Supramolecular polymer clean fracturing fluid resistant to high temperature of 170 DEG C

A technology of supramolecular polymers and clean fracturing fluids, applied in drilling compositions, chemical instruments and methods, etc., can solve unsatisfactory reservoir stimulation effects, reservoir residue blockage damage, difficult fractures and Suspension of sand and other issues to achieve the effect of improving the pumpability of the liquid, increasing the productivity of the reservoir, and reducing the damage of the liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

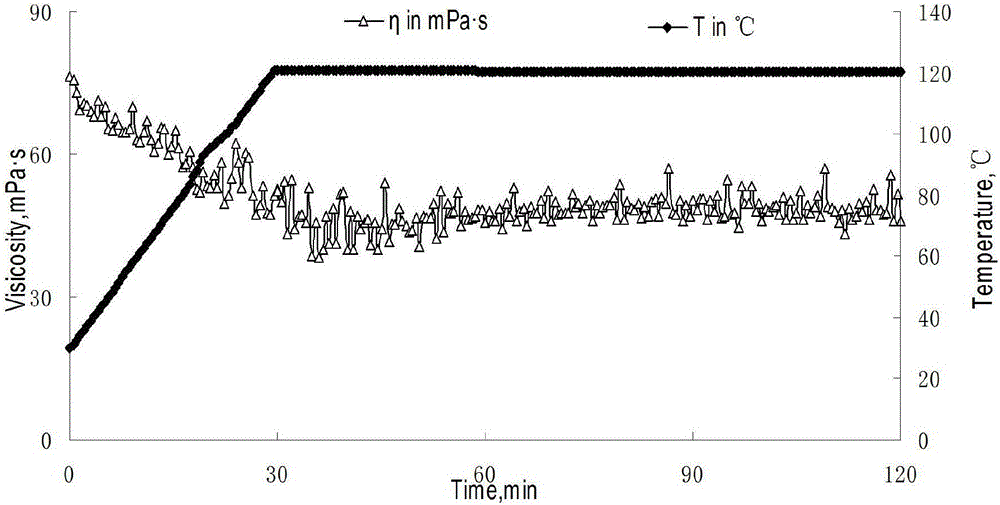

[0058] The formulation of supramolecular polymer clean fracturing fluid resistant to 120℃ and its temperature and shear resistance performance evaluation:

[0059] The supramolecular polymer clean fracturing fluid components are as follows by weight percentage: 0.38% thickener for clean fracturing fluid, 0.1% metal ion chelating agent, 0.3% viscosity synergist, 0.25% structure enhancer, oxygen scavenger 0.1%, clay stabilizer 1%, and the balance is clear water.

[0060] Use RS6000 high temperature rheometer in 170s -1 , under the condition of 120 ℃, the supramolecular polymer clean fracturing fluid was tested for temperature resistance and shear resistance for 120 minutes, and the test curve is as follows figure 1 shown.

[0061] From the viscosity-time curve of the fracturing fluid at 120°C, it can be seen that the viscosity of the fracturing fluid of this formula is always greater than 30mPa·s after the temperature stabilizes, and there is a dynamic equilibrium, which shows...

Embodiment 2

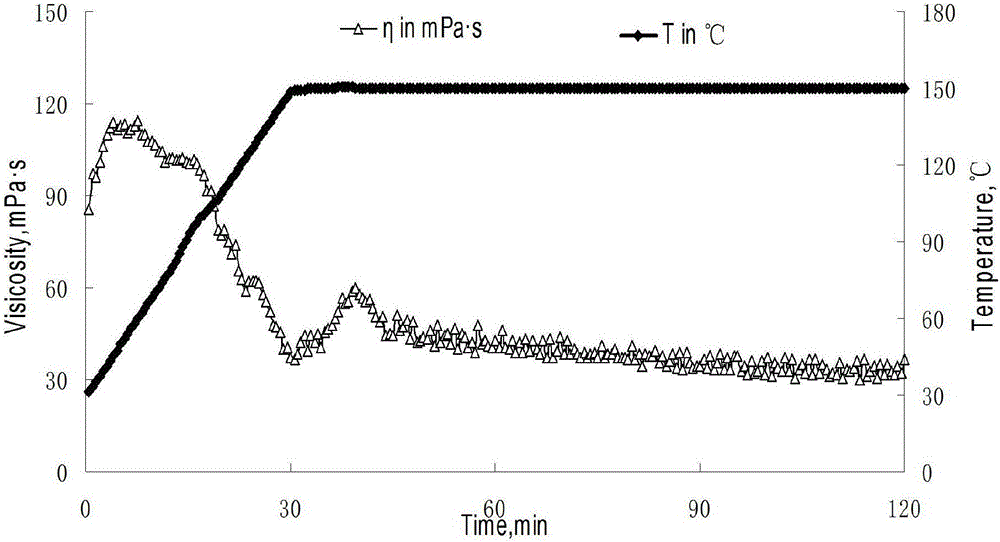

[0063] The formulation of supramolecular polymer clean fracturing fluid resistant to 150℃ and its temperature and shear resistance performance evaluation:

[0064] The supramolecular polymer clean fracturing fluid components are as follows by weight percentage: 0.45% thickener for clean fracturing fluid, 0.2% metal ion chelating agent, 0.4% viscosity synergist, 0.3% structural enhancer, oxygen scavenger 0.2%, clay stabilizer 1%, and the balance is clear water.

[0065] Use RS6000 high temperature rheometer in 170s -1 , under the condition of 150°C, the supramolecular polymer clean fracturing fluid was tested for temperature resistance and shear resistance for 120 minutes, and the test curve is as follows figure 2 shown.

[0066] From the viscosity-time curve of fracturing fluid at 150℃, it can be seen that in 170s -1 In the case of continuous shearing, the viscosity of the fracturing fluid of this formulation first decreases, then increases, then decreases, and finally rea...

Embodiment 3

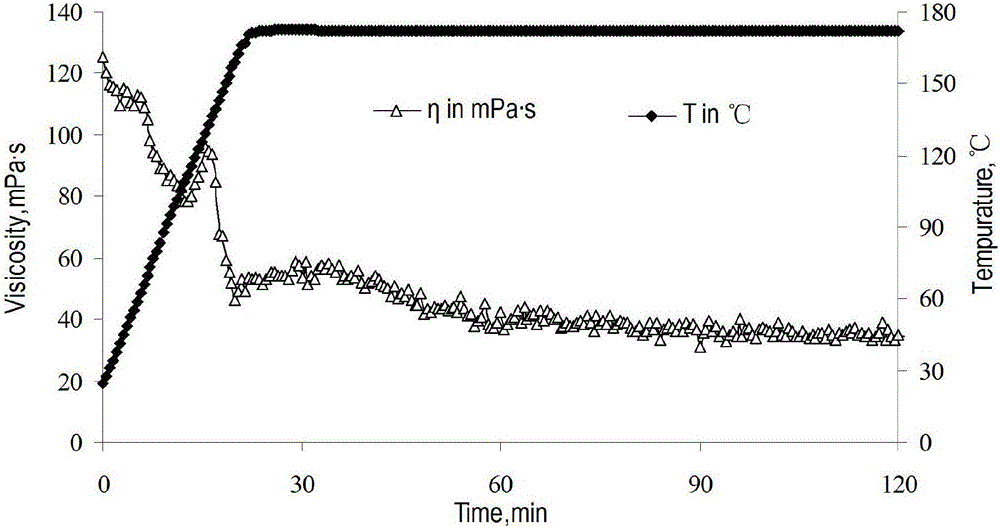

[0068] The formulation of supramolecular polymer clean fracturing fluid resistant to 170℃ and its temperature and shear resistance performance evaluation:

[0069] The supramolecular polymer clean fracturing fluid components are as follows by weight percentage: 0.5% thickener for clean fracturing fluid, 0.2% metal ion chelating agent, 0.5% viscosity synergist, 0.4% structural enhancer, oxygen scavenger 0.2%, clay stabilizer 1%, and the balance is clear water.

[0070] Use RS6000 high temperature rheometer in 170s -1 , under the condition of 170°C, the supramolecular polymer clean fracturing fluid was tested for temperature resistance and shear resistance for 120 minutes, and the test curve is as follows image 3 shown.

[0071] From the viscosity-time curve of the fracturing fluid at 170°C, it can be seen that the viscosity change trend of the fracturing fluid of this formulation is similar to that of the fracturing fluid formulated at 170°C. With the optimization of additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com