Method for conducting goaf partial filling according to roof caving characteristics

A technology for gobs and roofs, which is applied to fillings, mining equipment, earthwork drilling, etc., can solve problems such as difficult control of roof deformation, unsatisfactory filling effects, and single filling forms, so as to reduce filling costs and prevent Chain reaction, the effect of saving filling materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The minable coal seam of a mine is stable, the geological structure is simple, and the Platts coefficient of the coal seam is f=2~4. The dip angle of the coal seam is 2°~10°, with an average of 4°; the thickness of the coal seam is 3.20~3.30m. The immediate roof is 3.8m thick siltstone (unidirectional tensile strength is 6.8MPa, elastic modulus is 20.8MPa), the old roof is fine sandstone (unidirectional tensile strength is 7.98MPa), 6.87m thick, respectively Carbonaceous mudstone, siltstone and conglomerate with a thickness of 0.34m, 5.17m and 5.23m.

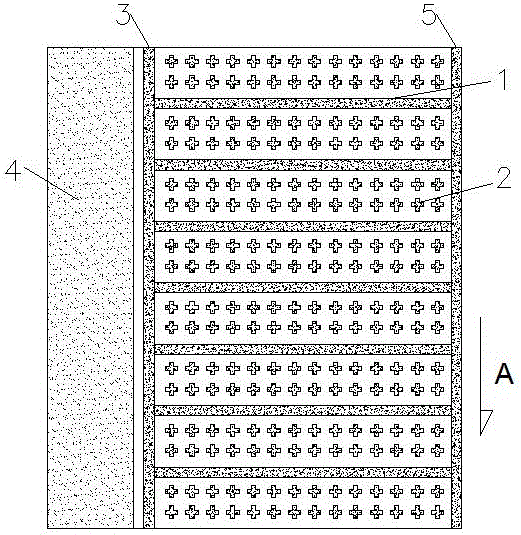

[0037] 1. According to the calculation: the uniform load on the direct roof q=0.095MPa, the initial collapse step of the direct roof L=26.3m;

[0038] 2. Design filling strips perpendicular to the mining direction with a spacing of L 1 =25m, evenly arrange the filling cells between the filling strips;

[0039] 3. Select the gangue-fly ash paste filling material, the proportion is 285kg / m3 for fine gangue 3 , the amount ...

Embodiment 2

[0043] The minable coal seam of a mine is stable, the geological structure is simple, and the Platts coefficient of the coal seam is f=2~4. The dip angle of the coal seam is 2°~10°, with an average of 4°; the thickness of the coal seam is 3.20~3.30m. The immediate roof is 3.8m thick siltstone (unidirectional tensile strength is 6.8MPa, elastic modulus is 20.8MPa), the old roof is fine sandstone (unidirectional tensile strength is 7.98MPa), 6.87m thick, respectively Carbonaceous mudstone, siltstone and conglomerate with thickness of 0.34m, 5.17m and 5.23m.

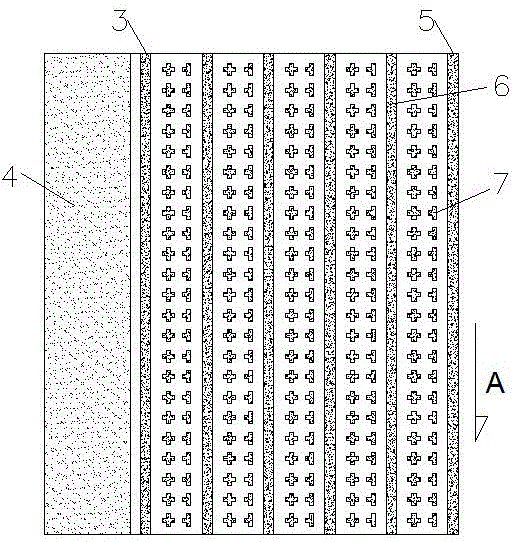

[0044] 1. According to the calculation: the uniform load on the direct roof q=0.095MPa, the initial collapse step of the direct roof L=26.3m;

[0045] 2. Design filling strips parallel to the mining direction, with a spacing of 25m, and evenly arrange filling monomers between the filling strips;

[0046] 3. Choose gangue-waste concrete paste filling material, the ratio is: 0-5mm fine gangue and 10-15mm coarse gangue are b...

Embodiment 3

[0050] The immediate roof of the No. 3 coal seam mined in a coal mine is light gray sandy mudstone and fine-grained sandstone (including two layers of thin coal, with an average thickness of 0.5m), dense massive structure, with an average thickness of 4.40m, mainly in layers, The fractures are not well developed, the compressive strength is 30.3-75.9MPa, with an average of 65.3MPa, and the tensile strength is 1.5MPa.

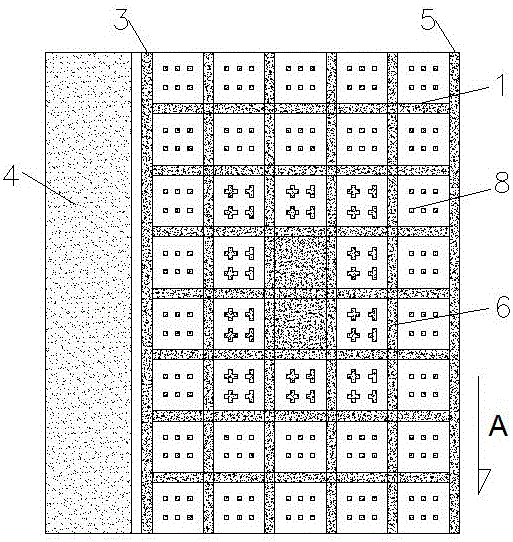

[0051] 1. According to the calculation of the uniform load q=0.946MPa on the direct roof, the initial collapse step distance of the direct roof is L=22m;

[0052] 2. Due to the low strength of the direct roof, two-way filling strips parallel and perpendicular to the mining direction are designed, with a spacing of 22m, and filling monomers are evenly arranged between the filling strips;

[0053] 3. Select the gangue-fly ash paste filling material, the proportion is 285kg / m3 for fine gangue 3 , the content of medium and coarse gangue is 332.5kg / m 3 , the amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com