Corrosion prevention and scale inhibition treating method for shield pump

A treatment method and technology of shielded pumps, which are applied to parts, pumps, and pump components of pumping devices used for elastic fluids, can solve problems such as endangering the functions of supporting systems, reducing the gap between stator and rotor, and endangering the life of pumps, etc., to achieve Thin thickness of grease prevents water from entering the rotor and protects against rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited to the following specific examples.

[0024] In the prior art, the anti-scaling means of shielded pumps mainly focus on the treatment of the surface finish of the inner hole of the shielding sleeve. This kind of process is complicated, equipment investment and product cost are high, but the effect is not obvious, which makes many people who originally used Manufacturers of this process are also in trouble.

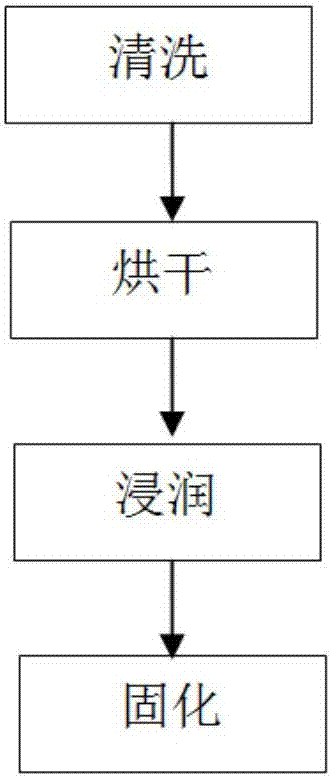

[0025] The technical scheme of the present invention mainly includes four steps, namely cleaning→drying→wetting→curing.

[0026] This embodiment discloses a treatment method for anti-scaling of shielded water pumps, including the following steps:

[0027] (1) Cleaning: Ultrasonic cleaning is used to clean t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com