Interval skip-mining type filling coal mining method

A technology of filling coal mining and coal pillars, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of high material consumption, high labor intensity, high filling rate, etc., to control surface subsidence, save filling costs, and reduce filling material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention proposes a filling coal mining method with skip mining at intervals. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be further clearly and completely described below in conjunction with specific embodiments.

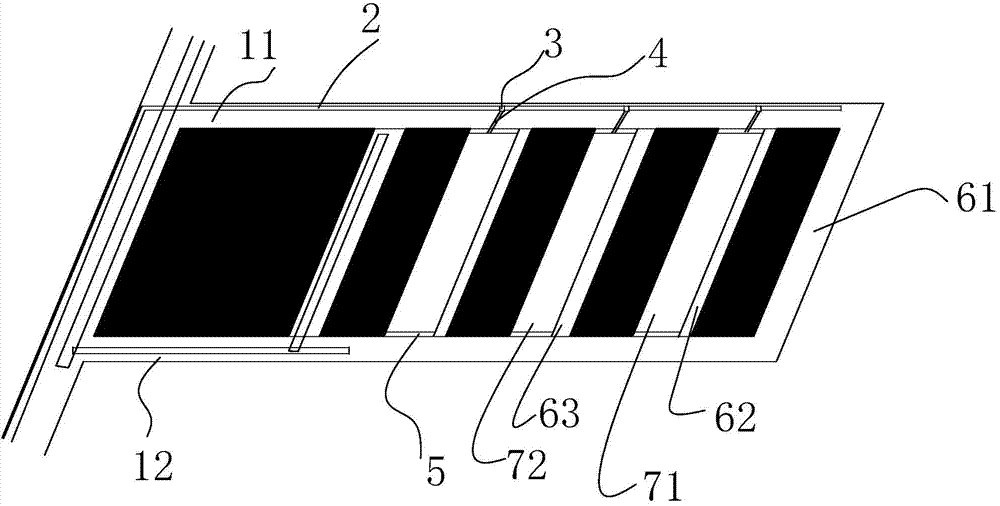

[0022] Such as figure 1 As shown, taking a certain coal mine as an example, the filling coal mining system is first arranged. In the present invention, the filling coal mining system includes a filling main pipe 2, a high-pressure rubber hose and a plurality of filling branch pipes 4 arranged in the section roadway of the working face. The reducing tee 3 is arranged, and the reducing tee 3 is arranged in the middle of the section aisle 11 according to the arrangement of the filling surface. The high-pressure rubber hose is connected to the filling main pipe 2 through the reducing tee 3, and multiple filling branch pipes 4 are connected in parallel. On the high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com