Gas-bearing coal seams U-shaped well drilling and exploiting method

A coal-measure gas, U-shaped technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the difficulty of coal-measure gas drilling construction, coal-measure gas multi-layer co-production, single target layer To achieve the effect of increasing the affected area and venting area of mining, reducing the number of drilling wells in the region and the total cost of drilling, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

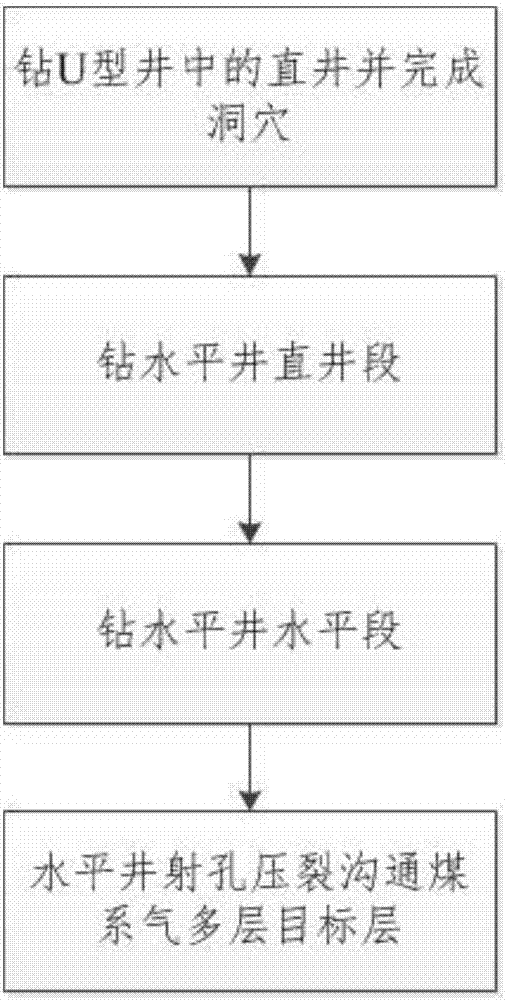

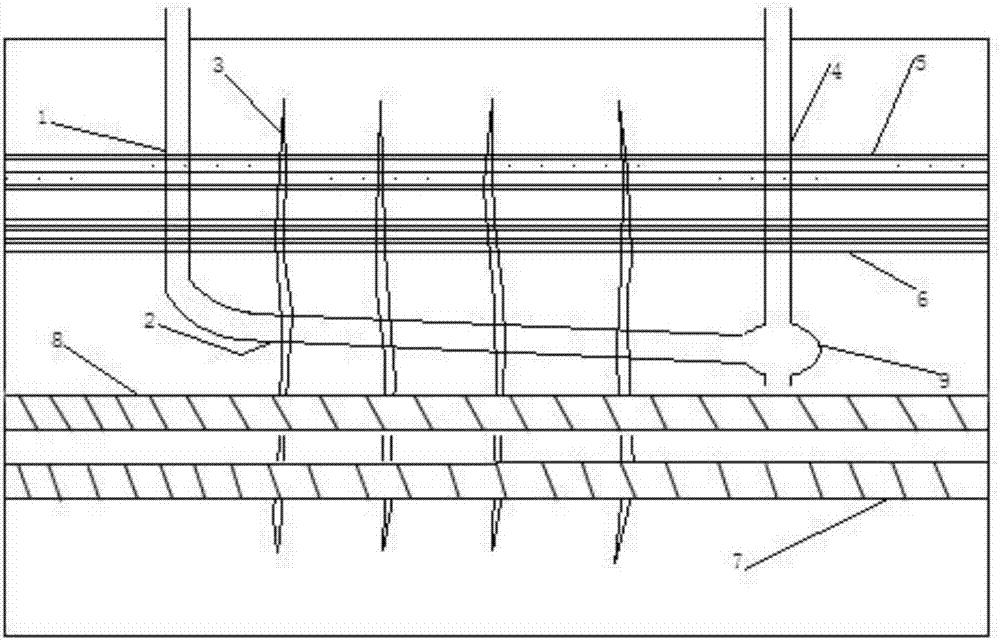

[0033] Such as figure 1 and figure 2 As shown, a U-shaped well drilling and development method for coal-measure gas comprises the following steps:

[0034] ① Drill the vertical well 4 in the U-shaped well and complete the cave 9: pass through the target reservoir, drill the vertical well 4 in the U-shaped well, and complete the cave 9 at the bottom of the wellbore of the vertical well 4, and the cave 9 is located in the non-target reservoir; The target reservoirs are tight sandstone gas layer 5, shale gas layer 6, coalbed methane layer No. 27 and coalbed methane layer No. 18;

[0035] ②Drilling the vertical well section 1 of the horizontal well: through the target reservoir, drill the vertical well section 1 of the horizontal well;

[0036] ③Drilling the horizontal section 2 of the horizontal well: building deflection in the selected non-target reservoir and drilling the horizontal section 2 of the horizontal well. When drilling, the horizontal section 2 of the horizontal w...

Embodiment 2

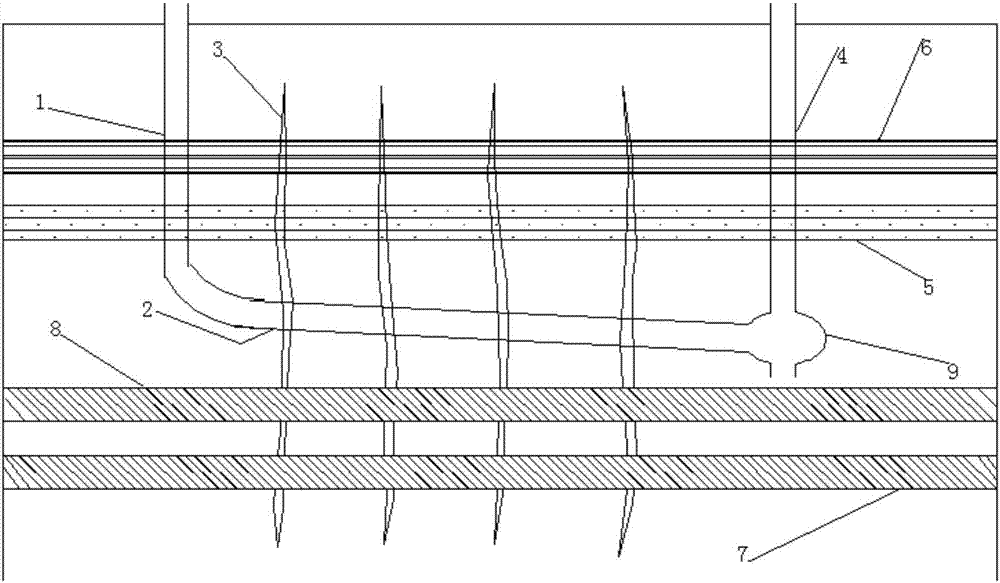

[0039] Such as figure 1 and image 3 As shown, a U-shaped well drilling and development method for coal-measure gas comprises the following steps:

[0040] ① Drill the vertical well 4 in the U-shaped well and complete the cave 9: pass through the target reservoir, drill the vertical well 4 in the U-shaped well, and complete the cave 9 at the bottom of the wellbore of the vertical well 4, and the cave 9 is located in the non-target reservoir; The target reservoirs are tight sandstone gas layer 5, shale gas layer 6, coalbed methane layer No. 27 and coalbed methane layer No. 18;

[0041] ②Drilling the vertical well section 1 of the horizontal well: through the target reservoir, drill the vertical well section 1 of the horizontal well;

[0042] ③Drilling the horizontal section 2 of the horizontal well: building deflection in the selected non-target reservoir and drilling the horizontal section 2 of the horizontal well. When drilling, the horizontal section 2 of the horizontal we...

Embodiment 3

[0045] Such as figure 1 and Figure 4 As shown, a U-shaped well drilling and development method for coal-measure gas comprises the following steps:

[0046] ①Drill the vertical well 4 in the U-shaped well and complete the cave 9: pass through the target reservoir, drill the vertical well 4 in the U-shaped well, and complete the cave 9 at the bottom of the wellbore of the vertical well 4, and the cave 9 is located in the non-target reservoir; The target reservoirs are tight sandstone gas layer 5, shale gas layer 6, coalbed methane layer No. 27 and coalbed methane layer No. 18;

[0047] ②Drilling the vertical well section 1 of the horizontal well: through the target reservoir, drill the vertical well section 1 of the horizontal well;

[0048] ③Drilling the horizontal section 2 of the horizontal well: build up the deflection in the selected non-target reservoir and drill the horizontal section 2 of the horizontal well. When drilling, the horizontal section 2 of the horizontal w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com