Bag-type delamination grouting material for controlling surface subsidence, its preparation and grouting method

A grouting material and surface subsidence technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problem of difficulty in grasping the location and timing of grouting in the separated layer, adverse effects of the working face environment, and weak cementation ability of fly ash, etc. problems, to achieve the effect of flexible control of grouting time, shortening of setting time and good expansibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

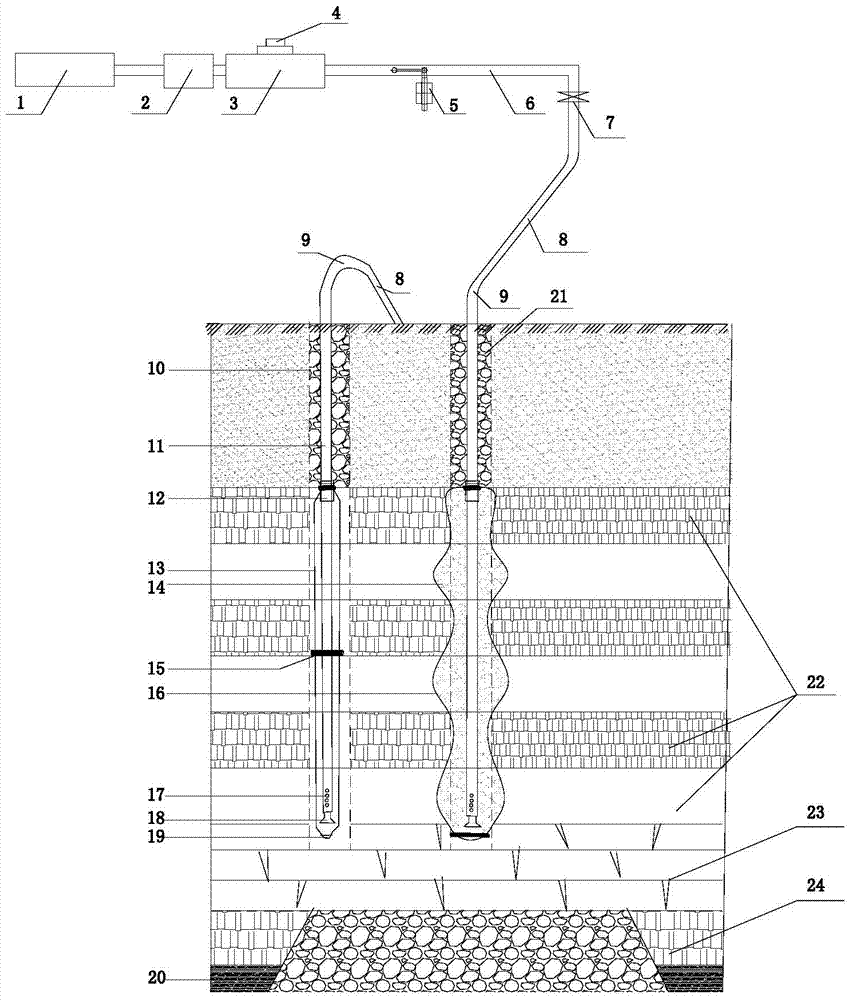

Method used

Image

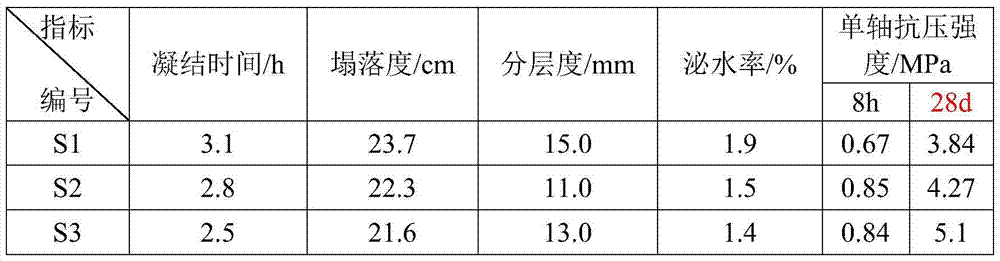

Examples

Embodiment 1

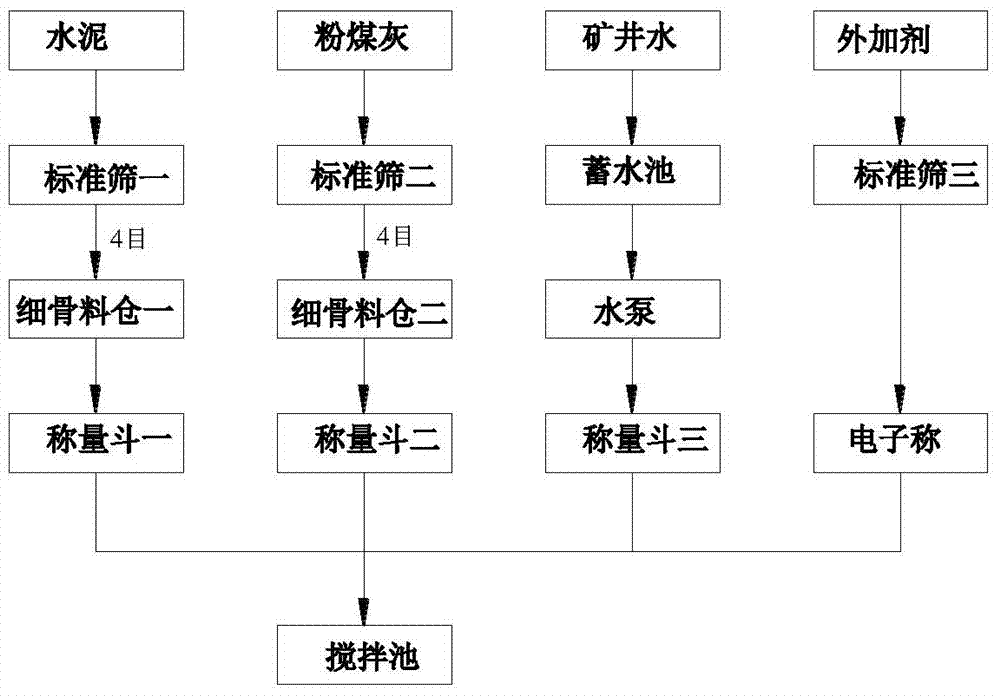

[0037] A bag-type delamination grouting material to control surface subsidence, per m 3The bag-type delamination grouting material is composed of the following main ingredients and water, the main ingredients are composed of cement, fly ash and additives, fly ash 490Kg, cement 580Kg, water 450Kg, the added Agent is bentonite and early-strength agent, and described bentonite and early-strength agent are respectively 21Kg, and in the present embodiment, described fly ash is three grades of fly ash of coal mine power plant, and its performance accords with " the fly ash that is used for cement concrete "National Standard" (GB1596-1991); the cement is ordinary Portland cement of 42.5 grades; the bentonite is natural sodium bentonite; the early strength agent is a sulphoaluminate quick-setting agent, and its main component aluminum sulfate and sodium aluminate, and the water is purified mine drainage.

[0038] The preparation method of the bag-type delamination grouting material f...

Embodiment 2

[0054] A bag-type delamination grouting material to control surface subsidence, per m 3 The bag-type delamination grouting material is composed of the following main ingredients and water, the main ingredients are composed of cement, fly ash and additives, fly ash 522Kg, cement 580Kg, water 406Kg, the added Agent is bentonite and early-strength agent, and described bentonite and early-strength agent are 31.5Kg and 21Kg respectively, and in the present embodiment, described fly ash is three-grade fly ash of coal mine power plant, and its performance accords with " powder for cement concrete Coal ash national standard "(GB1596-1991) regulation; Described cement is the ordinary portland cement of 42.5 grades; Described bentonite is natural sodium base bentonite; Described early strength agent is sulphoaluminate quick-setting agent, and its The main components are aluminum sulfate and sodium aluminate, and the water is purified mine drainage.

[0055] The preparation method of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com