A goaf local filling supporting structure under a hard roof condition and a construction method thereof

A technology of hard roof and goaf, applied in fillings, mining equipment, earth-moving drilling, etc., can solve the problems of weak bearing capacity, instability and damage, and high compressibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

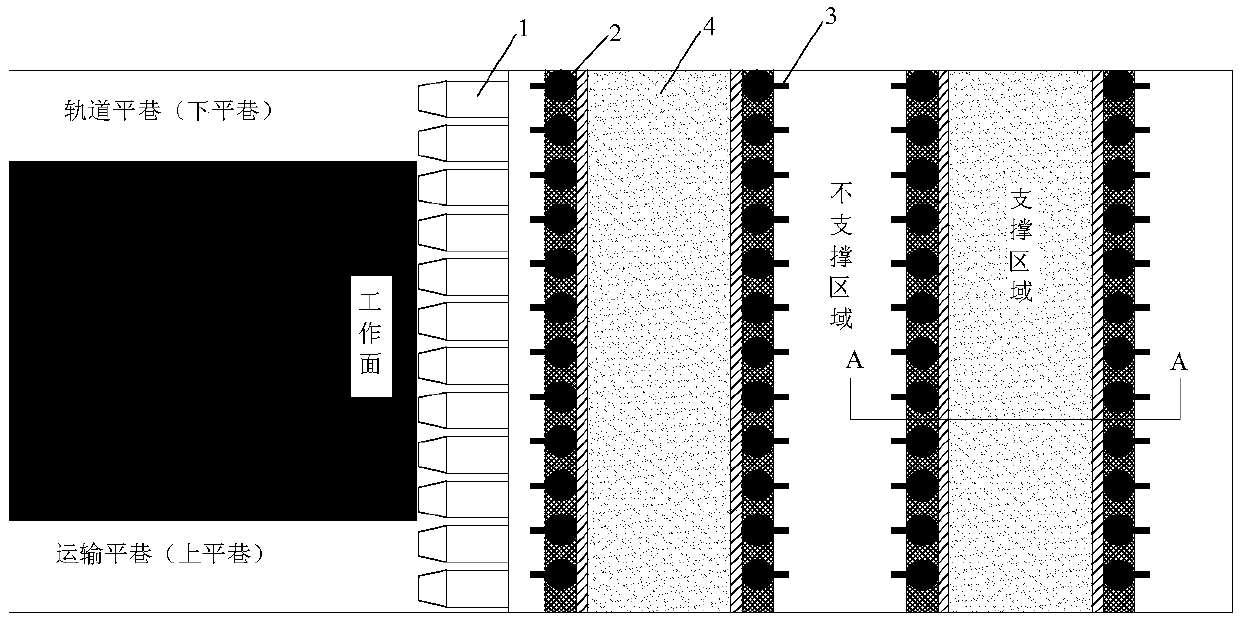

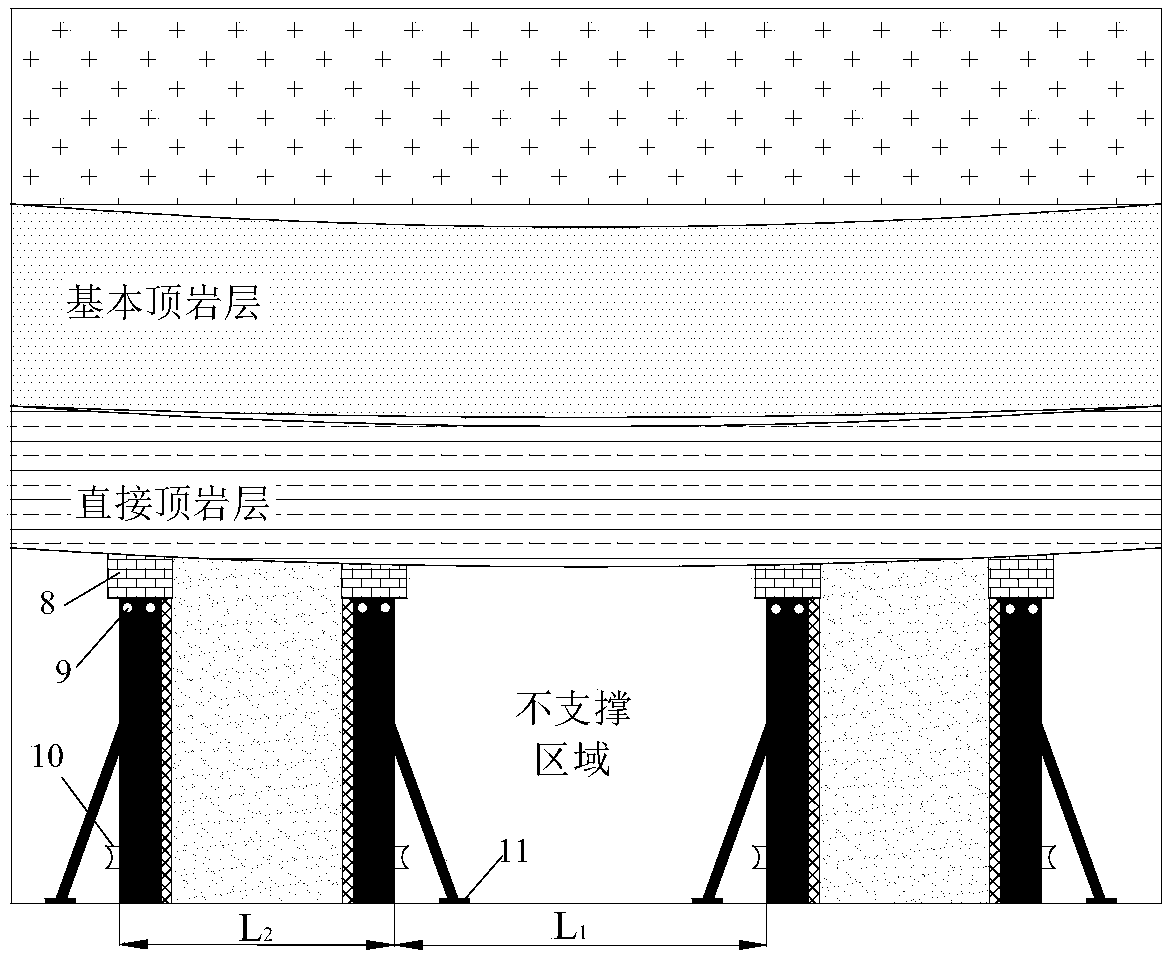

[0081] Taking a certain working face as a specific engineering case, a further explanation is given for the construction method of the gob local filling support structure under the condition of a hard roof proposed by the present invention.

[0082] The specific engineering geological conditions include: the length of a fully mechanized mining face is 150m, the mining height of the coal seam is 2m, the coal is cut by a double-drum shearer, and the footage of each cut coal is 1.0m; the immediate top rock layer is hard limestone with a thickness of 4.0m , the basic top rock layer is medium-strength sandstone with a thickness of 5m.

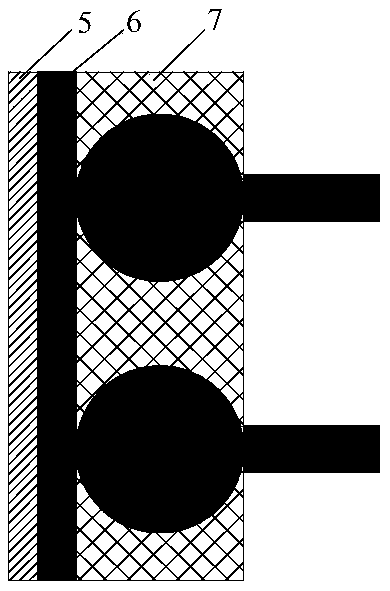

[0083] combine Figure 4 to Figure 6 As shown, a method for constructing a support structure for partial filling of a gob under the condition of a hard roof includes the following steps:

[0084] a. Determine the width of the support body and the width of the unsupported area,

[0085] First, analyze the structure of the roof strata above the coal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com