Method for conducting goaf partial filling according to ground surface subsidence characteristics

A technology for surface subsidence and goaf, which is applied to filling materials, mining equipment, earthwork drilling and mining, etc. It can solve problems such as difficult control of roof deformation, unsatisfactory filling effect, and single filling form, so as to reduce filling costs, Effect of preventing chain reaction and saving filling materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A coal mine exploits coal seams 5-6 of Group D, with a thickness of 2-2.2m, an average mining depth of 570m, a coal seam inclination of 15°, a loose layer thickness of about 300m, and a bedrock thickness of 270m. 820m long, inclined 140m long;

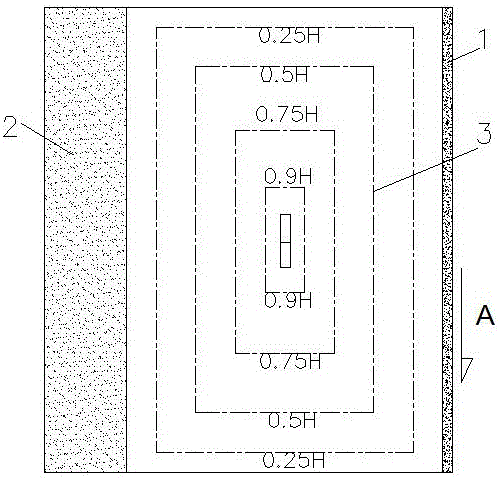

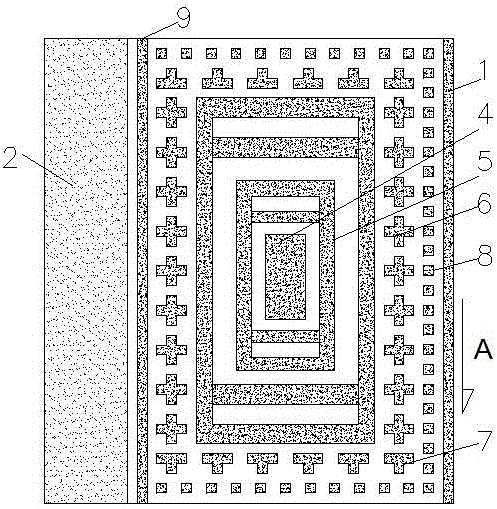

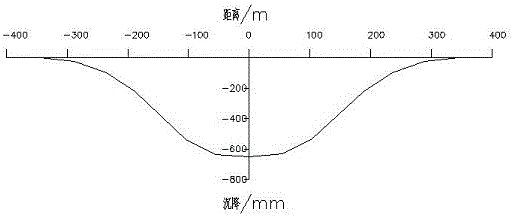

[0039] 1. According to the geological conditions of the coal mine, use the elastic plate theory to predict the surface subsidence, such as image 3 , 4 , calculate the maximum subsidence H=660mm, and draw the subsidence contour line of the subsidence surface;

[0040] 2. According to the surface subsidence contour map, design the position of the filling body; the specific method: carry out full filling within the central area where the subsidence amount is equal to 600-660mm, and control the subsidence center, where the direction is 150m and the inclination is 10m; in the subsidence amount Arrange several layers of strip filling bodies within the range of 330-600mm to control the large area of subsidence, including 150m on b...

Embodiment 2

[0046] The buried depth of an iron ore body is 136-679m, the shape of the ore body is a "crescent" protruding southward on the plane, and the geological reserves are 7.90971×10 7 t, Mining by segmental caving mining method without pillars, the designed annual output is 1.8×10 6 t, the service life is 35a. Due to the poor integrity of the overlying rocks and the gravel layer of nearly 100 meters, the surface is strongly affected by mining for only one year. Mining subsidence causes violent movement of rock formations and ground surfaces, seriously affecting safe production. Therefore, MSDAS-GIS is used to predict the surface mining subsidence of this iron ore, and it is partially filled and mined.

[0047] 1. According to the geological conditions of the iron ore, the MSDAS-GIS prediction system based on GIS and probability integration method is used to predict the surface subsidence, and it is obtained that the maximum subsidence displacement occurs in the center of the stop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com