Method of local filling to control surface subsidence in gob

It is a technology for surface subsidence and goaf, which is applied in the direction of filling, mining equipment, earthwork drilling and mining, etc. It can solve problems such as difficulty in the location and amount of abscission, has not been widely used, and application restrictions. The method is simple, The effect of controlling surface subsidence and reducing filling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

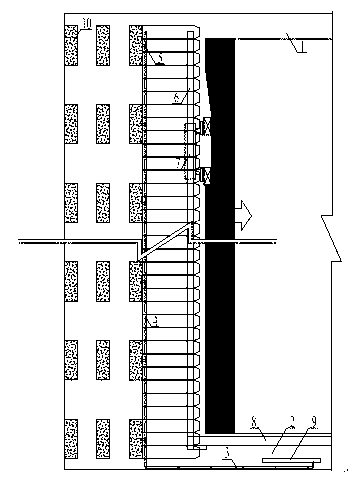

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] The method for local filling of goaf of the present invention to control surface subsidence:

[0021] a. First, arrange the concrete conveying pipeline 3 in the transport levelway 2 of the working face, install the concrete conveying pump on the equipment train 9 of the underground working face at the same time, and hang the filling pipeline connected with the concrete conveying pipeline 3 on the tail beam of the hydraulic support of the working face 4. Multiple filling areas are set at intervals between the hydraulic supports at the upper and lower ends of the working surface, and a discharge port 5 is set at the position of the filling pipe 4 corresponding to each filling area;

[0022] b. From the cutting hole, as the coal shearer starts to cut coal and moves to the hydraulic support of the working face, the metal mesh is suspended at intervals on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com