Method for controlling ground surface subsidence through coal mining filling

A technology for surface subsidence and coal mining face, which is applied in the direction of filling, ground mining, mining equipment, etc., which can solve the problems of large amount of waste rock filling and high cost, and achieve the effects of reducing filling process, increasing propulsion speed and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

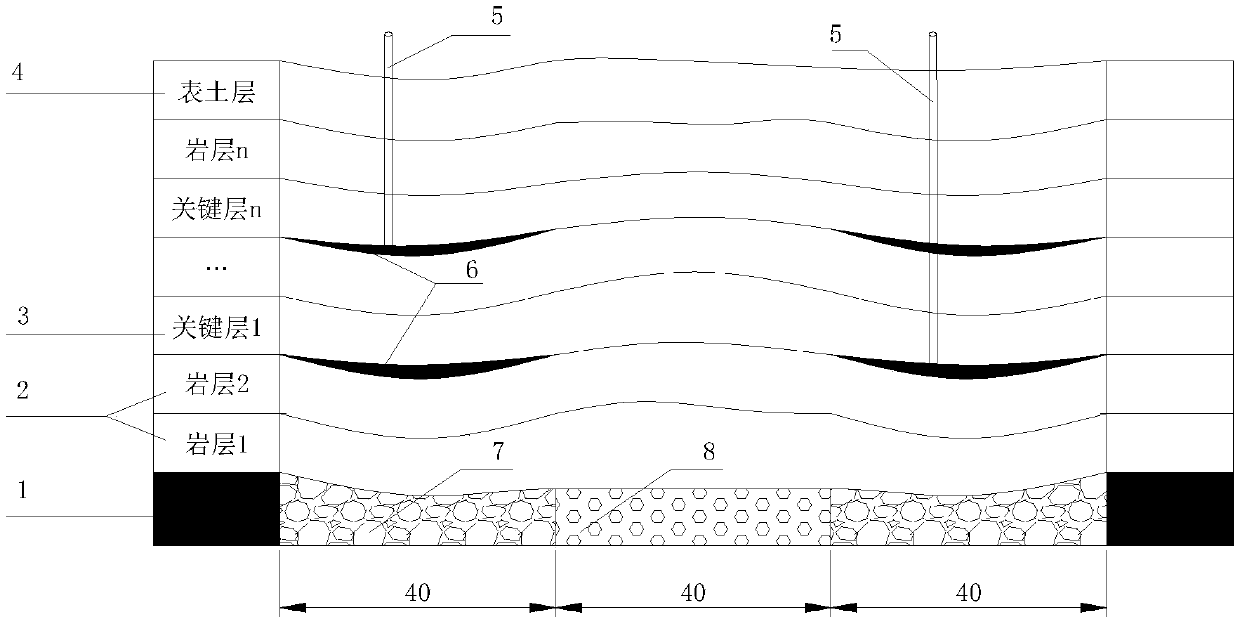

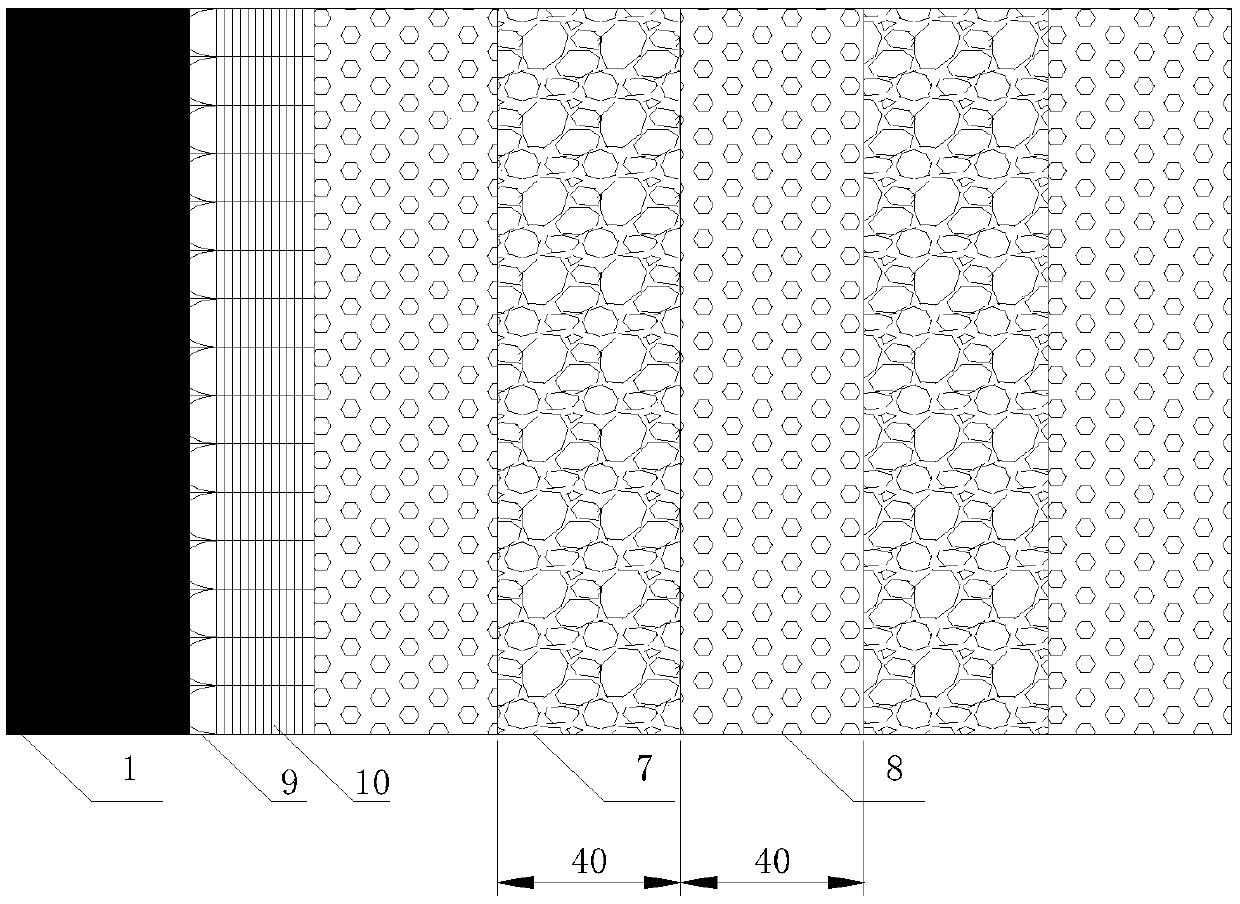

[0039] A method of coal mining filling to control surface subsidence, such as figure 1 and figure 2 As shown, behind the coal seam 1 in front is the comprehensive mechanized gangue filling coal mining face 9, the coal mining face 9 is arranged with filling hydraulic supports 10, the gangue filling strips 8 are arranged at intervals of 40 m, and the gangue filling strips 8 are arranged at intervals of 40 m. The roof is managed by the caving method, and the collapsed roof strip 7 is formed after it collapses.

[0040] The coal mining face 9 of comprehensive mechanized gangue filling is advanced every 40m for filling operations, and a gangue filling strip 8 with a width of 40m along the advancing direction is constructed. The gangue filling strip 8 and the collapsed roof strip 7 are arranged at intervals. The roof strip 7 also has a width of 40 m.

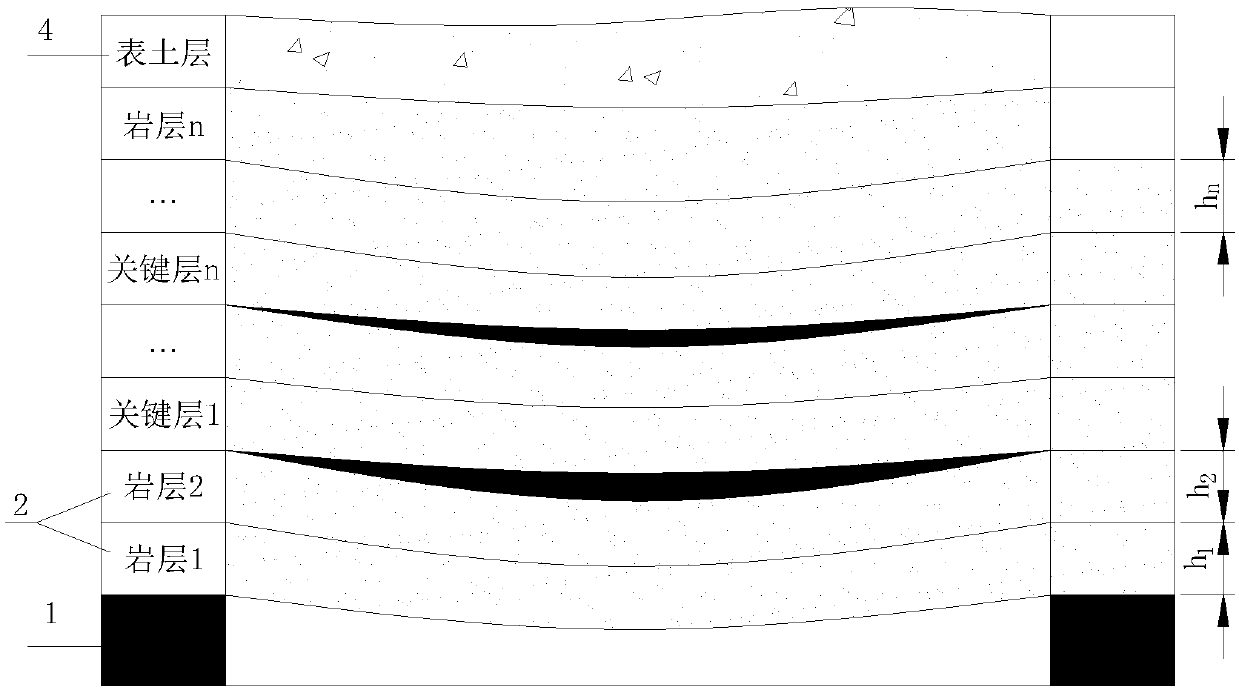

[0041] Such as image 3 shown, according to the formula Calculate the rock formation load, where, E i 、h i and gamma i Resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com