Dragging tube type filling method of thin coal bed fractured roof

A tube-drag, thin coal seam technology, applied in the direction of filling, earthwork drilling, safety devices, etc., can solve the problems of high filling cost, achieve the effects of improving filling efficiency, reducing pressure, and controlling surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

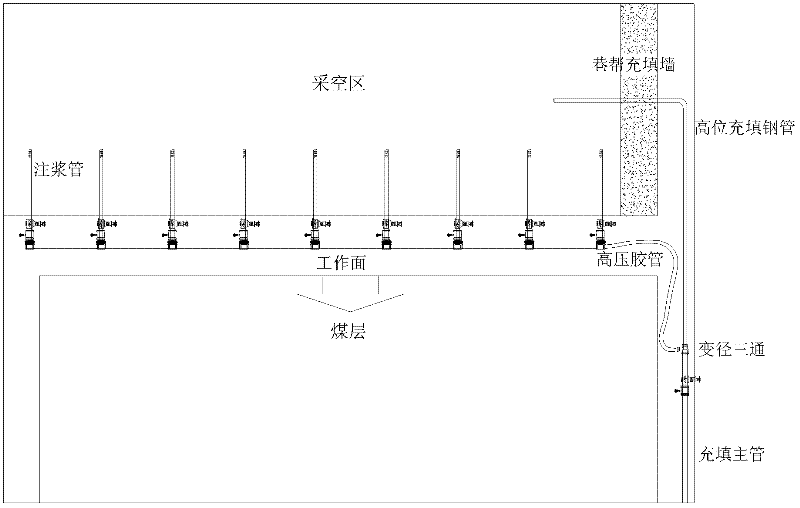

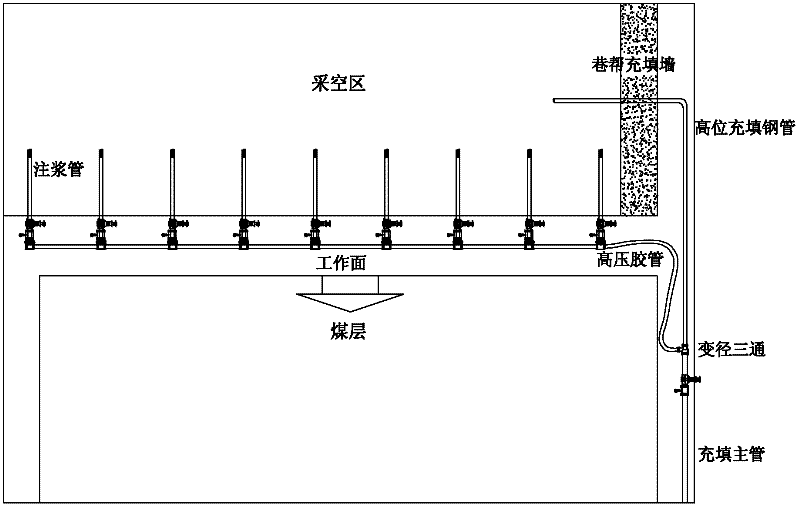

[0019] See attached figure 1 , a thin coal seam dragging pipe filling system, including a filling main pipe, high-level filling steel pipe, high-pressure rubber hose and multiple filling pipes arranged in the trough of the working face. Free choice, the pressure resistance of the high-pressure rubber hose should meet the needs of the filling pressure. The filling pipe can be an ordinary filling flower pipe in the well. On the main pipe, multiple filling pipes are connected in parallel to the high-pressure rubber hose. At the same time, the filling pipes are fixedly connected to the hydraulic support of the working face between the goaf and the coal seam, and move with the movement of the hydraulic support to form a "drag pipe" filling system. , the filling mouth (flower pipe end) of the filling pipe extends into the goaf, and the number of filling pipes is preferably the same as the number of hydraulic supports on the working face, that is, one filling pipe is set on each hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com