Local filling support structure and its construction method in goaf under hard roof condition

A technology of hard roof and goaf, which is applied in filling, mining equipment, earth-moving drilling, etc., can solve the problems of weak bearing capacity, instability failure, settlement deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

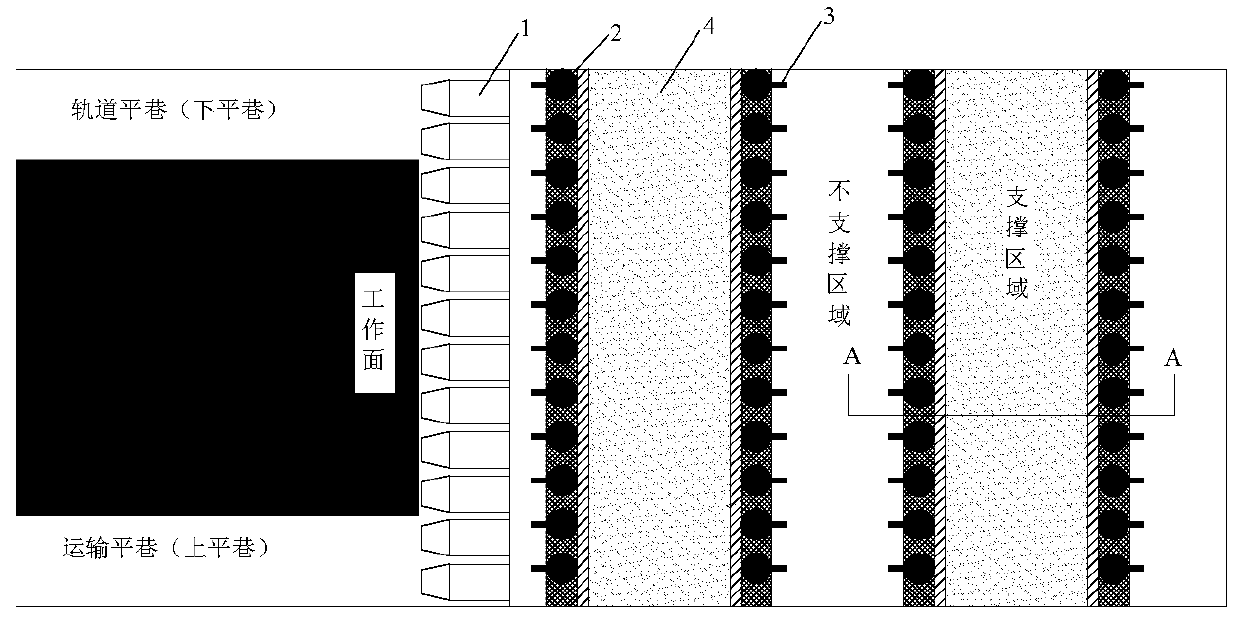

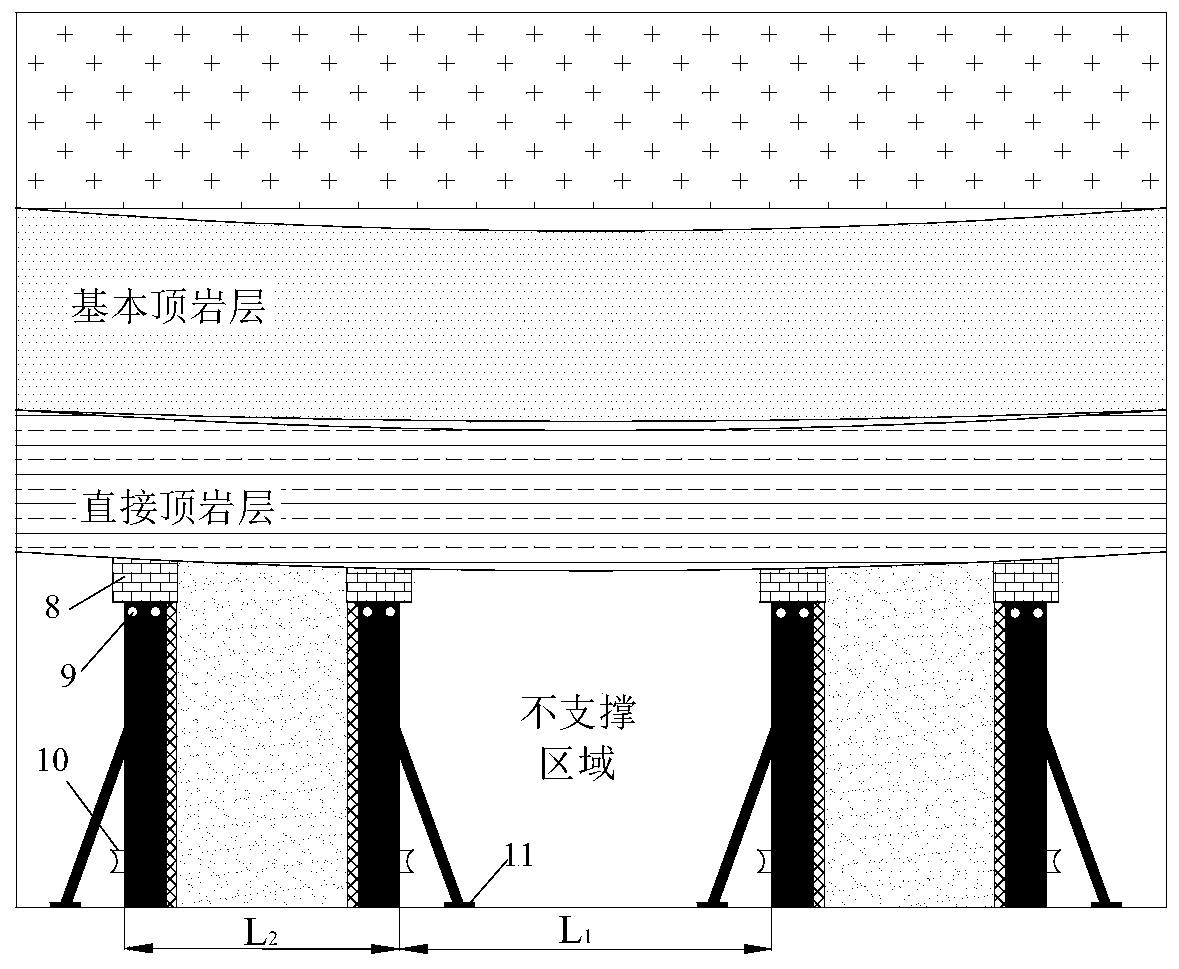

[0081] Taking a certain working face as a specific engineering case, a further explanation is given for the construction method of the gob local filling support structure under the condition of a hard roof proposed by the present invention.

[0082] The specific engineering geological conditions include: the length of a fully mechanized mining face is 150m, the mining height of the coal seam is 2m, the coal is cut by a double-drum shearer, and the footage of each cut coal is 1.0m; the immediate top rock layer is hard limestone with a thickness of 4.0m , the basic top rock layer is medium-strength sandstone with a thickness of 5m.

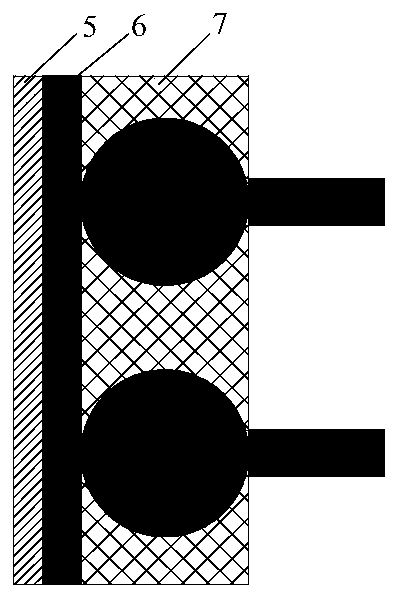

[0083] combine Figure 4 to Figure 6 As shown, a method for constructing a support structure for partial filling of a gob under the condition of a hard roof includes the following steps:

[0084] a. Determine the width of the support body and the width of the unsupported area,

[0085] First, analyze the structure of the roof strata above the coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com