Patents

Literature

36results about How to "Subsidence control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

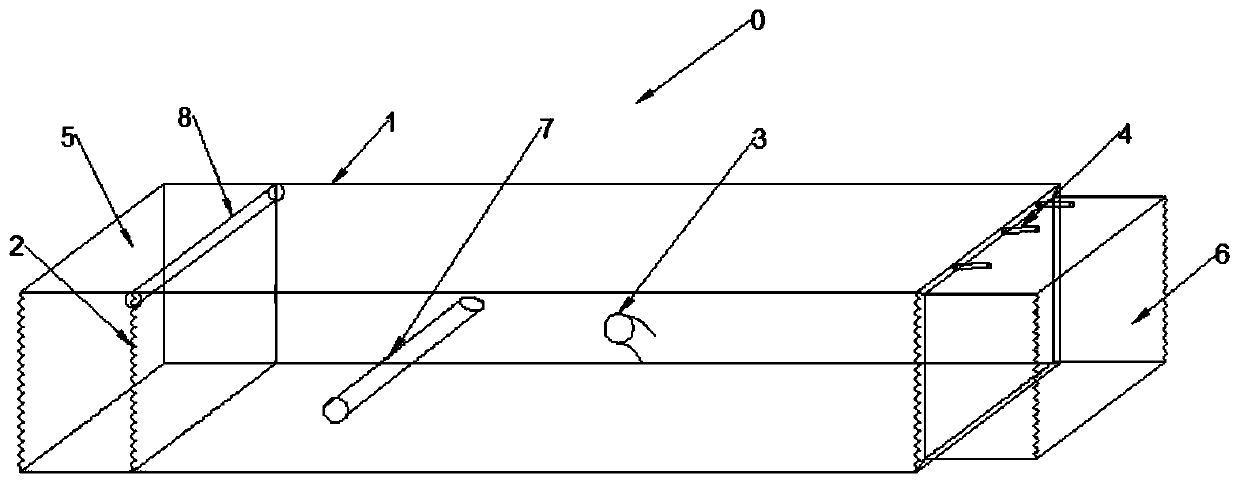

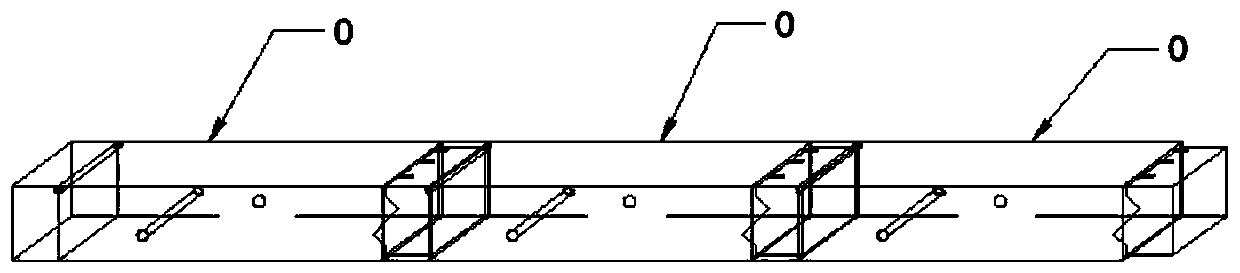

Inclined separated layer solid filling coal mining method for super thick coal seam

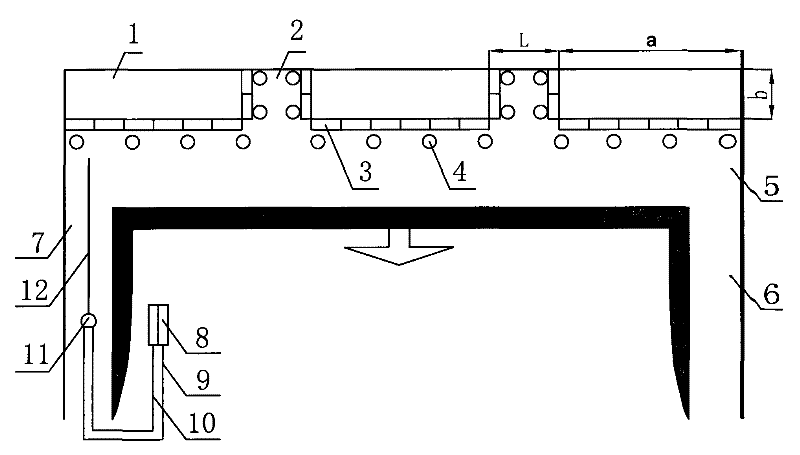

ActiveCN103306720ASolve sinkingFree resourcesUnderground miningSurface miningSolid massEarth surface

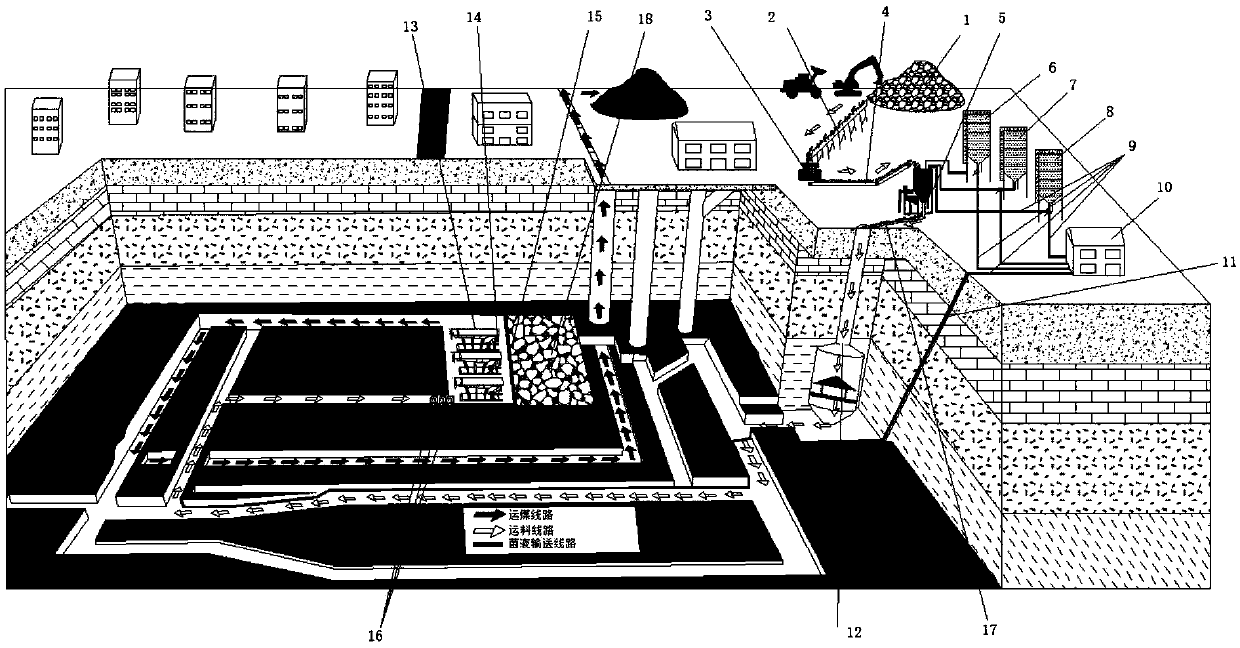

The invention discloses an inclined separated layer solid filling coal mining method for a super thick coal seam, which is suitable for the exploitation of an 'under three' super thick coal seam. The method comprises the following steps: determining the number of inclined separated layers according to the principle that thickness of each separated layer is 2.5-4.5 m; adopting a exploitation sequence that mining layer by layer, and filling at a next row; arranging tunnels and equipment according to the conventional solid filling coal mining method; carrying out a circulating sequence that coal mining firstly, metal nets and bamboo fences paving secondly, and filling finally to complete the filling exploitation of a first mining surface and a first separated layer; meanwhile, mining according to the same filling coal mining method under the shield of a manual false roof formed by the first separated layer at the corresponding position of a second separated layer 4 months after a working face of the first separated layer finishes mining; circulating in the way that the exploitation of one separated layer is performed under the shield of a manual false roof manufactured by an upper separated layer continuously until the whole super thick coal seam is mined out. Through the adoption of the method, resources of the 'under three' super thick coal seam can be utilized, the rock formation movement and earth surface sinking can be effectively controlled; and the recovery ratio is high, the production efficiency is high, the cost is low, and the method has wide practicability in the field of thick coal seam filling exploitation.

Owner:CHINA UNIV OF MINING & TECH

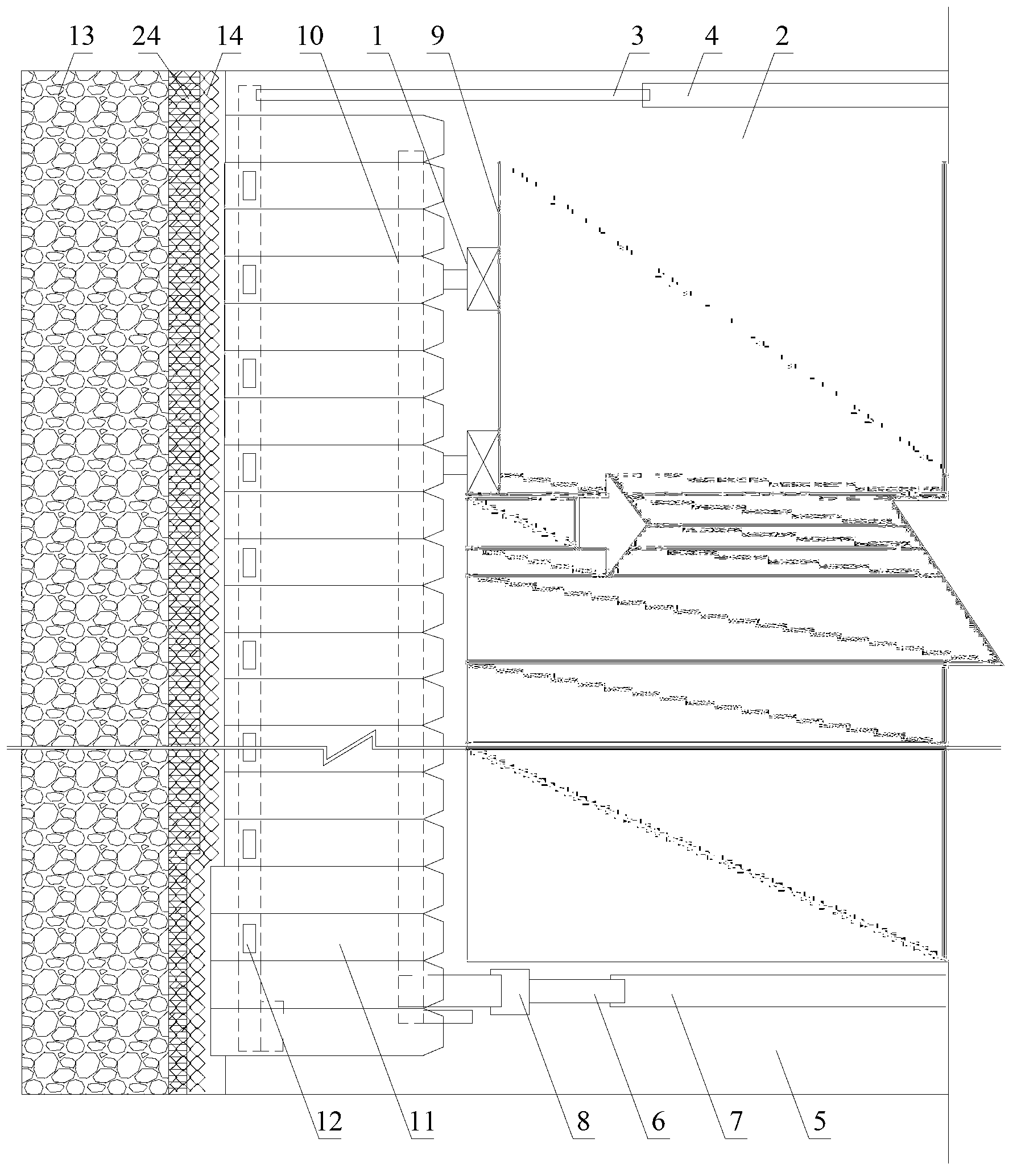

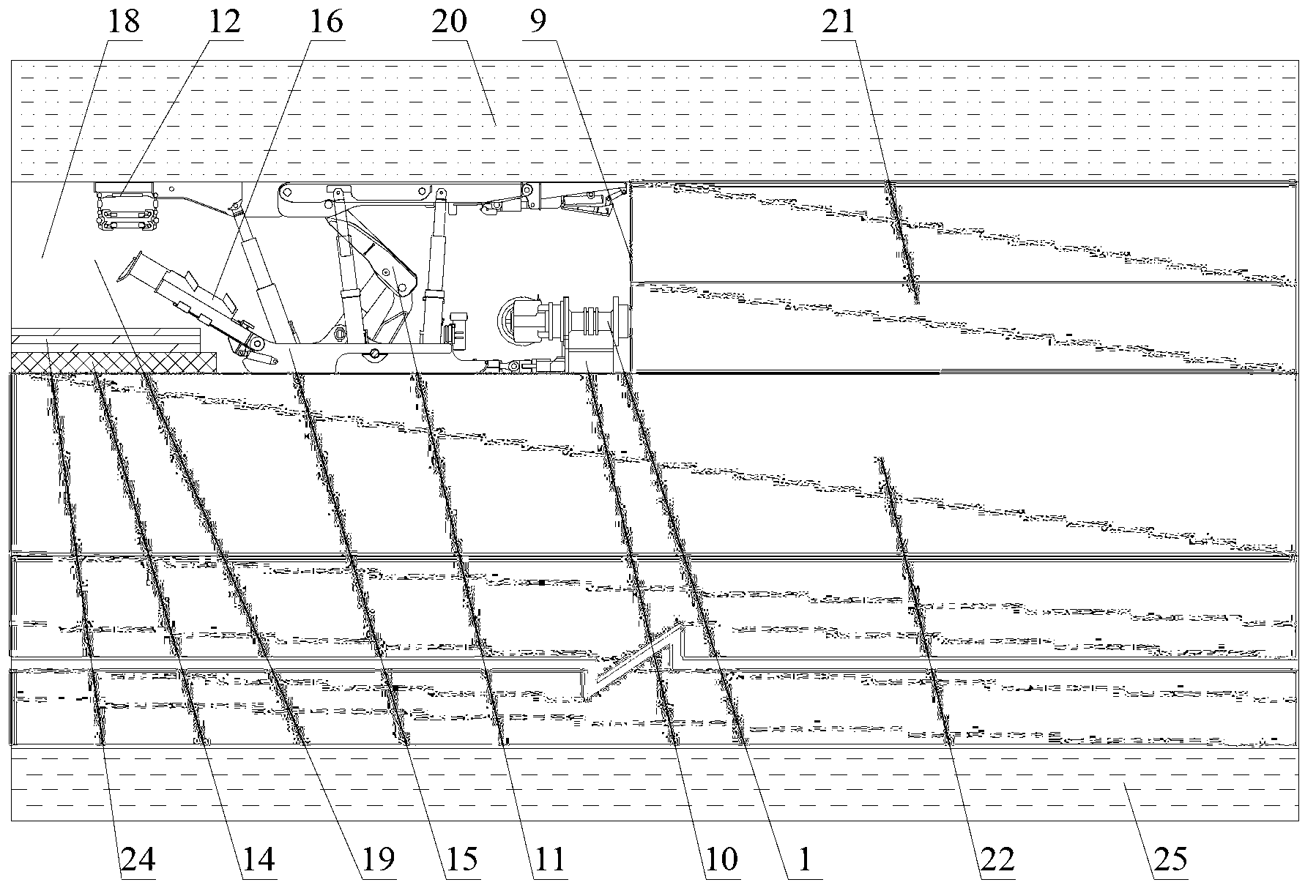

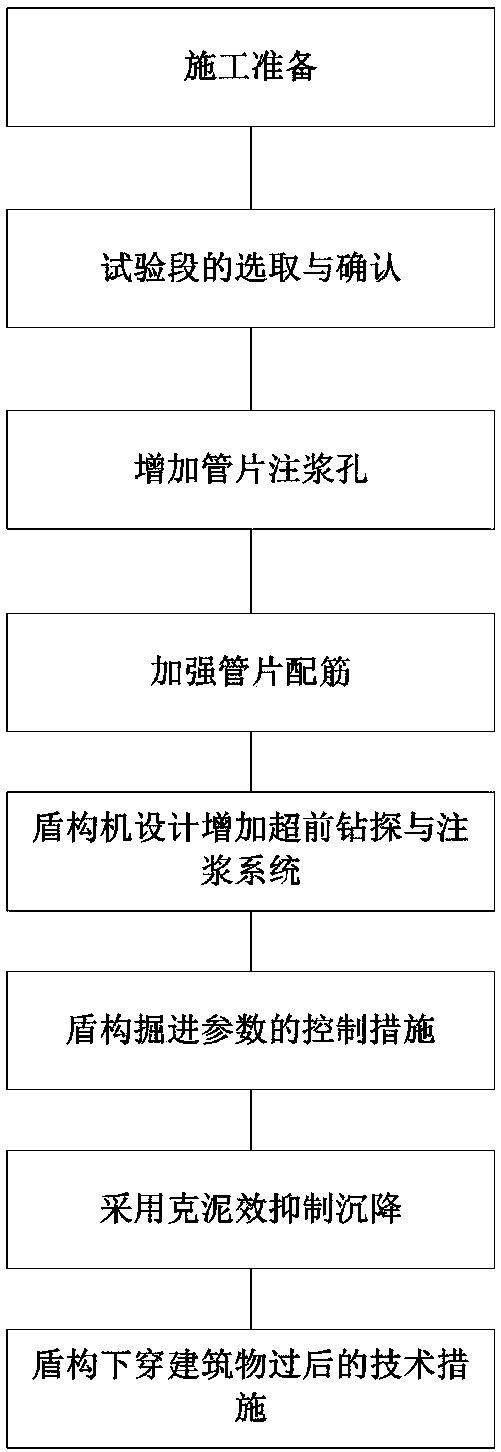

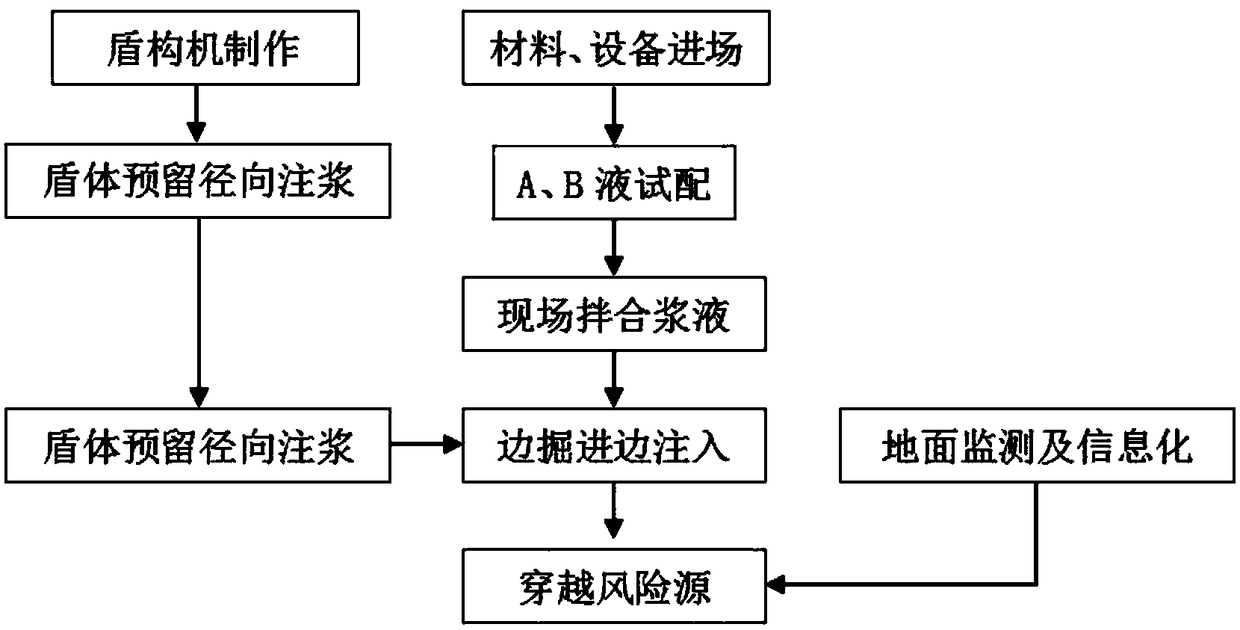

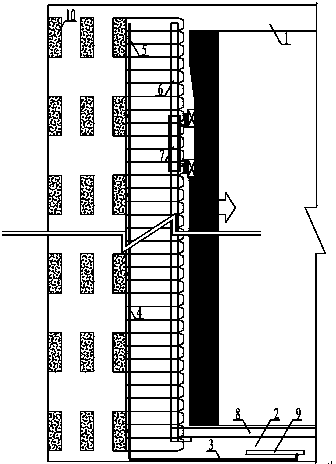

Construction method for earth pressure balance shield underneath crossing multi-track railway based on shallow buried soft soil layer

ActiveCN108590678AImprove stabilityStable pressureUnderground chambersTunnel liningShield tunnelingEarth surface

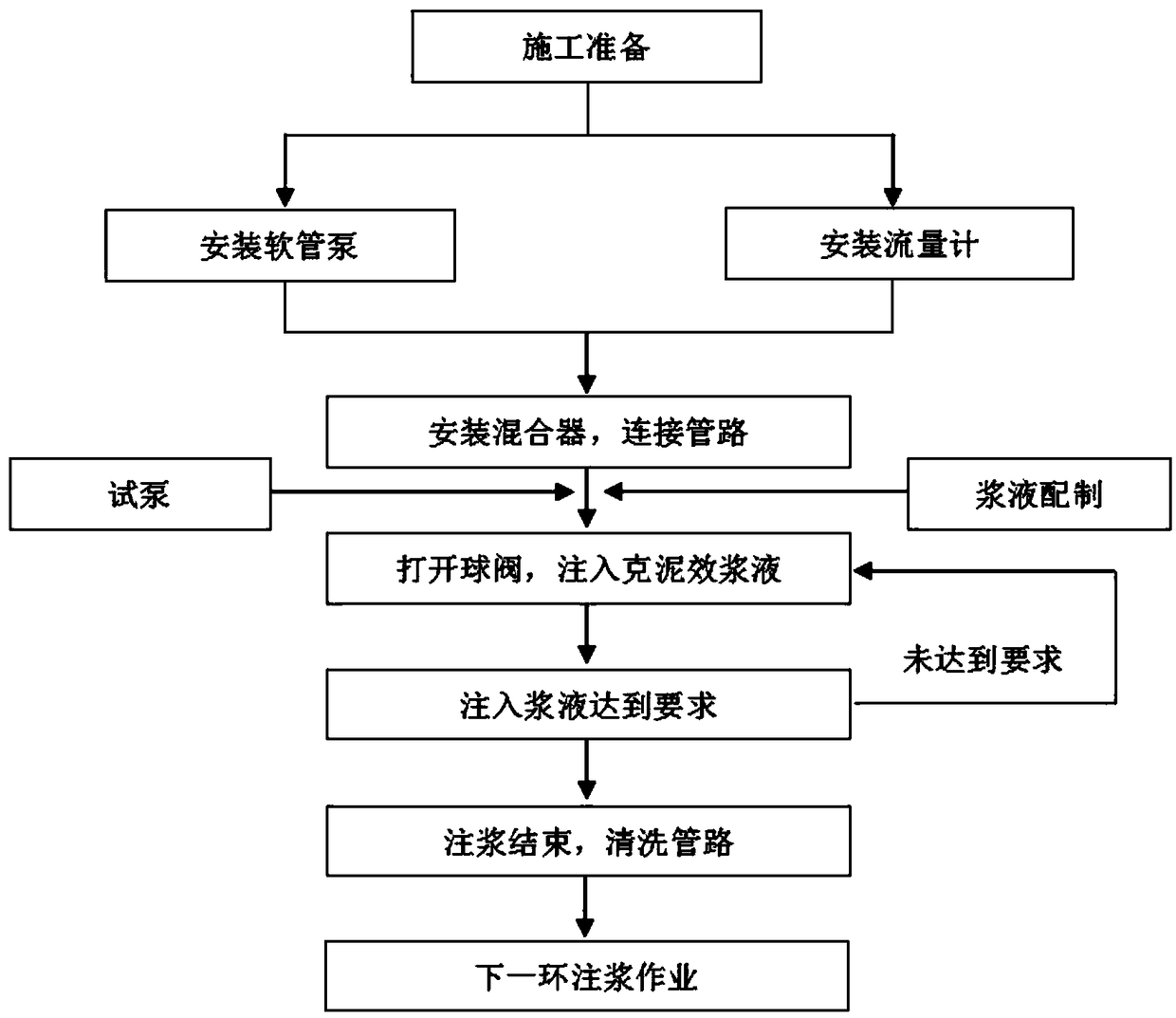

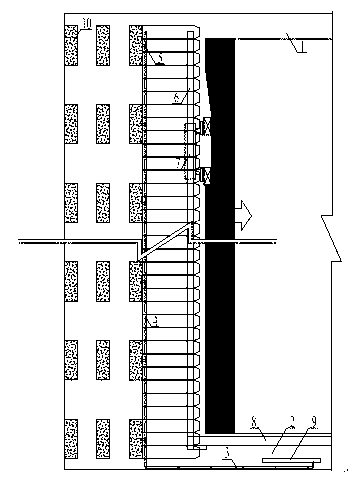

The invention discloses a construction method for an earth pressure balance shield underneath crossing a multi-track railway based on a shallow buried soft soil layer, and belongs to the technical field of metro construction. The construction method comprises the following steps that construction preparation is conducted, specifically, the situations that the construction geological condition at asection of a tunnel underneath crossing a building is poor, the ground-surface environment is complex, disturbance of stratum where the tunnel is located is large are determined, in order to ensure that underground water loss is reduced during the period of passing of a shield machine, overbreak of stratums near a house is prevented, disturbance to ground buildings is reduced, and downward excavation safety is ensured; selecting and determining of test sections are conducted; segment grouting holes are additionally formed; segment reinforcement is reinforced; an advance exploratory drilling and grouting system is designed and additionally arranged on the shield machine; control measures of shield tunneling parameters are implemented; and a clay shock method is adopted for inhibiting settlement. Through the technique process, it is ensured that the whole construction technology is smooth and complete before excavation, during excavation and after excavation, and the construction quality is ensured.

Owner:中交中南工程局有限公司 +1

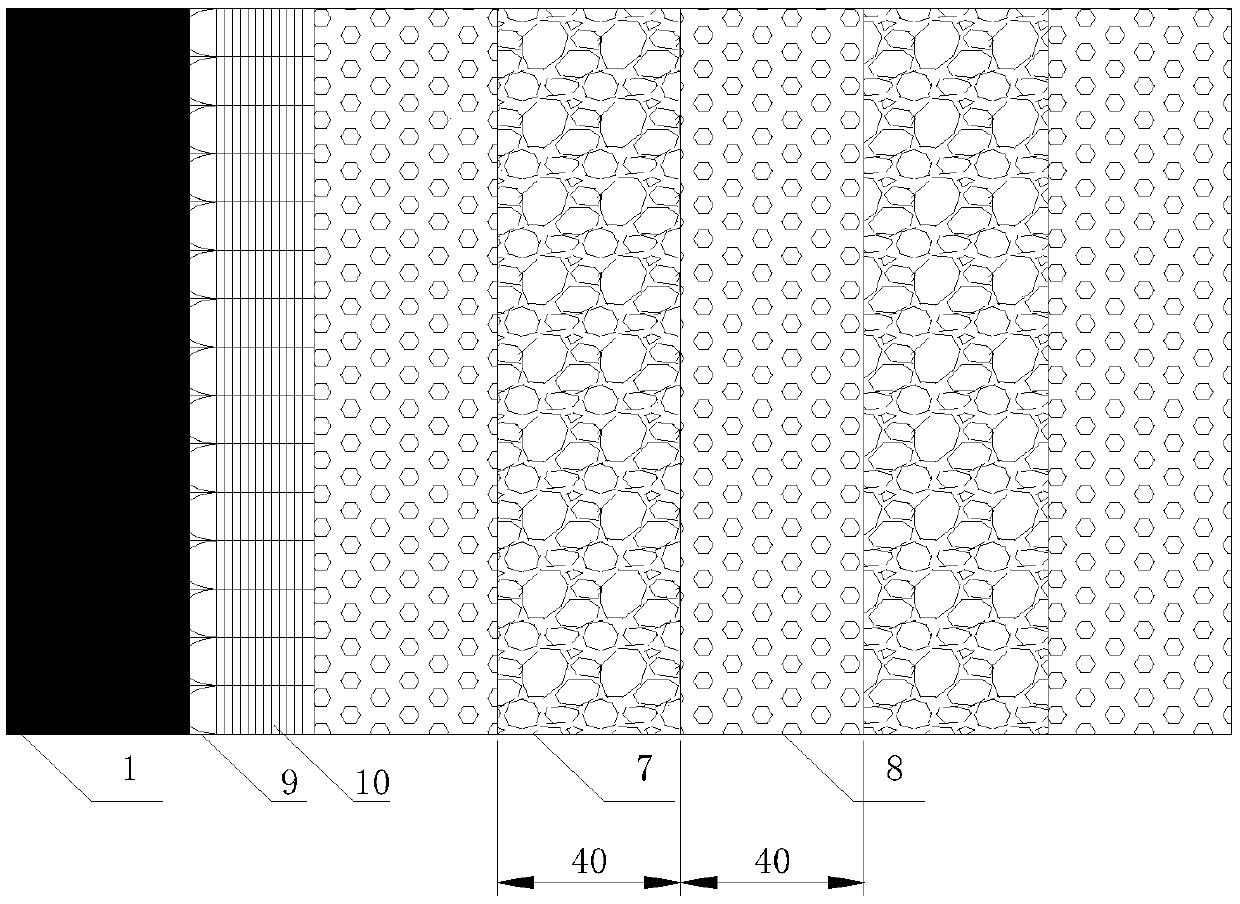

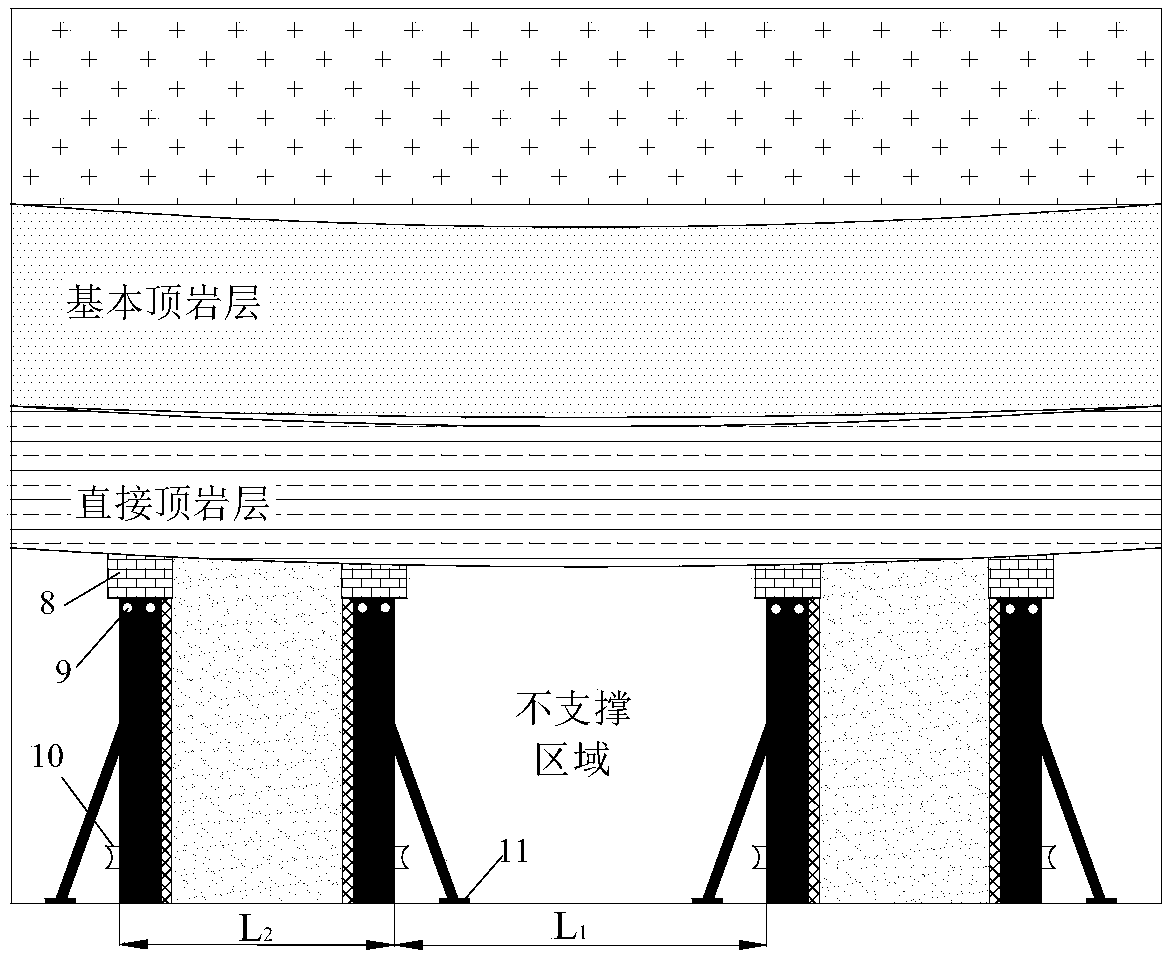

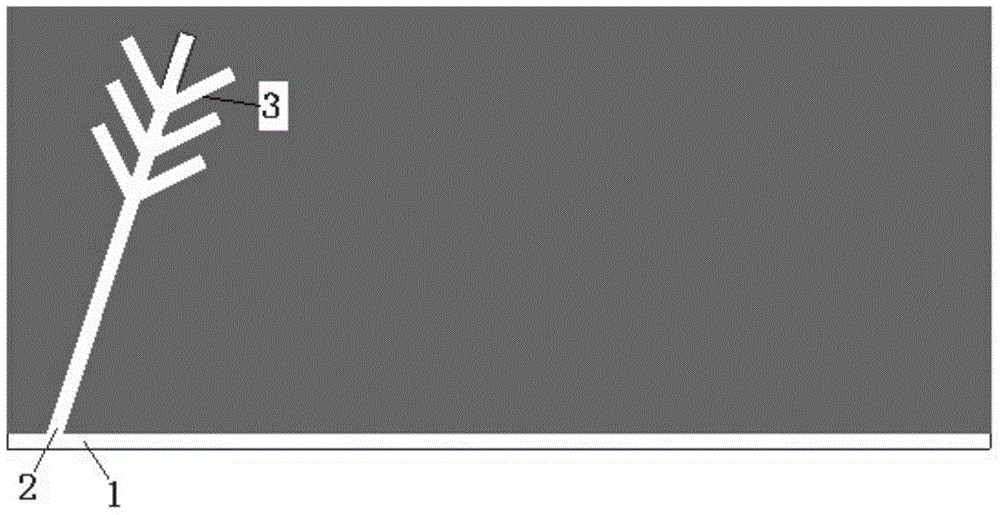

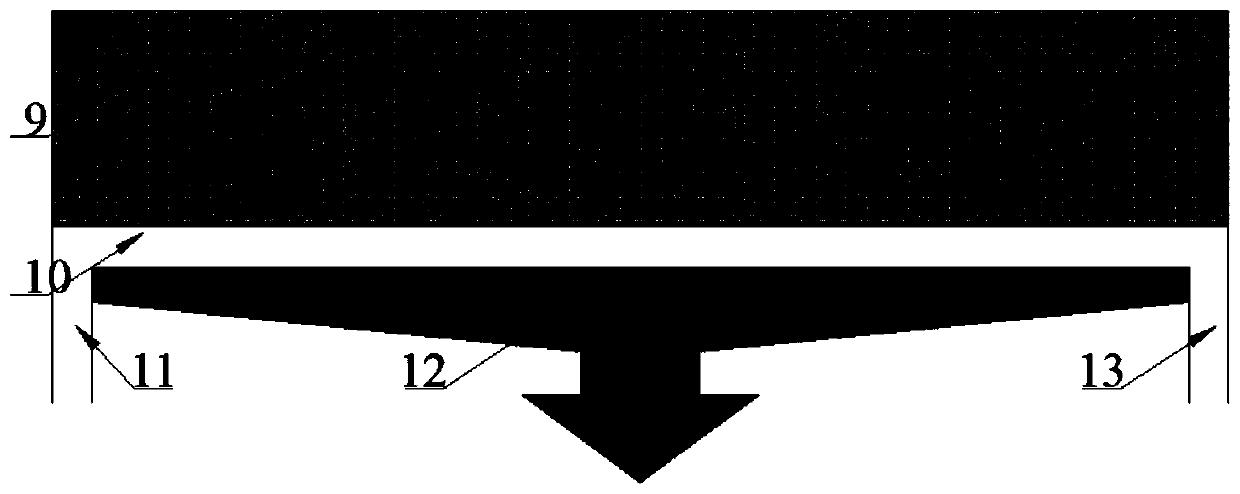

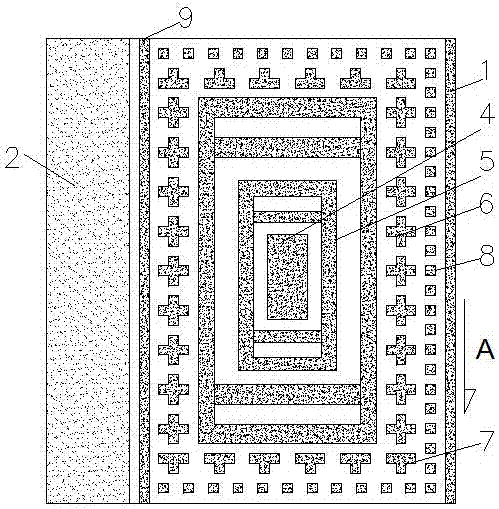

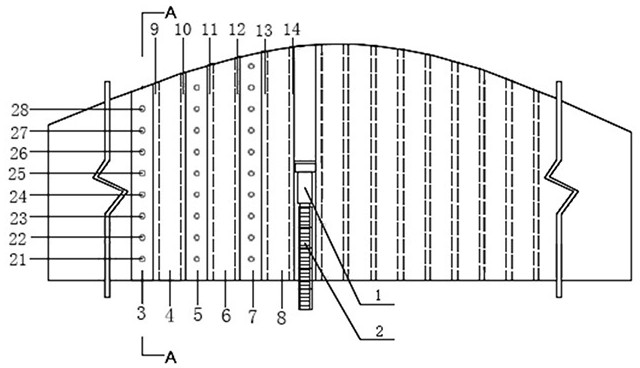

Method of local filling to control surface subsidence in gob

The invention relates to a method of local filling to control surface subsidence in a gob. Metal nets are suspended at intervals from open-off cuts and on top plates behind a hydraulic bracket on a working surface along with coal cutting of a coal cutter and movement of the hydraulic bracket on the working surface, and filling bags are arranged; coal cutting is stopped after cutting is performed once by the coal cutter, and concrete is filled into the filling bags in the metal nets in sequence until a roof; cutting is continuously performed once by the coal cutter, metal nets are continuously suspended on top plates adjacent to the two sides of the filled area, filling is continuously performed to complete a filling cycle, and a row of filled bodies are formed in a gob parallel to the working surface; and coal cutting is continuously performed four to five times by the coal cutter, the following filling cycle is completed continuously, and the procedures are repeated until filling of the whole gob is completed and a plurality of rows of filled bodies are formed in the gob. The method is simple, and the filling cost is low. Since the top plates in the gob are supported uniformly at intervals, the stability of an overburden layer, in particular a key layer, can be improved, and surface subsidence and damage to buildings can be effectively prevented.

Owner:CHINA UNIV OF MINING & TECH

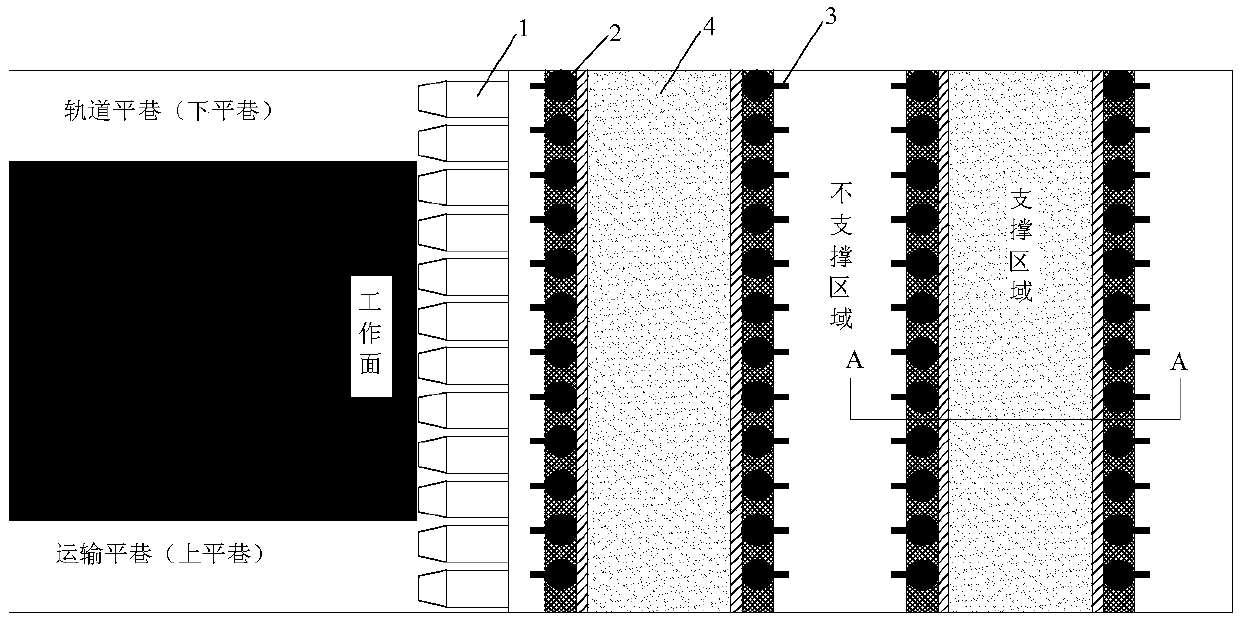

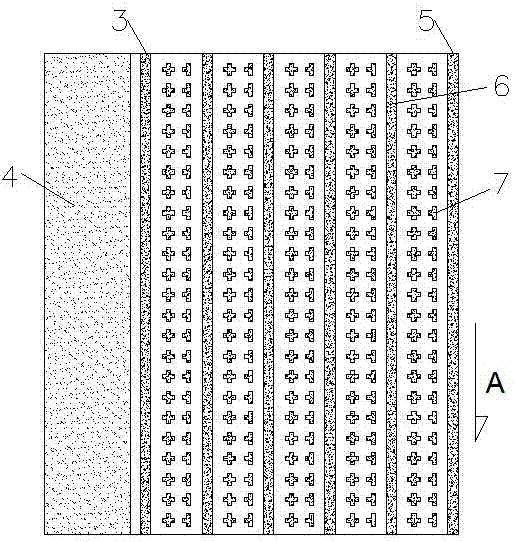

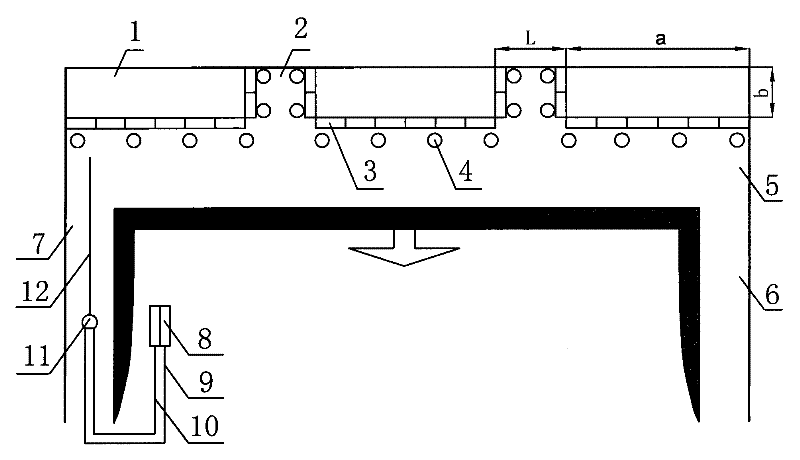

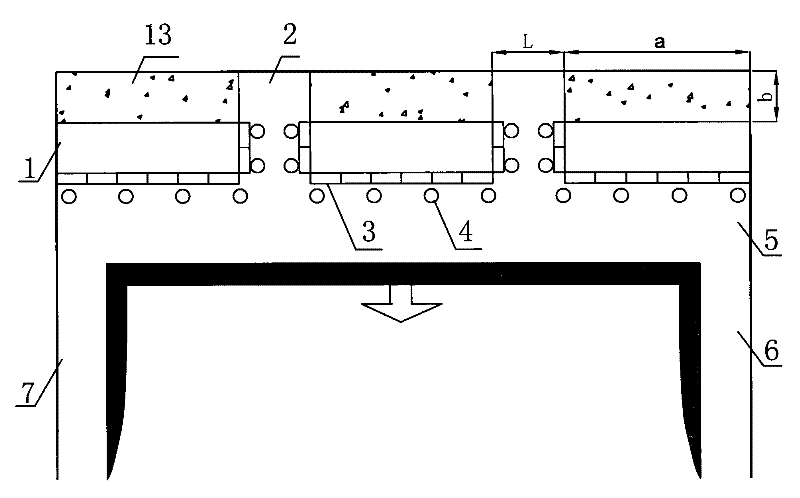

Interval skip-mining type filling coal mining method

InactiveCN103883350AIntegrity guaranteedReduce exerciseUnderground miningSurface miningFilling materialsSequential mining

The invention provides an interval skip-mining type filling coal mining method and belongs to the technical field of coal mine filling coal mining methods. The interval skip-mining type filling coal mining method comprises the steps that a first open-off cut is dug at the tail end of a butt entry, a second open-off cut is dug a certain distance away from the first open-off cut, and mining is conducted at the position of the second open-off cut with the wall type system coal mining method after the second open-off cut is well dug; a third open-off cut is dug a certain distance away from the second open-off cut, a gob formed after mining is conducted at the position of the second open-off cut is filled while the third open-off cut is dug, and the rest operation is conducted by analogy till mining is conducted on a mining stopping line. By the adoption of the interval skip-mining type filling coal mining method, mining can be conducted under the condition that the two ends are supported, sequential mining and sequential filling are achieved, the integrity of a base plate of a roof is guaranteed, movement of overlying rock is reduced, and the purpose of surface subsidence control is achieved; after mining with filling is completed, coal pillars left after mining do not need to be filled, filling materials are reduced, and filling cost is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

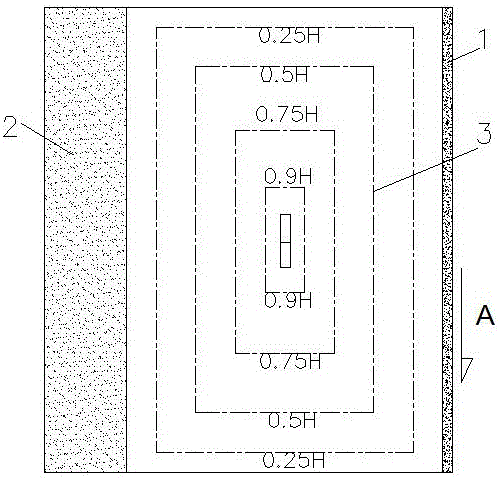

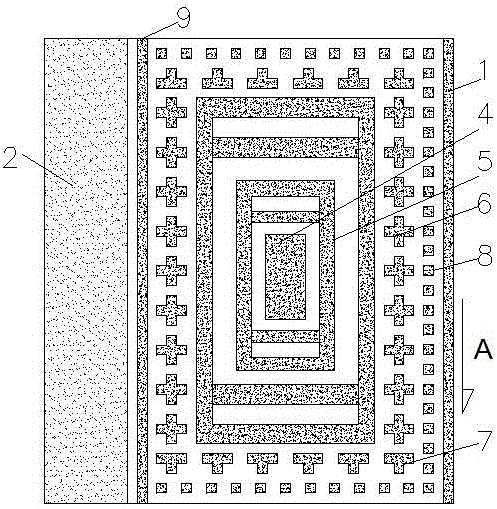

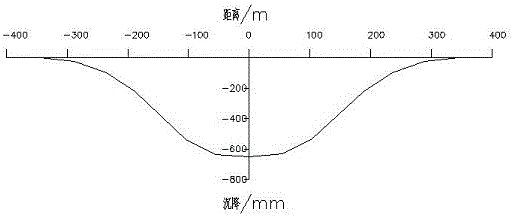

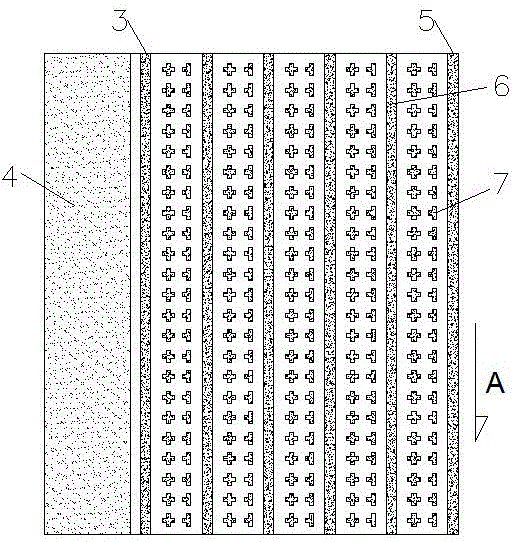

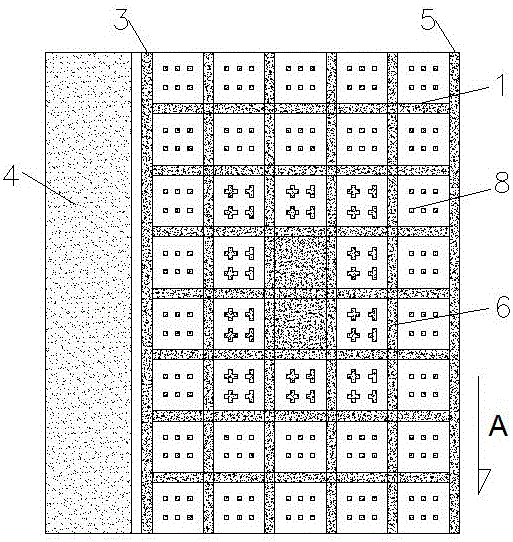

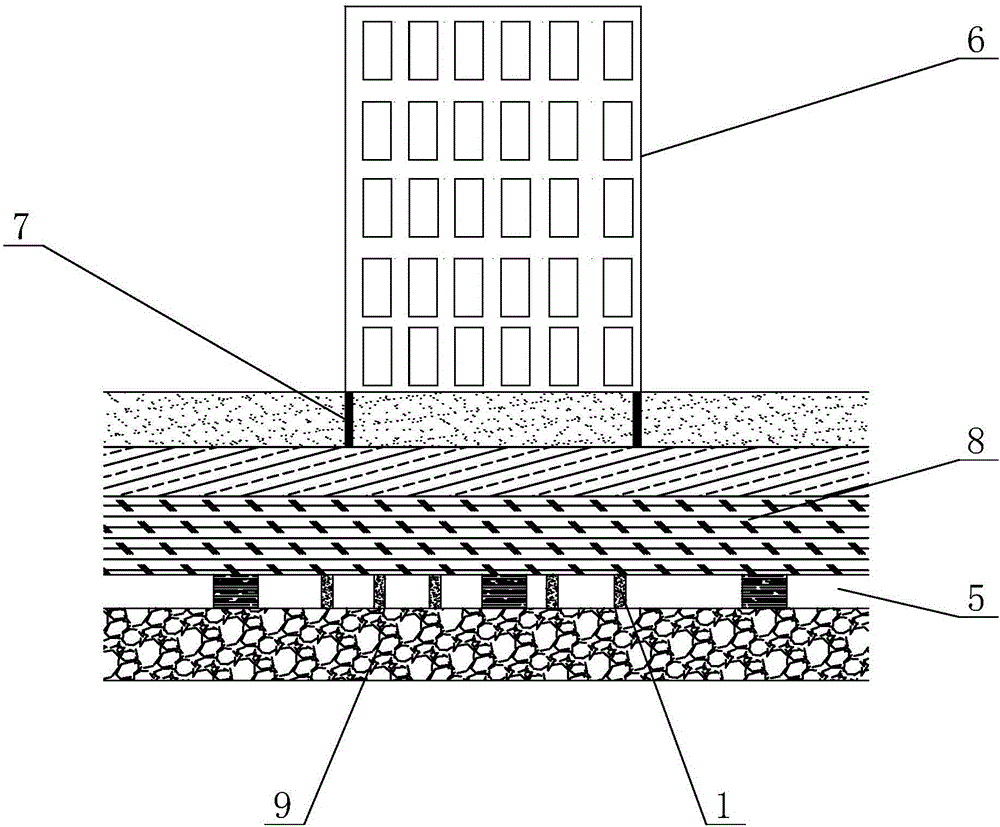

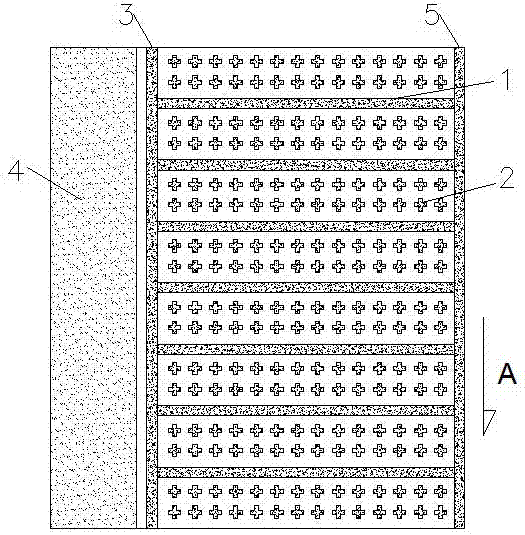

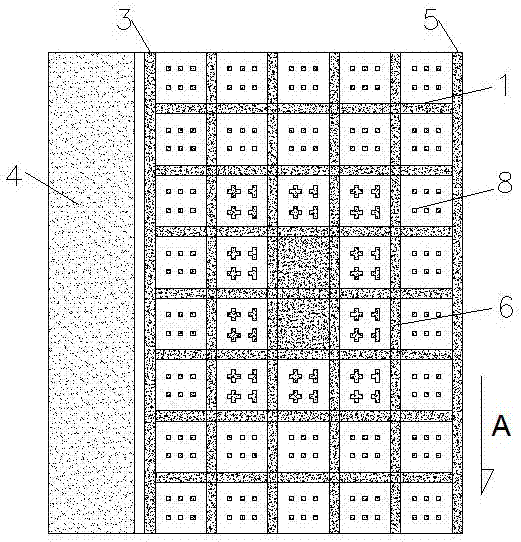

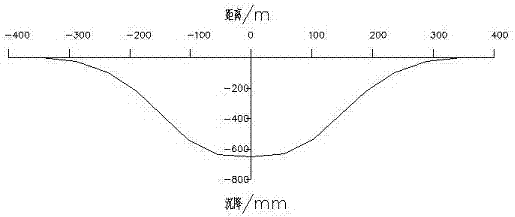

Method for conducting goaf partial filling according to ground surface subsidence characteristics

ActiveCN106150546ASave filling materialLower filling costsMaterial fill-upFilling materialsEarth surface

The invention discloses a method for conducting goaf partial filling according to ground surface subsidence characteristics. The method comprises the steps that the positions of filling bodies are designed according to a ground surface subsidence contour map; complete filling is conducted within a central area range, and a subsidence center is controlled; multiple circles of filling strips are arranged outside the complete filling range, and a larger subsidence region is controlled; multiple rows of filling monomers are arranged outside the filling strips, and a subsidence edge region is controlled; the filling bodies with different shapes are arranged in a goaf in a targeted mode, deformation destruction and ground surface subsidence of a roof are controlled, a filling body-roof structure control system is formed, and deformation destruction and ground surface subsidence of an upper overlying strata are controlled; narrow filling strip goaf-side retained roadways are arranged, the roadway driving workload of the next working face is reduced, and the goaf is filled in a sealed mode. According to the method for conducting goaf partial filling according to the ground surface subsidence characteristics, deformation destruction and ground surface subsidence of the roof can be effectively controlled, the recovery rate of coal mining under buildings, railways and water bodies is increased, and the environment is protected; filling materials are saved, the filling cost is reduced, and a large amount of underground space formed through filling is reused.

Owner:TAIYUAN UNIV OF TECH

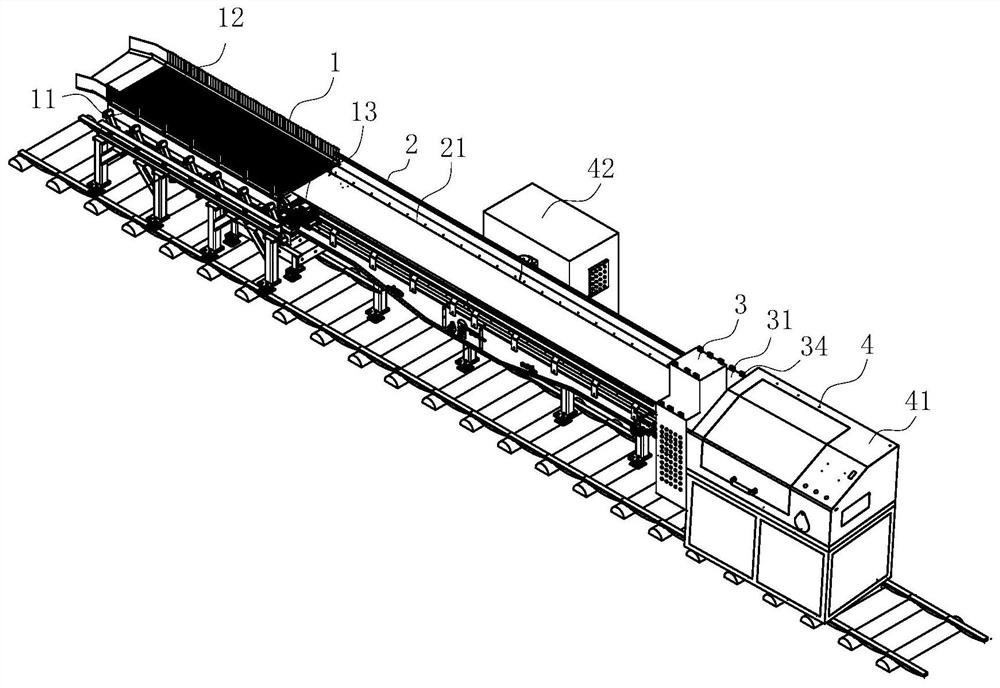

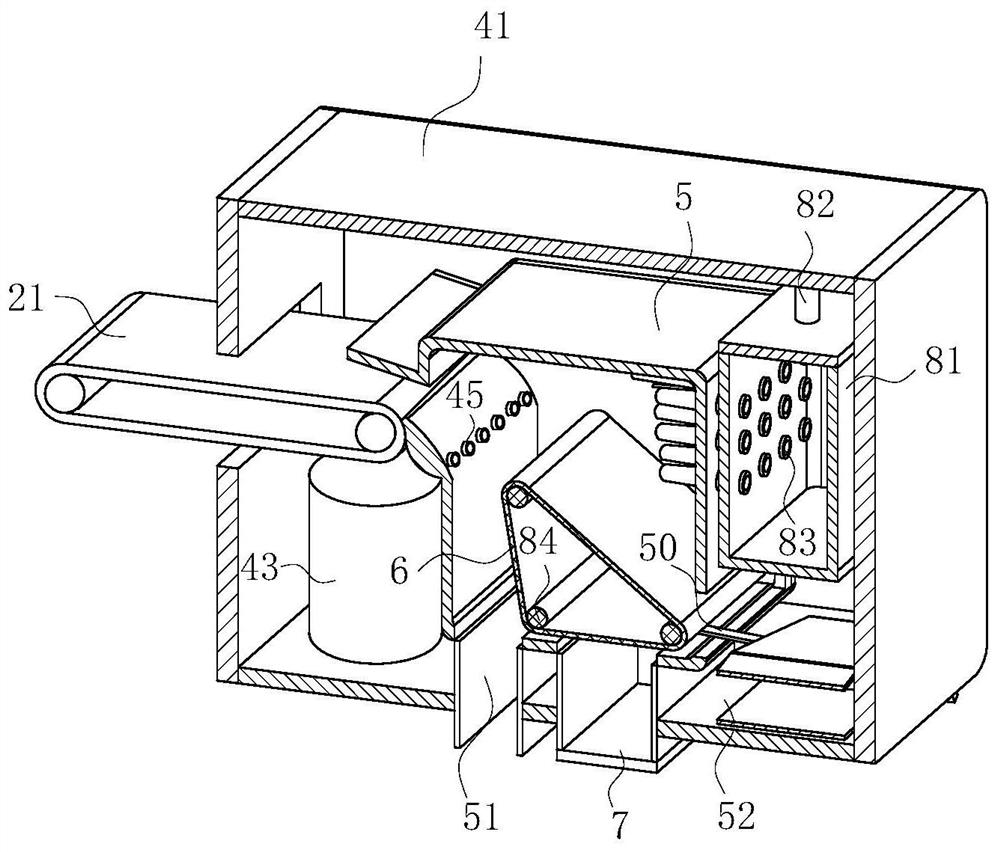

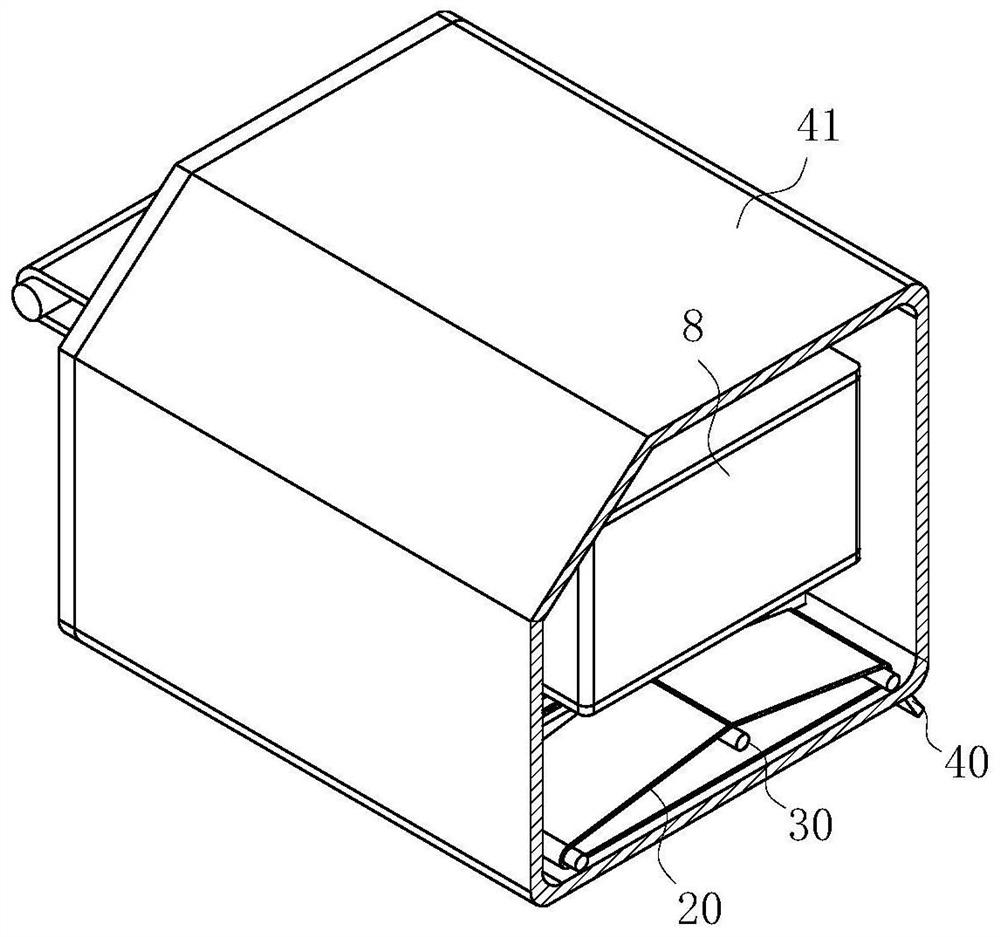

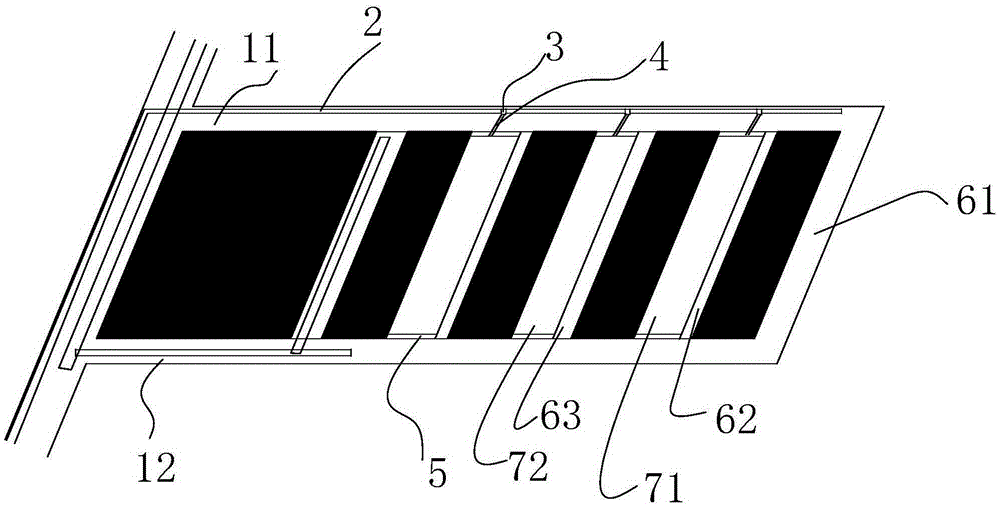

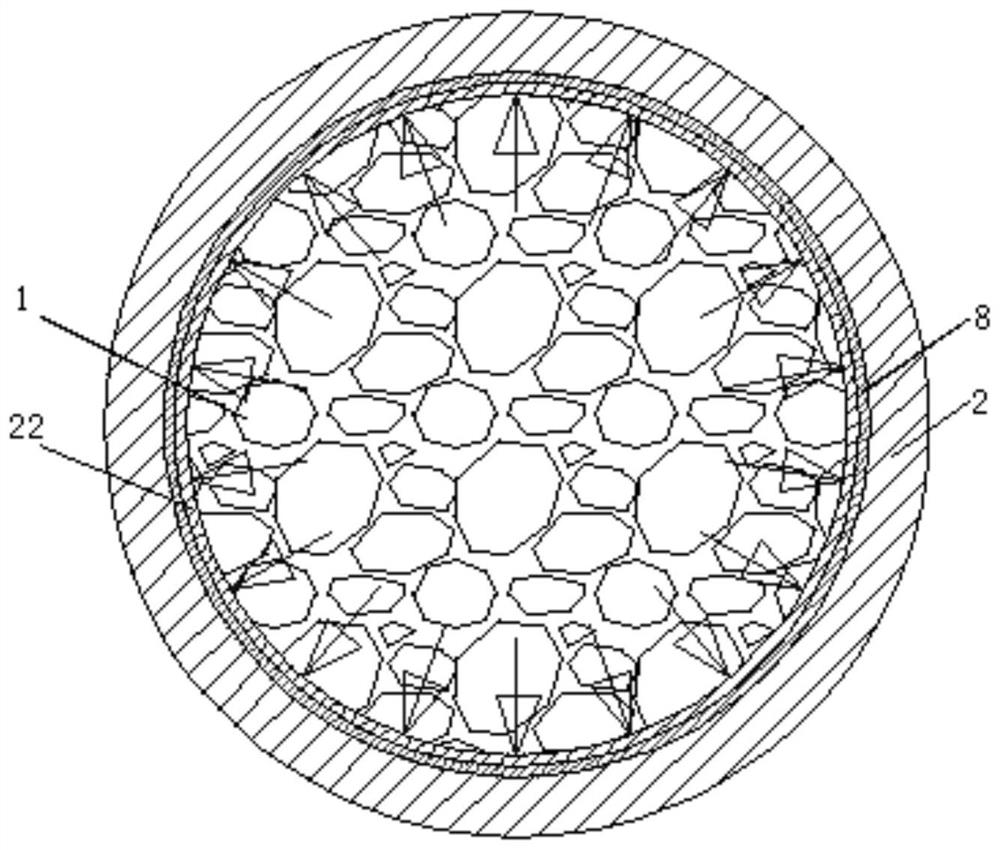

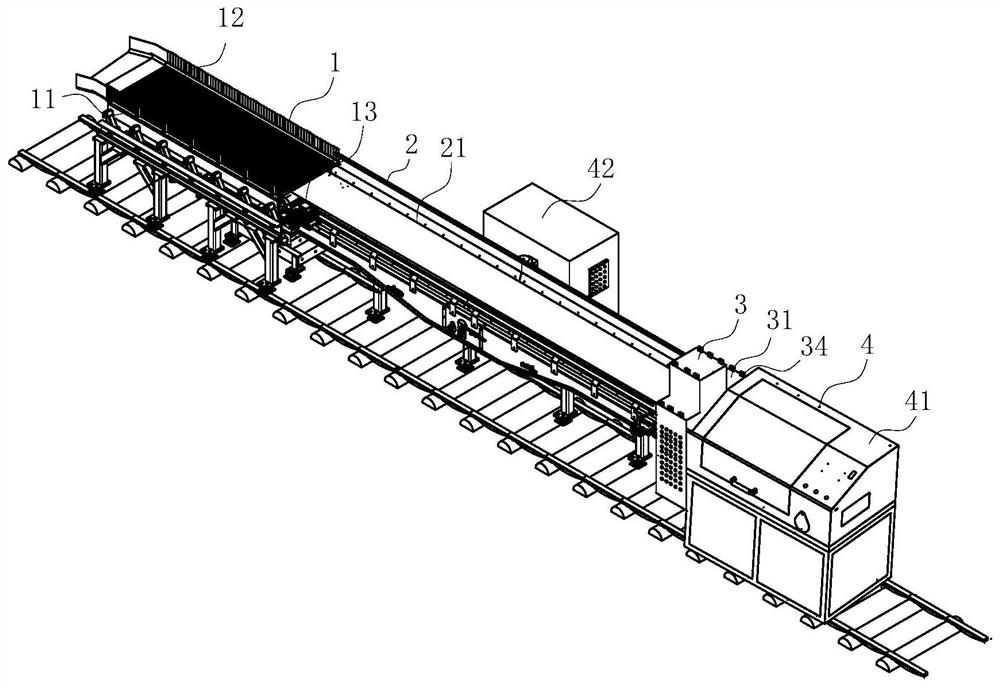

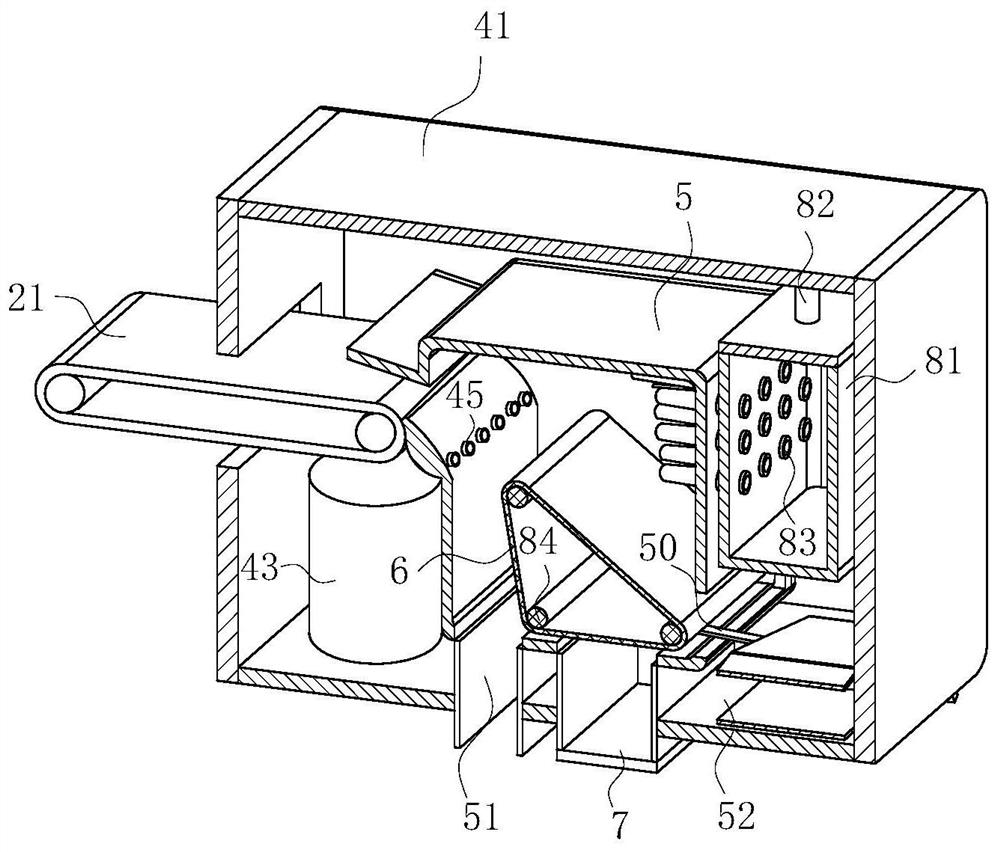

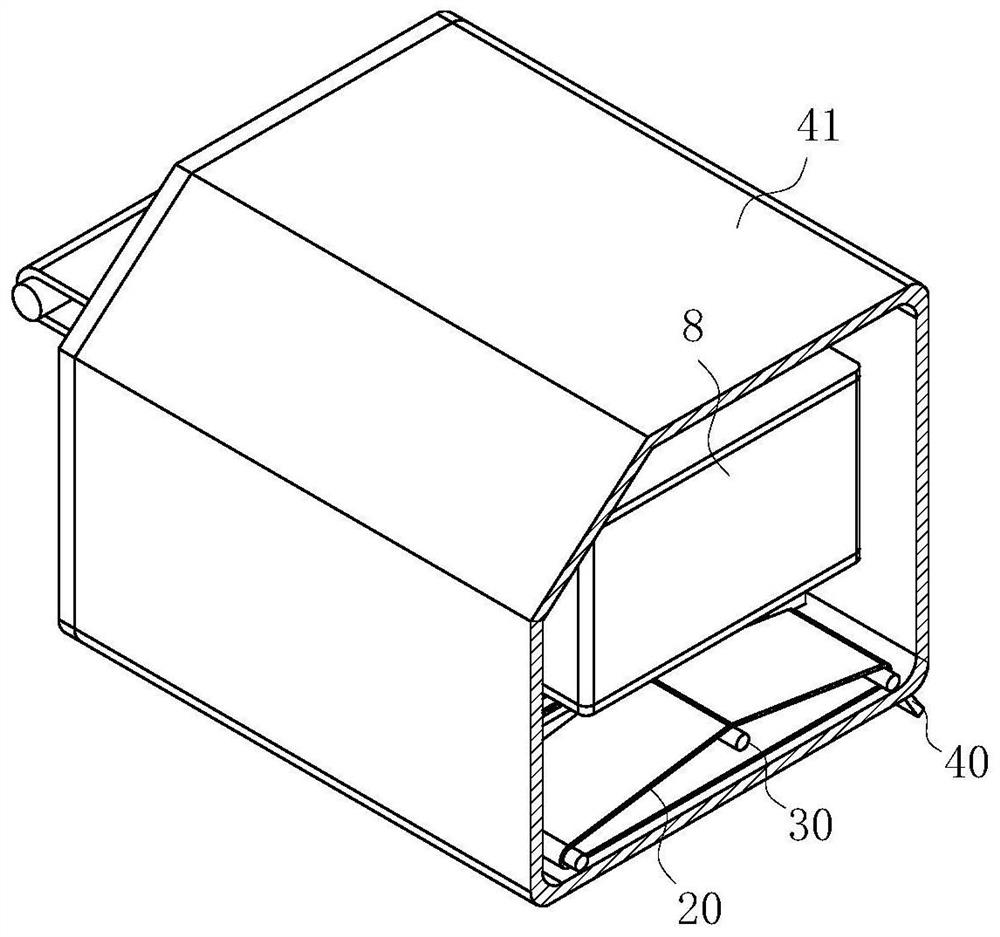

Movable photoelectric separation robot for coal and gangue

The invention belongs to the technical field of coal separation, and particularly relates to a movable photoelectric separation robot for coal and gangue. The robot comprises a vibration feeding module, a conveying module, a dual-energy X-ray identification and decision module and a coal and gangue separation module; a dual-energy X-ray source is fixedly installed in an installation box and is located above a conveying belt; an X-ray flat panel detector is installed under an empty belt of the conveying module and is right corresponding to the dual-energy X-ray source; a measurement and controlinstrument is in electric signal connection with the dual-energy X-ray source; a power supply device is used for supplying power to the measurement and control instrument, the dual-energy X-ray source and the X-ray flat panel detector. The intelligent and efficient coal and gangue separation equipment based on dual-energy X-ray transmission coal separation can achieve real-time and intelligent separation of coal and gangue underground, and compared with an underground jigger, a dense medium cyclone and the like, the equipment has the advantages that the coal separation technology is optimized, the coal and gangue separation rate is increased, the occupied area of a chamber is reduced, and the coal quality is improved.

Owner:ANHUI UNIV OF SCI & TECH

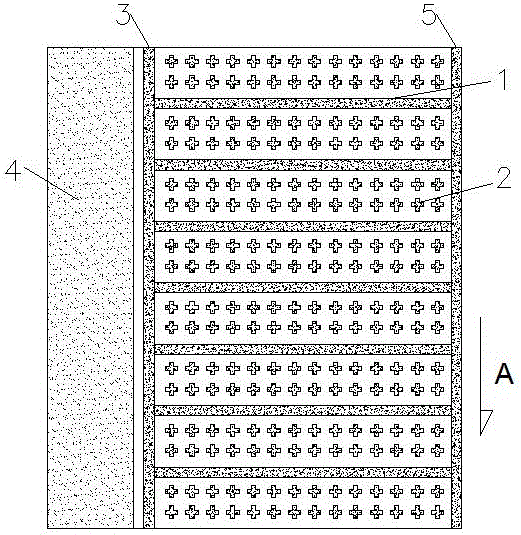

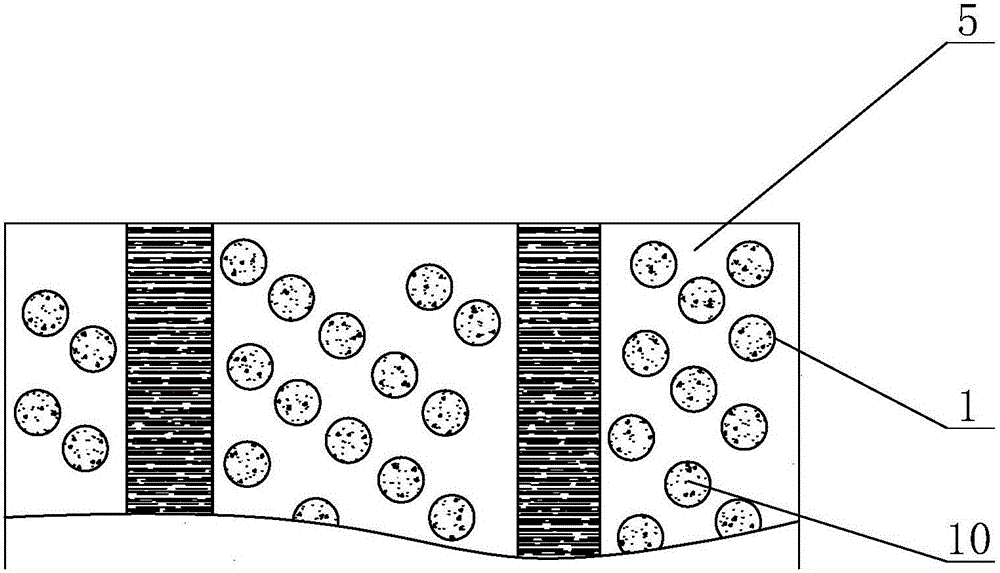

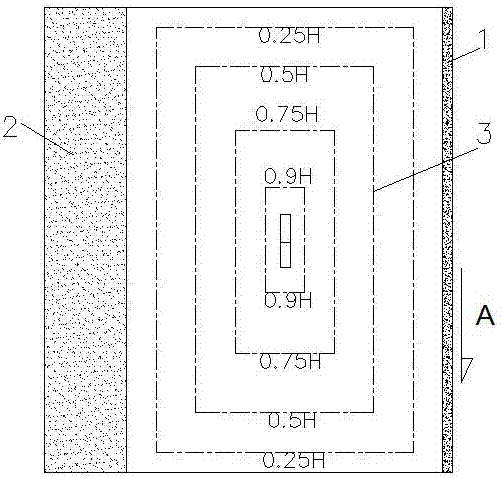

Method for conducting goaf partial filling according to roof caving characteristics

ActiveCN106150545ASave filling materialLower filling costsMaterial fill-upStress concentrationEngineering

The invention discloses a method for conducting goaf partial filling according to roof caving characteristics. The method comprises the steps that high-strength filling strips which are perpendicular or parallel to the mining direction are arranged in a goaf according to an initial caving pace of an immediate roof of the goaf to control caving of the immediate roof; multiple rows of high-strength filling monomers with different shapes are arranged among the filling strips at intervals according to the bending deflection of the immediate roof to control deformation of the immediate roof; large-range filling is conducted on positions with special geological structures to control stress concentration points; a high-strength filling body-immediate roof structure control system is formed, and an upper overlying strata is supported by the high-strength filling body and the immediate roof; narrow filling strip goaf-side retained roadways are arranged, the roadway driving workload of the next working face is reduced, and the goaf is filled in a sealed mode. According to the method for conducting goaf partial filling according to the roof caving characteristics, filling materials are saved, and the filling cost is reduced; the filling structure bodies with different shapes are arranged on key positions, the control effect on the roof is good, and a whole-region chain reaction caused by destruction of partial filling bodies is prevented; a large amount of underground space formed through filling can be reused.

Owner:TAIYUAN UNIV OF TECH

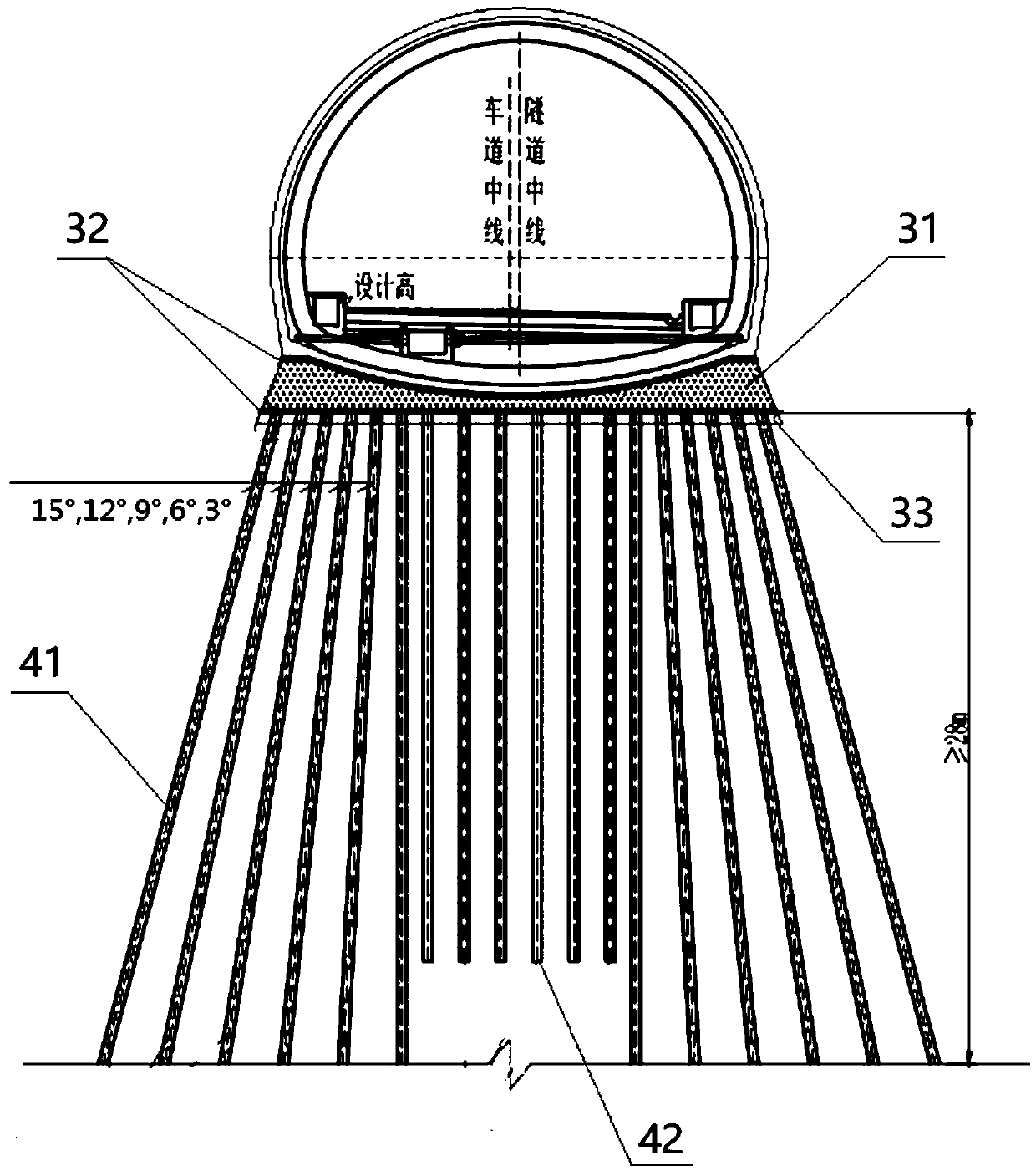

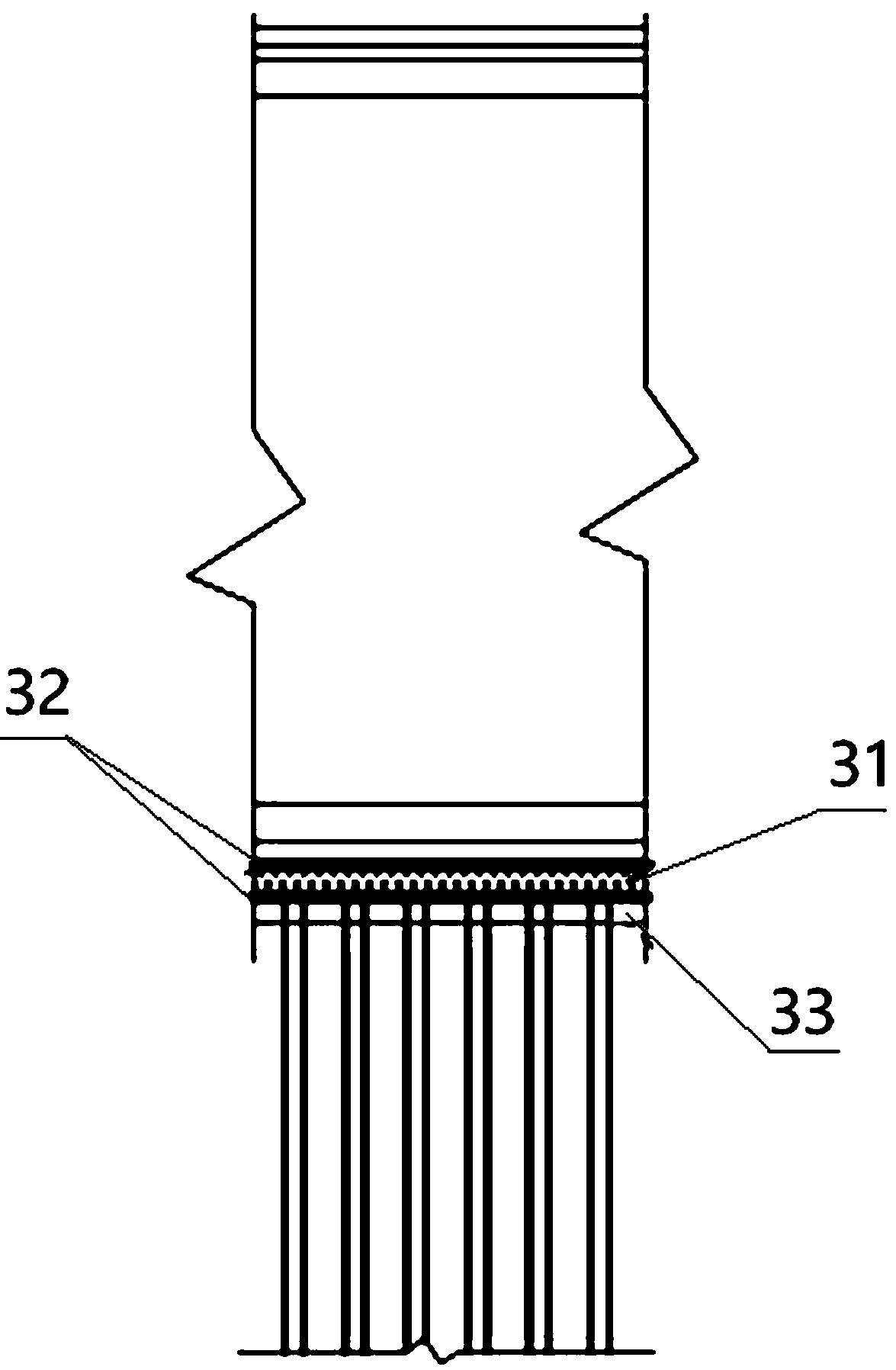

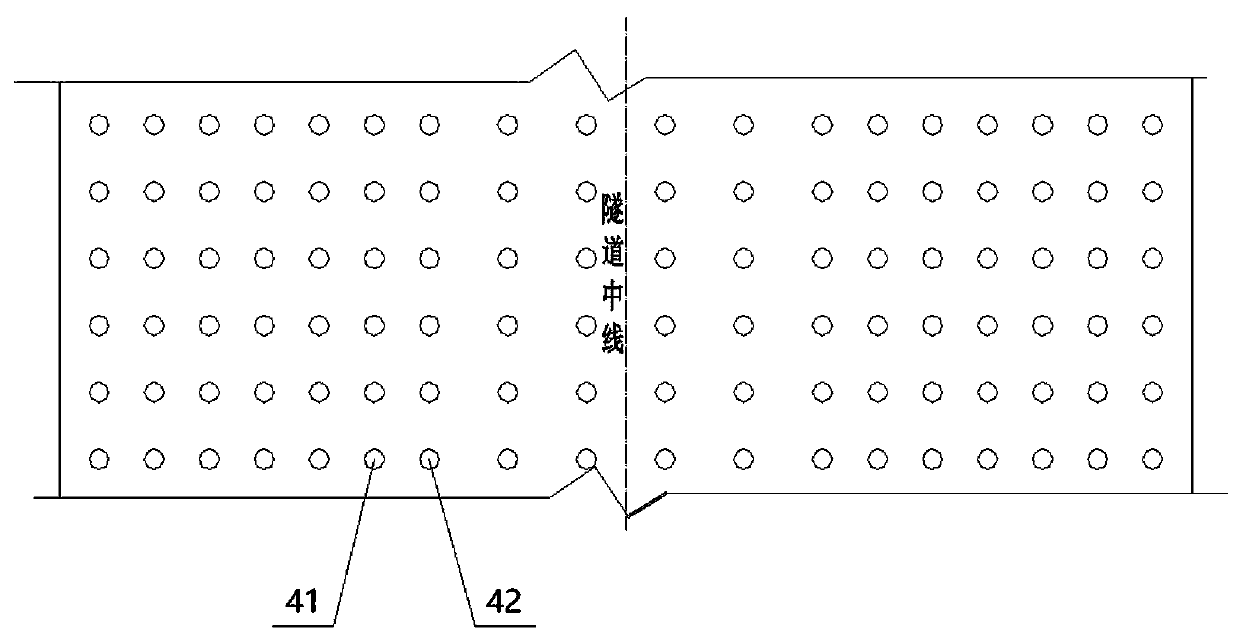

Large filling type karst cave geological tunnel foundation reinforcing structure and construction method thereof

PendingCN111594232ATightly boundIncrease static frictionUnderground chambersTunnel liningBedrockKarst

The invention discloses a large filling type karst cave geological tunnel foundation reinforcing structure. A plurality of rows of grouting steel pipe piles are arranged at the bottom of a tunnel inverted arch in the length direction of a tunnel and go deep into underground bedrock or a soil body with a certain depth, a graded broken stone hardcore is laid above the steel pipe piles at the bottomof the tunnel, and a concrete bearing platform is poured above the graded broken stone hardcore. The construction method comprises the following steps of on-site surveying and setting out, drilling, hole cleaning and hole inspection, steel floral tube installation, primary grouting, secondary grouting and tunnel inverted arch bottom concrete bearing platform construction. The requirements for theconstruction quality and the service life of a karst cave geological tunnel foundation can be met, the bearing capacity is high, subsidence of the karst cave geological tunnel foundation is effectively controlled, the mechanical property of the cast-in-place pile is good, the piles are not prone to breakage, and hole collapse and blockage are effectively controlled in the hole forming process of the cast-in-place pile; and the whole foundation reinforcing structure is beneficial to maintaining water and soil stability in a tunnel mountain, and the natural water system environment is not affected.

Owner:GUANGXI ROAD CONSTR ENG GRP CO LTD

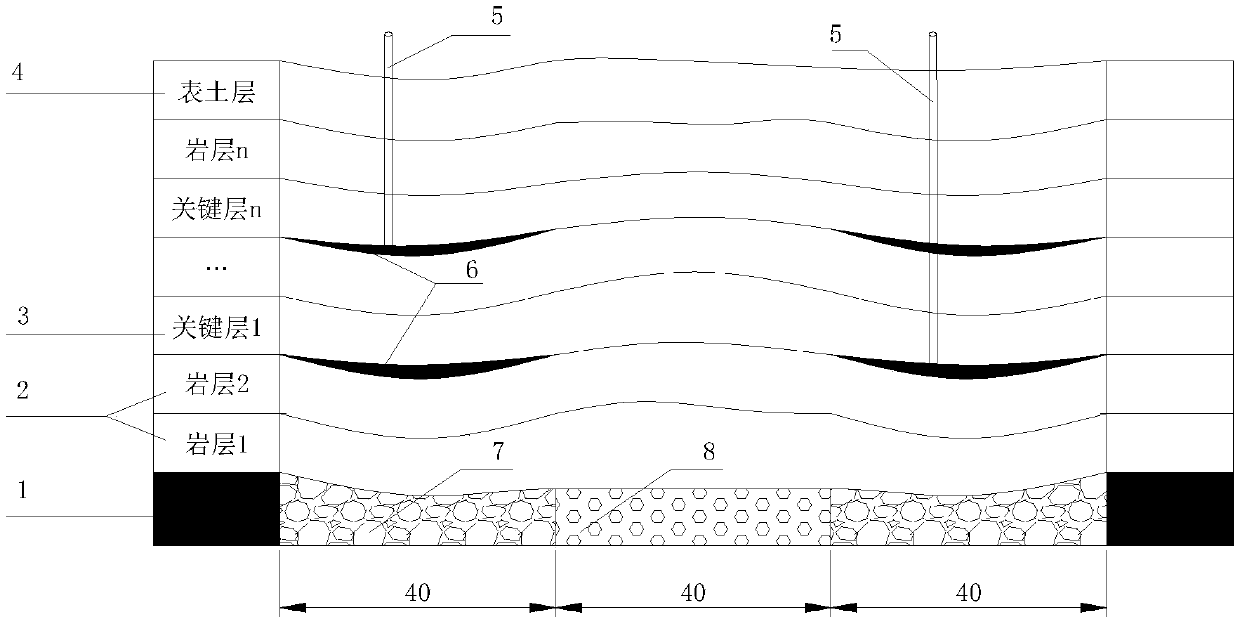

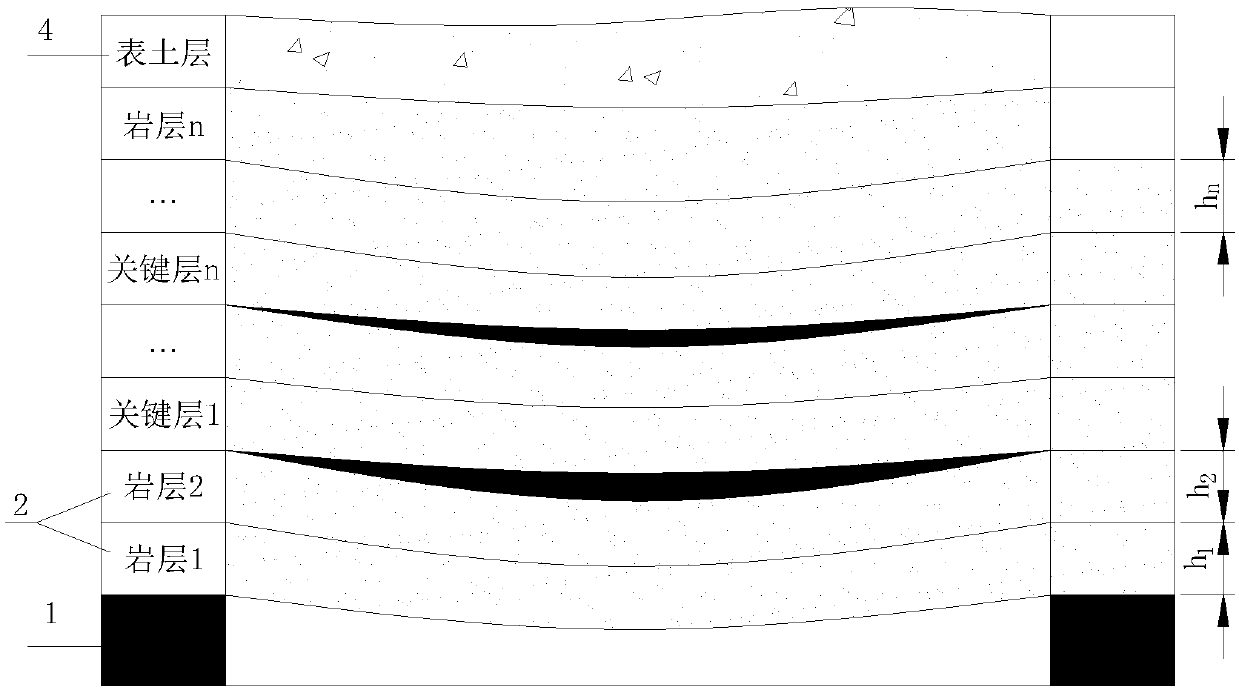

Method for controlling ground surface subsidence through coal mining filling

InactiveCN109681206AReduce dosageSpeed upUnderground miningSurface miningSupporting systemMining engineering

The invention discloses a method for controlling ground surface subsidence through coal mining filling. The method comprises the following steps that the load of each rock stratum is calculated according to the physical and mechanical properties of mine rock strata, if the load of the corresponding rock stratum is smaller than the load of the lower-layer rock stratum, the corresponding rock stratum serves as a key stratum, and all the key strata are found out; the side face of a coal bed serves as a coalface, a filling support is arranged on the coalface, in the coal mining process, every timewhen the coalface is propelled by a distance, gangue filling strips are constructed in the propelling direction, caving top plate strips are formed through a caving method, and the gangue filling strips and the caving top plate strips are arranged at intervals; in the caving process, a bed separation space is formed; and the bed separation space is filled with a high-water material to form a high-water filling body, and a combined support system of the filling strips and the high-water filling body is realized. The method for controlling the ground surface subsidence through coal mining filling has the advantages that gangue filling and high-water material filling are combined so as to control the ground surface subsidence, and therefore the supporting effect is improved, and the cost islowered.

Owner:NORTH CHINA INST OF SCI & TECH

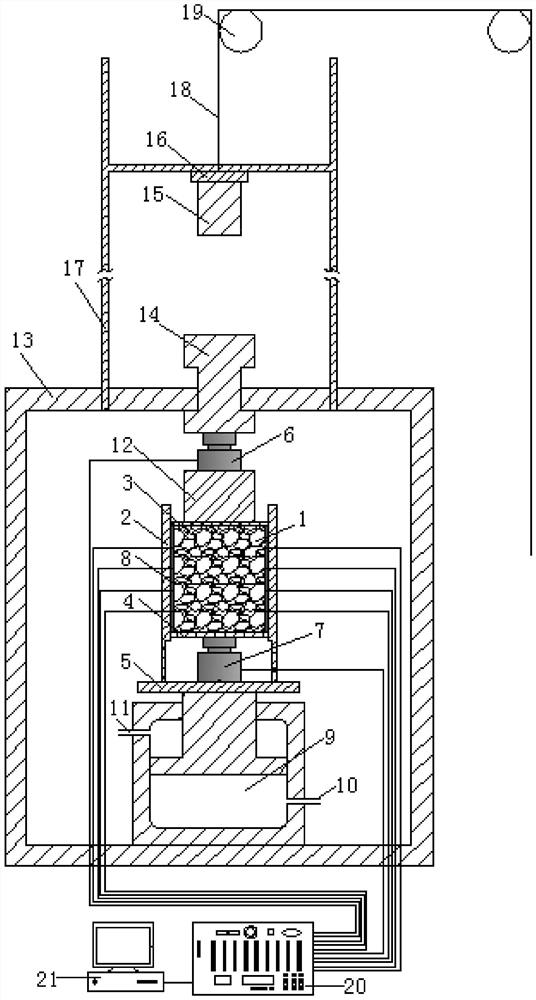

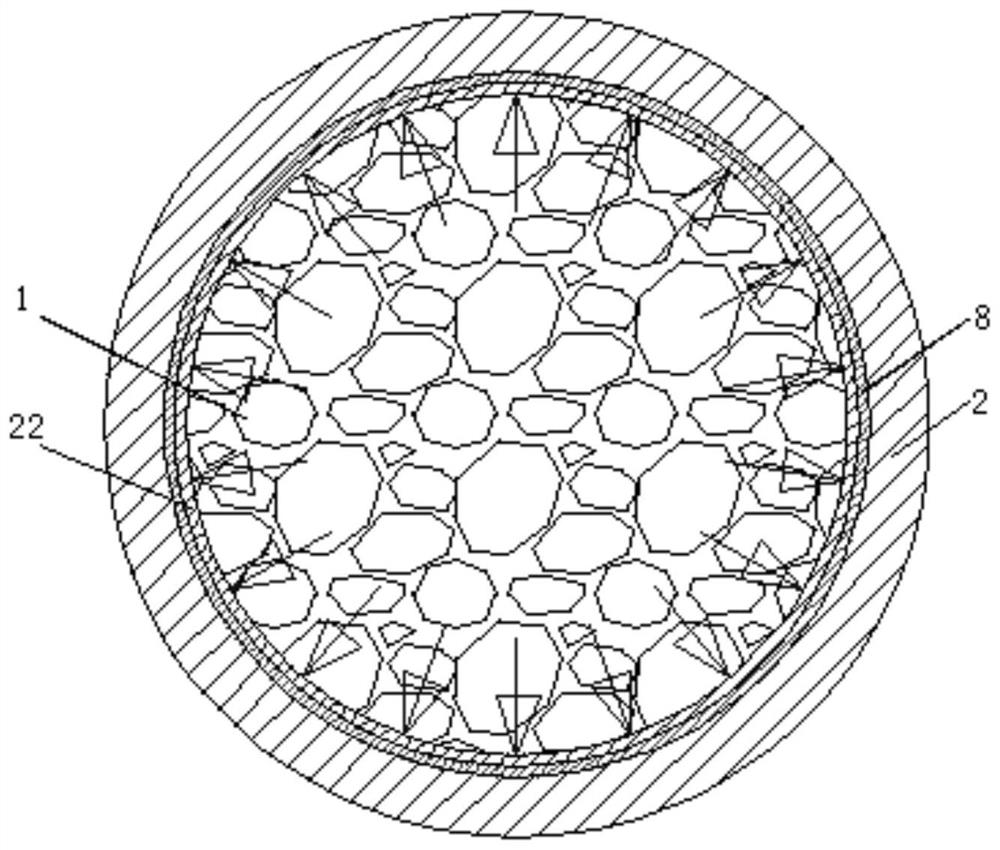

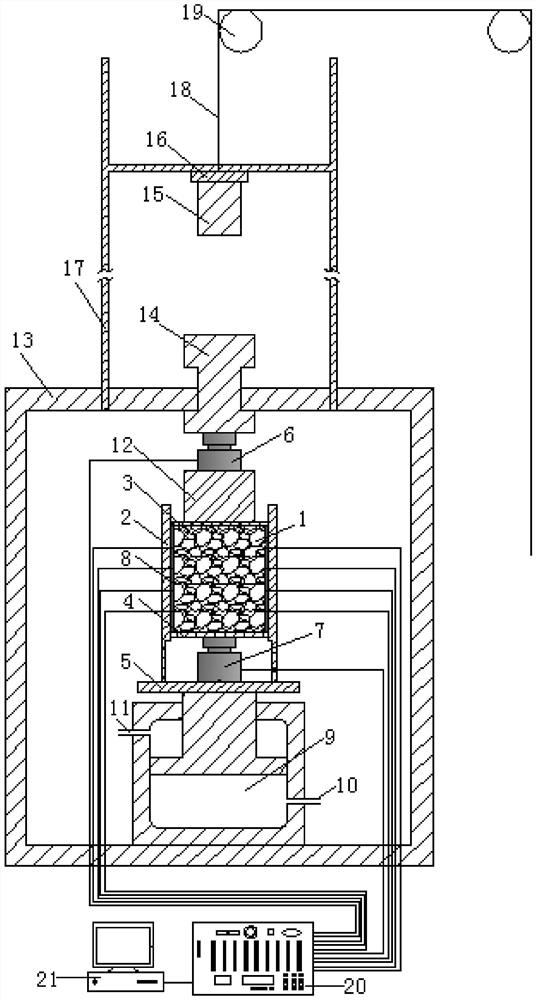

Device and method for testing compression performance of granular filling under dynamic-static acting force

ActiveCN111638138AEasy to operateLow costMaterial strength using tensile/compressive forcesHydraulic cylinderEngineering

The invention discloses a device and a method for testing compression performance of granular filling under dynamic-static acting force. The device comprises a hydraulic cylinder and a steel structureframe. The hydraulic cylinder is mounted in the upper surface of the bottom end of the steel structure frame. A lifting platform, a cylinder device, a first load sensor, a loading plunger and a second load sensor are sequentially arranged at the top of the hydraulic cylinder; a movable loading H-shaped block, a support, an impact iron block and an electromagnet are sequentially arranged at the top of the steel structure frame, the electromagnet is connected with a steel rope, the cylinder device is connected with a computer through a wire and a multi-channel static strain gauge, and the second load sensor and the first load sensor are connected with the multi-channel static strain gauge through wires. According to the device and method, the compression amount and modulus characteristics of waste rock particles under the static action can be obtained, the lateral pressure of the particles under pressure can be measured, the lateral pressure is beneficial to restraining deformation anddamage of pillar surrounding rock, the strength of pillars and surrounding rock is improved, the goaf stability is maintained, and the lateral pressure distribution in the filling particles plays an important guiding role in filling mining design.

Owner:NORTHEASTERN UNIV

Microorganism modification filling coal mining method

ActiveCN108035769ATo achieve reinforcementSubsidence controlMaterial fill-upEnvironmental resistanceBiotechnology

Provided is a microorganism modification filling coal mining method. The microorganism modification filling coal mining method includes the steps that filling materials on the ground are calcificatedby microorganisms, the calcificated filling materials are transported to a goaf to be compacted, the goaf is filled with the calcificated filling materials, then, microorganism grouting is conducted on a filling body, and after coal mining within each step is completed, microorganism grouting filling is carried out. The microorganism modification filling coal mining method is easy to implement andenvironmentally friendly; by the adoption of microorganism filling, the compressive strength of the filling body is effectively improved; a new trend is provided for biochemical-mechanism-based microorganism filling coal mining technologies under deep high-stress conditions.

Owner:CHINA UNIV OF MINING & TECH

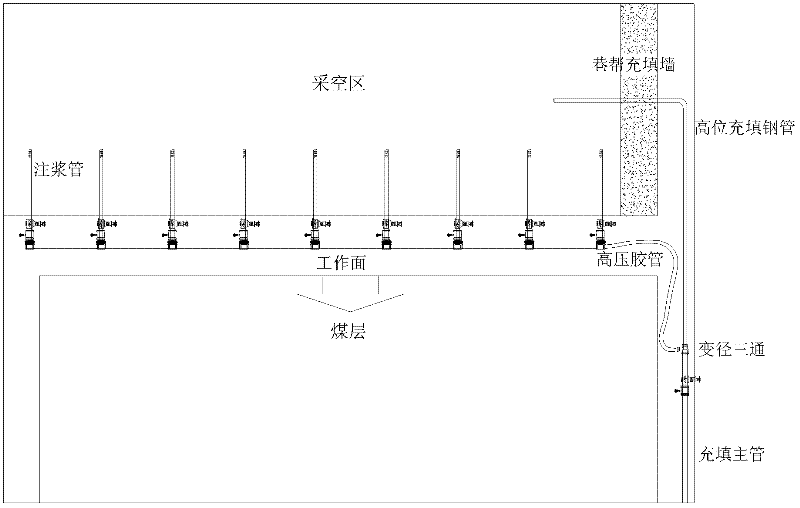

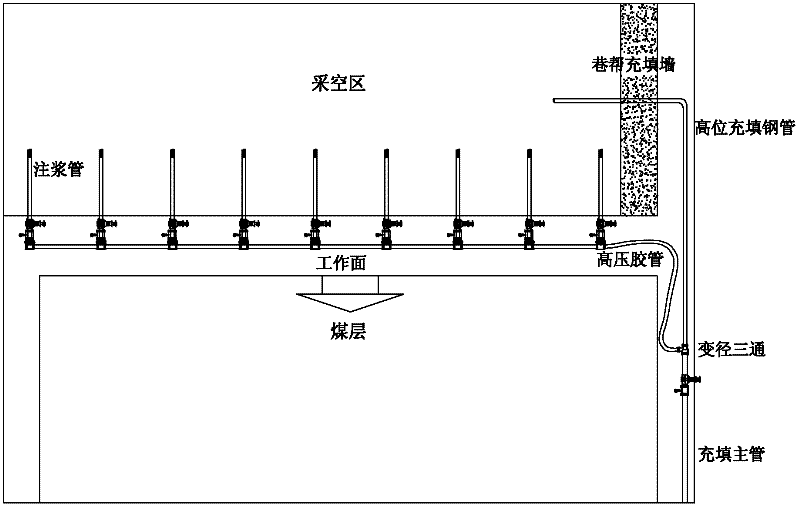

Dragging tube type filling method of thin coal bed fractured roof

A dragging tube type filling method of a thin coal bed fractured roof includes arranging a filling main pipe in a gateway, connecting a high-pressure rubber pipe to the filling main pipe through a reducing tee, and connecting a high-level filling steel pipe to the filling main pipe; connecting a plurality of filling pipes to the high-pressure rubber pipe in parallel mode, simultaneously fixedly connecting each filling pipe to a work face hydraulic support between a gob and a coal bed and extending filling openings of the filling pipes into the gob; penetrating a filling opening of the high-level filling steel pipe through a roadside filling wall and extending the filling opening into the gob, wherein the height of the filling opening is higher than that of the filling opening of each filling pipe; starting to fill the gob till the gob is filled up, and finishing the filling work of the gob; when the working face is pushed forwards, moving the filling pipes along with the hydraulic support to enter a new gob, manually adjusting the position of the high-level filling steel pipe to enable the forwards moving distance of the high-level filling steel pipe to be synchronous with forwards moving step distance of the hydraulic support; and repeatedly filling till excavating is finished.

Owner:SHANDONG UNIV OF SCI & TECH

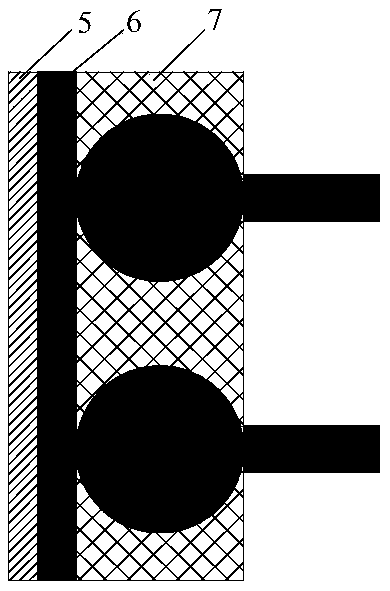

A goaf local filling supporting structure under a hard roof condition and a construction method thereof

The invention discloses a goaf local filling supporting structure body under a hard roof condition and a construction method thereof, and belongs to the technical field of rock stratum motion controlin coal mining. The supporting structure body comprises a filling body located in the goaf, lateral supporting bodies disposed on two sides of the filling body and isolation bodies. Each lateral support body comprises a concrete filled steel tube pier column, an anti-falling supporting leg and a flexible yielding component. The concrete filled steel tube pier column is a main supporting structure.The concrete-filled steel tube pier column is manufactured by pouring concrete grout into a seamless steel tube, the anti-falling supporting legs are arranged in the middle of the concrete-filled steel tube pier column, and each isolation body comprises a gangue bag wall built between the adjacent concrete-filled steel tube pier columns, a flexible side protection steel plate erected in a mannerof being tightly attached to the pier column and a waterproof plastic curtain hung on one side of the steel plate. Sufficient and long-term supporting resistance can be provided for overlying rock roofs, especially hard roofing rock stratums, in the goaf, and it is guaranteed that an elastic nuclear area exists in the center of the structure for a long time.

Owner:SHANDONG UNIV OF SCI & TECH

Cover rock crack and surface subsidence controlled digging, mining and filling parallel operation coal mining method

ActiveCN104481536AReduce in quantitySafe and efficient subsidenceUnderground miningSurface miningEngineeringEarth surface

Owner:CHINA UNIV OF MINING & TECH

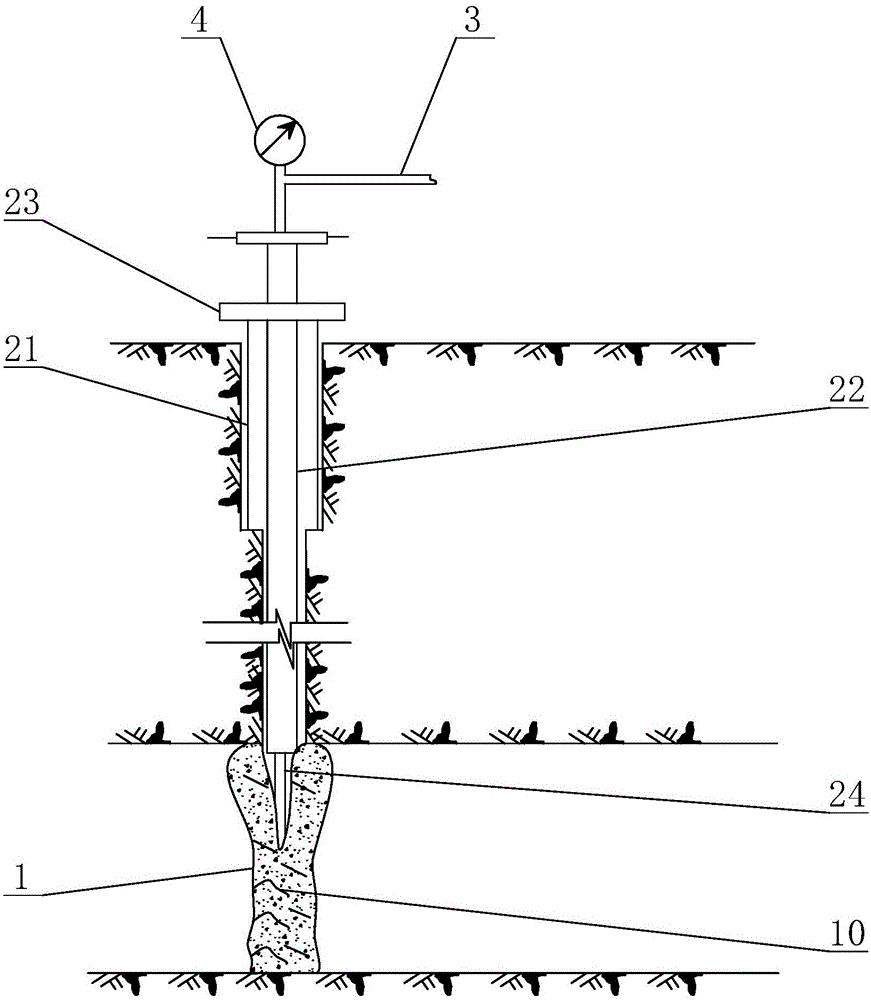

Structure under-covering gob area filling expansion bag and construction method

InactiveCN106285775AImprove bearing capacitySimple construction processMaterial fill-upPoint locationEngineering

The invention discloses a structure under-covering gob area filling expansion bag and a construction method, and relates to the technical field of structure under-covering gob area filling. The structure under-covering gob area filling expansion bag comprises a film filling expansion bag, wherein one end of the film filling expansion bag is provided with an opening; a filling pipeline device is arranged at the position of the opening; the filling pipeline device comprises a drilling inner sleeve A and a drilling inner sleeve B which is positioned in the drilling inner sleeve A; a cover plate A is arranged at the top of the drilling inner sleeve A; the two ends of the drilling inner sleeve B extend out of the drilling inner sleeve A; a filling pipeline is arranged in the drilling inner sleeve B; a grouting pipe which is communicated with the filling pipeline is arranged at the top of the filling pipeline. The structure under-covering gob area filling expansion bag and the construction method have the beneficial effects that the structure is simple; the basic bearing capacity of a building foundation can be improved quickly and obviously; the construction process is simple; the cost is low; the point location of the filling area is accurate.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

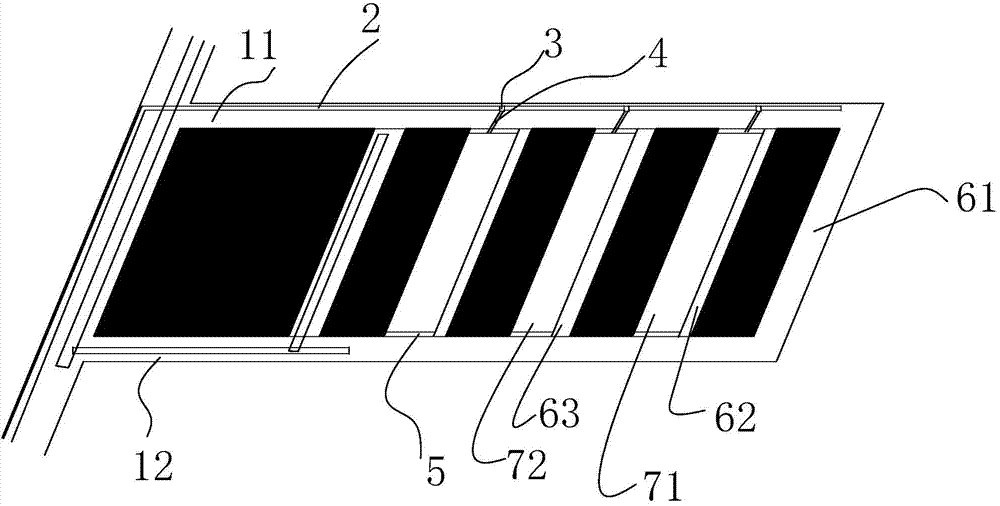

Super high-water secondary filling bag and filling method

The invention discloses a super high-water secondary filling bag and a filling method and belongs to the technical field of mine filing and mining. The secondary filling bag comprises a flexible bag body and a telescopic framework. The flexible bag body is rectangular when being propped up through the telescopic framework. A liquid injection hole is formed in the front side surface of the flexiblebag body and used for injecting filling liquid into the super high-water filling bag body. Exhaust holes are formed in the positions, close to the upper portion of the flexible bag body, of the rightside surface of the flexible bag body. A connecting groove is formed in the left side surface of the flexible bag body, and a connecting bulge is arranged on the right side surface of the flexible bag body. A secondary filling pipe penetrating through the front and rear side surfaces is further arranged on the flexible bag body. A filling inspection pipe penetrating through the front and rear side surfaces is further arranged in the position, close to the position above the front side surface, of the flexible bag body. A plurality of secondary filling bags are connected in series so as to block off an outlet of a worked-out section, the super high-water filling liquid is injected into the worked-out section from secondary filling pipes until the worked-out section is full, and secondary filling operation is completed. The super high-water secondary filling bag is practical in structure, convenient to operate and capable of being used for performing secondary filling on the worked-outsection and controlling earth surface subsidence.

Owner:CHINA UNIV OF MINING & TECH

A Method for Partial Filling of Gobs According to the Characteristics of Roof Caving

ActiveCN106150545BControl deformation damagePromote recoveryMaterial fill-upStress concentrationEngineering

The invention discloses a method for conducting goaf partial filling according to roof caving characteristics. The method comprises the steps that high-strength filling strips which are perpendicular or parallel to the mining direction are arranged in a goaf according to an initial caving pace of an immediate roof of the goaf to control caving of the immediate roof; multiple rows of high-strength filling monomers with different shapes are arranged among the filling strips at intervals according to the bending deflection of the immediate roof to control deformation of the immediate roof; large-range filling is conducted on positions with special geological structures to control stress concentration points; a high-strength filling body-immediate roof structure control system is formed, and an upper overlying strata is supported by the high-strength filling body and the immediate roof; narrow filling strip goaf-side retained roadways are arranged, the roadway driving workload of the next working face is reduced, and the goaf is filled in a sealed mode. According to the method for conducting goaf partial filling according to the roof caving characteristics, filling materials are saved, and the filling cost is reduced; the filling structure bodies with different shapes are arranged on key positions, the control effect on the roof is good, and a whole-region chain reaction caused by destruction of partial filling bodies is prevented; a large amount of underground space formed through filling can be reused.

Owner:TAIYUAN UNIV OF TECH

A Method for Partial Filling of Gob Area According to Surface Subsidence Characteristics

ActiveCN106150546BControl deformation damagePromote recoveryMaterial fill-upMining engineeringStructural engineering

The invention discloses a method for conducting goaf partial filling according to ground surface subsidence characteristics. The method comprises the steps that the positions of filling bodies are designed according to a ground surface subsidence contour map; complete filling is conducted within a central area range, and a subsidence center is controlled; multiple circles of filling strips are arranged outside the complete filling range, and a larger subsidence region is controlled; multiple rows of filling monomers are arranged outside the filling strips, and a subsidence edge region is controlled; the filling bodies with different shapes are arranged in a goaf in a targeted mode, deformation destruction and ground surface subsidence of a roof are controlled, a filling body-roof structure control system is formed, and deformation destruction and ground surface subsidence of an upper overlying strata are controlled; narrow filling strip goaf-side retained roadways are arranged, the roadway driving workload of the next working face is reduced, and the goaf is filled in a sealed mode. According to the method for conducting goaf partial filling according to the ground surface subsidence characteristics, deformation destruction and ground surface subsidence of the roof can be effectively controlled, the recovery rate of coal mining under buildings, railways and water bodies is increased, and the environment is protected; filling materials are saved, the filling cost is reduced, and a large amount of underground space formed through filling is reused.

Owner:TAIYUAN UNIV OF TECH

A continuous mining machine drilling type paste filling mining method for side-side coal

ActiveCN111364992BPromote recoveryProtect environmentUnderground miningSurface miningMining engineeringResource recovery

A continuous miner drilling type paste filling mining method for side-side coal, belonging to the field of coal mining methods, can solve the problems of existing side-side coal mining, personnel entering the tunnel to lay filling pipelines, filling rate and roof connection effect Poor environmental protection, low resource recovery rate, damage to the ecological environment of the mining area, poor slope stability, etc., the open-pit coal mine is divided into several sections, and several mining tunnels are planned in the section, and the mining tunnels are reserved between the mining tunnels. In the section, the initial mining jumping is carried out. At the same time, a number of filling holes are arranged on the surface above the middle of the mining tunnel, and steel casing walls are used to inject high-concentration filling bodies into the mining tunnel. After mining, a mining tunnel is formed. In the empty area, the filling operation is completed in two stages. After the primary mining is completed in the section, the secondary mining is carried out until the mining and filling of all section mining tunnels are completed. The method can improve the safety during mining and filling, and does not require personnel to enter the roadway for operation; the filling process is simplified and the filling cost is reduced.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

A filling coal mining method with skip mining at intervals

InactiveCN103883350BIntegrity guaranteedReduce exerciseUnderground miningSurface miningFilling materialsSequential mining

The invention provides an interval skip-mining type filling coal mining method and belongs to the technical field of coal mine filling coal mining methods. The interval skip-mining type filling coal mining method comprises the steps that a first open-off cut is dug at the tail end of a butt entry, a second open-off cut is dug a certain distance away from the first open-off cut, and mining is conducted at the position of the second open-off cut with the wall type system coal mining method after the second open-off cut is well dug; a third open-off cut is dug a certain distance away from the second open-off cut, a gob formed after mining is conducted at the position of the second open-off cut is filled while the third open-off cut is dug, and the rest operation is conducted by analogy till mining is conducted on a mining stopping line. By the adoption of the interval skip-mining type filling coal mining method, mining can be conducted under the condition that the two ends are supported, sequential mining and sequential filling are achieved, the integrity of a base plate of a roof is guaranteed, movement of overlying rock is reduced, and the purpose of surface subsidence control is achieved; after mining with filling is completed, coal pillars left after mining do not need to be filled, filling materials are reduced, and filling cost is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

Bag-type delamination grouting material for controlling surface subsidence, its preparation and grouting method

Owner:ANHUI UNIV OF SCI & TECH

A kind of microbial modification filling coal mining method

ActiveCN108035769BTo achieve reinforcementSubsidence controlMaterial fill-upBiochemical mechanismMining engineering

A microbial modification filling-based coal mining method, comprising the operation steps of performing ground microbial calcification on a filling material, conveying the calcified filling material to a goaf for tamping and filling, and then performing microbial grouting on a filling body, where microbial grouting and filling is performed after each step of coal mining is completed. By means of microbial filling, the compressive strength of the filling body is effectively improved, environment-friendliness is realized, and the biochemical mechanism-based microbial filling-based coal mining technology in a high-stress deep part is taken to a new direction.

Owner:CHINA UNIV OF MINING & TECH

Loess-filling coal-mining method in a coal mine

InactiveCN101915100BAbundant resourcesEasy to collectUnderground miningSurface miningMining engineeringCoal pillar

The invention relates to a loess-filling coal-mining method in a coal mine, which solves the problems of relatively low mechanization degree, high production cost, poor production efficiency and difficulty in realizing large-scale mining in the existing filling coal-mining method in the coal mine. The method comprises a reverse transportation process, a filling coal-mining process and a filling coal-mining process without coal pillars, wherein, in the reverse transportation process, loess is thrown from a charging mine opening and transported to a coal-mining working surface for throwing; in the filling coal-mining process, firstly coal cutting is carried out on a coal-mining area, a certain filling space is reserved, and then coal cutting operation and filling operation are performed simultaneously; and in the filling coal-mining process without the coal pillars, a roadway is reserved along a mine goaf. By means of a rational design, the loess-filling coal-mining method in the coal mine of the invention can maximize recovery rate of coal resources, effectively avoid surface subsidence, greatly lower filling cost, improve filling and coal-mining mechanization degree, and is of great significance to field-making in barren mountains, ecological protection and resource conservation.

Owner:HUOZHOU COAL ELECTRICITY GROUP

Deep-well frozen filling body cooling design method

ActiveCN108104868APrevent subsidenceSubsidence controlMining devicesTunnel/mines ventillationDynamic monitoringTemperature sensing

The invention discloses a deep-well frozen filling body cooling design method. From the design angle of mine cooling, when the cooling control value is reached, under the conditions of different sizegrading and filling materials, the refrigeration capacity and time and the cooling efficiency of a frozen filling body are tested; from the design angle of the filling rate, when the engineering control value is reached, under the freeze thawing conditions of the different size grading and filling materials, the compacting mechanical properties are tested; the optimum material ratio, the size grading and the temperature which reach cooling and achieve engineering control are determined; and by mounting top plate dynamic monitoring equipment and temperature sensing equipment, the temperature, the material ratio and the size grading of the frozen filling body are adjusted in real time, and thus the filling and cooling effects are guaranteed. Through the deep-well frozen filling body coolingdesign method, the difficult problem of cooling of the deep solid filling mining technology on an engineering site is solved.

Owner:CHINA UNIV OF MINING & TECH

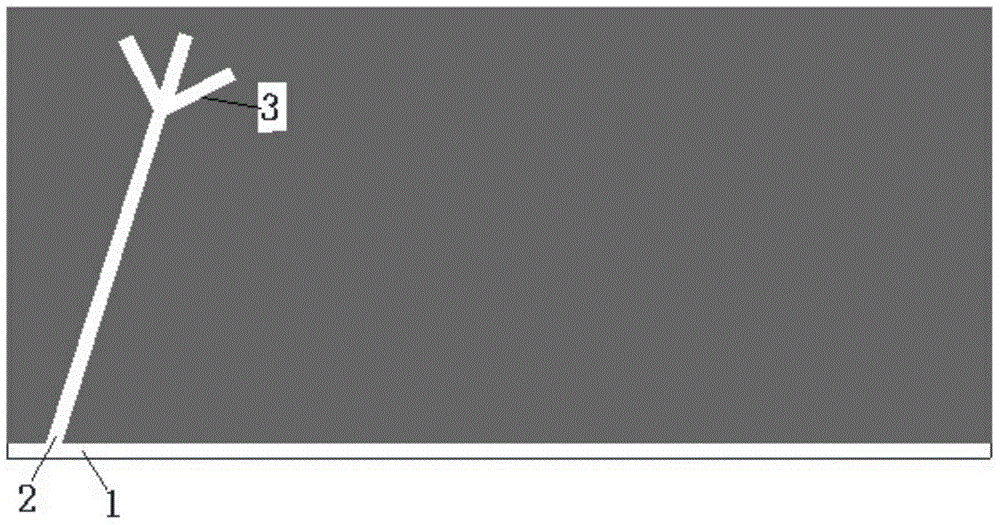

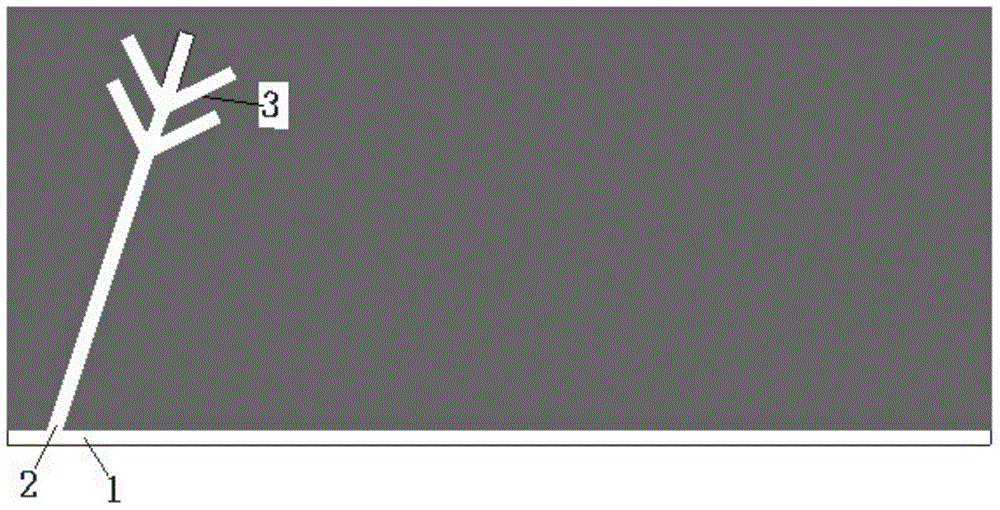

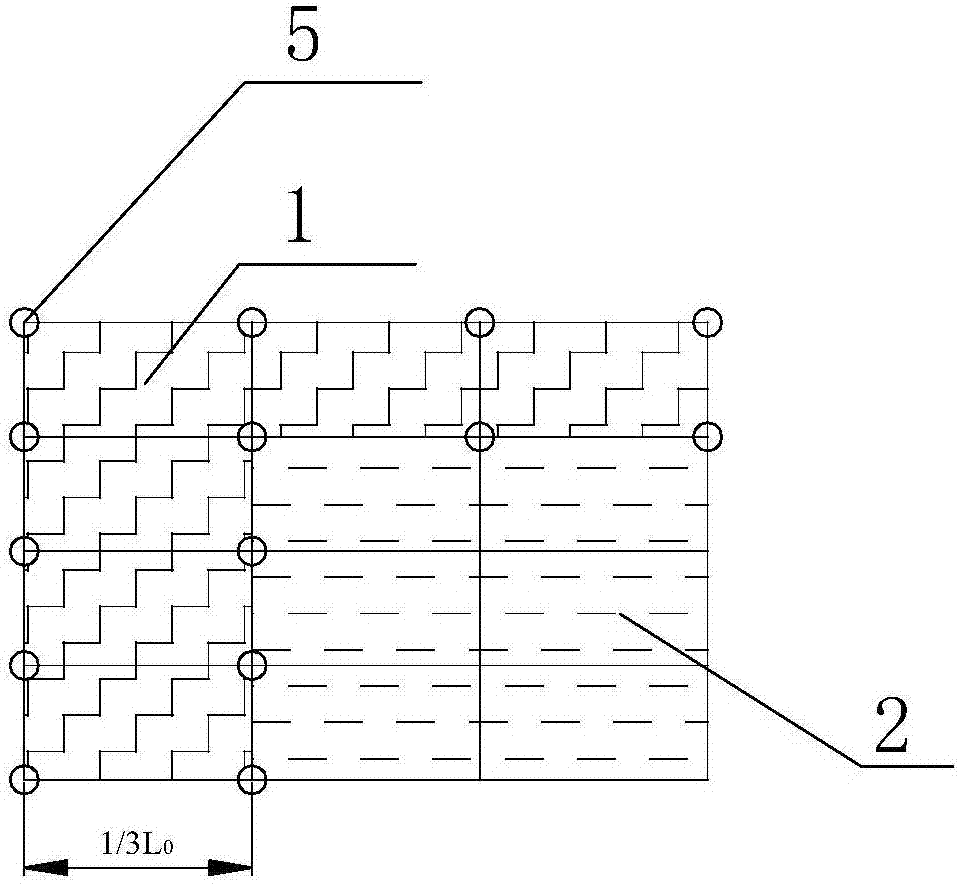

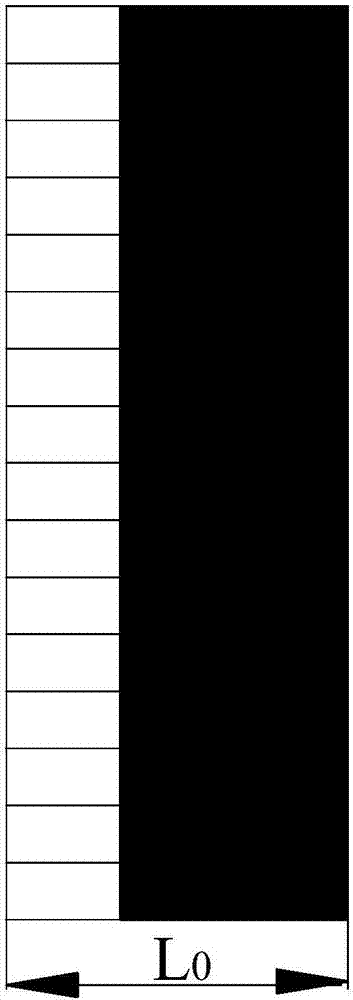

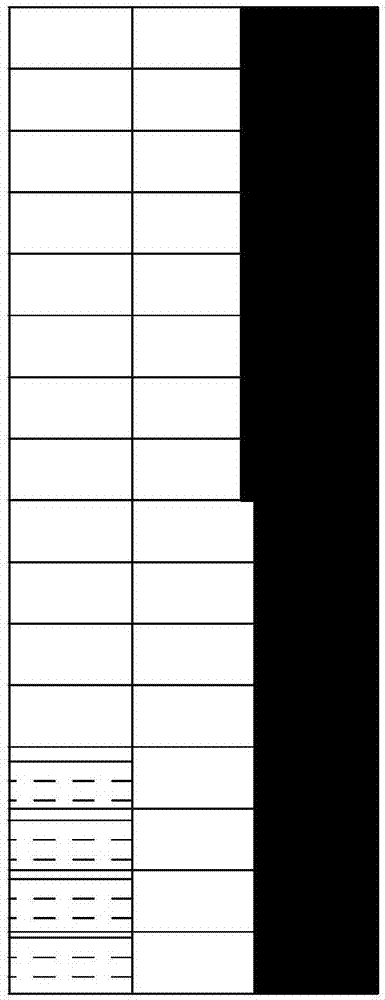

Room-pillar-like type coal mining method for filling near goafs through roof cutting

InactiveCN107575229AImprove recoveryEffectively control surface subsidenceUnderground miningSurface miningFilling materialsCoal mining

The invention discloses a room-pillar-like type coal mining method for filling near goafs through roof cutting. The direct roof initial caving pace L0 is obtained, and when footage of the coal miningprogress reaches one third of the initial caving pace L0, roof cutting is started from the position located behind a coal cutter by the distance of one basic unit; corresponding shot holes are formedin the roof cutting part of the corresponding basic unit, when the footage of the coal mining progress reaches two thirds of the initial caving pace L0, the roof cutting parts on the left side of thebasic unit are cut, and gangue produced at the three roof cutting parts are transferred to filling areas of the basic unit by mechanical equipment for filling; and the steps are repeatedly operated until coal mining of the coal mining area is completed. According to the room-pillar-like type coal mining method for filling the near goafs through roof cutting, the effect similar to that of room-pillar type coal mining is achieved finally, surface subsidence can be effectively controlled, and the sedimentation reduction effect is obvious; no external filling materials are required, only the costof the mechanical equipment is input at a time, and filling cost is reduced; and the room-pillar-like type coal mining method is not limited by slow solidification of paste materials, the supporting effect is achieved once filling is completed, and filling efficiency is high.

Owner:SHANDONG UNIV OF SCI & TECH

Device and method for testing compression performance of filling powder under dynamic-static force

ActiveCN111638138BEasy to operateLow costMaterial strength using tensile/compressive forcesHydraulic cylinderStrain gauge

A device and method for testing the compression performance of filling bulk under dynamic-static force, including a hydraulic cylinder, a steel structure frame, a hydraulic cylinder installed on the upper surface of the bottom end of the steel structure frame, and a lifting platform, a circular cylinder, etc. Barrel device, first load sensor, loading plunger, and second load sensor. The top of the steel structure frame is provided with movable loading I-shaped blocks and brackets, impact iron blocks and electromagnets in turn. The electromagnets are connected with steel ropes. The device is connected with the computer through wires and multi-channel static strain gauges, and the second load sensor and the first load sensor are respectively connected with the multi-channel static strain gauges through wires. The invention can not only obtain the compression amount and modulus characteristics of the waste rock bulk under static action, but also measure the lateral pressure of the bulk when the bulk is compressed. The strength of surrounding rock, maintaining the stability of the void and the distribution of lateral pressure in the filling bulk have an important guiding role in the design of filling mining.

Owner:NORTHEASTERN UNIV LIAONING

Method of local filling to control surface subsidence in gob

A method of local filling to control surface subsidence in a gob. Metal nets are suspended at intervals from open-off cuts and on top plates behind a hydraulic bracket on a working surface along with coal cutting of a coal cutter and movement of the hydraulic bracket on the working surface, and filling bags are arranged; coal cutting is stopped after cutting is performed once by the coal cutter, and concrete is filled into the filling bags in the metal nets in sequence until a roof; cutting is continuously performed once by the coal cutter, metal nets are continuously suspended on top plates adjacent to the two sides of the filled area, filling is continuously performed to complete a filling cycle, and a row of filled bodies are formed in a gob parallel to the working surface; and coal cutting is continuously performed four to five times by the coal cutter, the following filling cycle is completed continuously, and the procedures are repeated until filling of the whole gob is completed and a plurality of rows of filled bodies are formed in the gob. The method is simple, and the filling cost is low. The top plates in the gob are supported uniformly at intervals; therefore, the stability of an overburden layer, in particular a key layer, can be improved, and surface subsidence and damage to buildings can be effectively prevented.

Owner:CHINA UNIV OF MINING & TECH

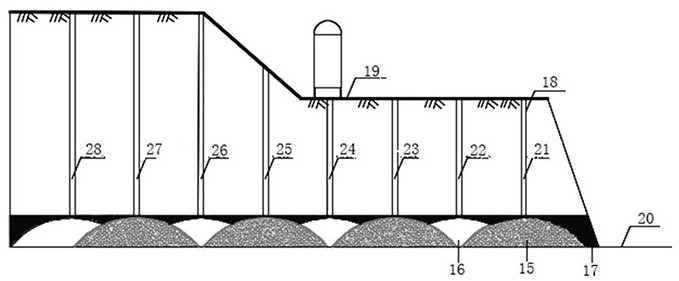

Goaf bag-type packing method

The invention discloses a goaf bag-type packing method, comprising the following steps: suspending a plurality of flexible filling bags at intervals in a goaf from an open-off cut, arranging a plurality of individual props at the outer side of a plurality of flexible packing bags, then erecting a formwork supported by the individual props outside the flexible filling bags; filling high-water material seriflux containing more than 85% of moisture into the bags until the bags are full, and removing the framework and the individual props after the high-water material in the bags are consolidatedto complete a row of filling cycle. With the propulsion of coal mining working face, the following row of filling work is carried out continuously, flexible filling bags are suspended next to the front row to perform bag suspension and filling circularly of the next cycle until the filling work of the whole goaf is finished. The invention can directly support the top plate of the goaf, thereby effectively reducing the submergence of the top plate and controlling ground surface movement. The bag-type packing method is particularly suitable for filling the goaf of an inclined mining working surface with smaller strike propulsion or coal seam pitch, and has the advantages of simple technology, easy construction, low cost, simple operation and high filling efficiency.

Owner:JIZHONG ENERGY HANDAN MINING GROUP +1

A mobile gangue photoelectric sorting robot

ActiveCN112170260BAccurate identificationSubsidence controlSortingFlat panel detectorProcess engineering

The invention belongs to the technical field of coal separation, in particular to a mobile gangue photoelectric separation robot; including a vibration feeding module, a conveying module, a dual-energy X-ray recognition decision-making module and a coal-gangue separation module; a dual-energy X-ray The source is fixedly installed in the installation box, and the dual-energy X-ray source is located directly above the conveyor belt; the X-ray flat panel detector is installed directly below the empty belt of the conveyor module, and the X-ray flat panel detector corresponds to the dual-energy X-ray source ; The measurement and control instrument is connected with the dual-energy X-ray source electrical signal; the power supply device is used to supply power to the measurement and control instrument, the dual-energy X-ray source and the X-ray flat panel detector; Intelligent and efficient separation of coal gangue based on dual-energy X-ray transmission coal preparation The equipment can realize real-time intelligent separation of coal and gangue underground. Compared with underground jigs and dense medium cyclones, etc., it optimizes the coal preparation process, improves the separation rate of coal and gangue, and reduces the cost of the chamber area. Occupy, improve the quality of coal.

Owner:ANHUI UNIV OF SCI & TECH

A Design Method for Cooling of Frozen Filling Body in Deep Well

ActiveCN108104868BPrevent subsidenceSubsidence controlMining devicesTunnel/mines ventillationFreeze thawingCooling effect

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com