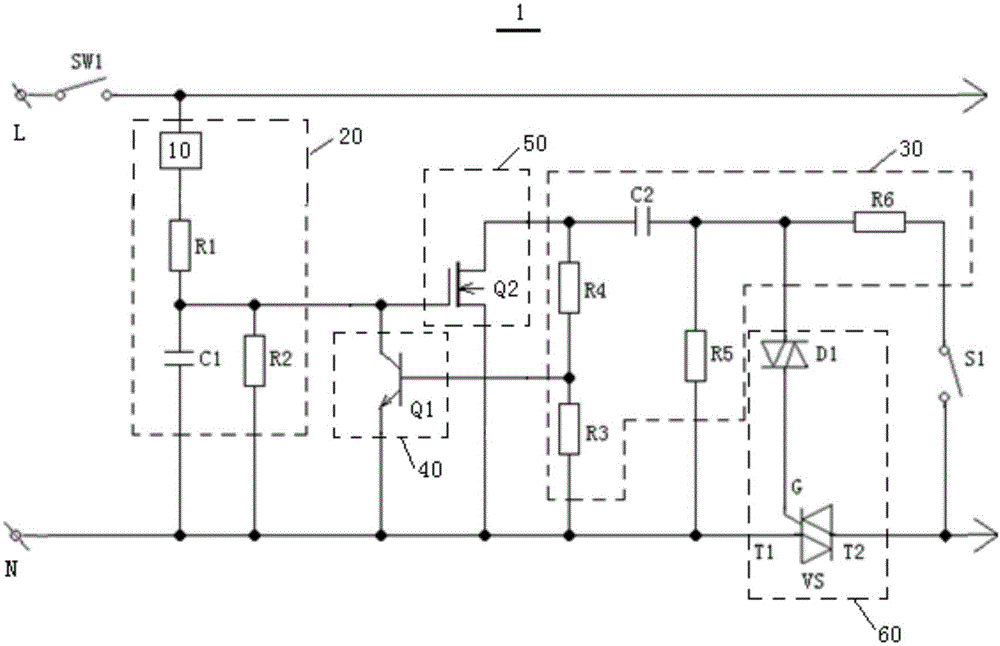

Non-arc power-off protection switch control circuit

ActiveCN104811169AProtective contactExtended service lifeElectronic switchingTime delaysElectric arc

The invention discloses a non-arc power-off protection switch control circuit. The control circuit comprises a first switch, a second switch, a first time delay circuit, a first controllable switch, a second controllable switch, a second time delay circuit and a thyristor circuit, wherein one end of the first switch is connected to a live wire of a power supply, and the other end of the first switch is connected with a load; the first time delay circuit is used for rectifying output of the power supply and controlling on and off of the second controllable switch; the second time delay circuit is used for controlling on and off of the first controllable switch; the time constant of the second time delay circuit is smaller than the time constant of the first time delay circuit; the second switch is connected between a second input end of the second time delay circuit and a null wire; the thyristor circuit is in circuit connection between the live wire of the power supply and the load. The non-arc power-off protection switch control circuit has the characteristics of long life, simple structure and low cost.

Owner:KEDU ELECTRIC CO LTD

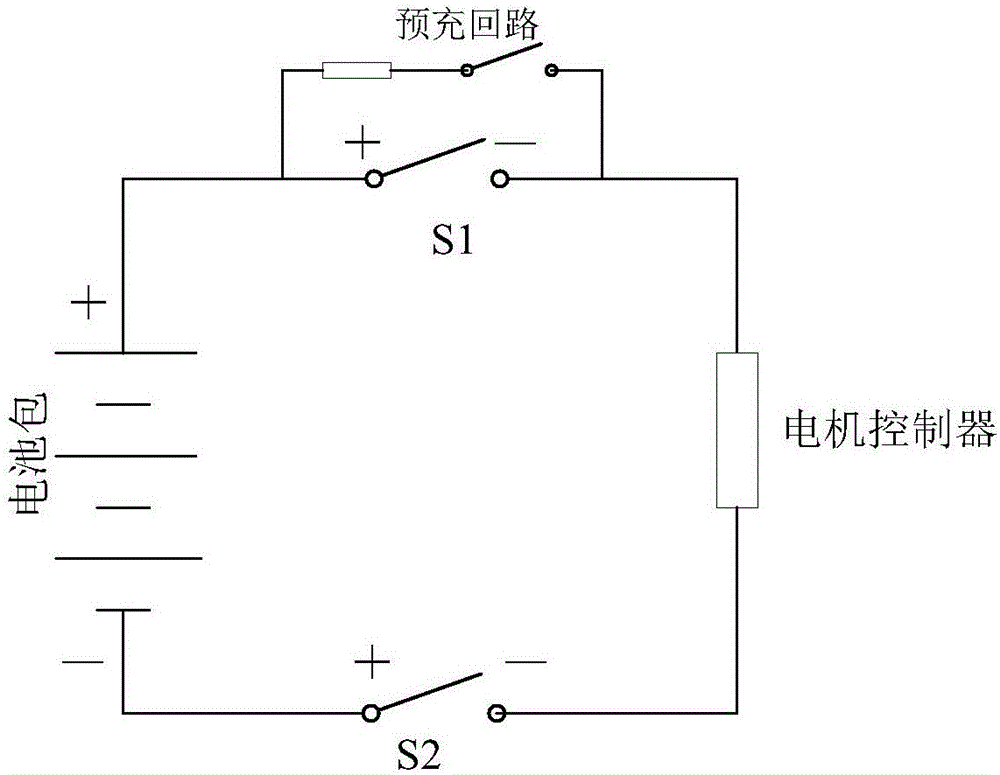

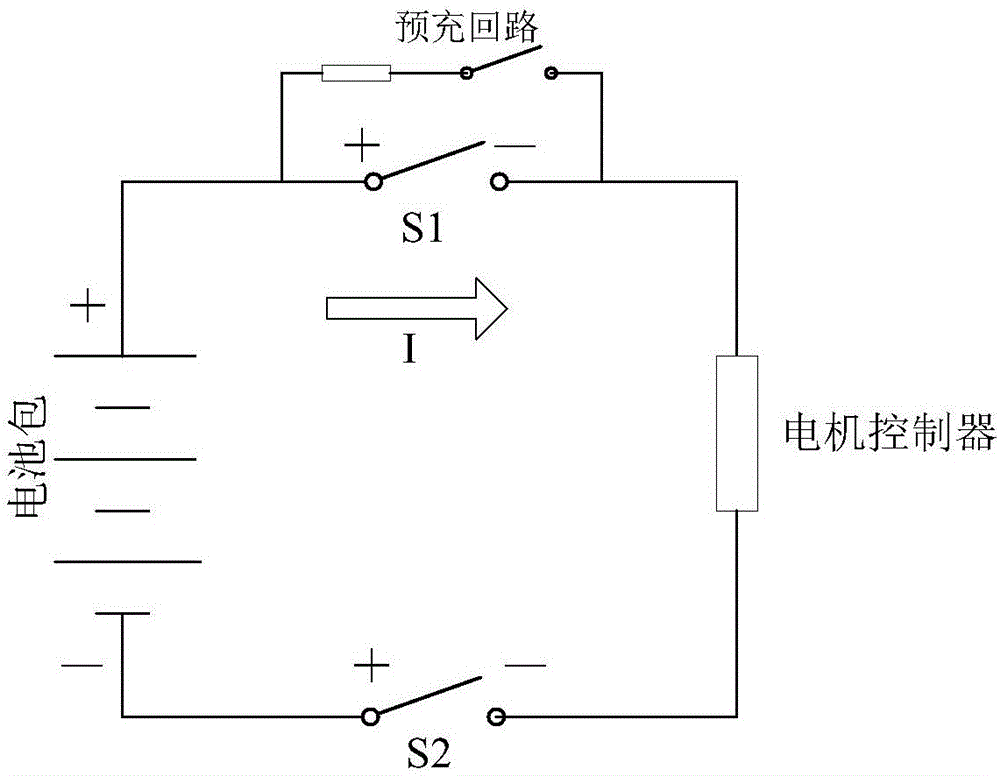

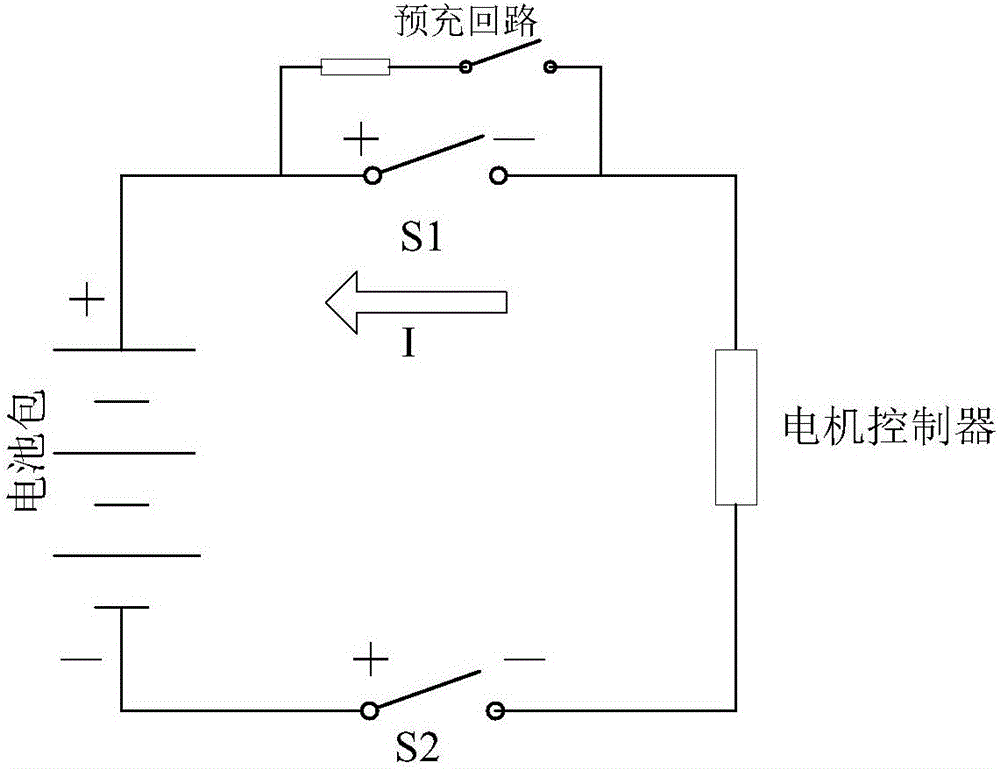

Using method of safety protection of high-voltage and direct current contactors for electric automobile

ActiveCN106696710AProtective contactElectric devicesPropulsion by batteries/cellsElectricityPower flow

The invention discloses a using method of safety protection of a high-voltage and direct current contactors for an electric automobile. The using method comprises the steps that at the time of precharging a motor controller, specifically, a main negative contractor is closed when high voltage power-on of an electric automobile direct current high voltage system is conducted, then a precharging loop is closed to finish precharging of the motor controller, and finally a main positive contractor in the electric automobile direct current high voltage system is closed; and partition current flow direction outage is adopted at the time of the outage of the electric automobile direct current high voltage system. The specific process comprises the steps that if the current flow direction in the system is consistent with the current flow direction when precharging is conducted on the motor controller, the main positive contractor is switched off firstly and then the main negative contractor is switched off; and if the current flow direction in the system is opposite to the current flow direction when precharging is conducted on the motor controller, the main negative contractor is switched off firstly and then the main positive contractor is switched off. In the process of charging and discharging of the high voltage system, the effect of protecting the contact points of the high voltage contractors is achieved by controlling different closing orders of the main positive and negative contractors.

Owner:天津易鼎丰动力科技有限公司

Crossing highway line height limit alarm device

InactiveCN107103764AInfluence voltageAffect line lossDetection of traffic movementAlarmsEngineeringAlarm device

The present invention discloses a crossing highway line height limit alarm device. The device comprises a support module, a detection module, an audible and visual alarm and a power supply module. The detection module is installed on the support module, the audible and visual alarm is installed on the support module and is connected with the detection module, and the power supply module supplies power to the audible and visual alarm and the support module; when a high vehicle passes through the line, the detection module detects whether the height of the vehicle can scrape off the line or not at first, and if the height of the vehicle is too high, an alarm module performs alarm to prompt the superhigh vehicle's driver to pay attention to the line so as to adopt corresponding measures and avoid scrapping off the line.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

Non-dismantling prefabricated concrete pile protecting die plate and construction method

ActiveCN106049491AOvercome construction neckingOvercome defects such as collapsed holesBulkheads/pilesPrecast concreteEconomic shortage

The invention provides a non-dismantling prefabricated concrete pile protecting die plate and a construction method. The non-dismantling prefabricated concrete pile protecting die plate comprises a prefabricated concrete protecting layer and concave arc shaped concrete bumps arranged at the inner side of the protecting layer, wherein a full-length hole is formed in the prefabricated concrete protecting layer; the concrete bumps are symmetrically arranged at intervals along the circumference of the inner side of the protecting layer. According to the design requirement, the construction method comprises the following steps: prefabricating and transporting the non-dismantling prefabricated concrete pile protecting die plate; levelling a site, and measuring a pile arranging position; hoisting and positioning the non-dismantling prefabricated concrete pile protecting die plate; performing a method combining mechanical soil excavation in the die plate and water injecting on the sidewall; constructing the bottom part of the die plate until the design height is reached, and then hoisting and positioning a reinforced cage; pouring concrete; grouting; maintaining until the pile is formed; and detecting a pile foundation. Compared with the prior art, the non-dismantling prefabricated concrete pile protecting die plate and the construction method have the advantages that the earth mass at the outside of a pile body, the underground water, the outer load and the like can be effectively stopped, so that the safety can be greatly improved; meanwhile, the non-dismantling prefabricated concrete pile protecting die plate is prefabricated in a factory, so that the construction quality can be ensured, and the construction period can be greatly reduced; the shortages such as necking down and hole collapse in traditional pile foundation construction can be overcome.

Owner:浙江长兴市政建设有限公司

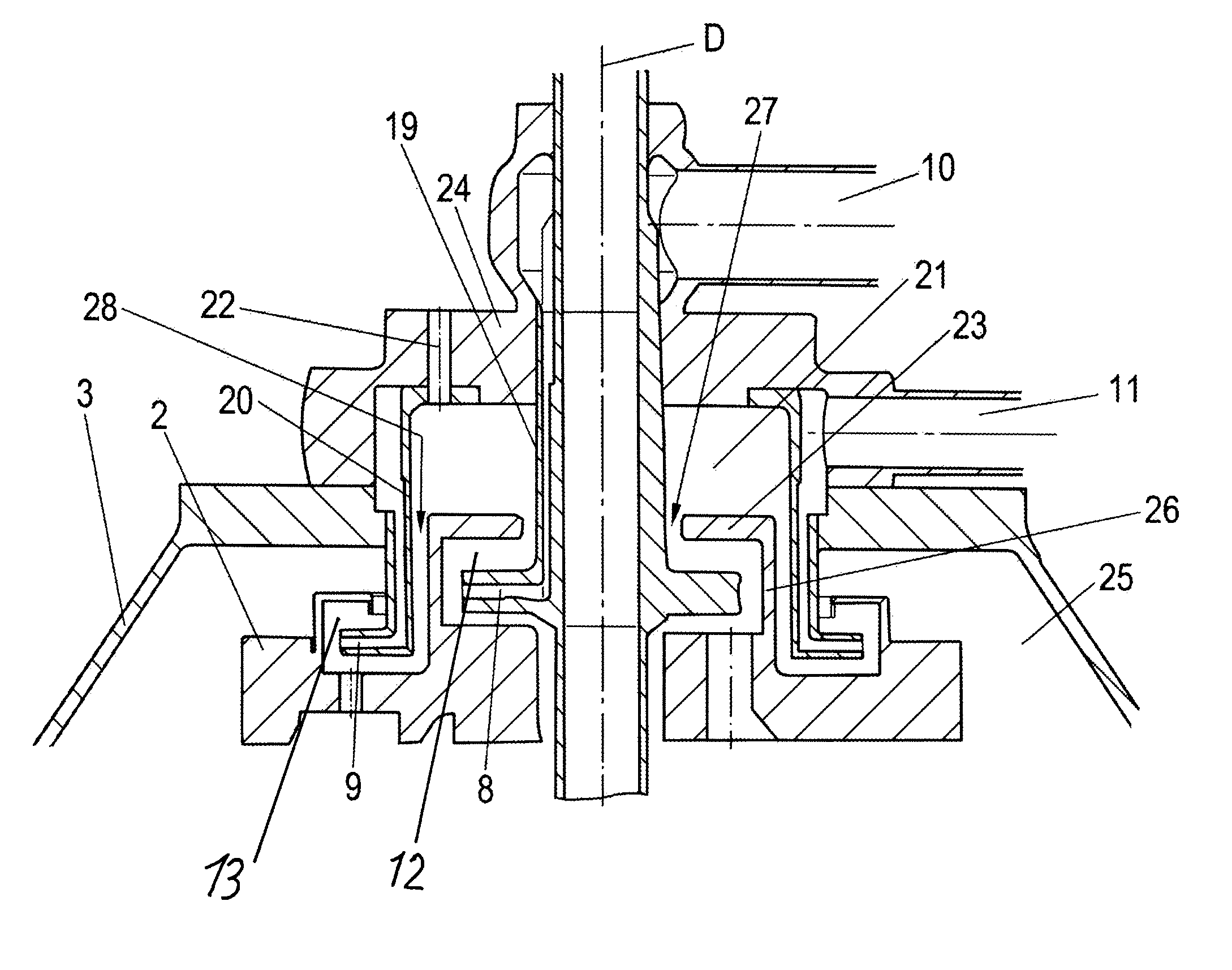

Separator having a centrifugal drum

ActiveUS20130309376A1Avoid contactEasy to operateWort preparationRotary centrifugesRotational axisEngineering

A separator includes a rotatable drum having a vertical rotational axis, a disk stack arranged in the drum, an inner gripper and an outer gripper that do not rotate with the drum are configured to discharge mutually-separated liquid phases. A discharge line is assigned to each gripper and is arranged in an associated gripper chamber of the drum. The inner gripper includes an inner gripper shaft and the outer gripper includes an outer gripper shaft both of which shafts protrude axially from the drum. Each associated gripper chamber, with its associated gripper, revolves on different radii with respect to the rotational axis such that a chamber is formed radially between an outer circumference of the inner gripper shaft and an inner circumference of the outer gripper shaft. A fluid is insertable into the chamber through a channel, which fluid is pressable from the chamber into the gripper chambers.

Owner:GEA MECHANICAL EQUIP

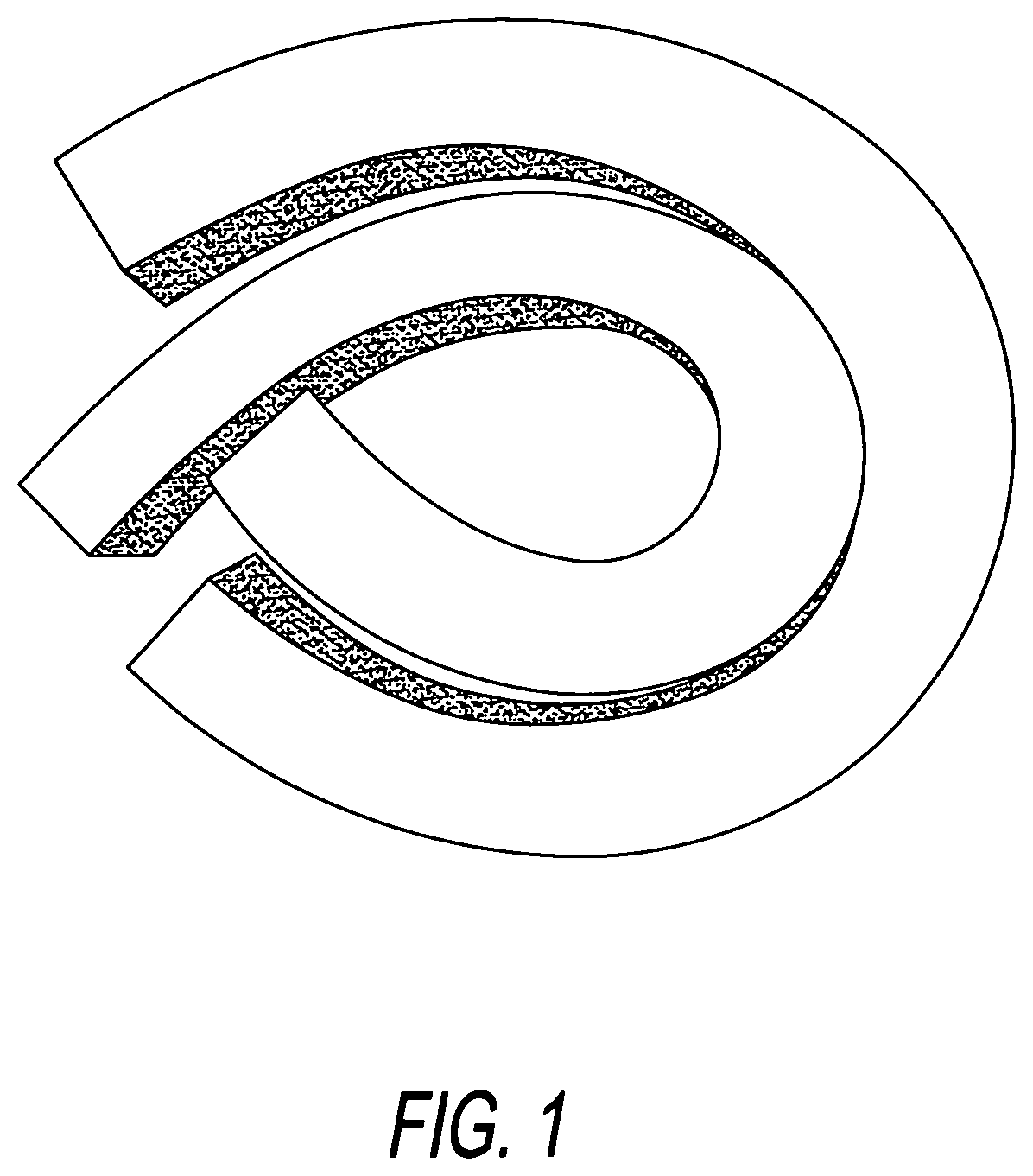

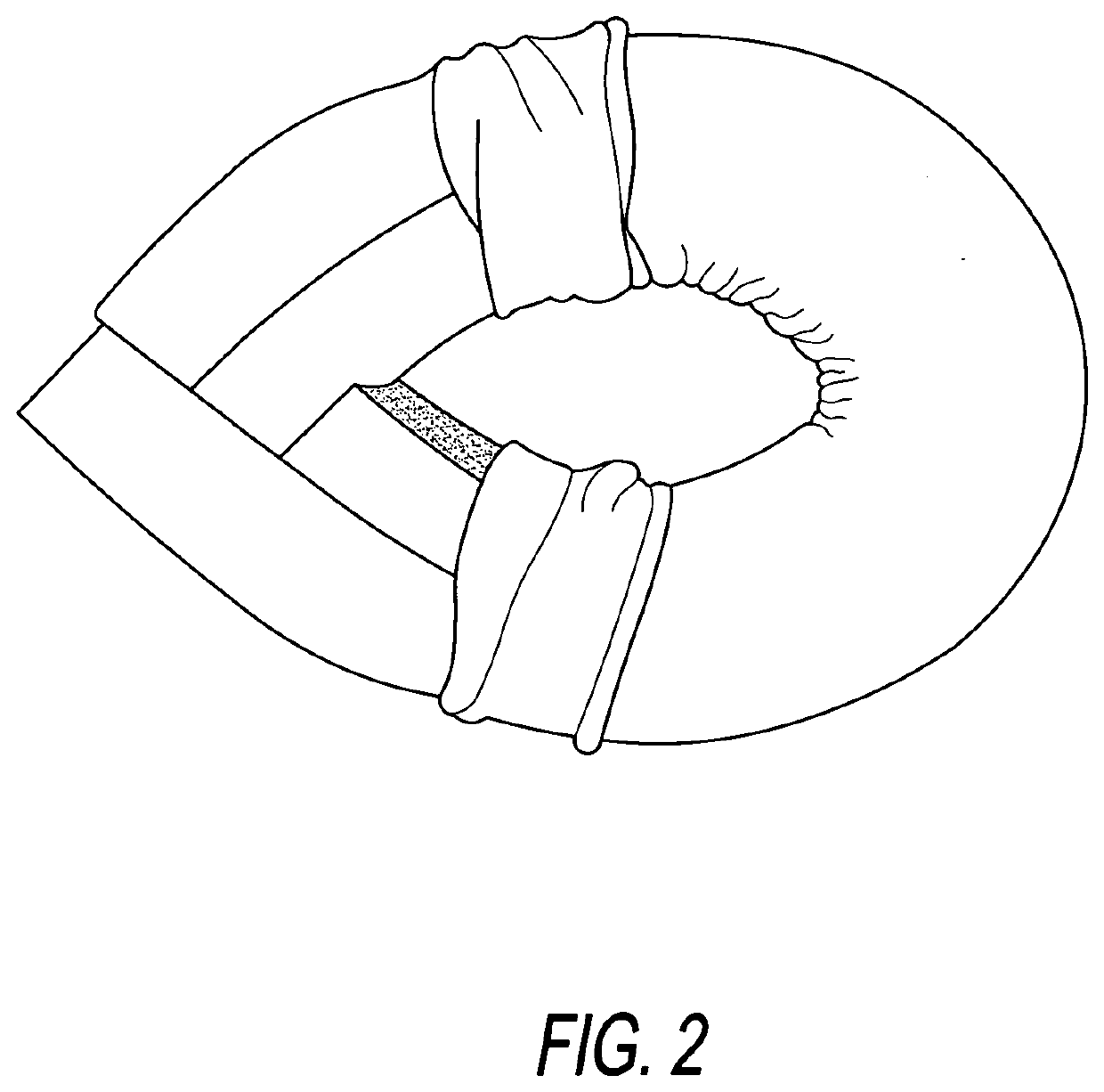

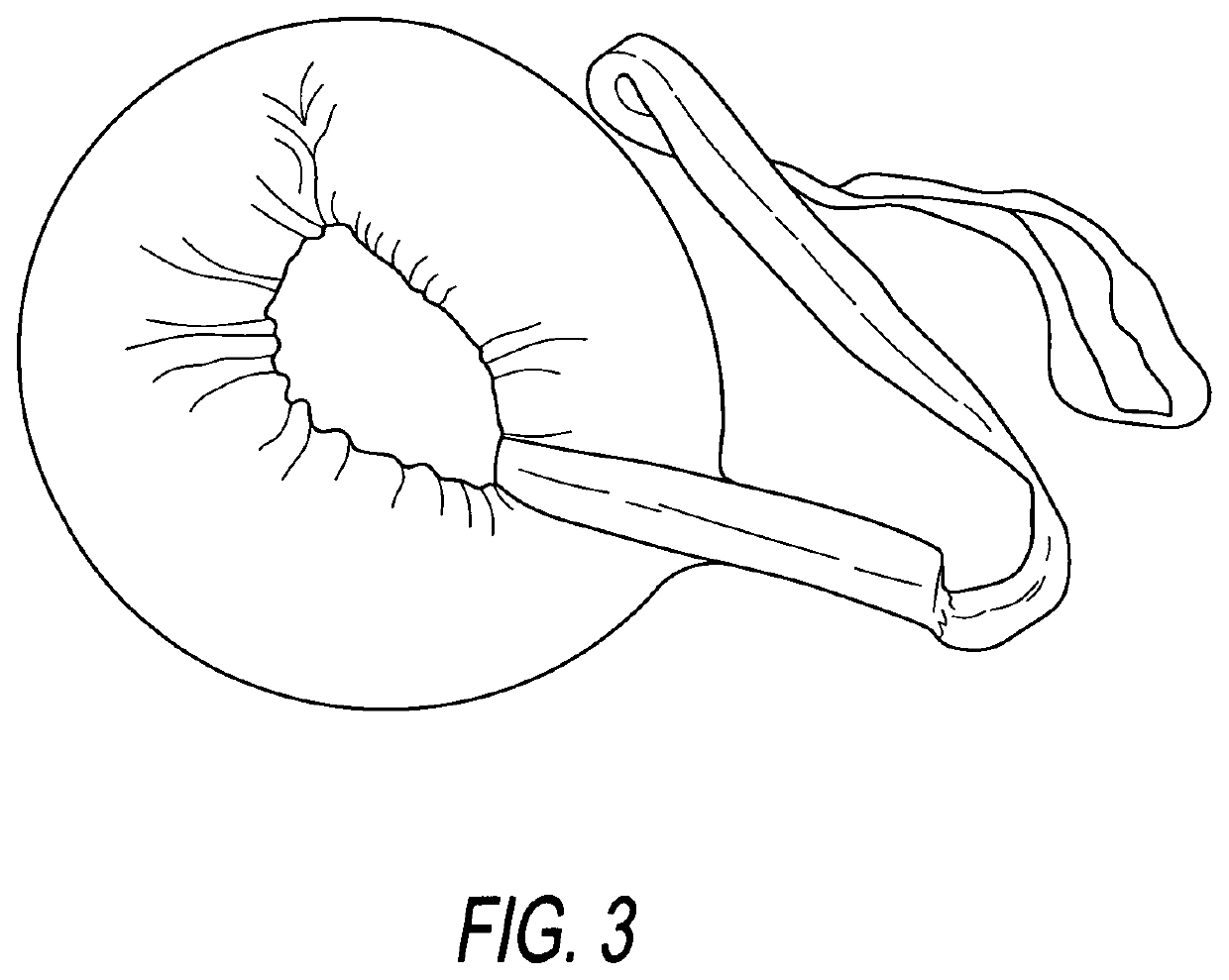

CNH Donut Pillow

ActiveUS20200205504A1Resists splayingImprove protectionPillowsOperating tablesNodular chondrodermatitisEar Injury

The claimed invention is a pressure and pain relieving prosthetic device, for the ear, to be used with a standard pillow, as a sleep aid, for persons suffering with Chondrodermatitis nodularis chronic helicis, CNH, and, or, Atresia and Microtia-anotia conditions of the ear. Invention is comprised of contiguous foam strips, curved into a teardrop shape, covered in cylindrical nylon spandex, with the ends sewn together, to form a donut shape, then affixed with a head strap. Device is lightweight, yet strong enough to support a head. Device protects, and isolates an ear injury, and permits faster healing. Device allows patients to sleep on their preferred side, without pain.

Owner:LAHERA ARLENE FRANCIS

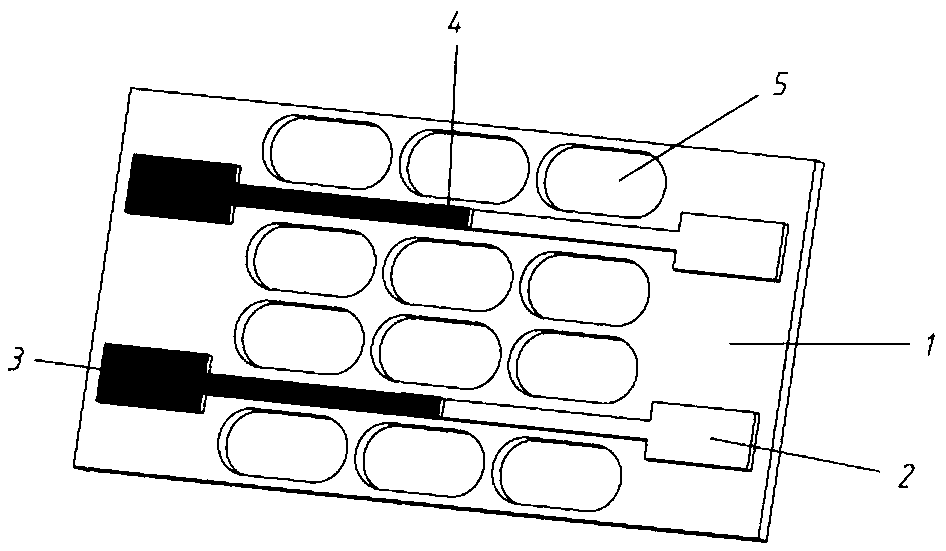

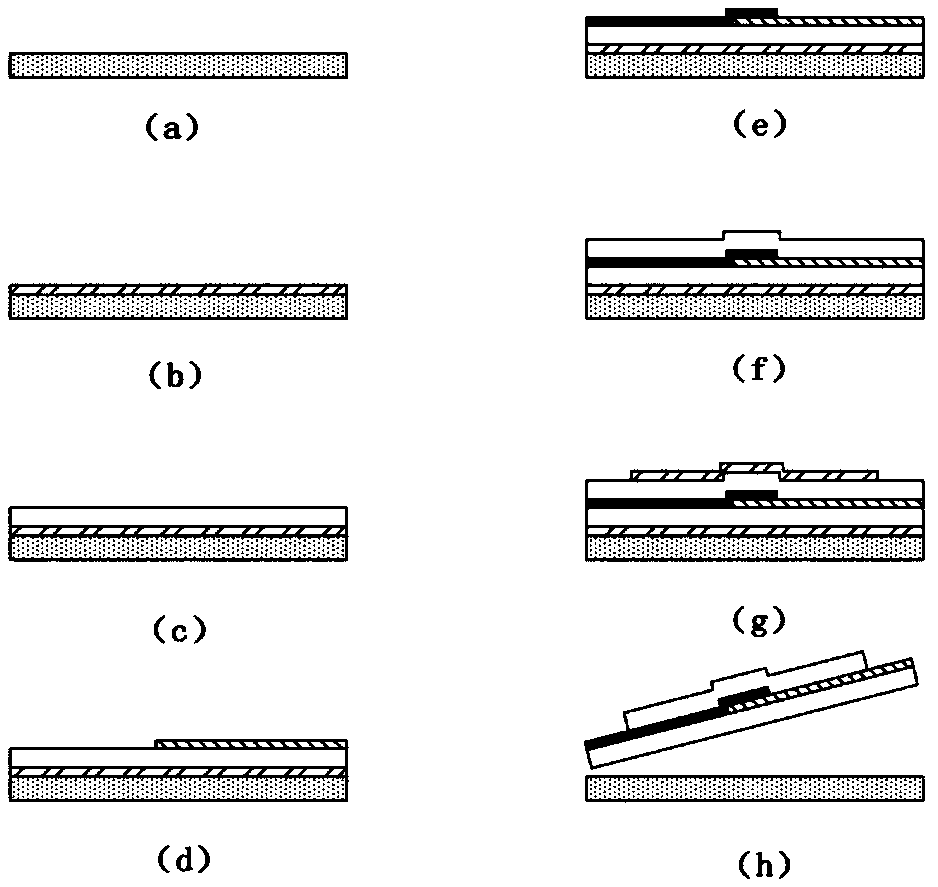

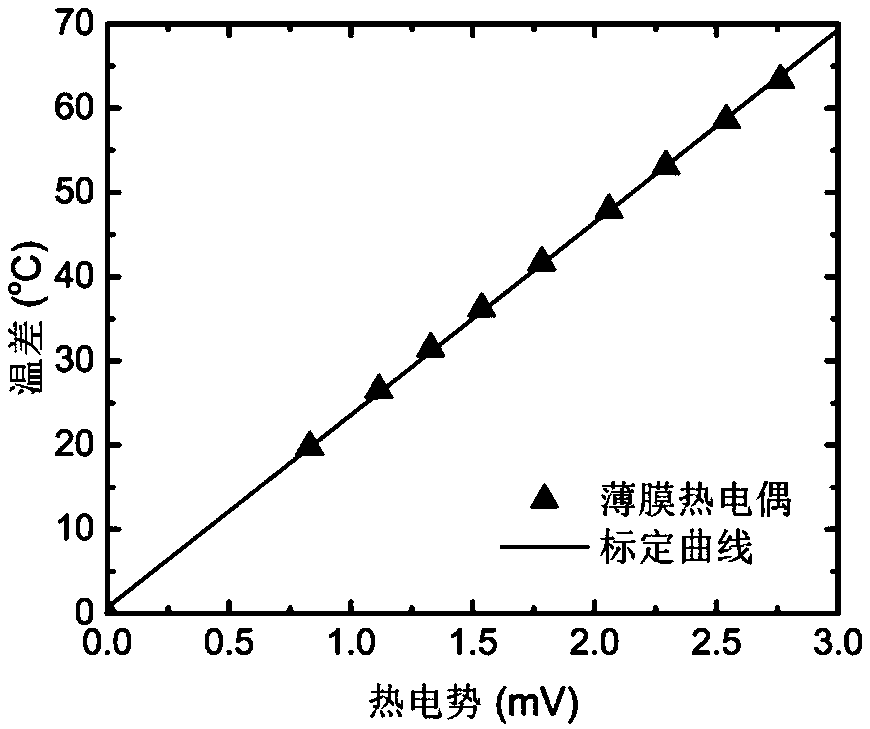

A method for manufacturing a thin film thermocouple for measuring a local temperature of a fuel cell

InactiveCN109216535AImprove machining accuracyImprove spatial resolutionFuel cell heat exchangeThermoelectric device manufacture/treatmentCopper nickel alloyPhotoresist

A method for manufacturing a thin film thermocouple for measuring local temperature of a fuel cell comprise plating a sacrificial layer on a silicon wafer; A layer of Parylene film is deposited on thesacrificial layer as the lower protective layer of the thin film thermocouple. The photoresist is spin-coated on the Parylene film for patterning, then a layer of copper-nickel alloy is plated, and the excess copper-nickel alloy is removed to obtain the patterned copper-nickel electrode; Spin-coating photoresist on Parylene film for patterning, then plating a layer of copper, removing excess copper to obtain patterned copper electrode; A layer of Parylene film is deposited on the copper-nickel electrode and the copper electrode as the upper protective layer of the thin film thermocouple. Spin-coating photoresist on Parylene film for patterning, then plating a layer of aluminum, removing excess aluminum to obtain patterned hard mask, then etching Parylene film, exposing electrode pins andetching through holes on the film; The sacrificial layer is dissolved and the thin film is peeled off from the silicon wafer to obtain a thin film thermocouple. The thin film thermocouple manufacturedby the invention has the advantages of thin thickness and small temperature measuring point size.

Owner:XI AN JIAOTONG UNIV

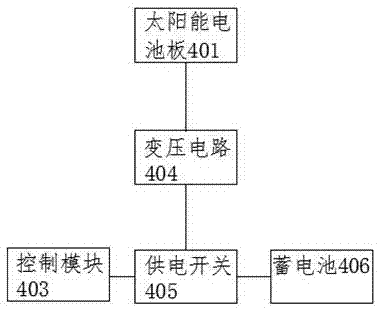

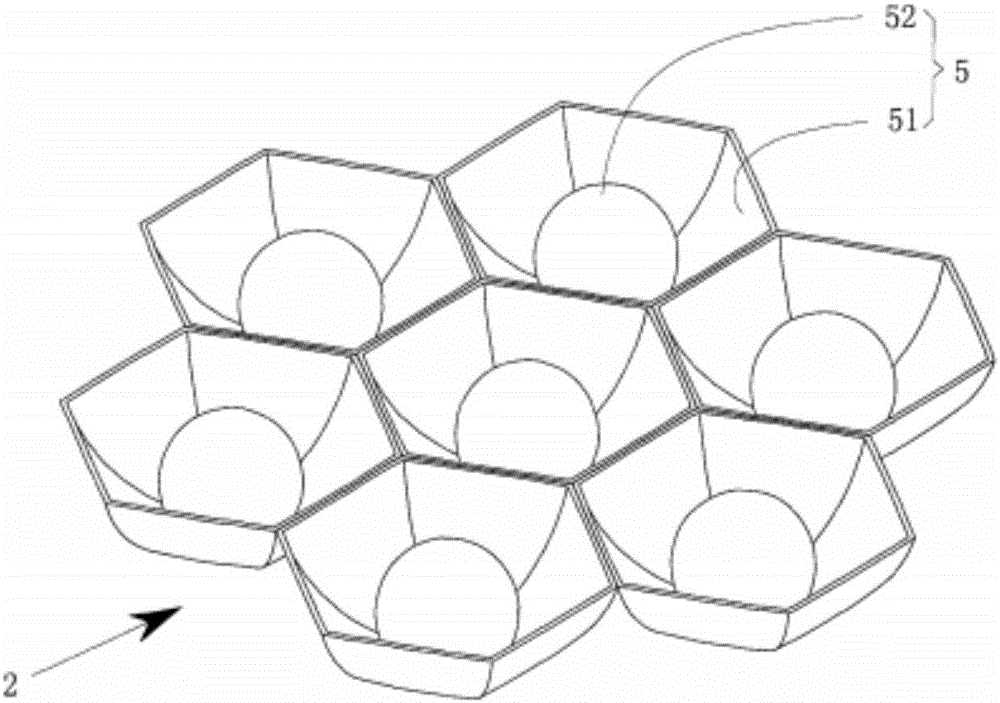

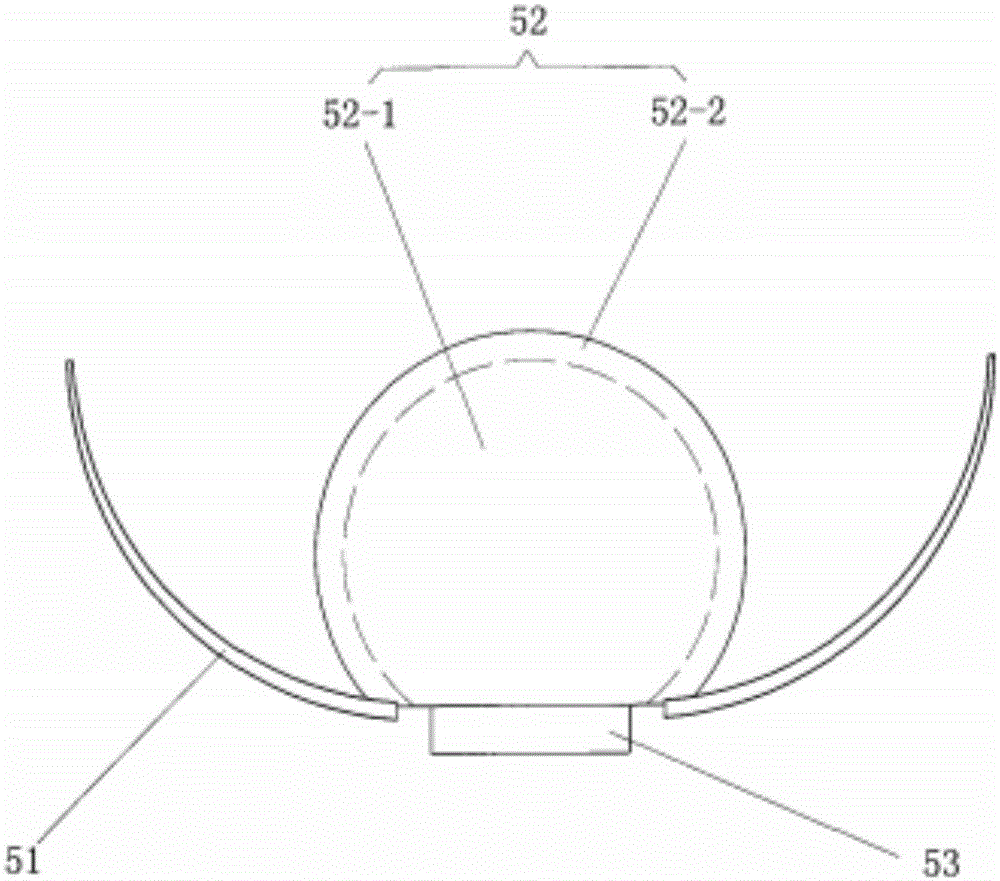

Light-focusing solar cell panel

InactiveCN106601846AImprove cooling effectProtective contactPhotovoltaic energy generationSemiconductor devicesEngineeringPhotoelectric conversion

The invention relates to a light-focusing solar cell panel, and the solar cell panel is provided with toughened glass located at the upper layer, a battery piece located at the central layer and a backboard located at the bottom layer. Ethylene and vinyl acetate copolymer adhesive films are disposed between the toughened glass and the battery piece and between the battery piece and the backboard. The toughened glass, the battery piece, the backboard and the ethylene and vinyl acetate copolymer adhesive films are pressed and bonded into one body through vacuum heating. According to the invention, the battery piece is disposed between the toughened glass and the backboard, thereby effectively preventing the battery piece from contacting with the outside, and prolonging the service life. A PN junction of the solar cell panel is shaped like a ball, can receive the sunlight to maximum degree, can eliminate the aberration of sunlight spots under the condition that the incident angle of the sun changes, and improve the photoelectric conversion rate. According to the invention, the PN junction of the solar cell panel is shaped like the ball, and there is no need of cutting operation, thereby greatly reducing the material loss. The usage amount of materials is one fifth of the usage amount of materials of a flat-type solar cell, thereby reducing the production cost.

Owner:梁结平

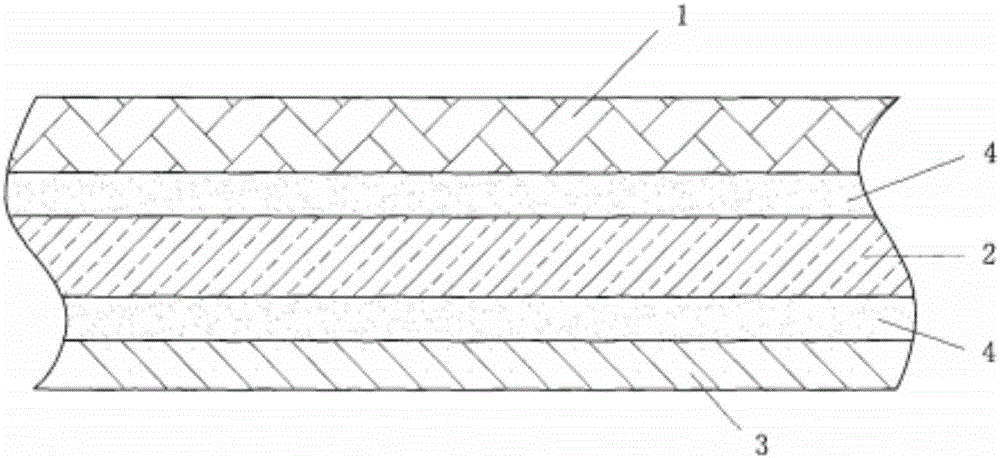

Leakage-proof air conditioner indoor and outdoor unit connecting pipeline

InactiveCN112145844AImprove practicalityIncreasing the thicknessHose connectionsThreaded pipeStructural engineering

The invention discloses a leakage-proof air conditioner indoor and outdoor unit connecting pipeline which comprises a connecting pipeline body. Threaded connecting blocks are fixedly connected to twosides of the connecting pipeline body through sealing bearings; surface threaded pipes are in threaded connection with the inner sides of the threaded connecting blocks; the outer sides of the surfacethreaded pipes communicate with the air conditioner indoor unit and outdoor unit connecting pipe body; and sealing mechanisms are fixedly connected to two sides of the top and two sides of the bottomof the connecting pipe body correspondingly. According to the leakage-proof air conditioner indoor and outdoor unit connecting pipeline provided by the invention, by arranging the sealing mechanisms,sealing plate sleeves can be located at the joints between the threaded connecting blocks and the air conditioner indoor and outdoor unit connecting pipeline body so as to carry out sealing, then clamping blocks are used for positioning the sealing plate sleeves through pulling mechanisms, and the occurrence of the phenomenon that the sealing plate sleeves move when air conditioner indoor and outdoor units vibrate is prevented, so that water leakage prevention is carried out on the joints through the sealing plate sleeves, and the problem that water leakage prevention cannot be carried out onthe joints through the air conditioner indoor and outdoor unit connecting pipeline is solved.

Owner:北京点域科技有限公司

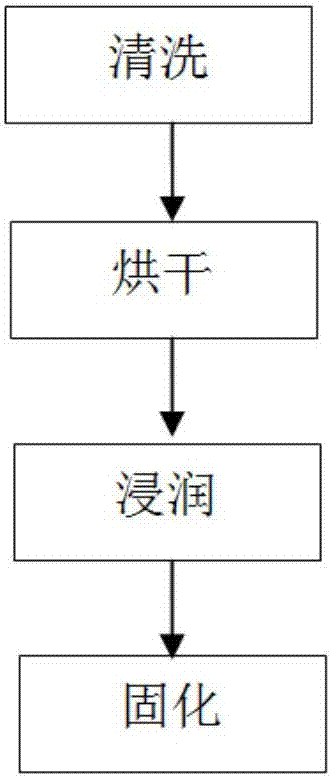

Corrosion prevention and scale inhibition treating method for shield pump

InactiveCN106968991AProtective contactAvoid generatingPump componentsPumpsForeign matterMegasonic cleaning

The invention discloses a treatment method for anti-corrosion and anti-scaling of shielded pumps. The surface of main parts is cleaned by ultrasonic waves to remove surface impurities and residual oil stains, and then the parts are soaked in grease to form a protective oil film on the surface of the parts. It effectively protects the contact between the shielding sleeve and external substances, prevents the formation of scale, and the thickness of the grease is thin, which will not cause any adverse effects on the operation of the motor stator and rotor. The method does not need to perform special process treatment on parts, has low cost, high efficiency, and obvious anti-corrosion and scale-inhibiting effects.

Owner:FANS TECH ELECTRIC CO LTD

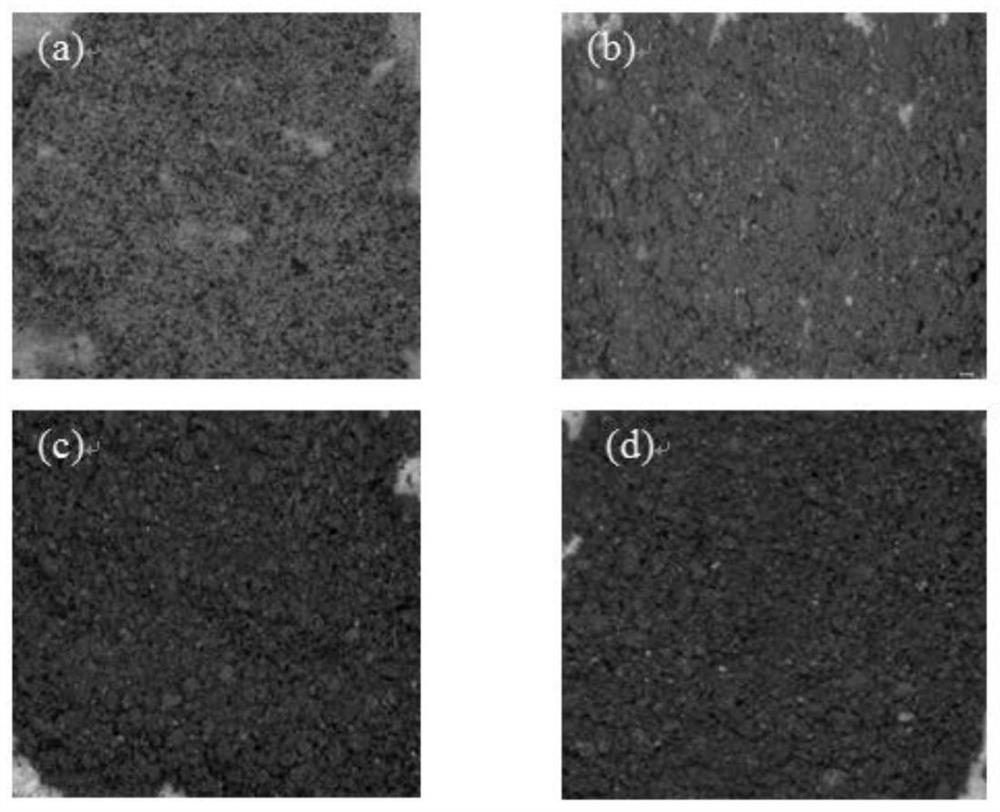

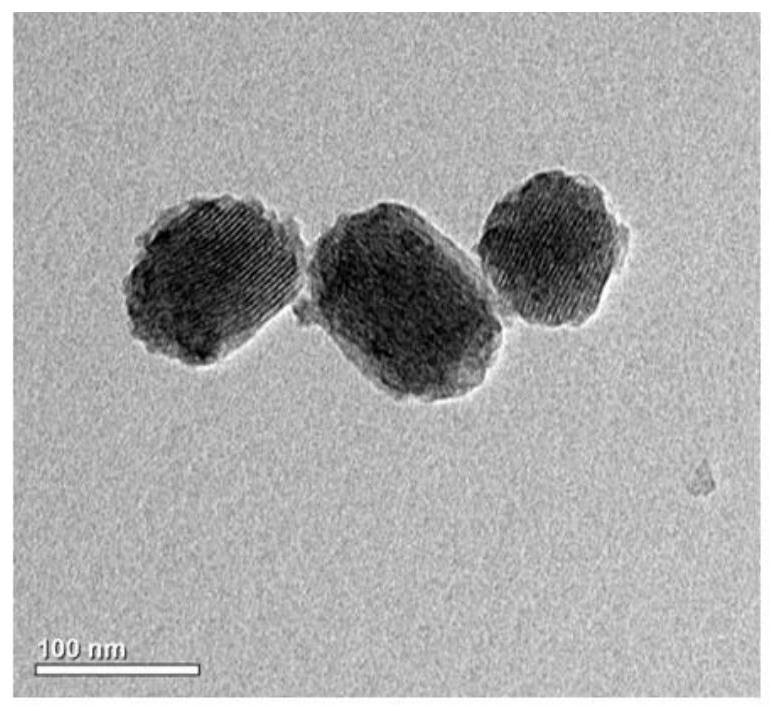

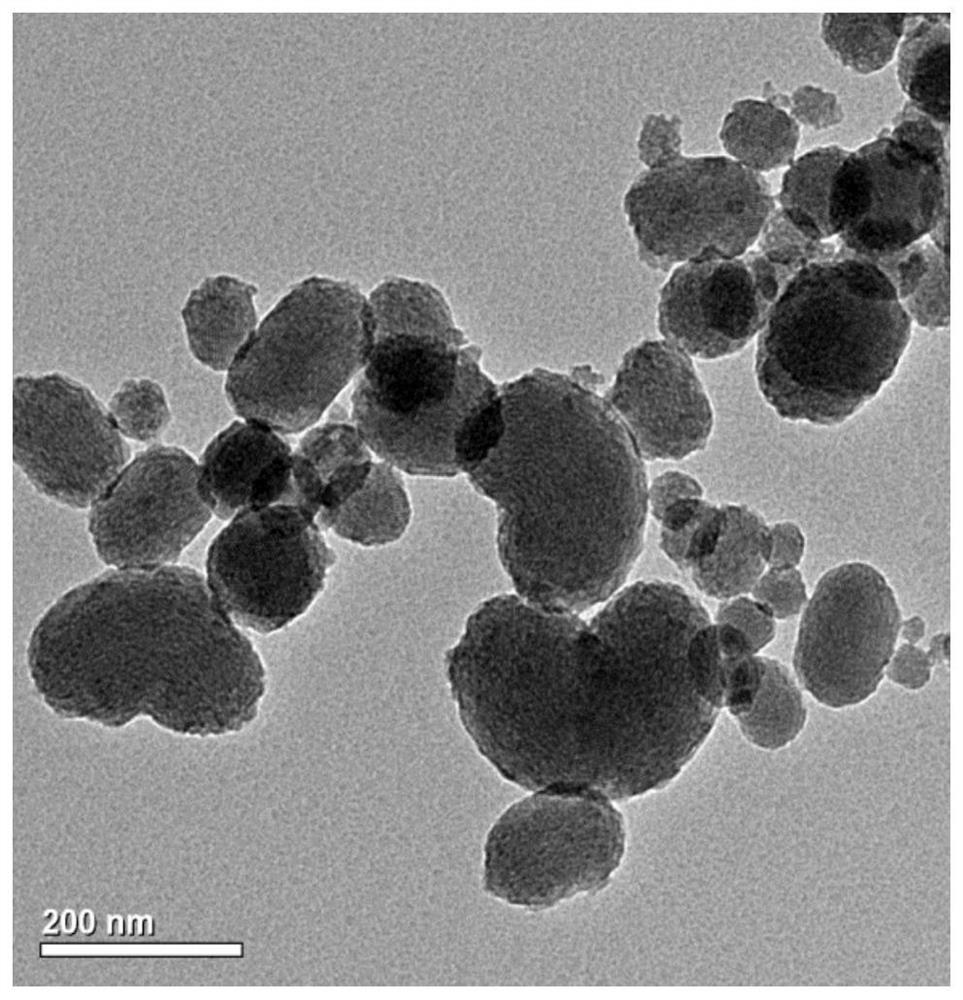

PH response type corrosion inhibition capsule based on metal polyphenol network structure and preparation and application of pH response type corrosion inhibition capsule

PendingCN113774385ALarge specific surface areaSurface is easy to modifyMicroballoon preparationMicrocapsule preparationPhenolsCorrosion inhibitor

The invention discloses a pH response type corrosion inhibition capsule based on a metal polyphenol network structure and preparation and application of the pH response type corrosion inhibition capsule, and belongs to the field of application of novel materials. Mesoporous silicon dioxide with a large specific surface area is used as a carrier for loading corrosion inhibitor molecules, and then the corrosion inhibitor molecules are loaded into the mesoporous silicon dioxide through a vacuum loading method. Finally, through modification of organic acid with a polyphenol structure and metal ions, a metal-phenol network structure is generated outside the silicon dioxide, and the corrosion inhibitor capsule with targeting, pH responsiveness and anti-ultraviolet activity can be formed. The capsule corrosion inhibitor can be quickly released at low pH and slowly released in neutral and alkaline systems, so that release of the corrosion inhibitor is intelligent, the utilization efficiency of the corrosion inhibitor is improved, meanwhile, as the corrosion inhibitor molecules are loaded in the whole capsule, direct irradiation of ultraviolet light can be avoided, and when the capsule corrosion inhibitor is applied to an ultraviolet environment, the utilization rate of the corrosion inhibitor molecules is greatly increased.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Integrated circuit board cutting device

ActiveCN107756663ASmooth transmissionFacilitate transmissionEdge grinding machinesFine working devicesCopperPrinted circuit board

The invention relates to the field of a circuit board, in particular to an integrated circuit board cutting device. Four angle lapping units are arranged in the device, and the angle lapping units canconduct simultaneous lapping for four rim angles of a copper-clad plate. In the lapping process, a second telescopic rod can be stretched, further multiple copper-clad plates are stacked on a receiving plate, the rim angles of the copper-clad plates can be convenient for simultaneous lapping, and the lapping efficiency of the rim angles of the copper-clad plates can be further improved. Meanwhile, the stacked copper-clad plates do not need to be arranged again, and the subsequent processing for the copper-clad plates is convenient. The integrated circuit board cutting device can improve the lapping efficiency of the rim angles of the copper-clad plates.

Owner:高唐融知融智科技服务有限公司

Device for grinding ultrasonic wave guide probe

ActiveCN104942685AAvoid shakingImprove stabilityMaterial analysis using sonic/ultrasonic/infrasonic wavesPortable grinding machinesBiochemical engineeringUltrasonic guided wave

A device for grinding an ultrasonic wave guide probe comprises a base, a stand column, a suspension arm, a probe clamp, a sliding guide rail base, a V-shaped sample tube fixing tank and a sample tube fixing clamp, wherein the base is provided with adjustment components for adjusting the level of the base; the stand column is fixedly connected on one side of the base; one end of the suspension arm is clamped on the stand column and can slide up and down along the stand column; the probe clamp is fixed at the other end of the suspension arm and connected with a probe when used; the sliding guide rail base is arranged on the other side of the base, and machining sliding rails are arranged on the sliding guide rail base; the V-shaped sample tube fixing tank is mounted right above the sliding guide rail base, the top of the V-shaped sample tube fixing tank is used for accommodating a tube with the diameter identical to that of a required ground probe, and lower sliding rails in fit connection with the machining sliding rails are arranged at the bottom of the V-shaped sample tube fixing tank; the sample tube fixing clamp is arranged above the V-shaped sample tube fixing tank and penetrates through the tube arranged on the V-shaped sample tube fixing tank, two ends of the sample tube are fixed on outer sides of the V-shaped sample tube fixing tank, the sample tube fixing clamp is matched with the V-shaped sample tube fixing tank to fix the tube, and accordingly, the tube can be prevented from shaking in the probe grinding process.

Owner:STATE GRID CORP OF CHINA +2

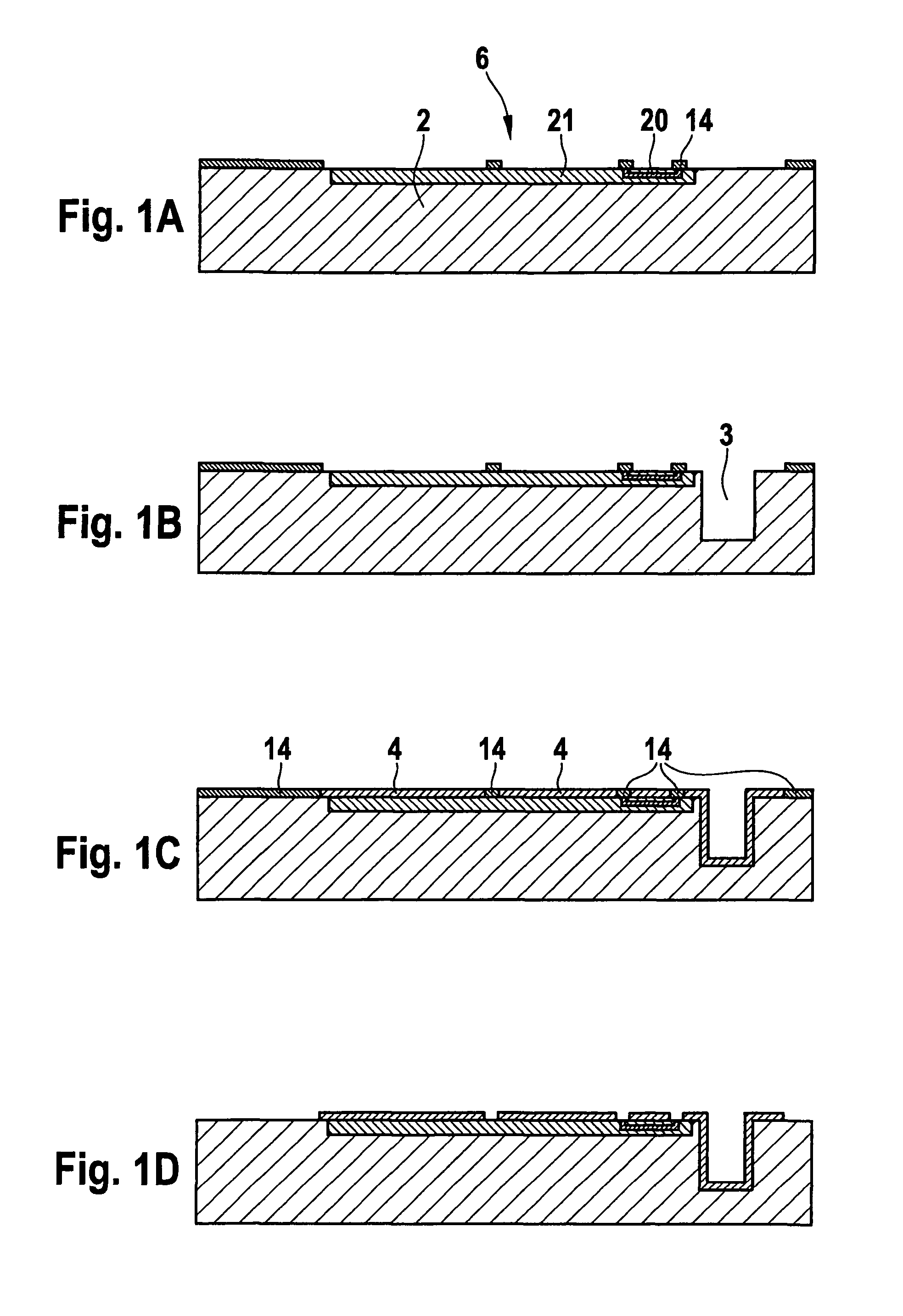

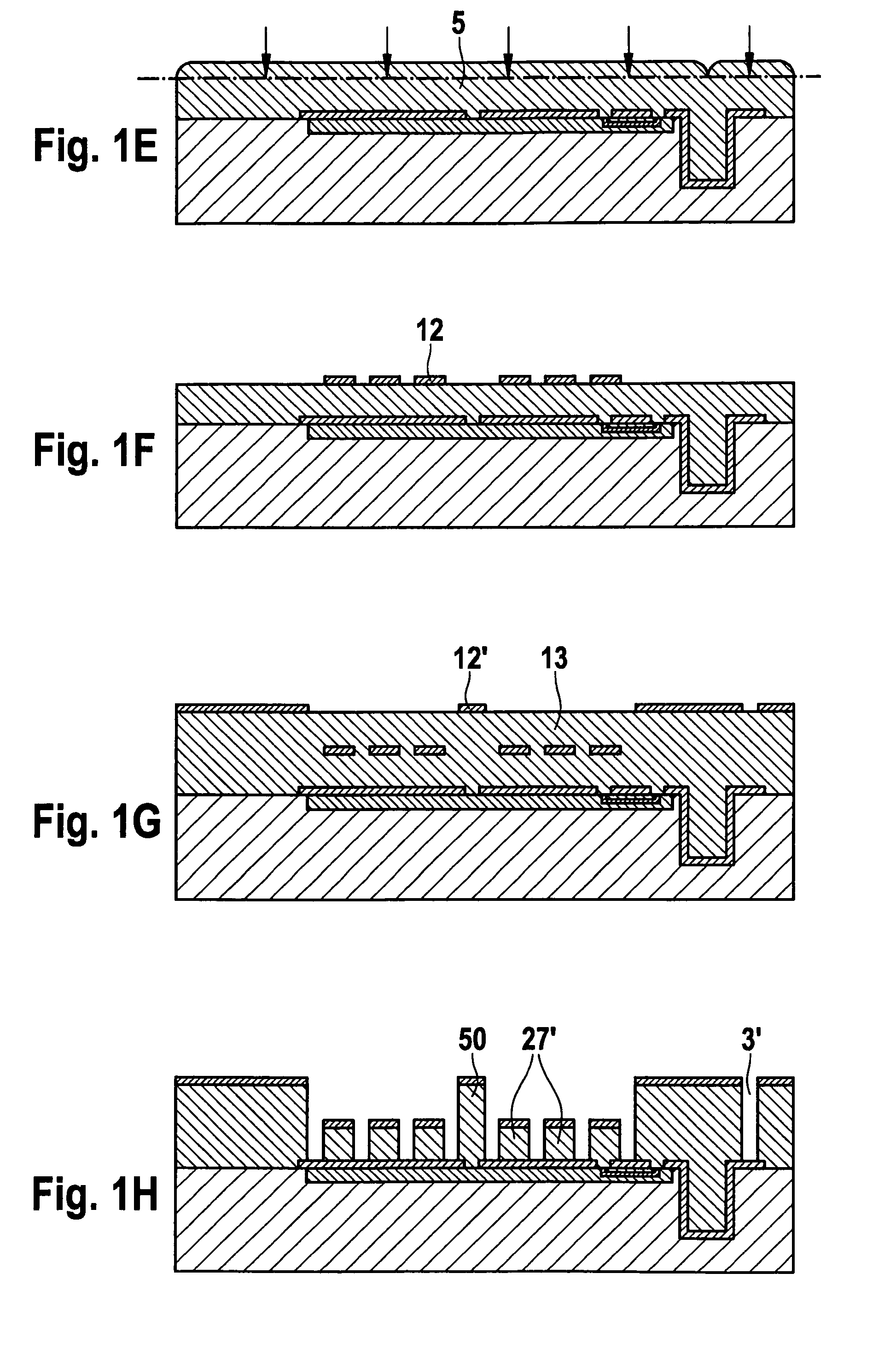

Method for producing a micromechanical component having a filler layer and a masking layer

InactiveUS8419957B2Avoid contactReduce deflectionDecorative surface effectsSemiconductor/solid-state device manufacturingMask layerPhysics

A method for producing a micromechanical component is proposed, a trench structure being substantially completely filled up by a first filler layer, and a first mask layer being applied on the first filler layer, on which in turn a second filler layer and a second mask layer are applied. A micromechanical component is also proposed, the first filler layer filling up the trench structure of the micromechanical component and at the same time forming a movable sensor structure.

Owner:ROBERT BOSCH GMBH

Energy storage device for electric operating mechanism

ActiveCN102779663BSimple and time-saving installationReduce volumeSwitch power arrangementsStored energyRelative Volume

The invention discloses an energy storage device for an electric operating mechanism. The energy storage device comprises a first spring chuck, a second spring chuck and a spring energy storage component which is arranged between the two spring chucks, wherein the spring energy storage component comprises an inner mounting sleeve and an outer mounting sleeve; the inner and outer mounting sleeves are provided with containing cavities capable of containing energy storage springs; one end of the inner mounting sleeve penetrates through the containing cavity of the outer mounting sleeve and is fixedly connected with the second spring chuck; the other end of the inner mounting sleeve is connected with the outer mounting sleeve through steps which are arranged corresponding to the inner and outer mounting sleeves; an outer energy storage spring is arranged between the outer mounting sleeve and the second spring chuck; an inner energy storage spring is arranged in the containing cavity of the outer mounting sleeve; and the outer ends of the first and second spring chucks are provided with mounting grooves. The energy storage device has the advantages that the device is simply mounted in a time-saving and labor-saving mode, the volume of the whole energy storage device can be effectively reduced, and the miniaturization development requirements of circuit breakers are met; and moreover, stored energy of the springs is increased in relative volume, contacts of the circuit breakers are effectively protected, and the cost is saved.

Owner:WUXI KAIXUAN MOTOR +1

A kind of processing method of wicker raw material wicker

ActiveCN107186846BThermally stableImprove strength and toughnessWood treatment detailsReed/straw treatmentCold treatmentFiber

The invention relates to the technical field of wickerwork artware and discloses a treatment method of wickerwork raw material wickers. The method comprises the following steps that (1) newly-cut wickers are dewatered through natural drying, the high temper of the wickers is improved, heating treatment is conducted in alkaline water, thus peeling is facilitated, the glossiness of the wickers can be improved, and cold treatment is conducted after peeling; (2) the wickers subjected to cooling treatment are immediately steeped through a steeping solution A, the steeping solution can be rapidly adsorbed by fibers with negative charges under the effect of positive charges in the aqueous solution, a thin film is formed on the surface of each fiber, binding force among the fibers is reinforced, and shrinkage deformation of the fibers is prevented; and (3) the wickers are heated and baked in a drying oven after being steeped by the steeping solution A and then put into a steeping solution B for steeping, the steeping solution B has oxidation resistance and heat stability, connection points among the fibers are protected, and heating deformation of the fibers is prevented.

Owner:阜南县猛发工艺品有限公司

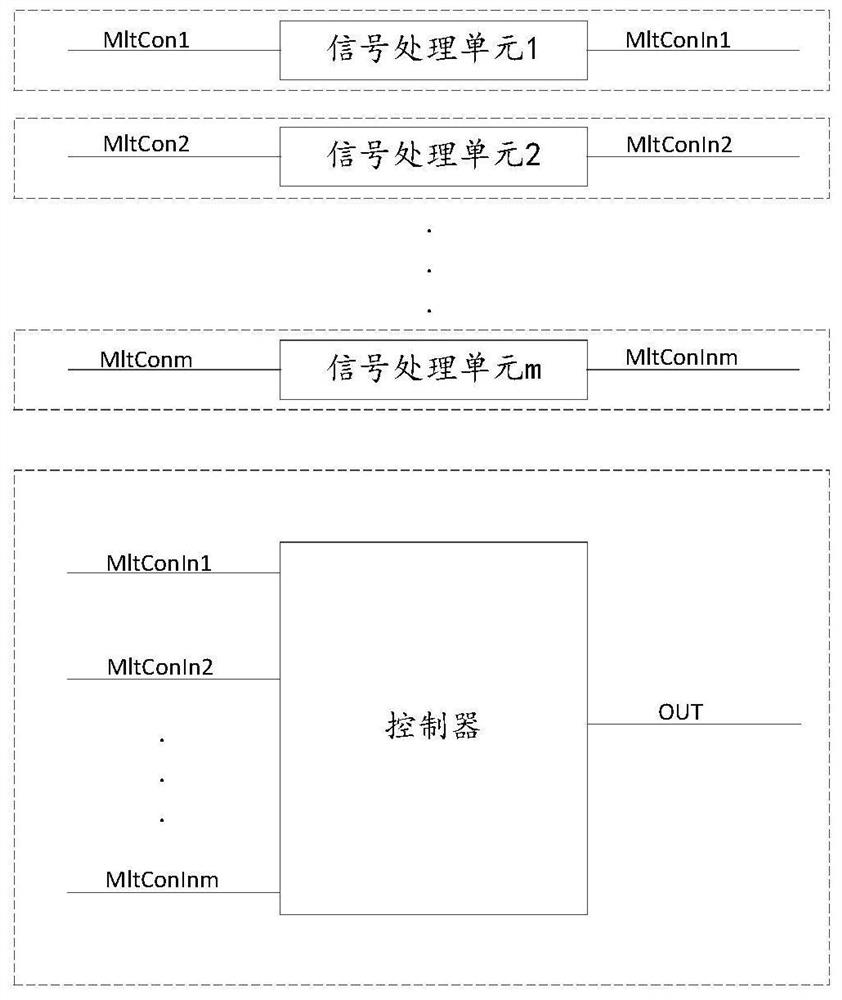

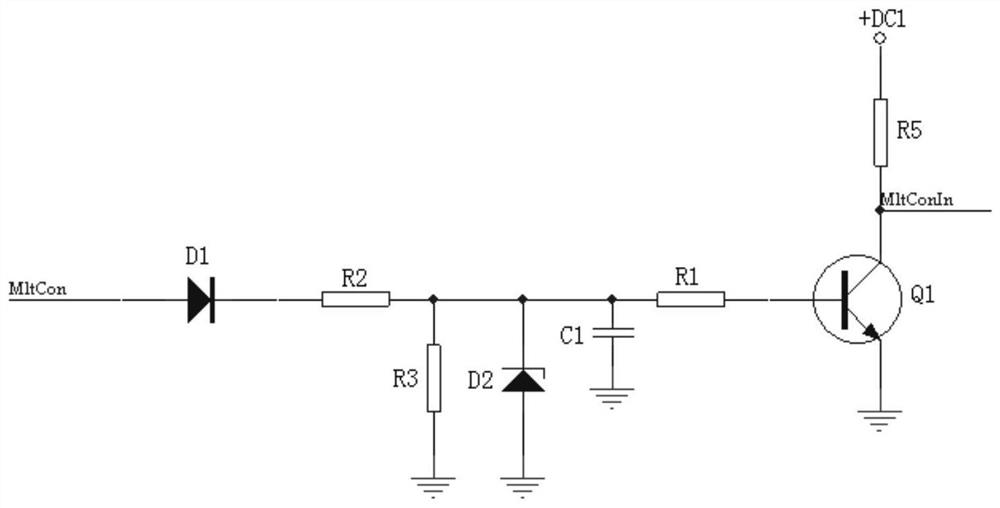

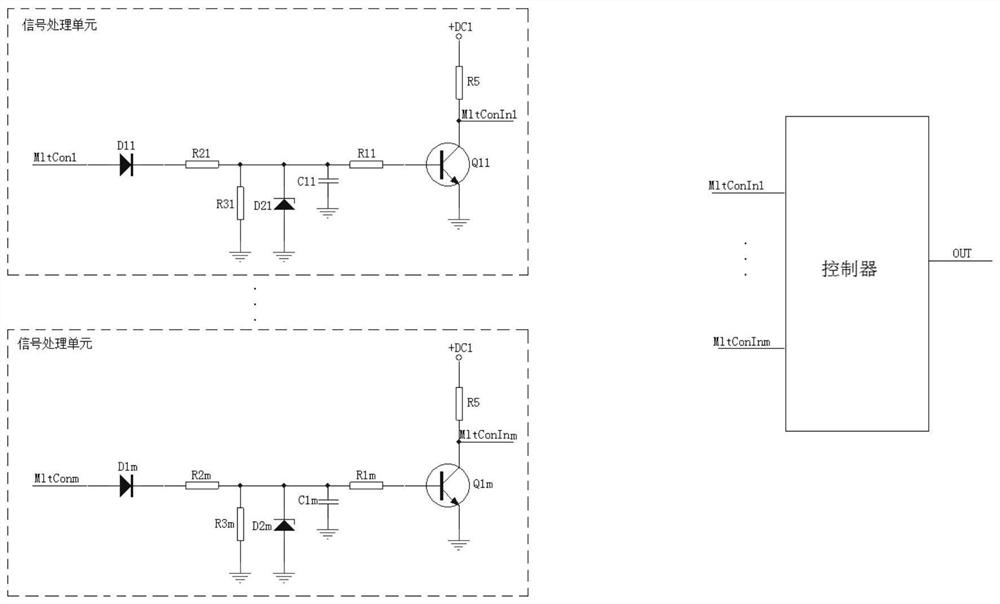

Switch control circuit and switch control system

ActiveCN109445336BPrecise closureProtective contactProgramme controlComputer controlMultiway switchingControl system

The present invention relates to the technical field of electronic circuits, and discloses a switch control circuit and a switch control system, wherein the control circuit includes: a plurality of parallel signal processing units, the signal processing unit has a first controllable switch; the first controllable The first end of the switch is connected to the first voltage signal, the second end is connected to the first port of the controller, and the third end is connected to the second voltage signal; the first voltage signal and the second voltage signal control the first control the on and off of the switch, and convert the first voltage signal into a third voltage signal; the third voltage signal is connected to the first port of the controller; the controller is configured to , and send the switch control command to the terminal to be controlled. After converting the high strong electric signal into a low stable weak electric signal, the circuit combines the controller to realize multi-channel switch control, and only processes the voltage signal in the whole circuit, avoiding the processing of various types of signals and ensuring the multi-channel Reliability of switch control.

Owner:WENZHOU MTLC ELECTRIC APPLIANCES

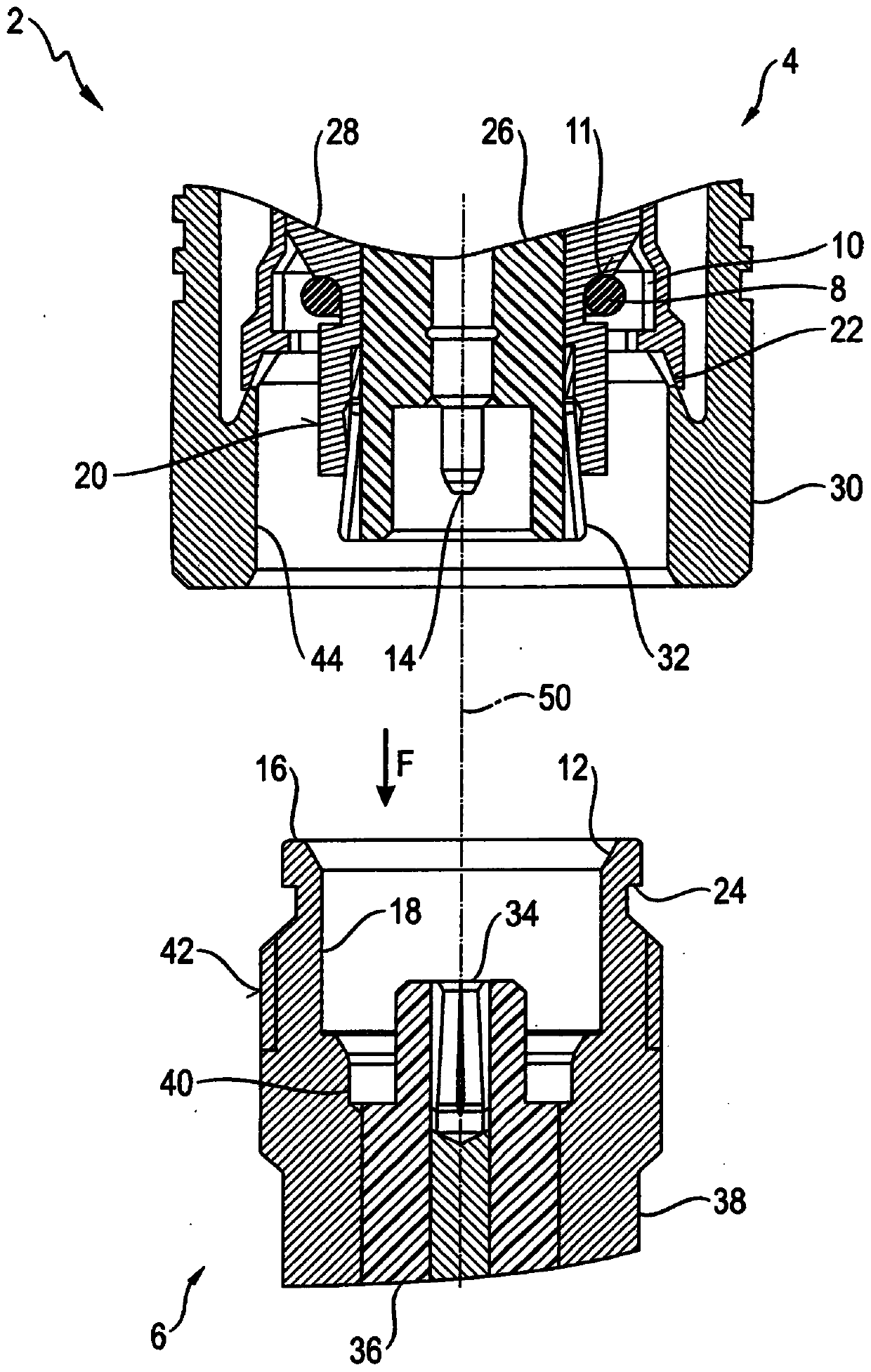

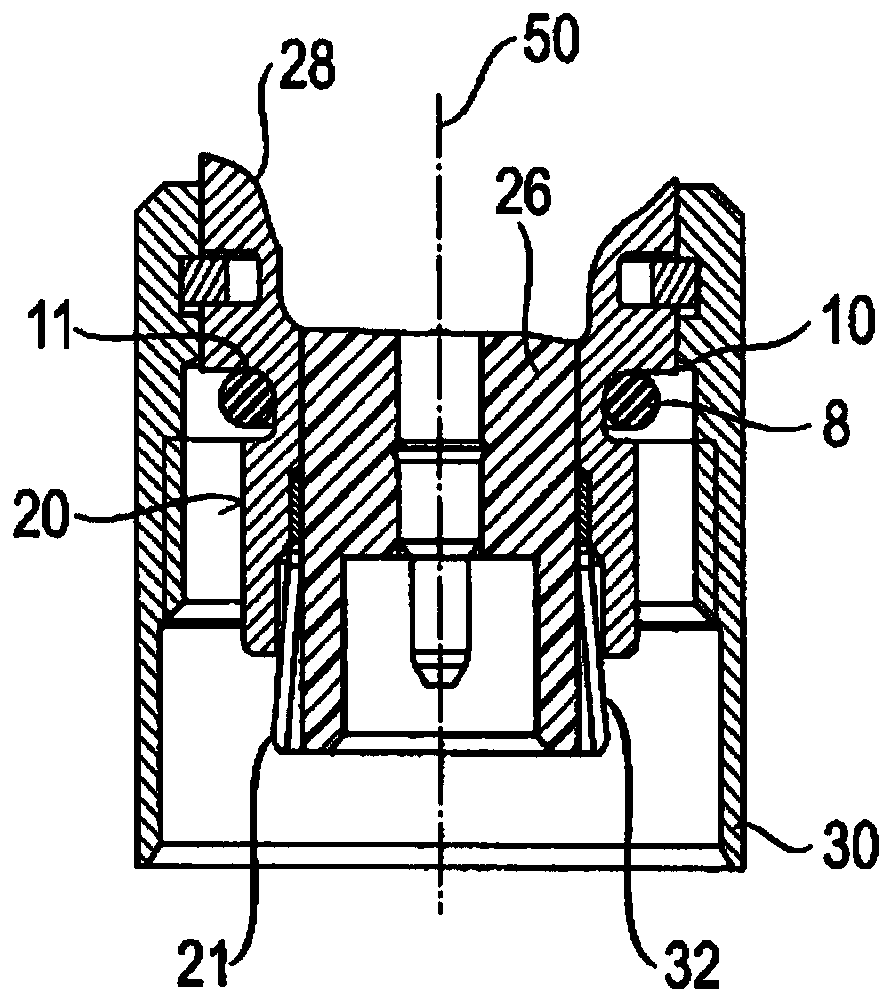

Connector

ActiveCN109155493BProtective contactAvoid misalignmentElectrically conductive connectionsTwo pole connectionsElectrical conductorMechanical engineering

Owner:ROSENBERGER HOCHFREQUENZTECHNIK GMBH & CO KG +2

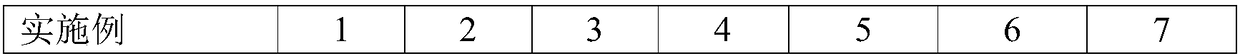

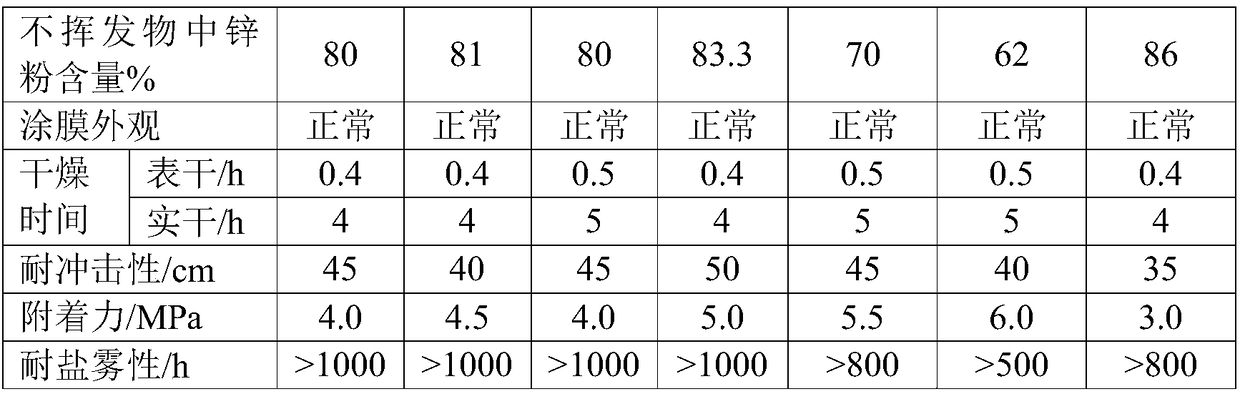

A modified water-based zinc-rich coating

ActiveCN106590088BImprove toughnessImprove film formationAlkali metal silicate coatingsAnti-corrosive paintsWater basedDepolymerization

The invention relates to metal corrosion prevention techniques and provides modified waterborne zinc-rich paint. The paint is prepared from flaky zinc powder and a waterborne adhesive base material in a weight ratio of 0.3-1.2:1. The waterborne adhesive base material is prepared from, by weight, 20-40 parts of potassium silicate, 10-20 parts of potassium methyl silicate, 10-20 parts of emulsified asphalt, 0.5-1 part of sodium bentonite, 0.2-0.5 part of tributyl phosphate, 0.2-0.5 part of sodium polyacrylate and 28.6-38.6 parts of water. The modified waterborne zinc-rich paint has advantages that toughness and film forming performance of a polysiloxane structure can be improved, and improvement of comprehensive performances of a zinc coating is benefited; due to excellent corrosion resistance of asphalt, corrosion resistance of a waterborne zinc-rich coating can be improved remarkably; depolymerization and electrochemical corrosion of the polysiloxane structure under water action can be reduced, and anticorrosion service life of the zinc-rich coating can be prolonged.

Owner:TAIZHOU BRANCH ZHEJIANG-CALIFORNIA INT NANOSYSTEMS INST

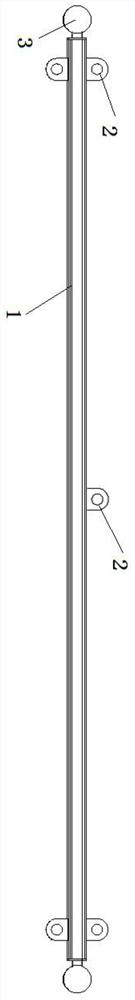

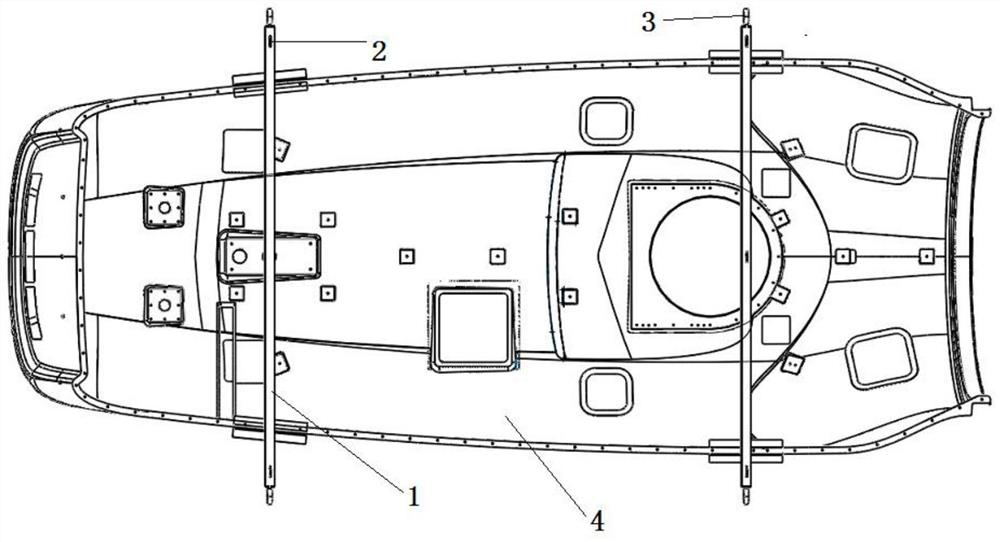

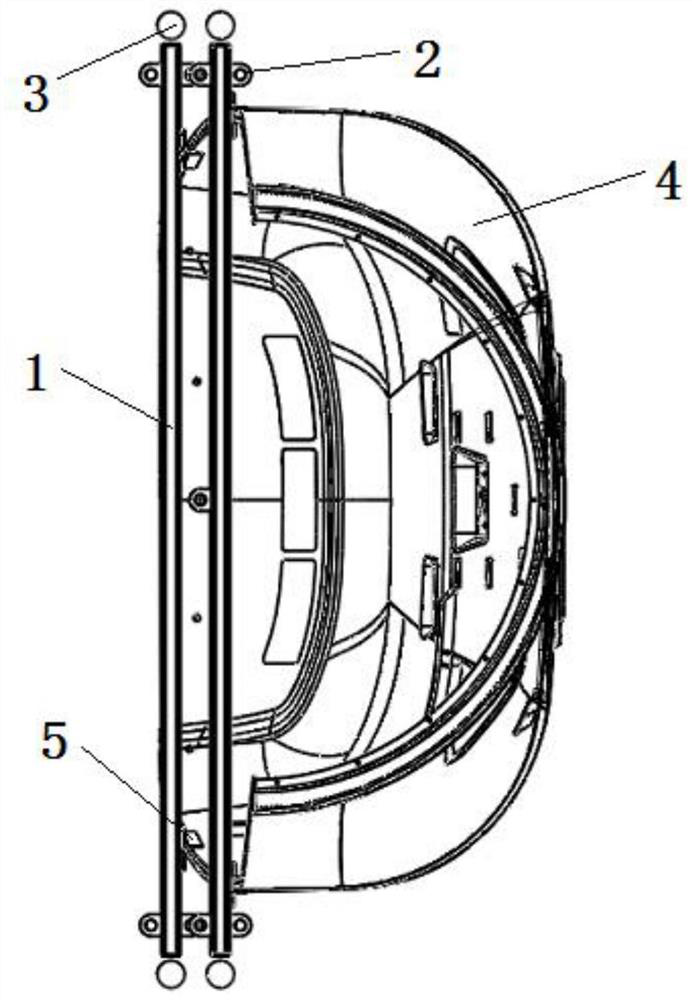

Cabin cover overturning tool and overturning method thereof

PendingCN112479004AProtective contactProtection stabilityWind motor assemblyWind energy generationNacelleJoist

The invention relates to the technical field of cabin cover assembly tools, in particular to a cabin cover overturning tool and an overturning method thereof. The cabin cover overturning tool comprises a plurality of supports, a plurality of bolt holes and lifting lugs are symmetrically arranged on each support, and pulleys are arranged at the two ends of each support respectively; because a cabincover is larger in size and belongs to a large part, when two joists in a workshop run together, the operation is difficult; when the joists run too close, interference winding of hoisting belts is caused; By applying the tool, the problems can be solved, and the stability of the product in the hoisting process is effectively protected when the product is fixed on the tool; otherwise, interference and friction between the product and the hoisting belts can be caused and the gel coat surface of the product is damaged; and after the product is turned over, the product is effectively protected from making contact with the ground, off-ground protection is achieved.

Owner:江苏常友环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com