Energy storage device for electric operating mechanism

A technology of electric operating mechanism and energy storage device, which is applied to the power device inside the switch, etc., to achieve the effect of saving time and effort, saving cost and strong applicability of installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

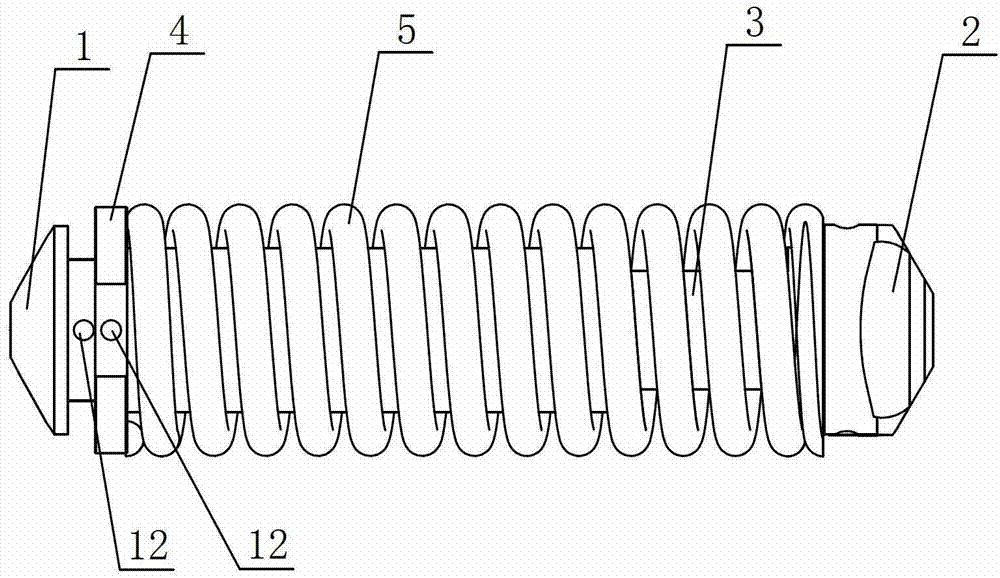

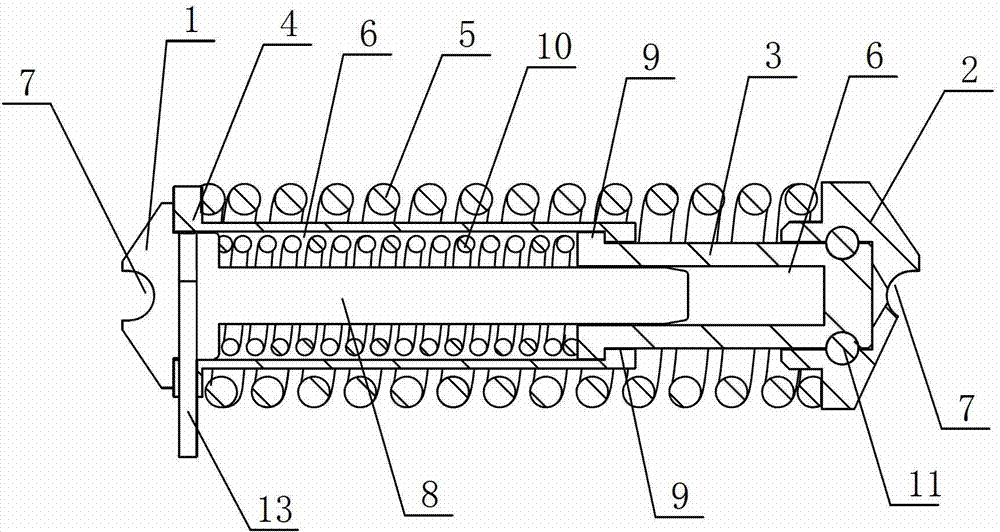

[0024] see figure 1 and figure 2 As shown, in this embodiment, an energy storage device for an electric operating mechanism includes a first collet 1, a second collet 2, an inner mounting sleeve 3, an outer mounting sleeve 4, an outer energy storage spring 5 and The inner energy storage spring 10, the outer ends of the first collet 1 and the second collet 2 are opened to facilitate fixing the entire energy storage device on the electric operating mechanism and run through the arc-shaped installation groove 7 of the entire collet, Both the inner mounting sleeve 3 and the outer mounting sleeve 4 have an accommodating cavity 6 for accommodating an energy storage spring, and an outer energy storage spring 5 is arranged between the outer mounting sleeve 4 and the second collet 2, after assembly One end of the outer energy storage spring 5 abuts against the inner wall of the second collet 2, and the other end abuts against the inner wall of the outer mounting sleeve 4, and the fir...

Embodiment 2

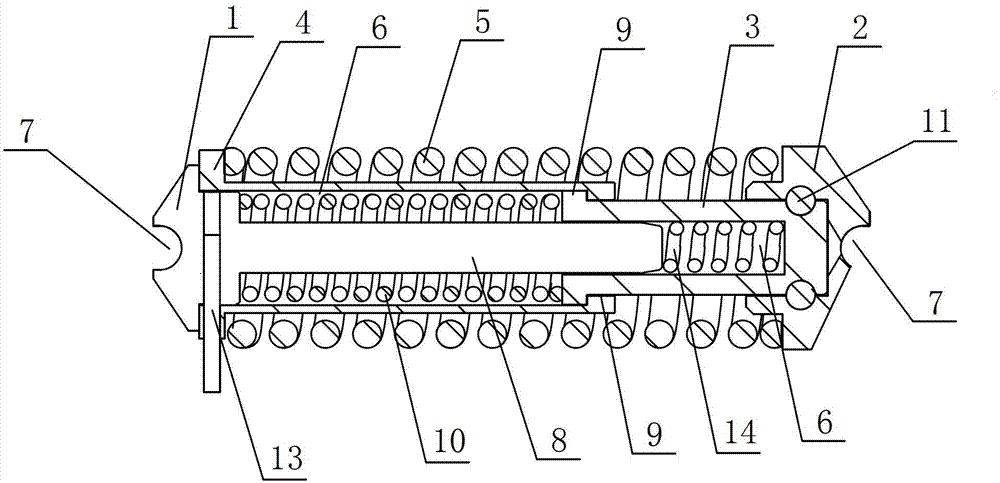

[0030] see figure 1 and image 3 As shown, this embodiment is based on the first embodiment, and when the accommodating cavity 6 of the inner mounting sleeve 3 has a sufficiently large stroke, an auxiliary energy storage spring is arranged in the accommodating cavity 6 of the inner mounting sleeve 3 14. One end of the auxiliary energy storage spring 14 abuts against the bottom of the accommodating chamber 6 of the inner mounting sleeve 3, and the other end abuts against the end of the guide rod 8, and relies on the outer energy storage spring 5 and the inner energy storage spring when storing energy. 10 and the auxiliary energy storage spring 14 are compressed simultaneously to store energy, so as to further reduce the volume of the entire energy storage device.

[0031] When working, the electric operating mechanism compresses the outer energy storage spring 5 and the inner energy storage spring 10 by compressing the installation slots 7 at both ends of the first collet 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com