Flexible gravity centering table

A technology of centering and gravity, applied in the field of centering, can solve the problems of inability to locate special-shaped sheets, low adaptability to multiple products and stations, and poor device flexibility, achieving high degree of freedom and applicability, realizing Flexible production, ensure the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

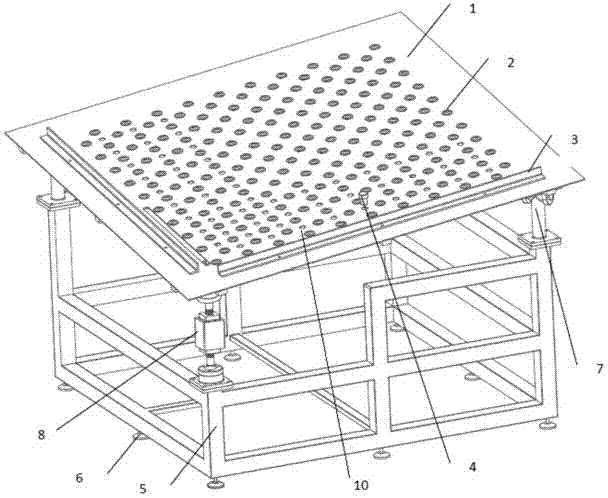

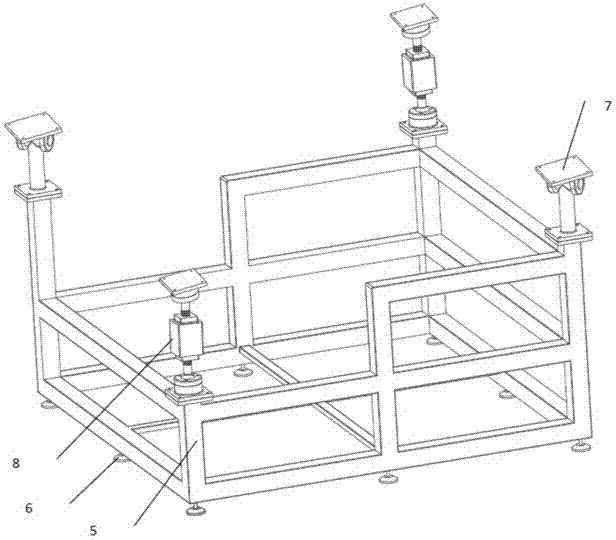

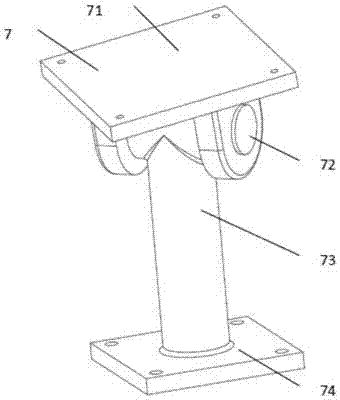

[0024] Such as Figures 1 to 7 As shown, the present invention provides a flexible gravity centering platform, which includes a workbench 1, the workbench 1 is connected to the loading station area and the unloading station area, and the workbench is separated from the loading station area. The direction from the area to the unloading station area is downwardly inclined, and universal rollers 2 are evenly distributed on the workbench to transfer the workpiece to the unloading station area located at the lower part of the workbench. The outer edge of the material station area is fixedly connected with a workpiece linear stopper 3, wherein: there is also an insertion pin type stopper 4 in the said blanking station area.

[0025] The blanking station area of the present invention is equipped with an insertion pin type stopper, which can be easily inserted and pulled out, and the layout and form of the stopper can be adjusted freely. Therefore, the position of the stopper can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com