Using method of safety protection of high-voltage and direct current contactors for electric automobile

A technology for electric vehicles and safety protection, which is applied in the direction of electric vehicles, battery/battery traction, electrical devices, etc., and can solve problems such as damage to contactor contacts and affecting the service life of contactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

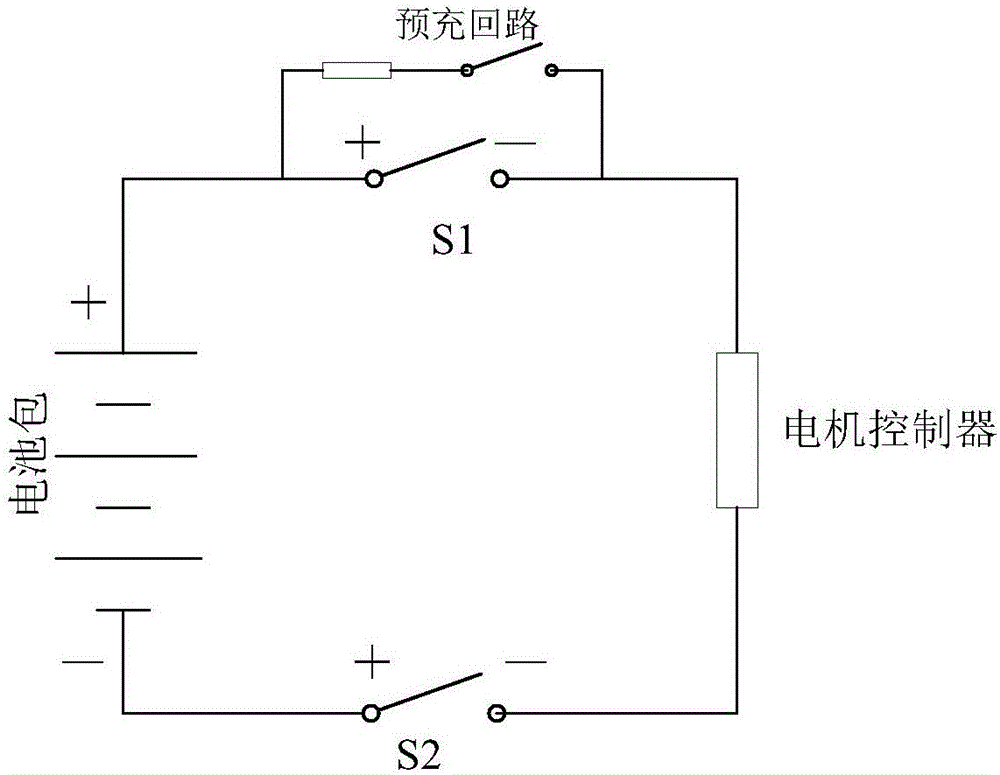

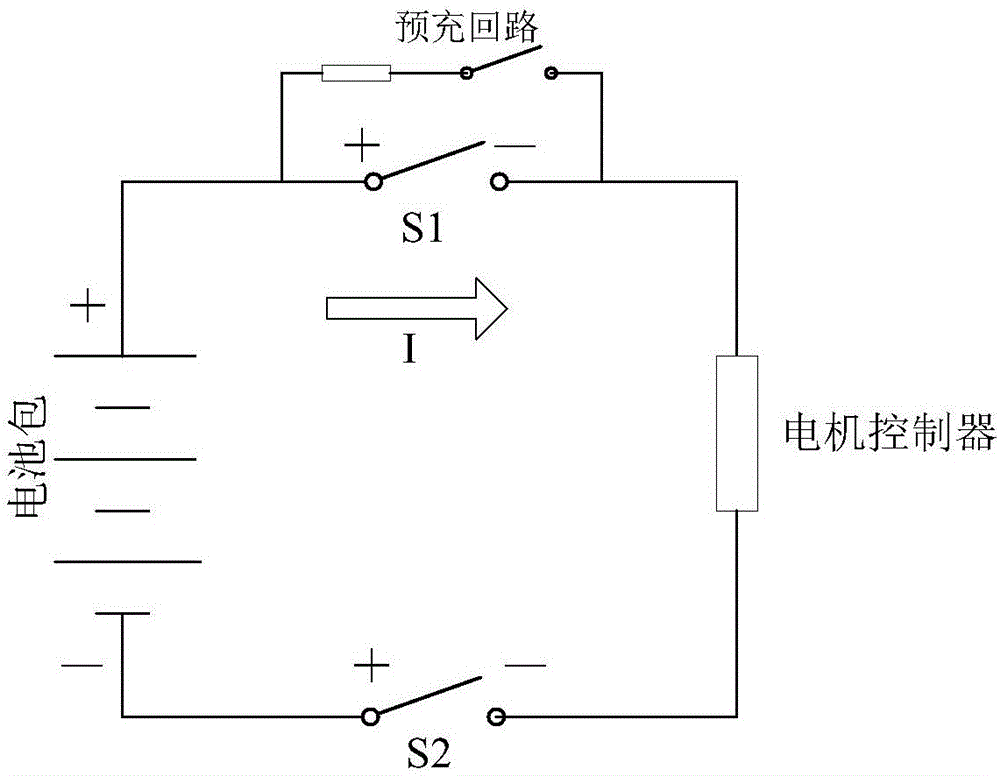

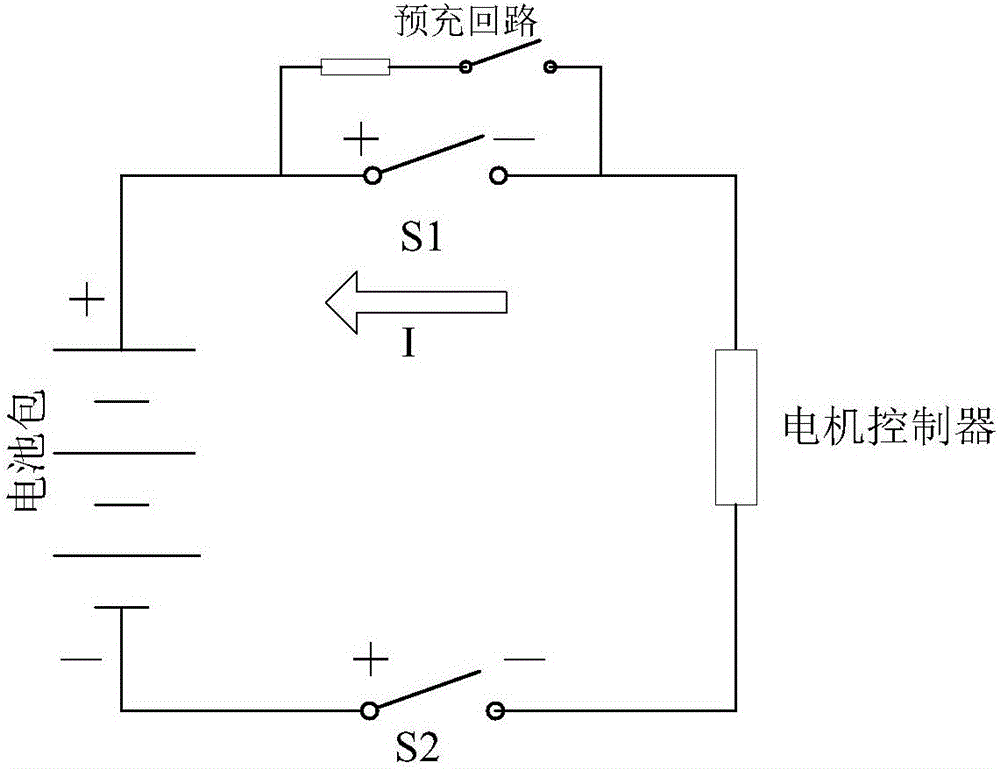

[0012] According to the accompanying drawings, the existing electric vehicle battery pack outputs high-voltage DC power, and forms a loop through the total positive contactor S1, the total negative contactor S2 and the motor controller. The positive pole of the battery pack is connected to the positive contact of the total positive contactor S1, and then The negative contact of the total positive contactor S1 is connected to the positive terminal of the motor controller, the negative pole of the battery pack is connected to the positive contact of the total negative contactor S2, and then the negative contact of the total negative contactor S2 is connected to the negative terminal of the motor controller, pre-charging circuit Set in parallel with the main positive contactor S1; the motor controller is in a state of power consumption when the vehicle is driving, and the curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com