A modified water-based zinc-rich coating

A coating and water-based technology, applied in the direction of anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of coating anti-corrosion performance, inconsistency between toughness and strength, coating waterproof, weak ability to prevent chloride ion penetration, etc. problem, to achieve the effect of enhanced anti-corrosion performance and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

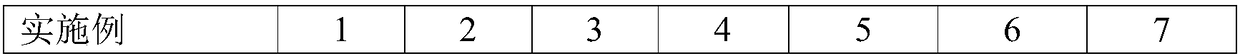

Examples

preparation example Construction

[0018] The preparation method of this modified water-based zinc-rich paint comprises the following steps:

[0019] (1) get each raw material component by described proportioning;

[0020] (2) Add water and sodium bentonite to the mixing tank and stir evenly; then add potassium silicate and potassium methyl silicate and stir evenly; then add emulsified asphalt and stir evenly; finally add tributyl phosphate and sodium polyacrylate , and stir evenly to obtain a water-based binder base material;

[0021] (3) adding scaly zinc powder to the water-based binder base material, and stirring evenly to obtain a water-based inorganic zinc-rich coating.

[0022] The stirring time and stirring speed in the preparation process can be adjusted according to the actual situation, and the stirring is kept during the process of adding each raw material component. In the embodiment provided by the present invention: after adding water and sodium bentonite, the stirring speed is controlled to be...

Embodiment 1

[0026] A modified water-based zinc-rich coating

[0027] Formula: including flaky zinc powder (particle size 200 mesh) and water-based binder base material, the weight ratio is 0.64:1. Wherein, the water-based binder base material includes the following components in parts by weight: Potassium Silicate (SiO 2 : K 2 O molar ratio is 5.0, solid content 20%) 40 parts, potassium methyl silicate (solid content 40%) 10 parts, emulsified pitch (pH=10, solid content 20%) 20 parts, sodium bentonite 0.5 part, phosphoric acid 0.2 parts of tributyl ester, 0.2 parts of sodium polyacrylate, and 29.1 parts of water.

[0028] Preparation process: Add water and sodium bentonite to the mixing tank, stir for 10 minutes (rotation speed 2000rpm), add potassium silicate and potassium methyl silicate, stir for 10 minutes (rotation speed 800rpm), slowly add emulsified asphalt (200ml / min), Continue to stir for 5 minutes (rotating speed 1000 rpm), then add tributyl phosphate and sodium polyacrylate,...

Embodiment 2

[0031] A modified water-based zinc-rich coating

[0032] Recipe: including flaky zinc powder (particle size 500 mesh) and water-based binder base material, the weight ratio is 0.8:1, wherein, the water-based binder base material includes the following components by weight: potassium silicate (SiO 2 : K 2 O molar ratio is 5.5, solid content 30%) 35 parts, potassium methyl silicate (solid content 20%) 20 parts, emulsified asphalt (pH=12, solid content 40%) 10 parts, sodium bentonite 1 part, phosphoric acid 0.5 parts of tributyl ester, 0.5 parts of sodium polyacrylate, and 33 parts of water.

[0033] Preparation process: Add water and sodium bentonite to the mixing tank, stir for 10 minutes (rotating speed 2000rpm), add potassium silicate and potassium methyl silicate, stir for 20min (rotating speed 500rpm), slowly add emulsified asphalt (50ml / min), Continue to stir for 10 minutes (rotating speed 500 rpm), then add tributyl phosphate and sodium polyacrylate, stir evenly to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com