Dead-weight pressing furnace door adopting rollers

A technology of rollers and furnace doors, which is applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of inability to adjust the sealing pressure of the furnace door, cannot be used repeatedly, and the workload of repairing is large, so as to achieve simple and time-saving installation, and two The effect of convenient maintenance and simple component configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

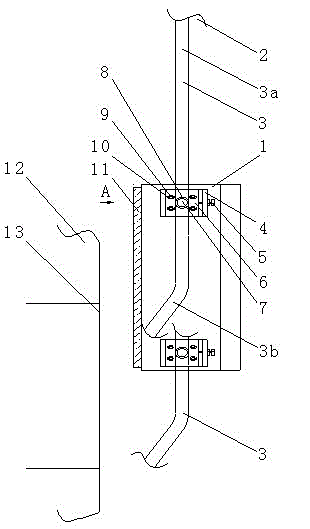

[0008] refer to figure 1 As shown, the self-weight pressing furnace door of the present invention is composed of a trolley, two hydraulic cylinders, a trolley door post, an outer sliding door frame, an inner layer sliding door frame, a sprocket wheel 8 and a roller chain, and the furnace door body 1 is fixed with Furnace door lining 11, adjusting screw 5 is installed on the positioning plate 4, and is fixed on the side of the furnace door body 1, the adjusting plate 6 has a long waist-shaped through-hole adjusting hole 10 for adjusting its installation position, and is fixed with a fulcrum 7. A sprocket 8 is installed on the support shaft 7, and the fixing screw 9 penetrates the adjusting hole 10 of the adjusting plate 6, and the adjusting plate 6 is fixedly installed on the positioning plate 4, and the adjusting plate 6 is positioned against the adjusting screw 5. By adjusting the adjusting screw 5 , the position of the adjusting plate 6 on the positioning plate 4 can be adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com