Structure under-covering gob area filling expansion bag and construction method

A construction method and expansion bag technology, which is applied in filling, mining equipment, earth cube drilling and mining, etc., can solve problems such as ineffective governance, and achieve the effects of low cost, flexible and convenient use, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

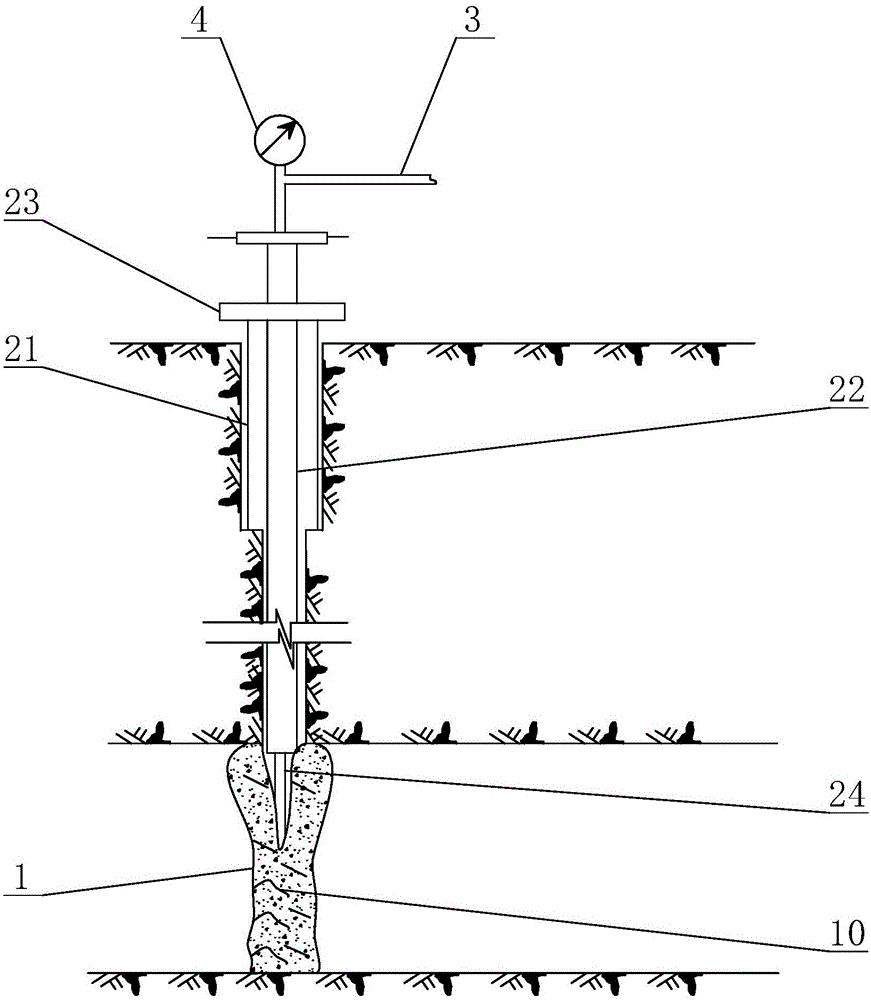

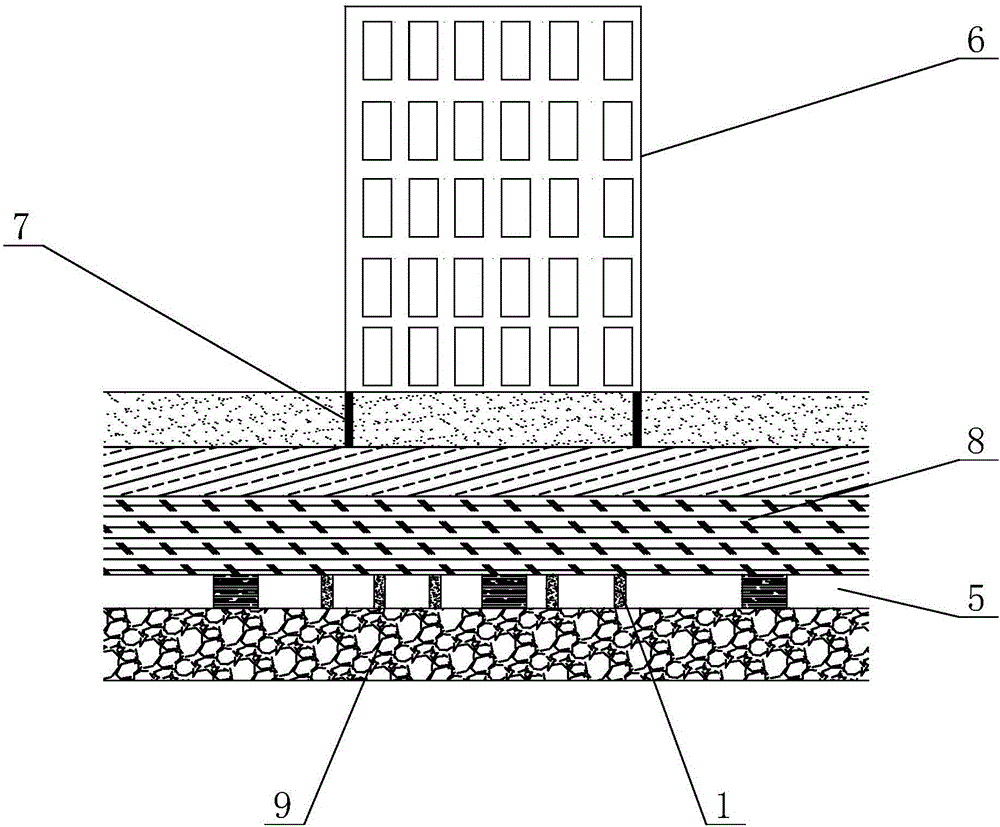

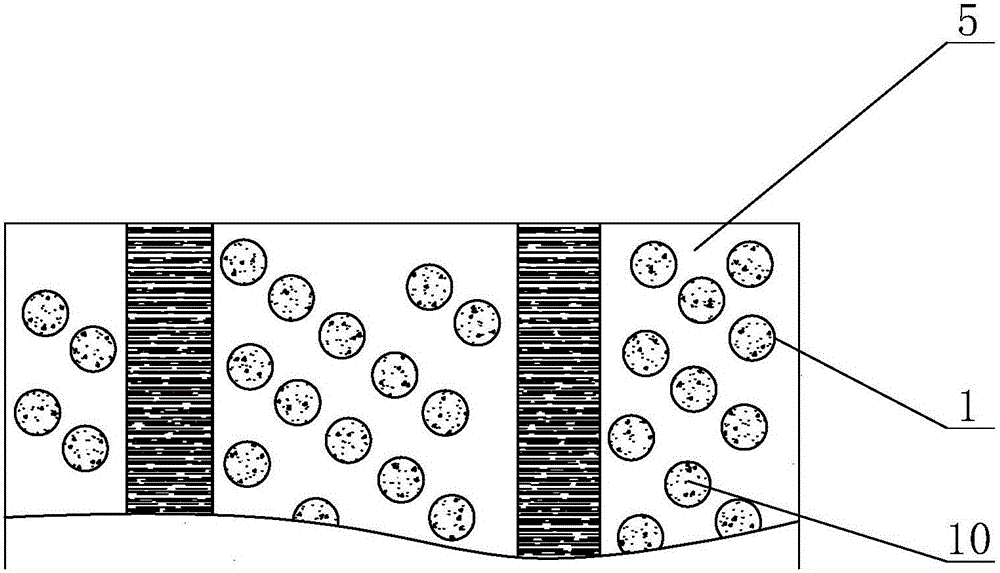

Method used

Image

Examples

Embodiment 1

[0043] Take a construction site in Shanxi Province as an example, with an area of 2102.47 square kilometers. The topography of the area is complex, with mountains as the main landform and the rest as hills and plains. The underground is the Bishui coal field, and the coal-bearing strata are the Carboniferous-Permian Taiyuan Formation and Shanxi Formation; the coal seams are well developed, and the main recoverable coal seams are No. 8, No. 9, No. 12 and No. 15 coal seams. The average thickness of the coal seam is 1.01-5.20 meters, and the 15th coal seam of the Taiyuan Formation is the thickest, reaching 10-11.26 meters. Coal is mainly anthracite. The existing buildings in the J1-8, 9, 10, and 11 buildings that have been built have "eight" cracks on the walls, and after several consecutive heavy rains, it was found that the J1-8 and 11 buildings had uneven settlement. The settlement of the side unit is serious, and the maximum settlement of the two buildings is 40mm and 26m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com