Device and method for testing compression performance of filling powder under dynamic-static force

A testing device and force technology, applied in the direction of applying stable tension/compression to test material strength, measuring device, strength characteristics, etc., can solve the problems of not considering the influence of dynamic load compression characteristics, single function, etc., to maintain air The effect of stable area, simple operation, and inhibition of deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

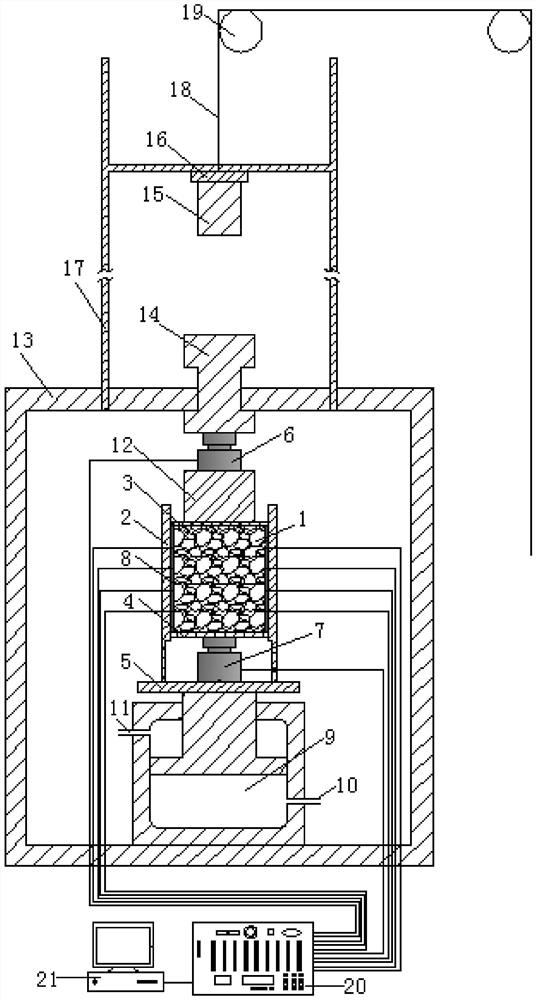

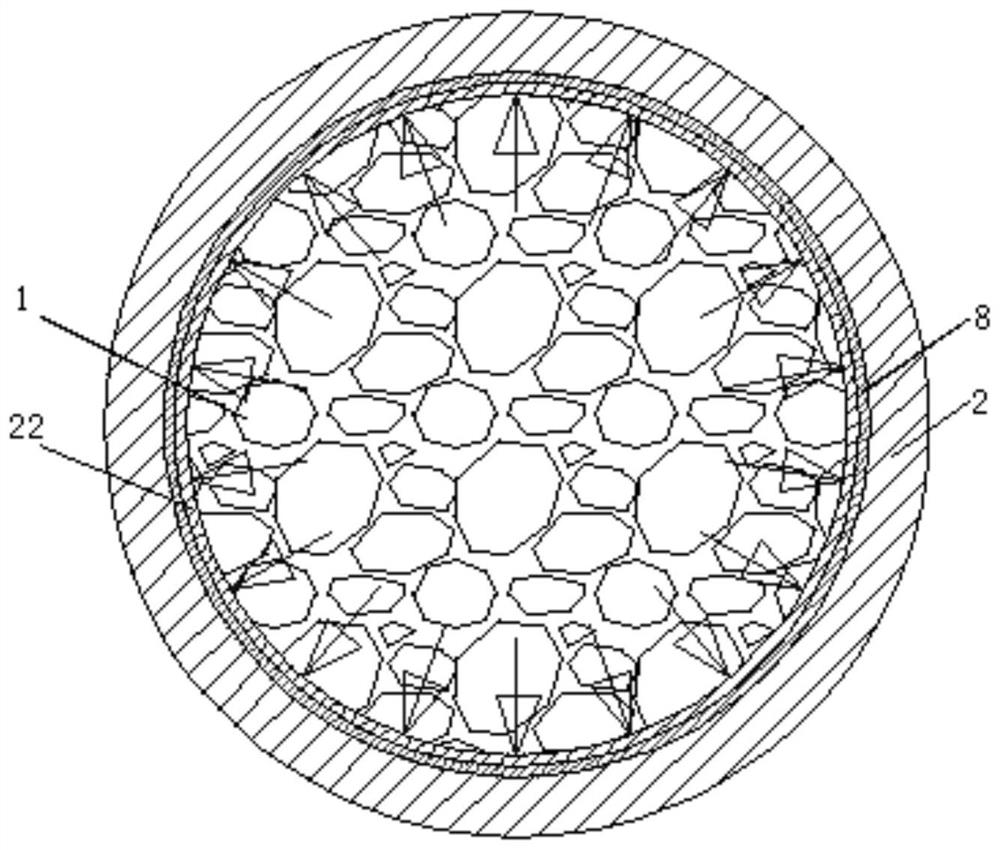

[0041] Such as figure 1 and figure 2 As shown, the test device for the compression performance of the filling powder under dynamic-static force includes a hydraulic cylinder 9, a steel structure frame 13, a lifting platform 5, and a loading plug 12; the bottom end of the steel structure steel frame is arranged on the ground A hydraulic cylinder 9 is installed on the upper surface of the bottom end of the steel structure frame 13, and the loading and unloading of the test bulk 1 is realized through the pressurized oil inlet 10 and the pressure relief oil inlet 11 of the hydraulic cylinder 9, and the piston rod of the hydraulic cylinder 9 extends The end of the cylinder part is provided with a lifting platform 5, and the upper surface of the lifting platform 5 is provided with a cylindrical device 2 and a first load sensor 7, and the first load sensor 7 is located in the inner cavity of the cylindrical device 2, and the cylindrical device 2 is connected to the The input end of...

Embodiment 2

[0055] The difference between embodiment 2 and embodiment 1 is that embodiment 2 is a dynamic impact test.

[0056] The test method for the compression performance of filling bulk under dynamic impact force includes the following steps:

[0057] Considering the influence of dynamic impact force on the compression performance of test bulk 1, the influence of different magnitudes of dynamic impact force on the compression performance of test bulk 1 under different bearing pressures was studied.

[0058] Step 1. Put the hydraulic cylinder 9 into the bottom of the steel structure frame 13, place the cylinder on the lifting platform 5 of the hydraulic cylinder 9, and ensure that the cylinder is aligned with the axial centerline of the lifting platform 5; place the first load sensor 7 and the bottom plate 4 are put into the cylinder in turn, and the bottom plate 4 is installed above the first load sensor 7, and the bottom plate 4 is adjusted to be horizontal by observing the four eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com