Movable photoelectric separation robot for coal and gangue

A photoelectric sorting and robotic technology, applied in sorting and other directions, can solve problems such as difficult medium recovery, environmental pollution, and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

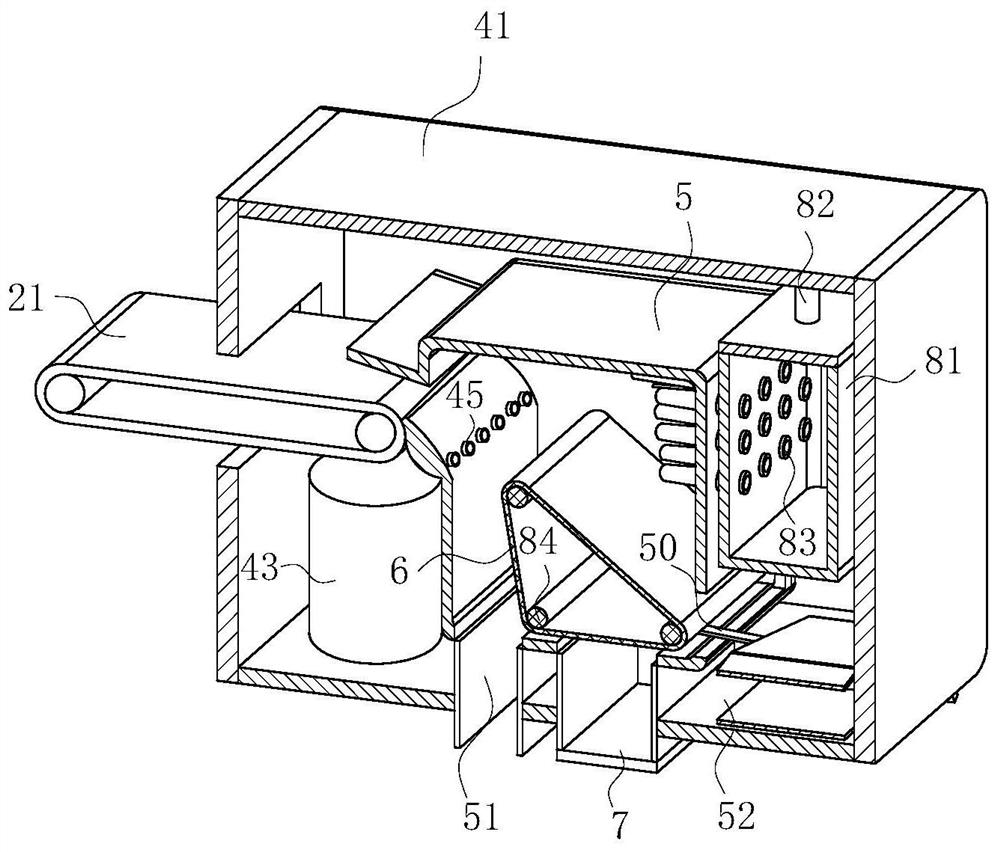

[0065] As an embodiment of the present invention, the separation soft board 6 is rotated and installed in the sorting bin 41 by the rotating column 84, and the separation soft board 6 is connected head to tail, and the cross section of the separation soft board 6 connected end to end is an obtuse triangle structure; the separation soft board 6 is made of mesh-like rubber material; the inclined plane corresponding to the obtuse angle of the separation soft board 6 with an obtuse triangle structure in cross section is connected with the gangue bin 52, and the bottom end of the separation soft board 6 is set There is a material box 7; when working, when the high-pressure airflow rushes out of the pneumatic nozzle 45 and hits the gangue in the process of throwing, the knocked out gangue will fall into the separation soft board 6 whose head and tail are connected with each other and whose cross section is an obtuse triangle structure. On the inclined surface, the rotation of the sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com