Cover rock crack and surface subsidence controlled digging, mining and filling parallel operation coal mining method

A technology of surface subsidence and parallel mining and filling, which is applied in the direction of surface mining, underground mining, filling, etc., can solve the problems of difficult coordination between mining and filling, complex filling system, large filling space, etc., and achieve control of overburden rock cracks and Surface subsidence, good control effect, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

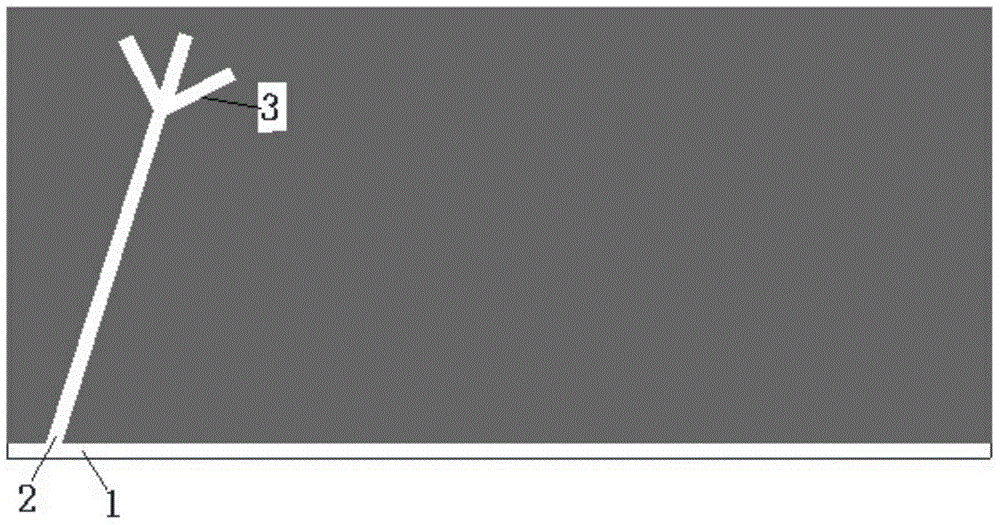

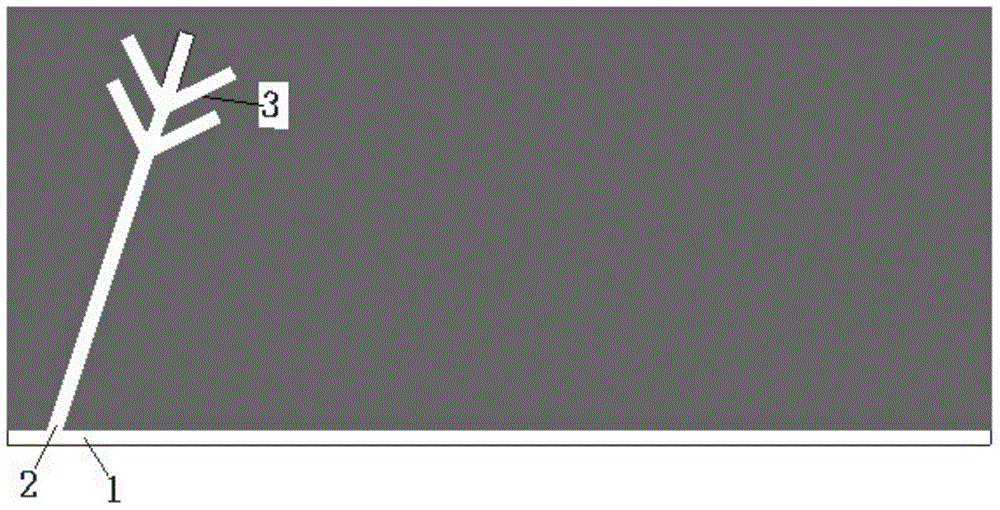

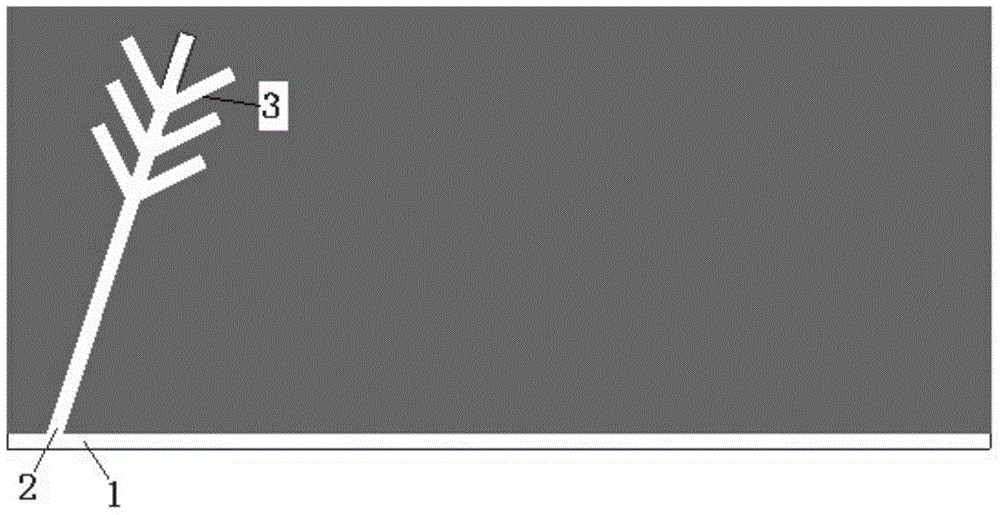

[0037] An embodiment of the present invention is further described below in conjunction with accompanying drawing, the coal mining method of the excavation and filling parallel operation of controlling overburden fissure and surface subsidence of the present invention, concrete steps are as follows:

[0038] a. If figure 1 As shown, a stope transport roadway-1 is arranged along the edge of the stope, and a stope branch roadway-2 is excavated vertically or obliquely from the stope transport roadway-1; a stope transport roadway-1 can also be directly arranged in the middle of the stope 1. Arrange stope branch lanes 1 and 2 on the left and right sides.

[0039] b. Then carry out multiple double-wing mining tunnels to the coal body of the stope branch roadway 12 from the inside to the outside, and the angle a between the vertical direction of the stope branch roadway 2 and the double-wing type mining tunnel 3 should meet the working turning requirements of the coal mining equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com