Room-pillar-like type coal mining method for filling near goafs through roof cutting

A coal mining method and room-and-pillar technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve problems such as unbalanced coal mining capacity and filling capacity, environmental loss, and difficulty in filling, and achieve effective control of surface subsidence , The effect of reducing the settlement is obvious, and the effect of reducing the filling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention provides a room-and-pillar coal mining method for roof cutting and filling adjacent goafs. In order to make the purpose, technical scheme and effect of the present invention clearer and more definite, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0038] The invention provides a room-and-pillar type coal mining method for roof cutting and filling near the goaf, which comprises the following steps:

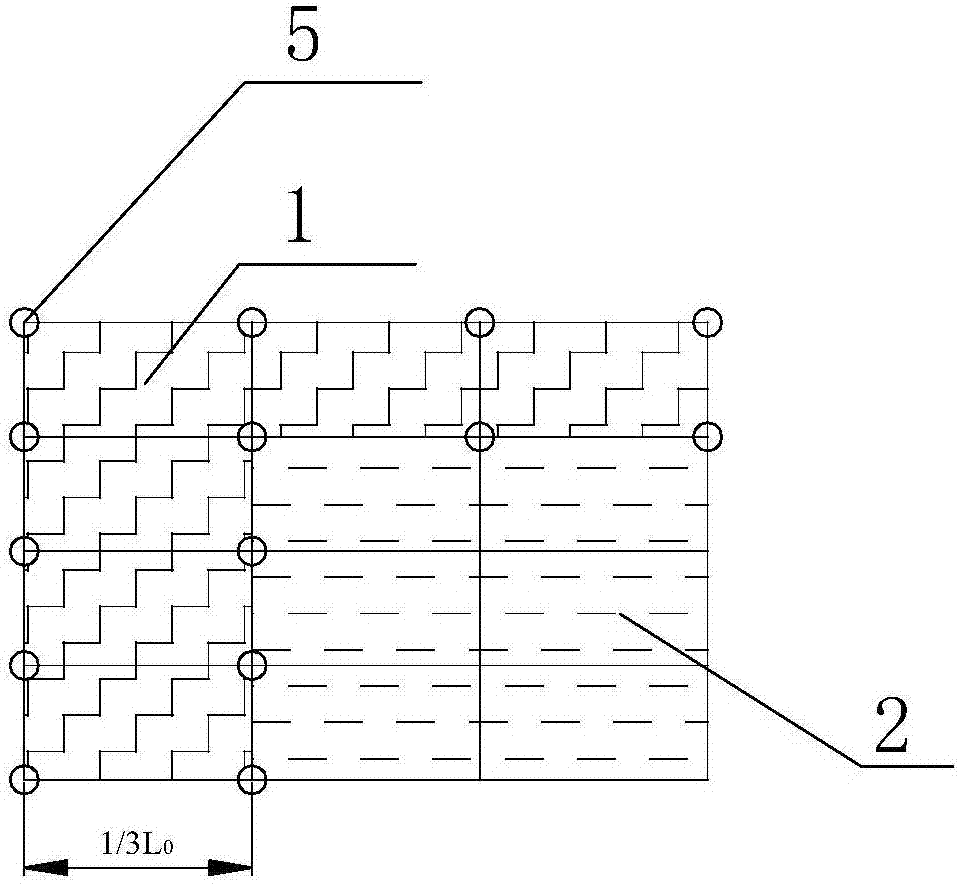

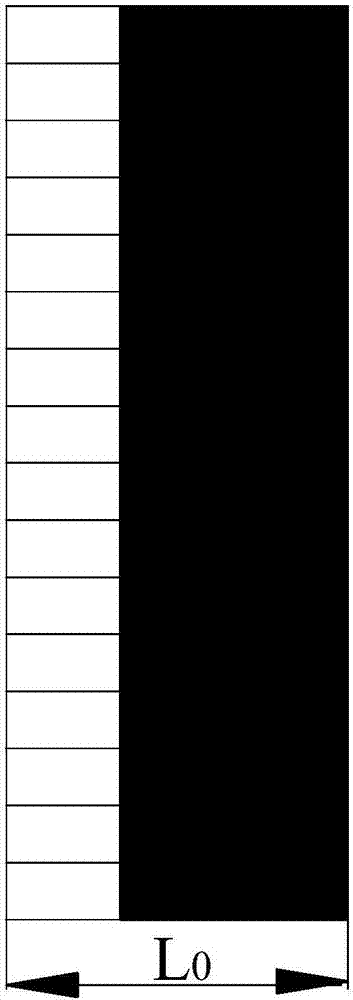

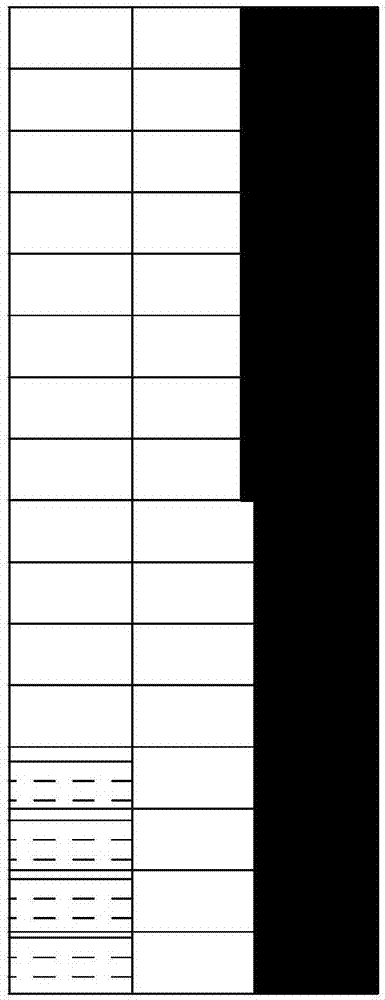

[0039] Step 1. Obtain the first collapse step distance L of the direct top 0 , and divide the area to be mined into several basic units. The size of the basic unit is the initial caving step multiplied by 4 times the width of the cut roof, among which the width of the cut roof is 8m; when the coal mining progress reaches the first Caving step distance L 0 When 1 / 3 of the time, star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com