Patents

Literature

48results about How to "Adjustable clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

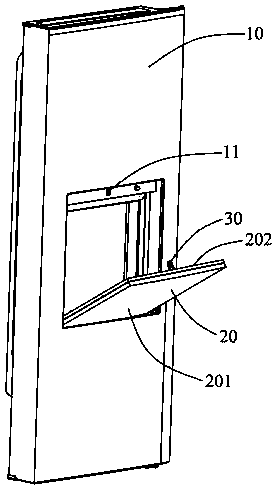

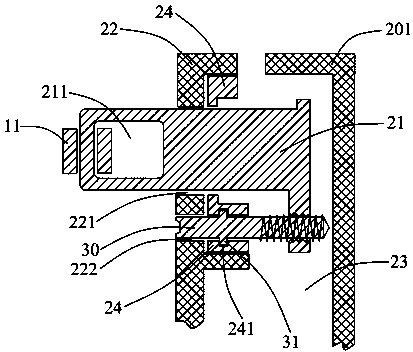

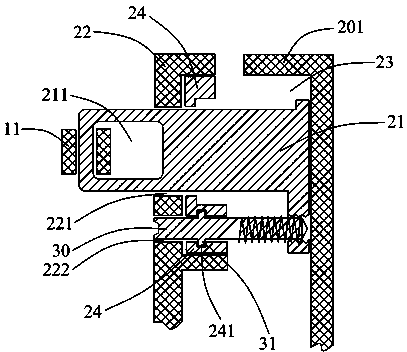

Refrigerator door

ActiveCN103644696AGood sealingSwitch smoothlyLighting and heating apparatusCooling fluid circulationRefrigerator carEngineering

Owner:HAIER GRP CORP +1

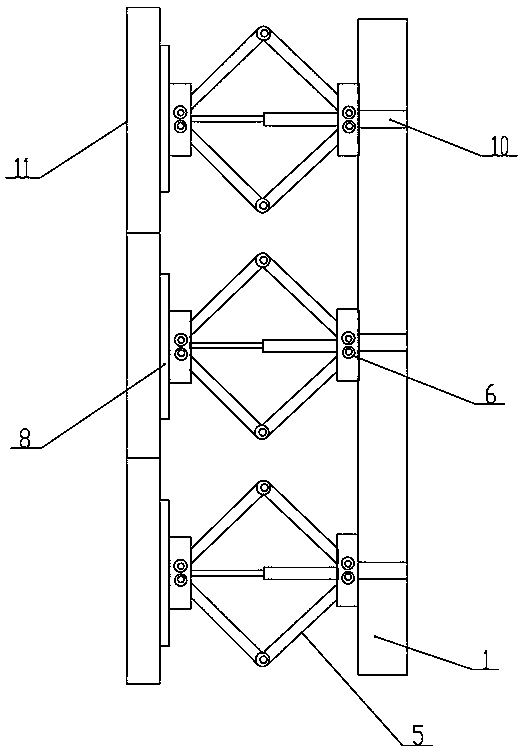

Large-screen monitoring device for dispatching

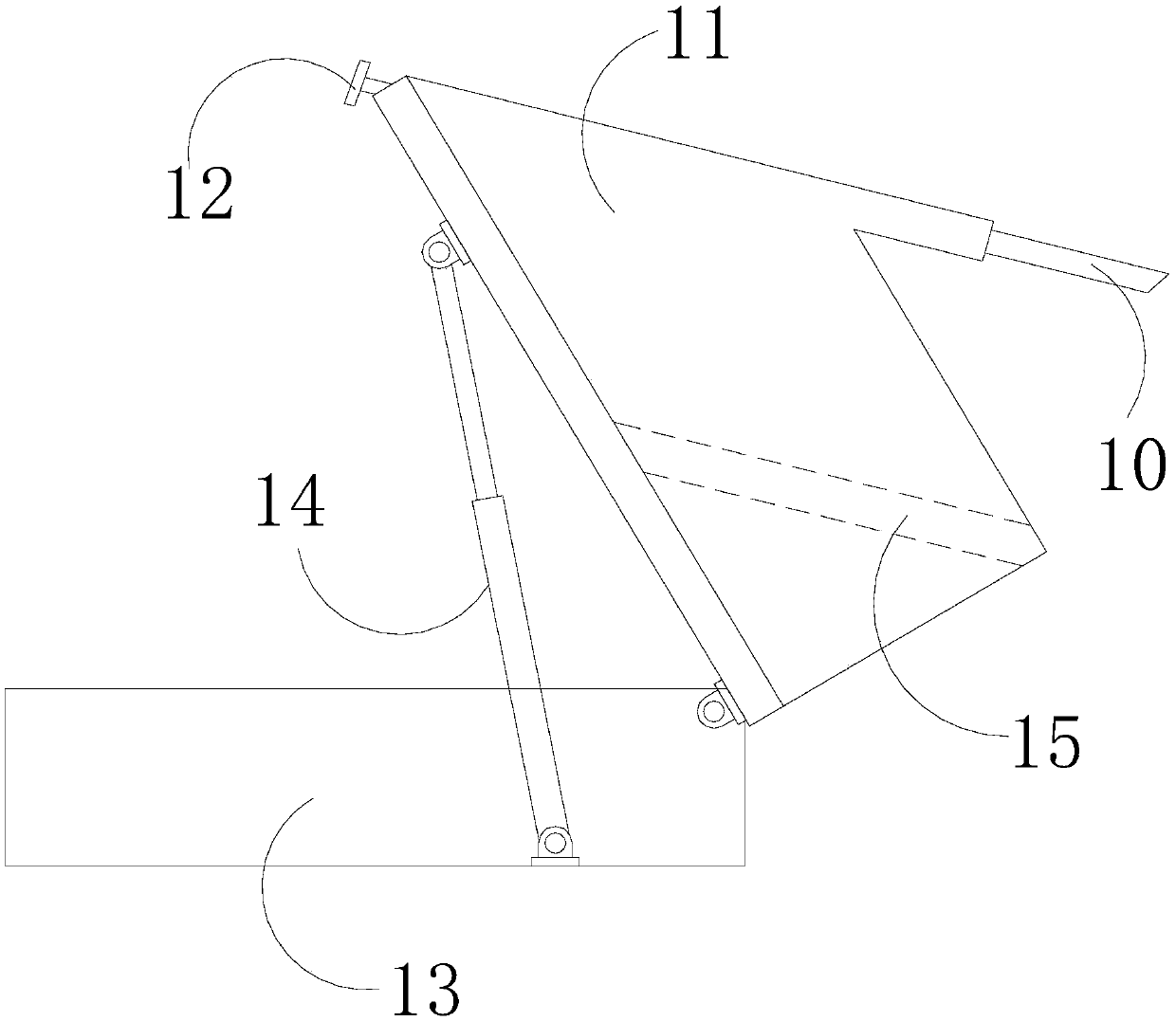

The invention relates to the technical field of monitoring devices, and discloses a large-screen monitoring device for dispatching. The large-screen monitoring device comprises a bracket and a foldingframe; at least two sliding rails are arranged on the left side of the bracket in the axial direction at intervals, and the left side of each sliding rail is mounted on a sliding groove; the right end of the folding frame is fixedly mounted on the corresponding sliding groove, a fixing device with displayers is fixedly mounted at the left end of the folding frame, and a telescopic device is arranged on the position, corresponding to the sliding rails, of the left side of the bracket; and a telescopic rod of the telescopic device and the fixing device are fixedly mounted together. According tothe large-screen monitoring device for dispatching, gaps between the displayers are regulated through interaction between the sliding rails and a regulating device, seamless connection between the displayers is achieved, so that a whole screen is more attractive, and the displaying effect is better; and an electric pushing rod is controlled through an external control system, so that extension ofthe folding frame is controlled, and the displayers can be regulated in the left-right direction, maintenance and set work of the displayers by people are facilitated, and damage caused by frequent disassembling of the displayers is avoided.

Owner:国网新疆电力有限公司营销服务中心 +1

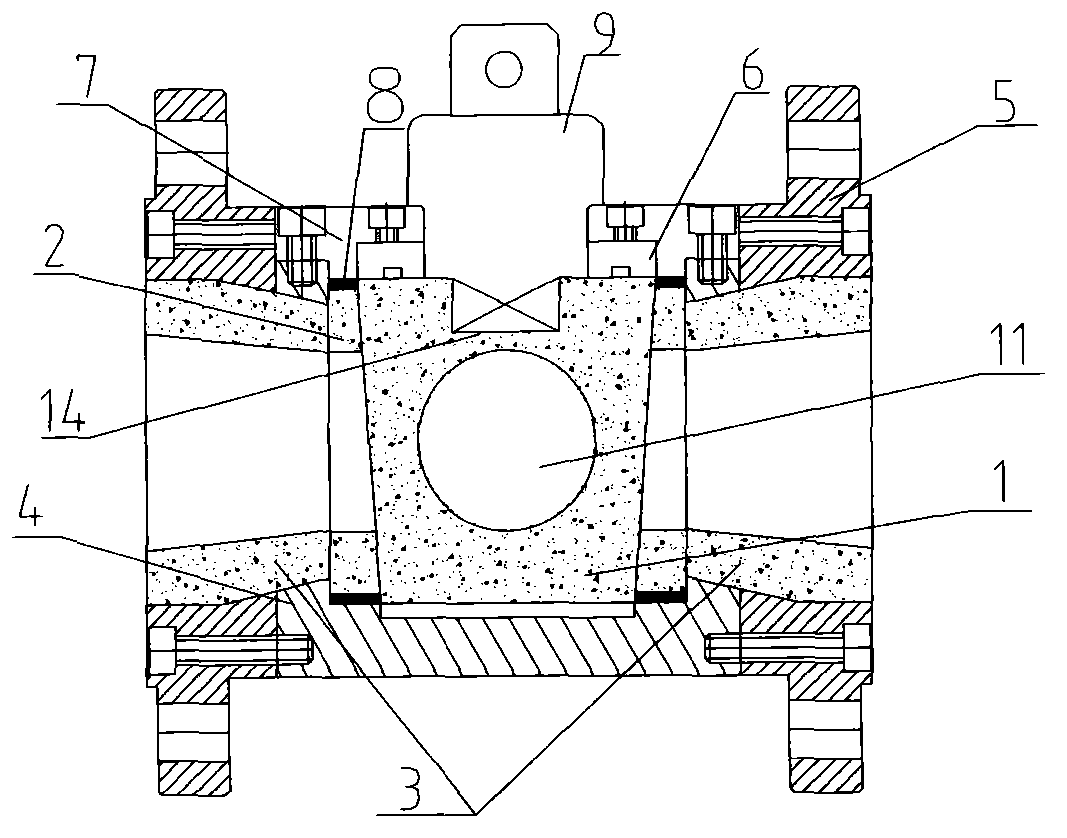

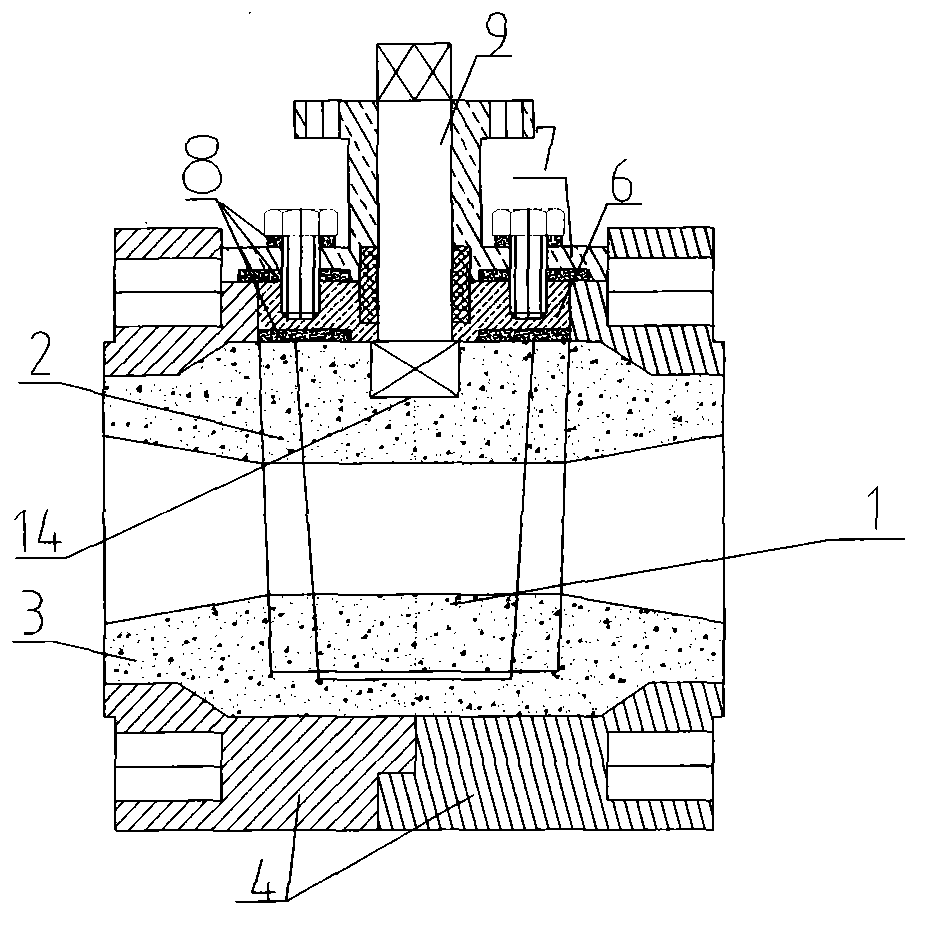

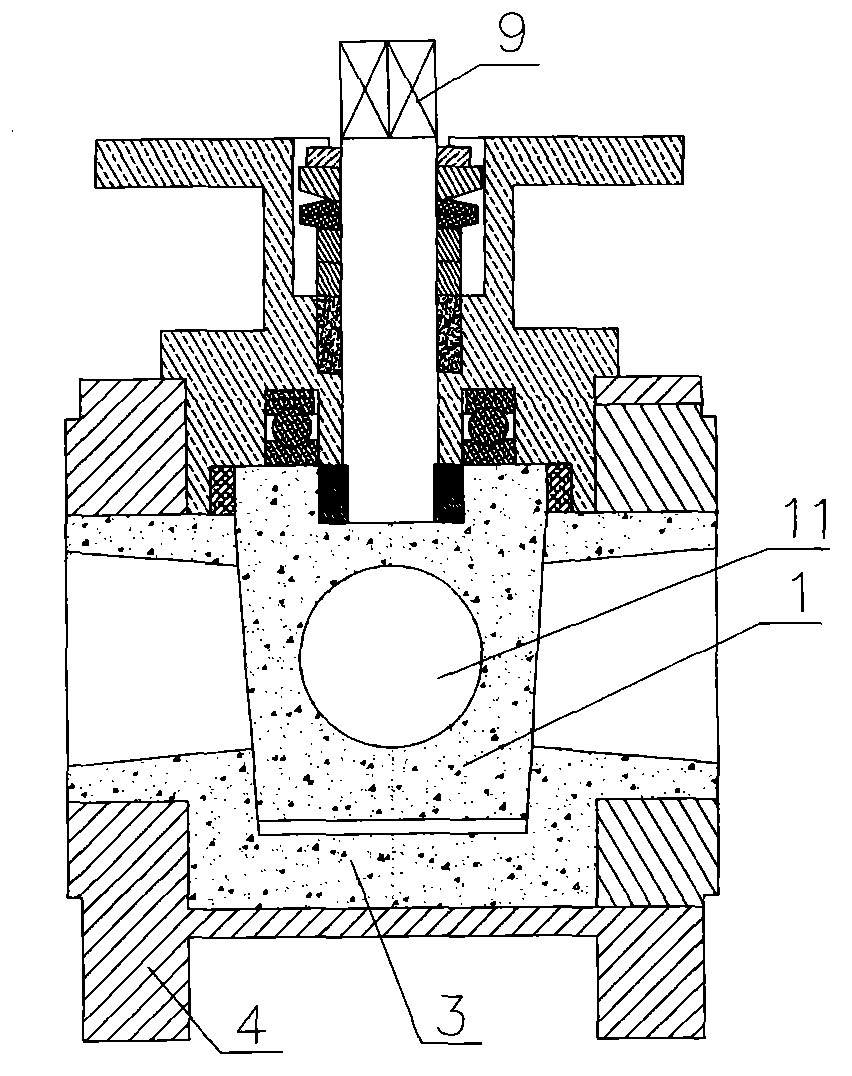

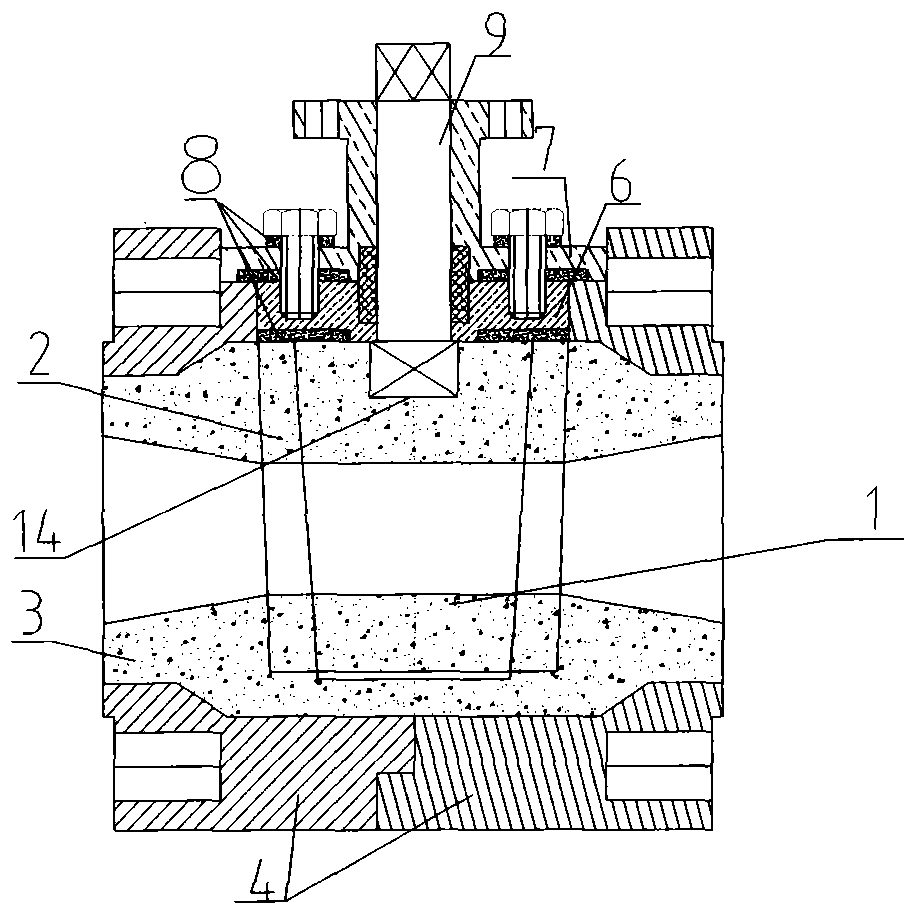

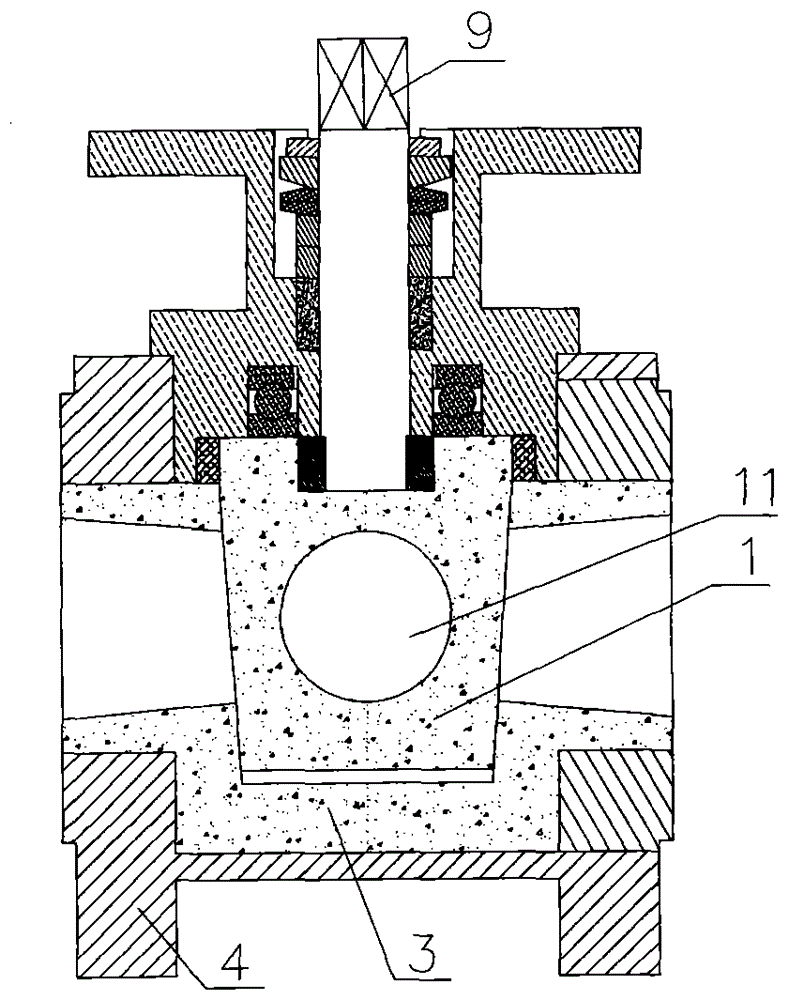

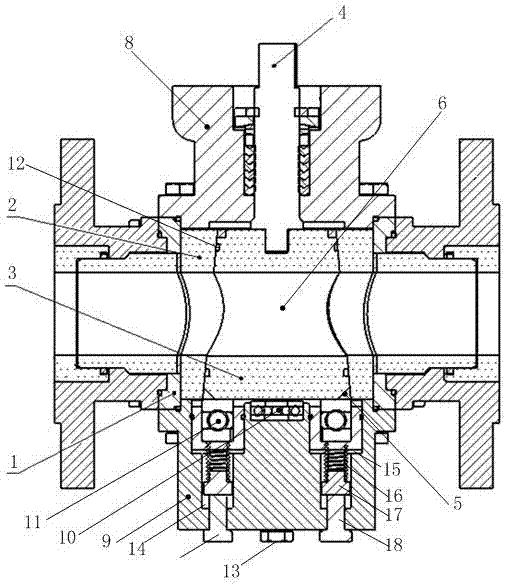

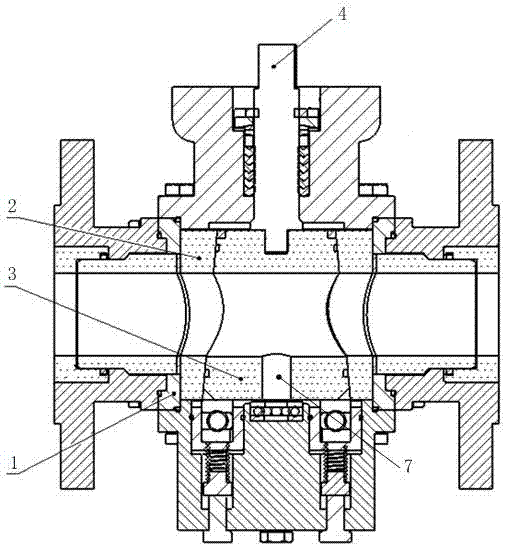

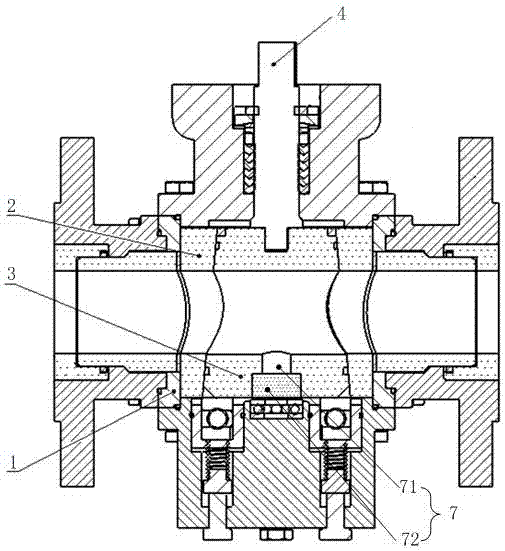

Ceramic rotary cone valve

The invention relates to a rotary cone valve, in particular relates to a ceramic rotary cone valve, and belongs to the technical field of rotary cone valves. The ceramic rotary cone valve comprises a shell, wherein the shell is a metal shell or a ceramic shell, has a split structure or an integrated structure, and is in threaded connection with a flange or a flange pressing ring; an intermediate is arranged in the shell and is made of ceramics or polytetrafluoroethylene; and a ceramic valve core is sleeved in the intermediate in a close fit manner. According to the ceramic rotary cone valve, a clearance between the ceramic valve core and the intermediate can be adjusted, so that an optimal sealing effect is achieved; a ceramic flange liner is in close fit with the flange pressing ring through an additionally arranged step, so that the problem that the ceramic flange liner easily drops off at high temperature in the prior art is solved; the intermediate can be made of a polytetrafluoroethylene material, so that the ceramic rotary cone valve is high in sealing performance, cannot be scratched, is small in torque, and is smoothly turned on and turned off; and with the structure, the ceramic rotary cone valve is long in service life and low in using cost.

Owner:烟台明珠陶瓷科技有限公司

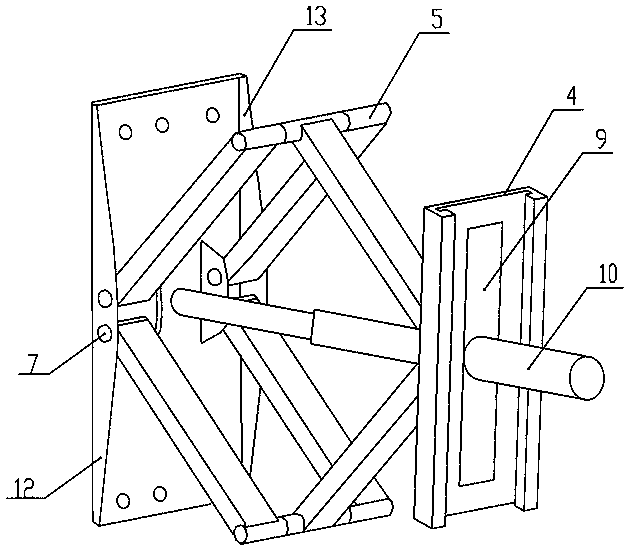

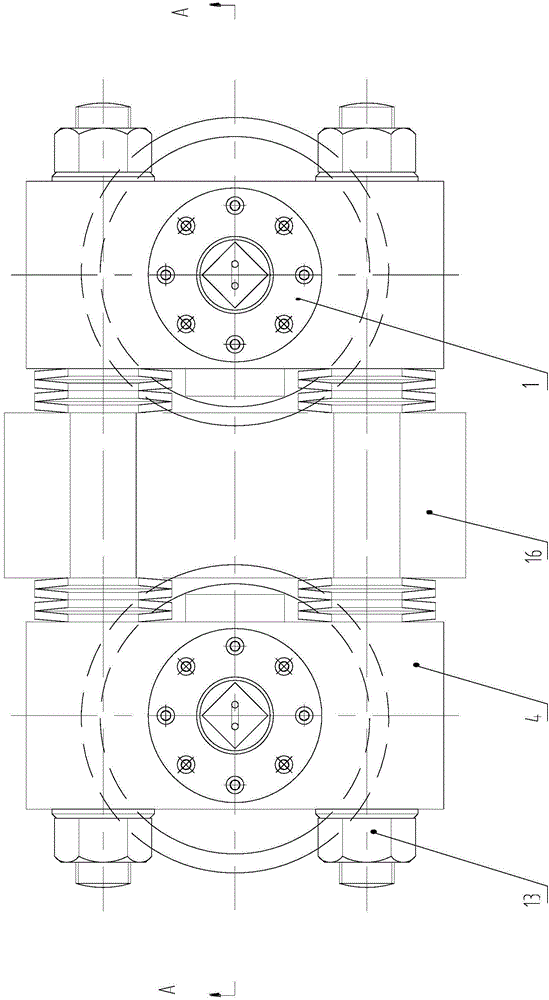

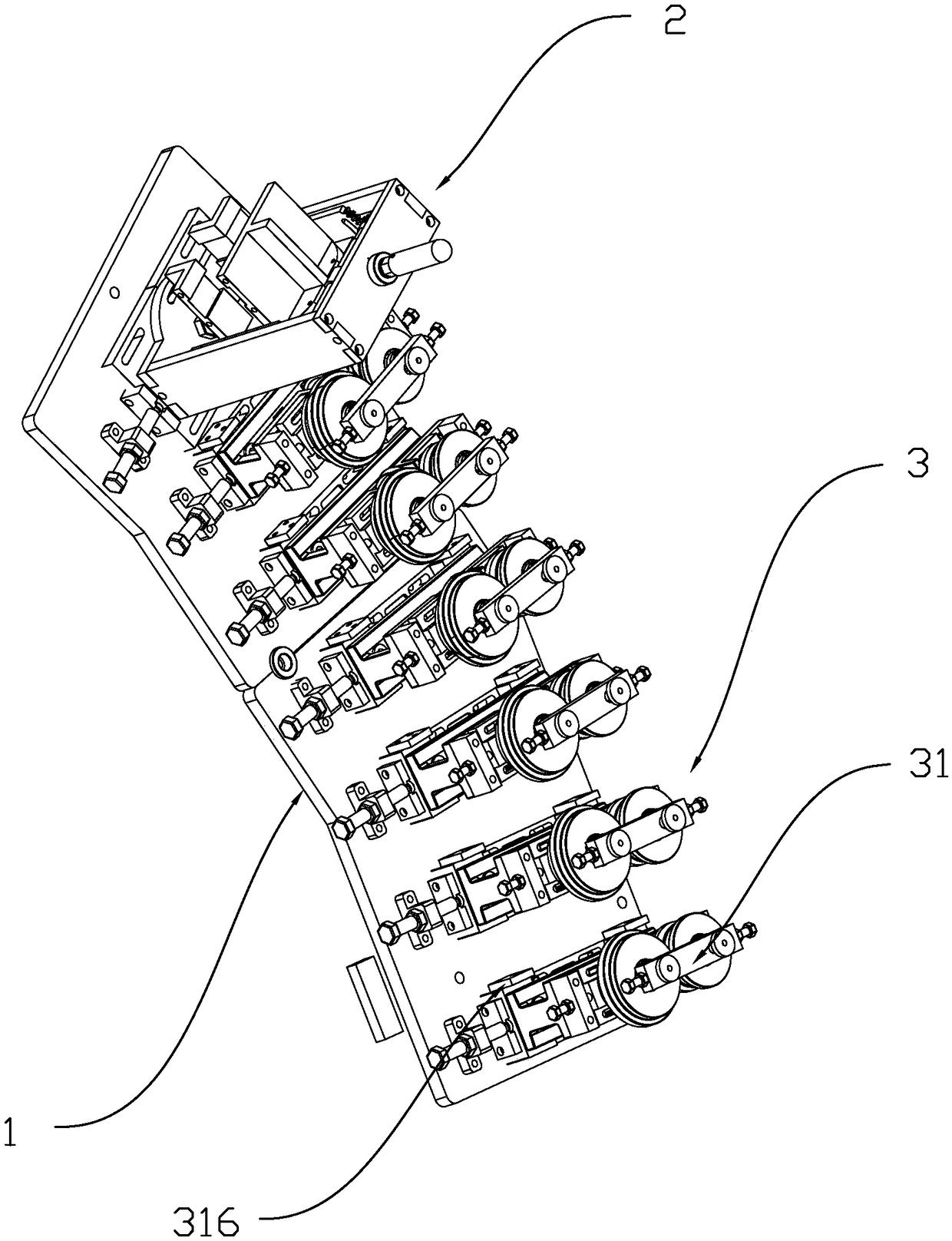

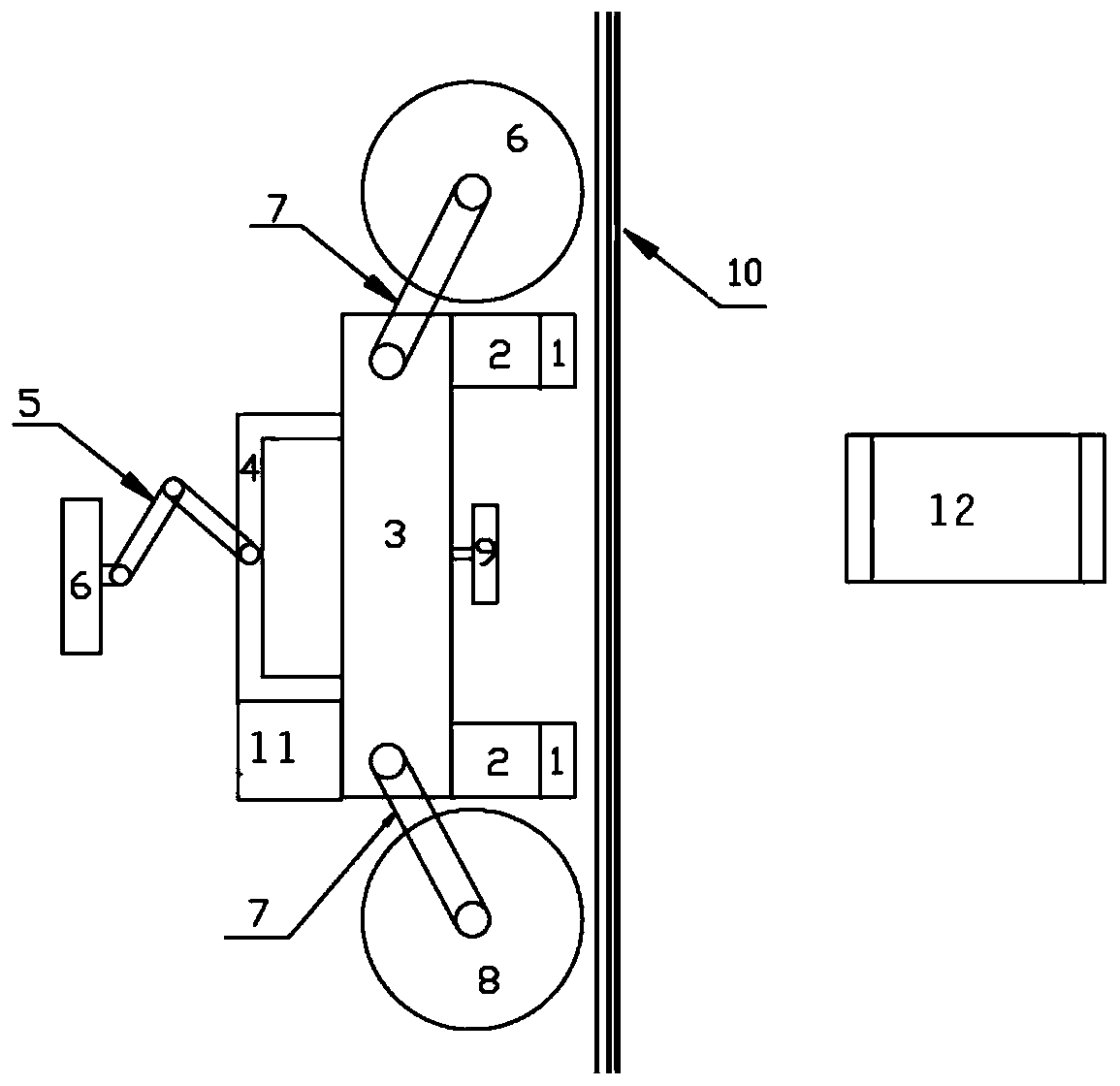

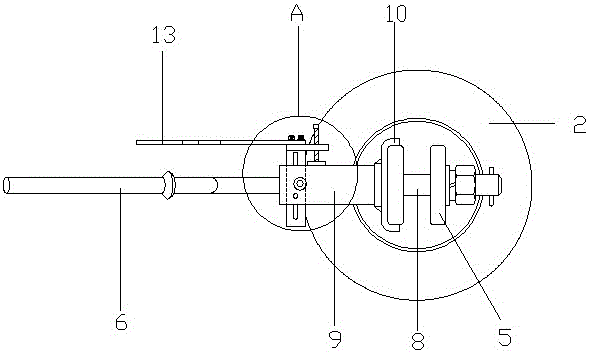

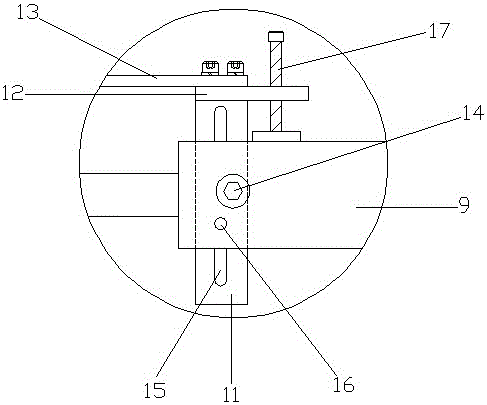

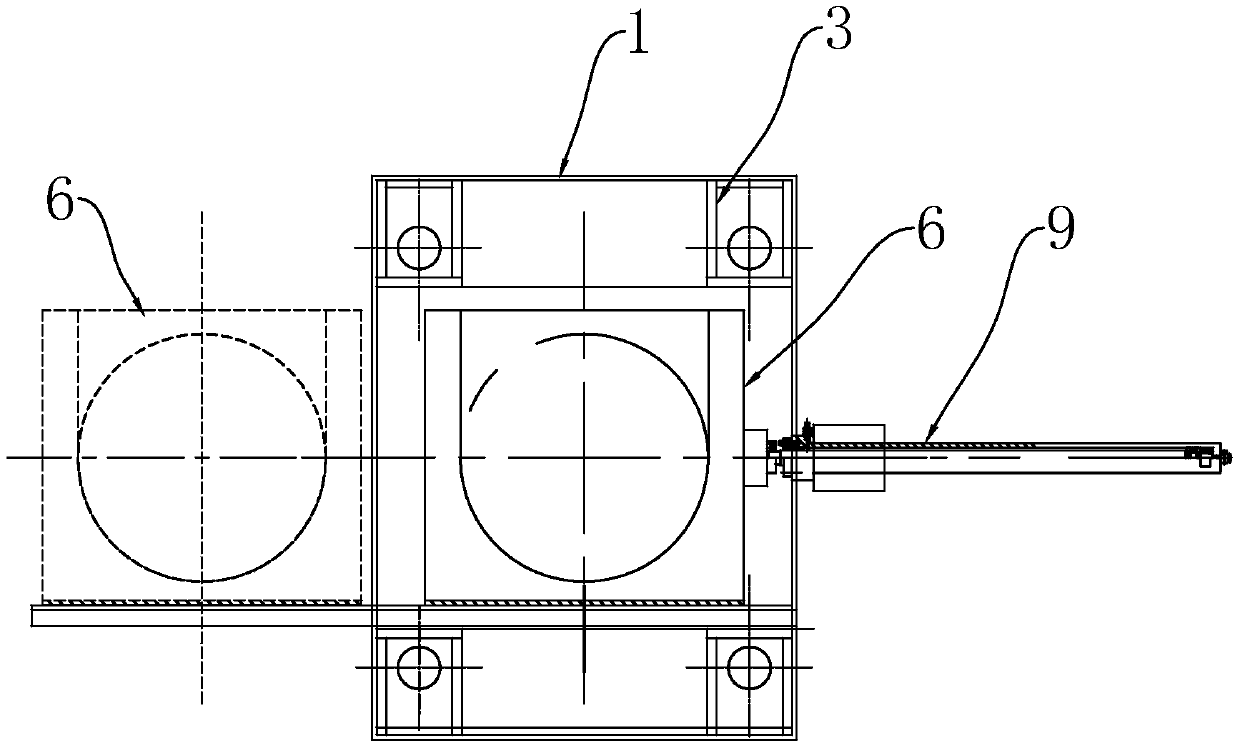

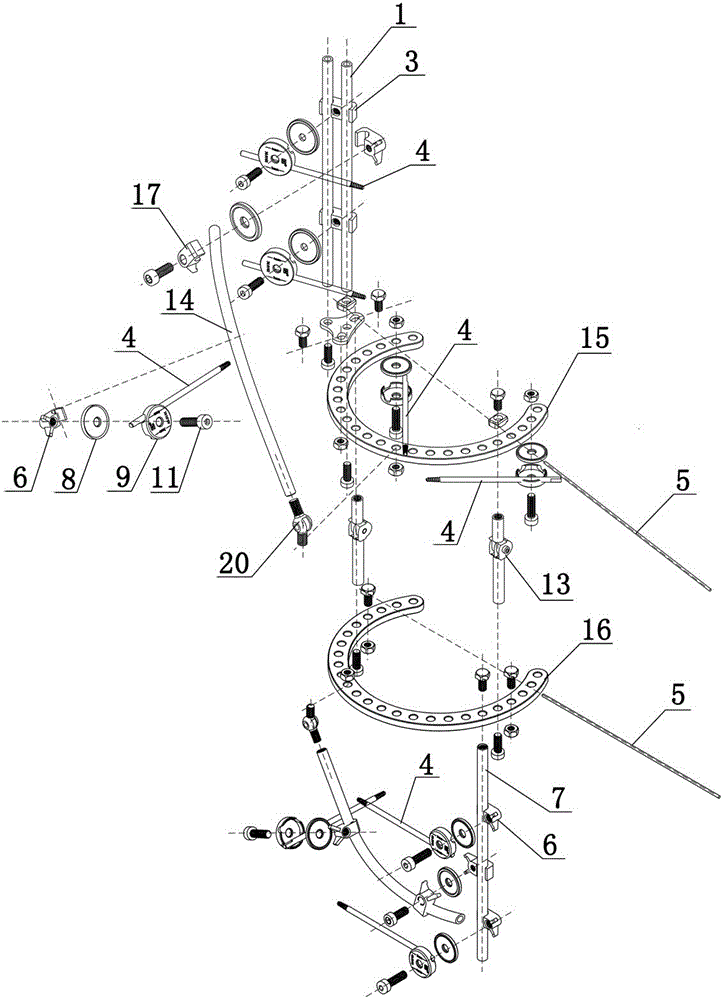

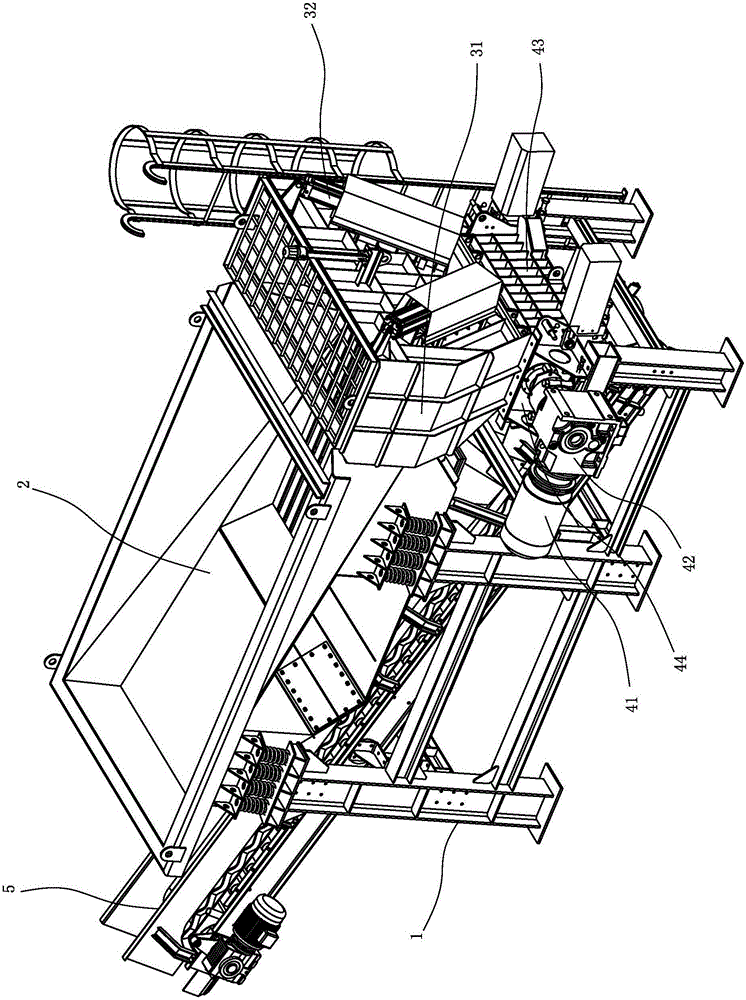

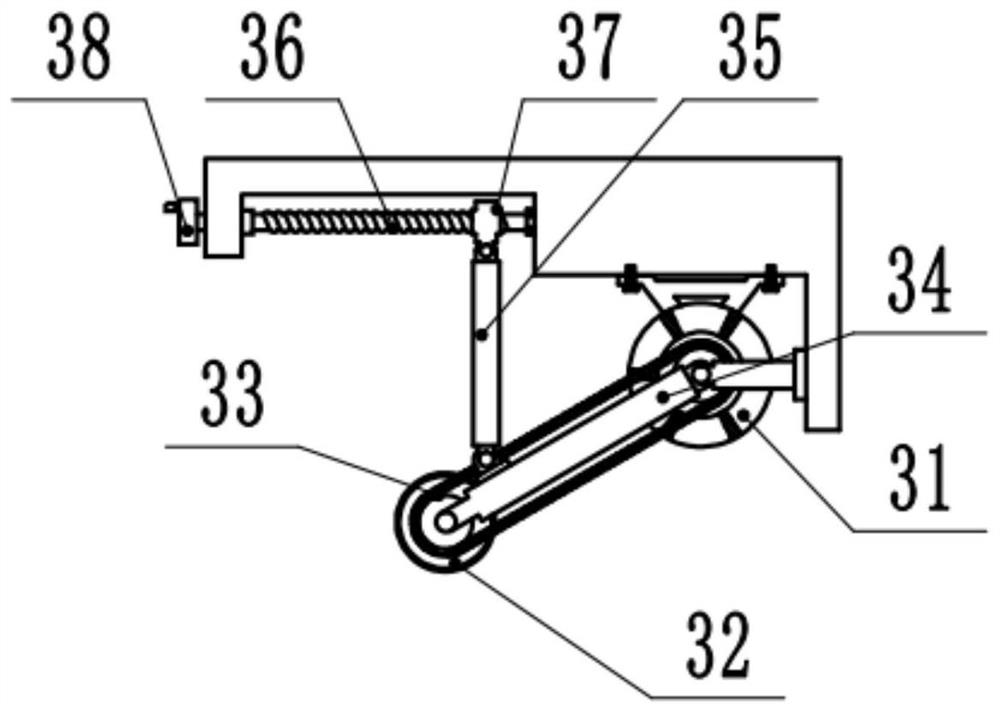

Guide wheel device of movement mechanism of mechanical equipment

InactiveCN104309628AAdjustable clearanceNo impactRail derailment preventionEngineeringMechanical equipment

The invention discloses a guide wheel device of a movement mechanism of mechanical equipment, relates to mechanical equipment, and solves the technical problem that impact is caused to the mechanical equipment for a reason that a gap exists between the existing horizontal guide wheel and a track. Two installation seats are symmetrically arranged on the two sides of a fixed seat, the middle parts of the two installation seats are respectively and fixedly connected with eccentric shafts in a direction perpendicular to the horizontal direction of the track, bearings respectively sleeve the lower parts of the two eccentric shafts, and the two bearings are respectively installed in horizontal wheels; through holes for installing pull rods are respectively formed in the two sides of the eccentric shafts in the transverse direction of the two installation seats, corresponding through holes are also formed in the transverse direction of the fixed seat, the two pull rods connect the two installation seats and the fixed seat, disc spring sets are sleeved between the fixed seat and the installation seats, and nuts are installed at the ends of the two pull rods and can apply certain pretightening force to the disc spring sets. The guide wheel device is used for the movement mechanism of the mechanical equipment and has the advantages of compact structure, high safety and reliability in operation and convenience in disassembling, assembling and adjustment.

Owner:TAIYUAN HEAVY IND

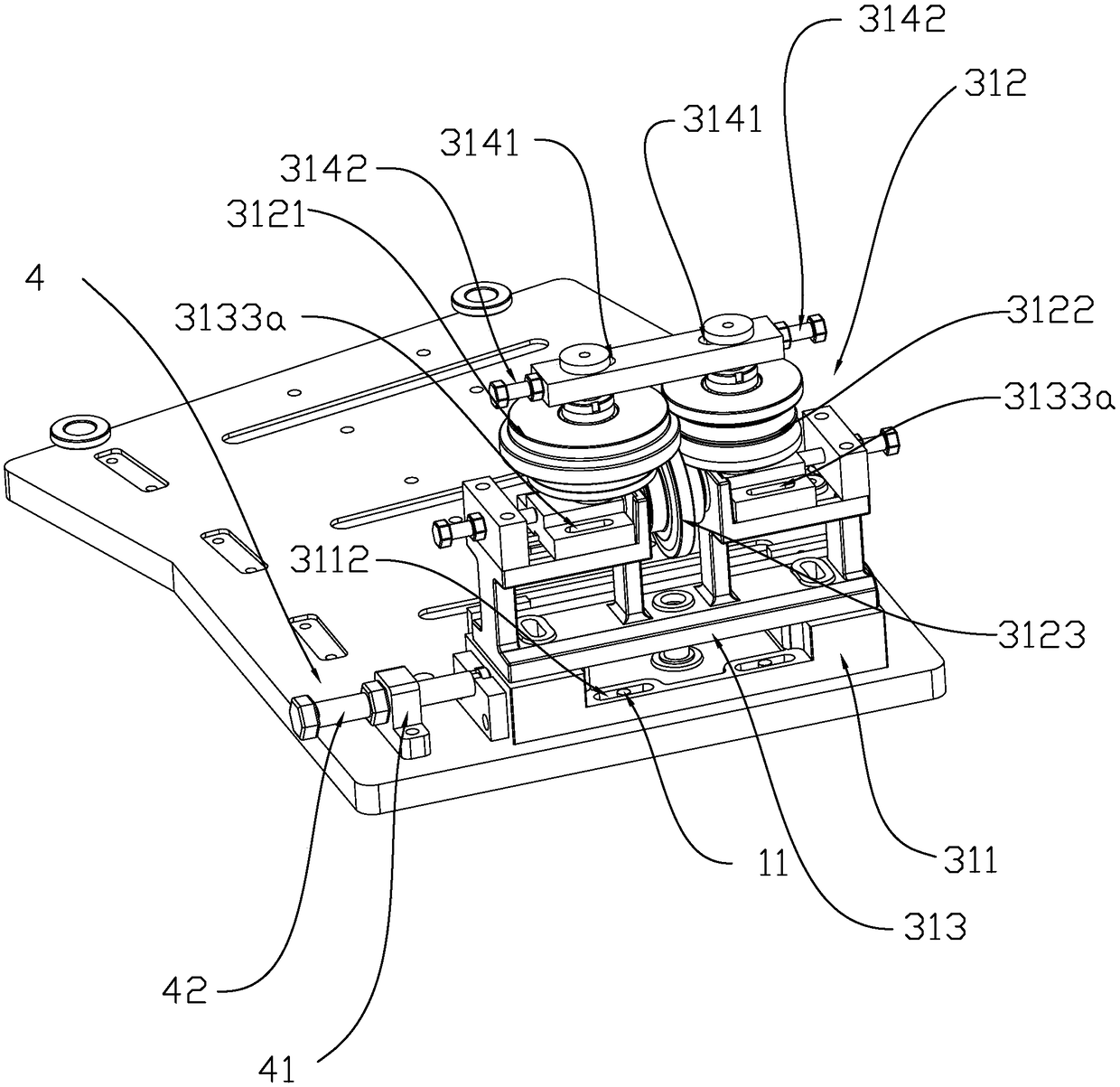

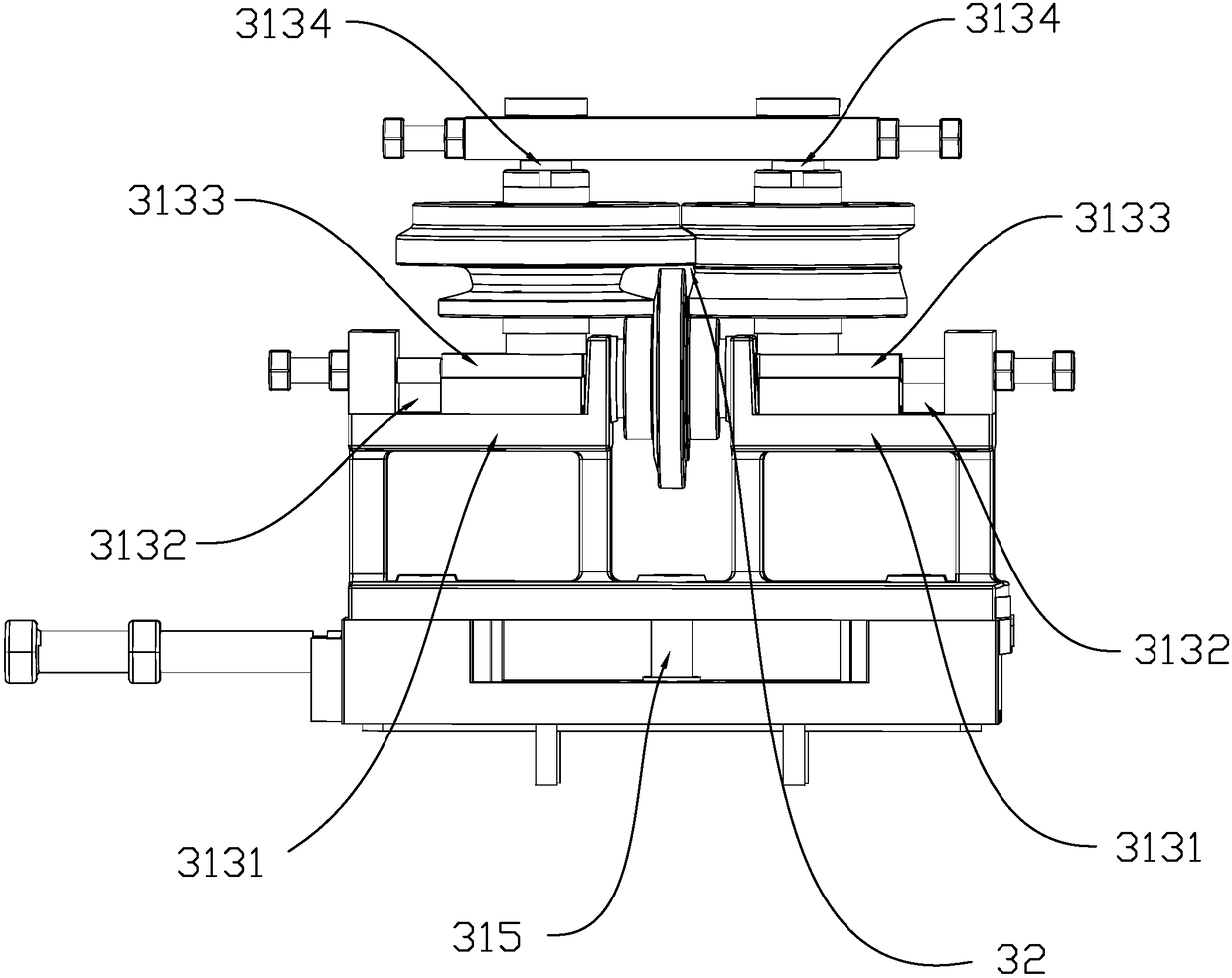

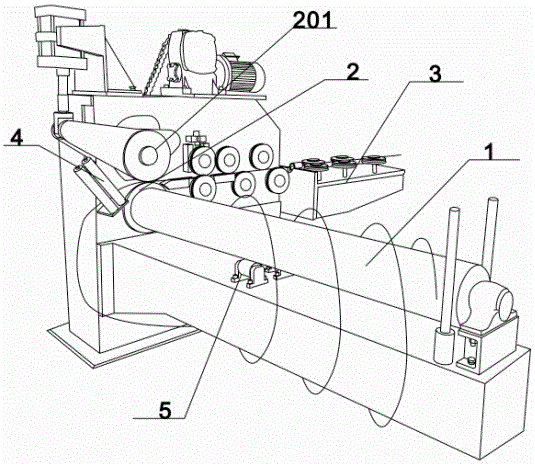

Adjustable universal rolling device

PendingCN108526256ASimple structureEasy to adjustMetal-working feeding devicesVehicle componentsEngineeringMachining

The invention relates to the technical field of machining, in particular to an adjustable universal rolling device. The rolling device comprises an operation table, wherein a feeding mechanism and a radian mechanism are arranged on the operation table, and the radian mechanism comprises a plurality of roller wheel assemblies arranged in an arc shape; each roller wheel assembly comprises an adjusting seat arranged on the operation table, an adjusting seat for driving the adjusting seat to move, and a roller wheel part which is arranged on the adjusting seat; and the feeding mechanism comprisesa sliding base arranged on the operation table, the sliding seat is also provided with an adjusting part, a supporting frame is arranged on the sliding seat, wherein a feeding port mounting plate is arranged on the supporting frame, a feeding port is formed in the feeding port mounting plate, and a fine adjusting mechanism capable of adjusting the inclination angle between the feeding port and theoperating table is arranged between the feeding port mounting plate and the supporting frame. By the adoption of the structure, the adjustable universal rolling device has the advantages that the feeding mechanism and the radian mechanism can be adjusted, the machining radian range is wide, the structure is simple, and the application range is wide.

Owner:浙江创大汽车部件有限公司

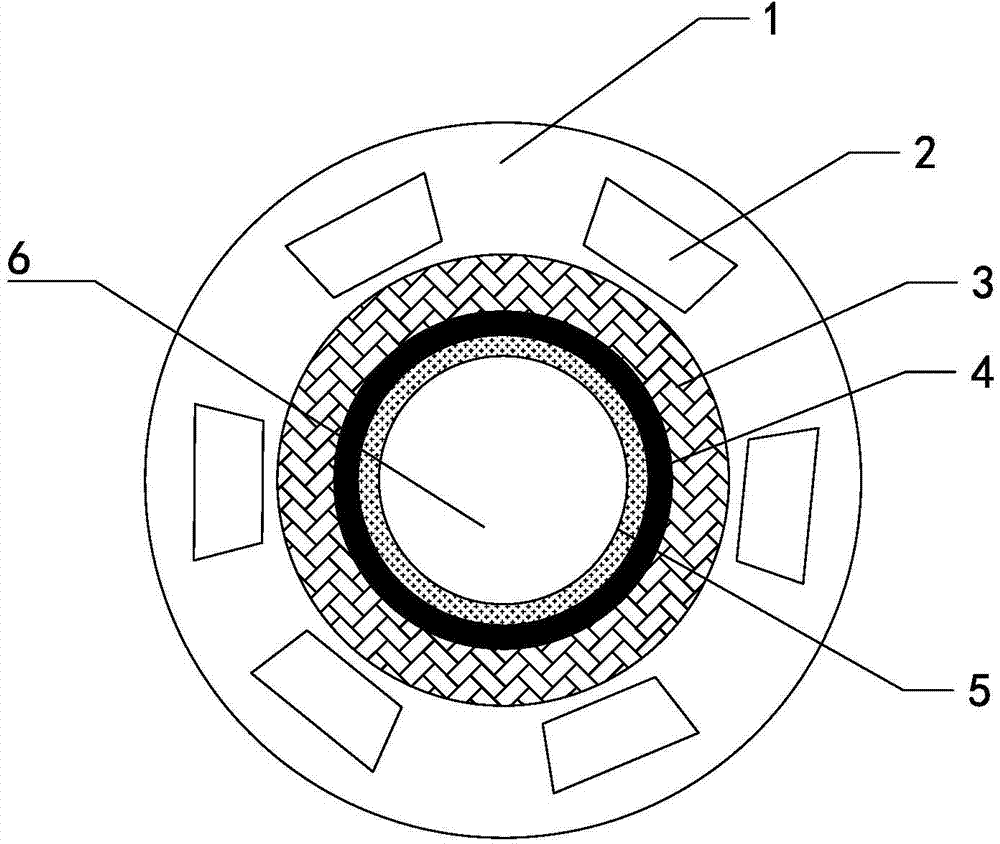

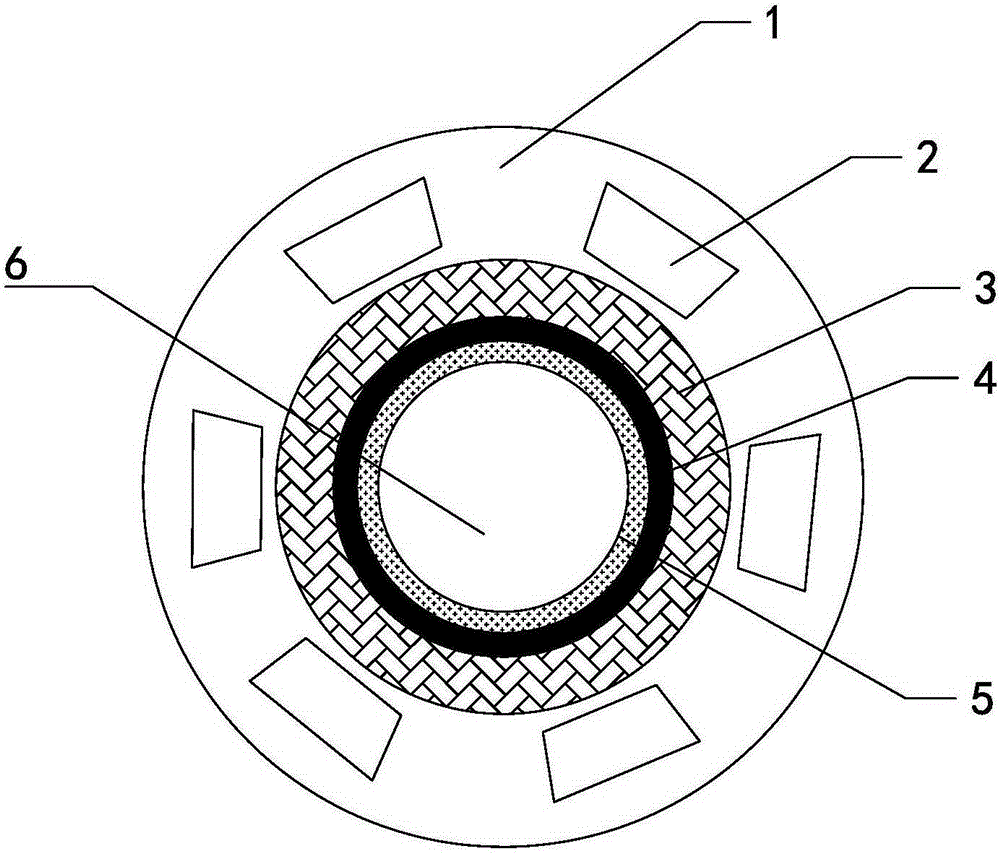

Easy-installation high-strength carbon fiber printing cylinder support

The invention relates to a component of an offset printing machine, in particular to an easy-installation and high-strength carbon fiber printing cylinder support comprising a printing cylinder and a central solid shaft, wherein a support body is arranged between the printing cylinder and the solid shaft. The support is characterized by compositing a carbon fiber layer, an EVA elastic body layer and a glass fiber layer to be cylindrical. The support is high in strength and adjustable in strength by adjusting the thickness of the carbon fiber layer and the thickness of the glass fiber layer. In addition, the support has certain elasticity and is convenient to install, and the play of the cylinder can be adjusted by adjusting the thickness of the EVA elastic body layer.

Owner:ZIBO LANGDA COMPOSITE TECH

Hydrogel 3D printing material and preparation method thereof

ActiveCN108359143APromote differentiationProvides a suitable site for differentiation and directly contributes to cell growth promotionAdditive manufacturing apparatusCelluloseBiocompatibility Testing

The invention provides a hydrogel 3D printing material and a preparation method thereof. The hydrogel 3D printing material is composed of a gel A and a gel B, wherein the gel A is prepared from, by weight, 8 to 15 parts of aminated hyaluronic acid, 5 to 12 parts of cellulose, 2 to 8 parts of cationic chitin and 20 to 30 parts of water; and the gel B is prepared from, by weight, 10 to 20 parts of alkaline gelatin and 30 to 40 parts of alginic acid. The invention also provides a preparation method for the hydrogel 3D printing material. The hydrogel 3D printing material of the invention has the advantages of good biocompatibility, good affinity to cells, no toxicity to cells and tissue, adjustability in shape and gap, controllability by any program and source code, safety, high efficiency, controllability, good rheological properties, good shear thinning characteristics and good flexibility; and all the raw materials used in the invention are clinically usable under the approval by the USFDA, and have good biodegradability, no harm to human beings and low cost.

Owner:天使召唤生物科技(重庆)有限公司

Device and method for detecting and evaluating defects of elevator composite steel belt

PendingCN110243925AConvenient inspectionKeep relatively parallelElevatorsMaterial magnetic variablesSteel beltEngineering

The invention discloses a device and a method for detecting and evaluating defects of an elevator composite steel belt. The device comprises an armature connected with a handle, two permanent magnets, a guide wheel, a clamping tool and a magnetic flux leakage testing sensor, wherein the permanent magnets are connected with the side faces, close to a traction steel belt of a detected elevator, at two ends of the armature respectively so that a closed loop is formed in a magnetic field, and the permanent magnets are connected with pole shoes; the guide wheel is connected with the armature, a guide groove matched with the traction steel belt of the detected elevator is formed in the guide wheel, and limiting is formed by the left and right side walls of the guide groove and two sides of the traction steel belt of the detected elevator; the clamping tool is connected with the armature, and is fixed to a surrounding rail during detection; and the magnetic flux leakage testing sensor is connected with the armature, and is used for receiving a leakage magnetic field generated when metal steel wires inside the traction steel belt of the detected elevator are lost or broken. The detection device is carried through the handle and is handheld for detection, and inspection of front-line operators in elevator inspection organizations and elevator maintenance units for the traction steel belt is facilitated.

Owner:HANGZHOU SPECIAL EQUIP INSPECTION & RES INST

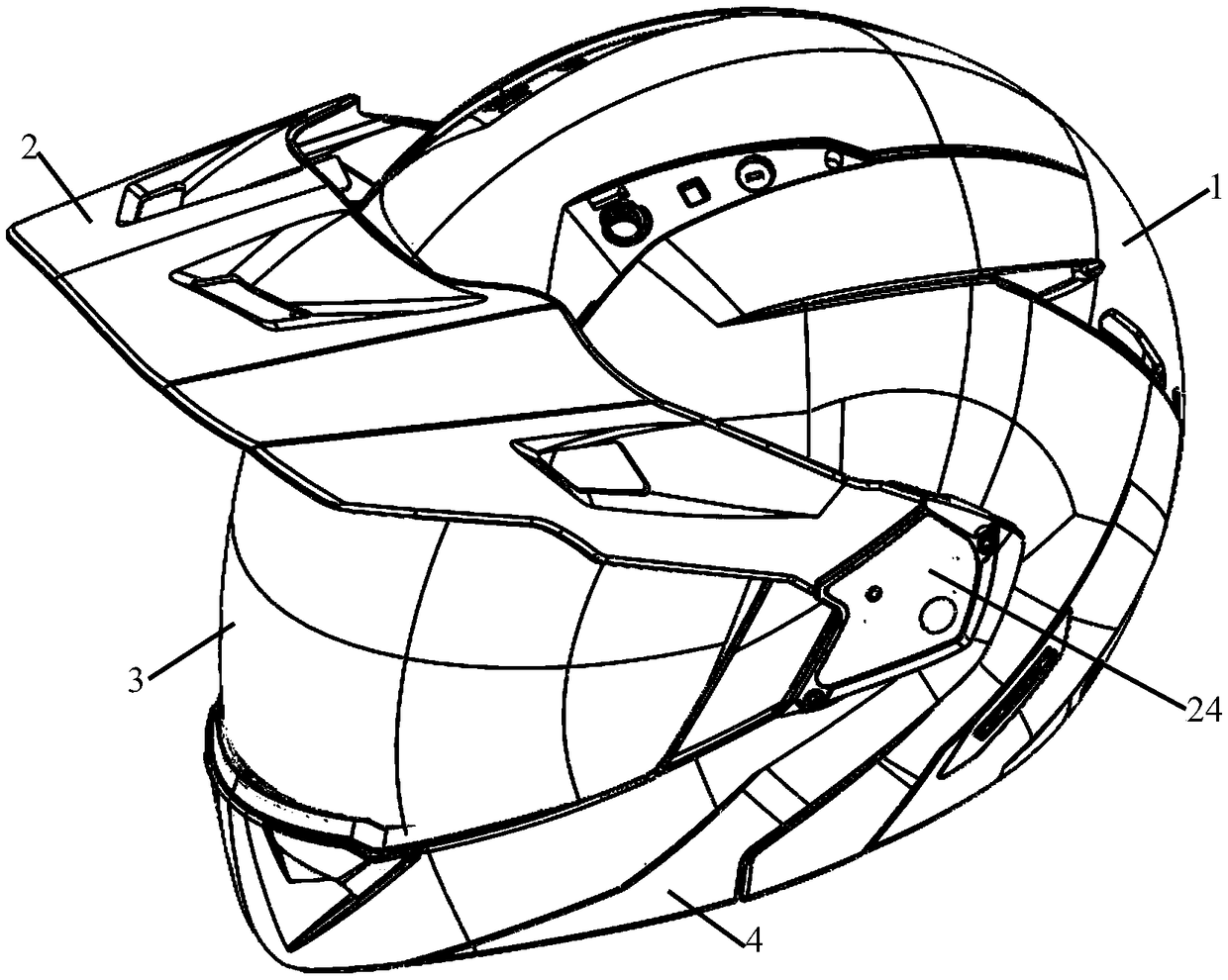

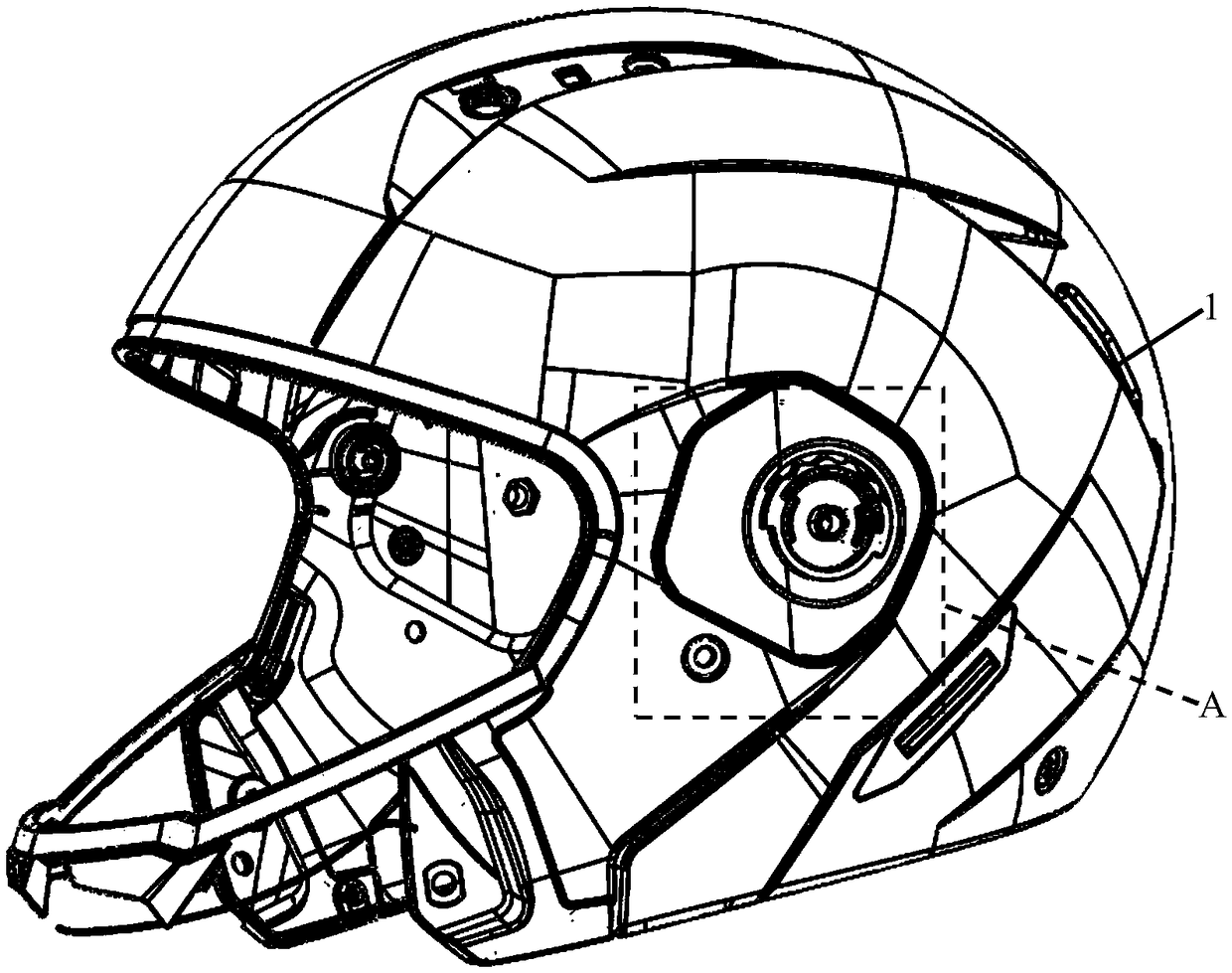

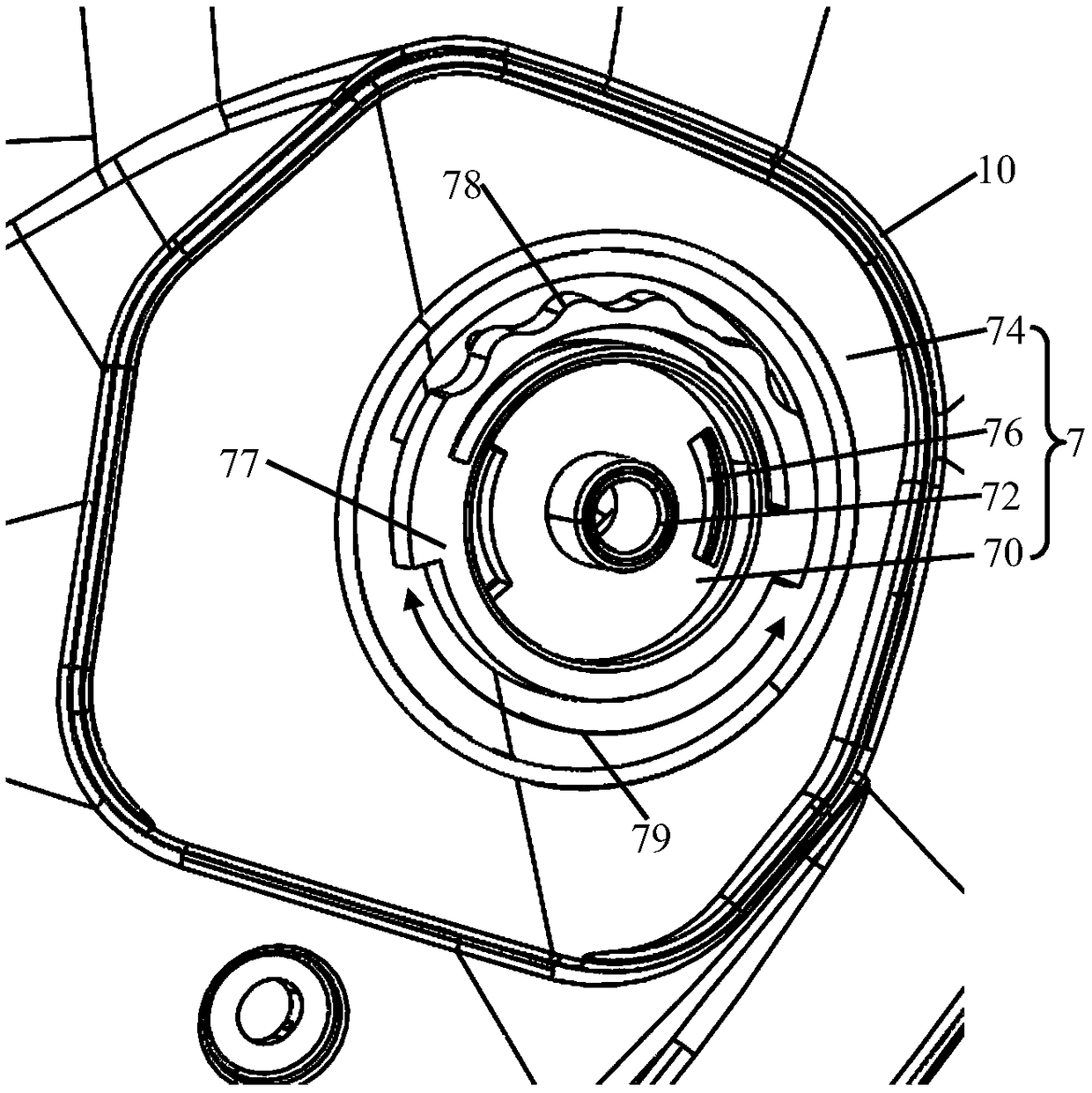

Dual purpose helmet

PendingCN109363286APlay a limiting roleEasy to replace and maintainHelmetsHelmet coversChinEngineering

The invention discloses a dual purpose helmet. The helmet comprises a helmet shell, a brim, a goggle, a chin rest and positioning and mounting mechanisms, the positioning and mounting mechanisms are detachably mounted on two sides of the helmet shell, the brim, the goggle and the mounting end of the chin rest are respectively mounted on the positioning and mounting mechanism at the same position,and the brim, the goggle and the chin rest can be simultaneously opened or closed around the positioning and mounting mechanism at the same position. The dual purpose helmet adds the brim, the brim can be opened with the chin rest, and the goggle can be opened with the chin rest or opened separately.

Owner:上海和汇安全用品有限公司

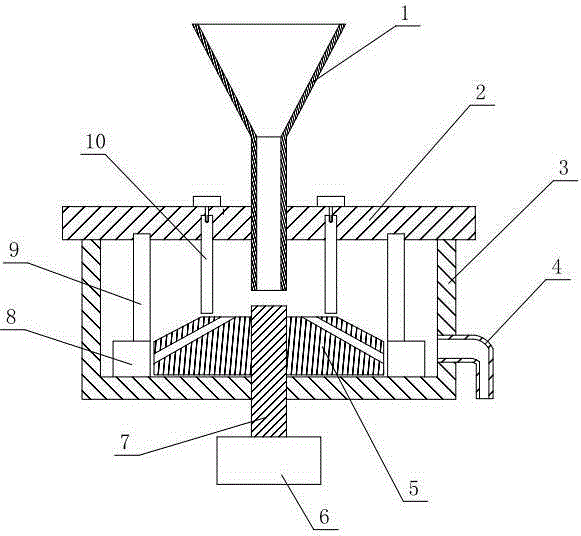

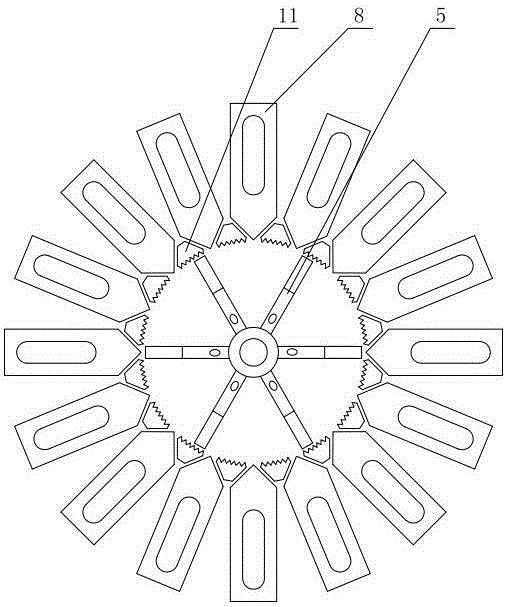

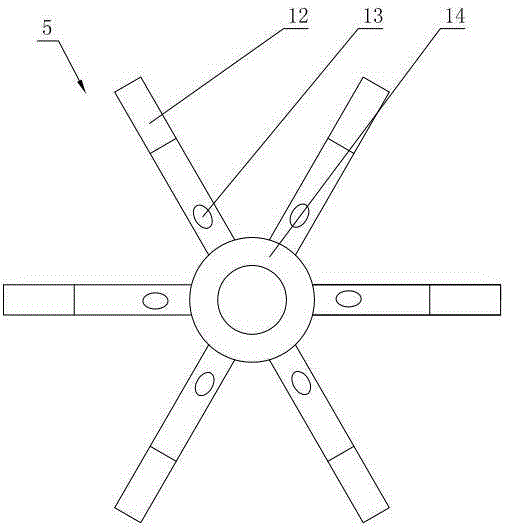

Spirulina cell wall breaking shear device

ActiveCN104450509BImprove cutting effectGuaranteed finenessBioreactor/fermenter combinationsBiological substance pretreatmentsImpellerDrive shaft

The invention discloses a spirulina cell-wall breaking shearing device comprising a shearing cavity, wherein an upper cover round plate is fixed at the top of the shearing cavity, a rotor shearing impeller is arranged on a base plate of the shearing cavity by virtue of a driving shaft in a sealed manner, and the driving shaft penetrates through the base plate of the shearing cavity and is connected with a motor and is connected with a hole formed in the base plate of the shearing cavity in a sealed manner; a plurality of stator blades are uniformly arranged in the peripheral direction of the base plate of the shearing cavity at intervals, the head part of each stator blade is provided with symmetrical blade surfaces, the top parts of the two blade surfaces form a cutting edge, a stator tooth blade is arranged between the blade surfaces of every two adjacent stator blades respectively, and gaps are formed among the cutting edges of the stator blades, the cutting edges of the stator tooth blades and the rotor shearing impeller; a material blocking circular ring is clamped on the inner end surface of the upper cover round plate, the bottom of the material blocking circular ring presses against the stator blades and the stator tooth blades, and a material guide circular ring is also fixed on the inner end surface of the upper cover round plate by virtue of a fastening piece and is positioned at the upper part of the rotor shearing impeller; and a feeding cavity is formed in the middle part of the upper cover round plate, and a discharge opening is formed at the bottom of the side wall of the shearing cavity. The spirulina cell-wall breaking shearing device has a good shearing and breaking effect.

Owner:WUXI HOPE LIGHT IND EQUIP TECH

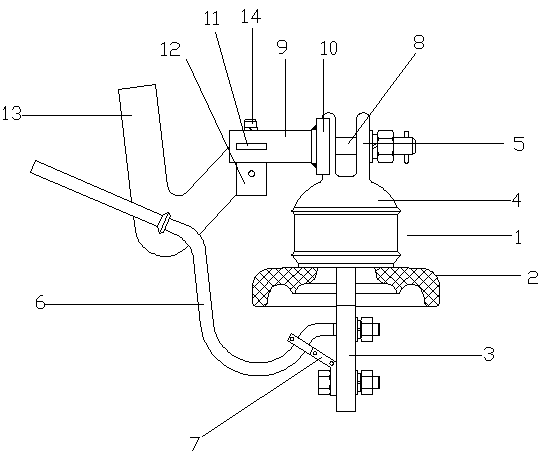

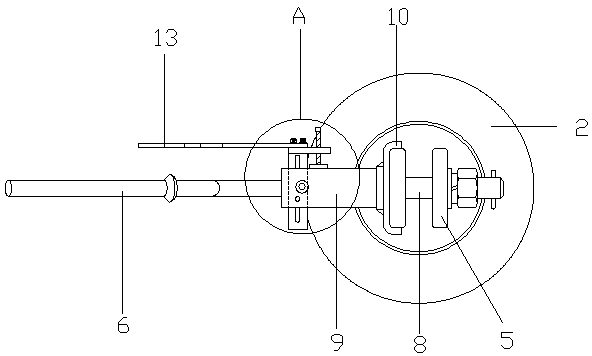

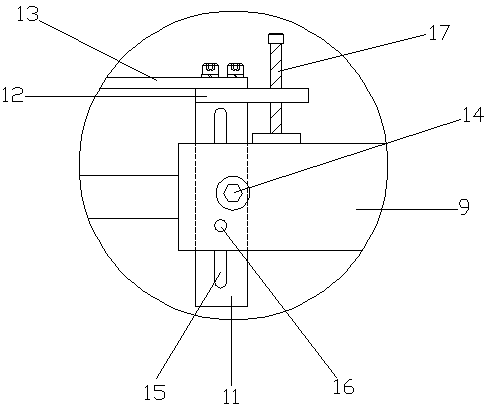

Insulator lightning protection device capable of adjusting discharging gap

ActiveCN107180689AAdjustable clearanceLightning protection is stableInsulatorsOvervoltage arrestors using spark gapsEngineeringElectric power

The invention relates to the electric power aerial line lightning protection technical field, and discloses an insulator lightning protection device capable of adjusting a discharging gap; the insulator lightning protection device comprises an insulator; the insulator comprises a porcelain body, a core bar, and a steel cap; the steel cap has a connecting lug with a connecting hole; the core bar is provided with a rod electrode; one end of the rod electrode is provided with threads; the core bar is provided with an electrode positioning hole; the rod electrode penetrates the electrode positioning hole and is locked by a nut; a stud is arranged in the steel cap connecting hole; one end of the stud is welded with a connecting rod; the other end of the stud is locked by a nut; a rectangular hole penetrating two sides of the connecting rod is arranged outside the connecting rod; a slide piece is arranged in the rectangular hole; the slide piece outer end bends and extends to form a connecting piece; the connecting piece is provided with a plate electrode; the side face of the connecting rod is provided with a locking bolt used for fixing the slide piece. The insulator lightning protection device can adjust the gap, and is stable in lightning protection effect.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JINHUA POWER SUPPLY CO +1

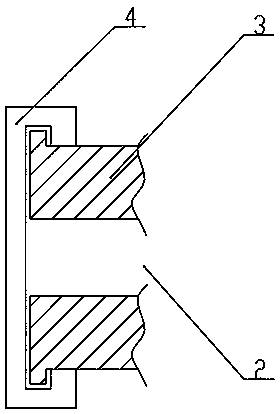

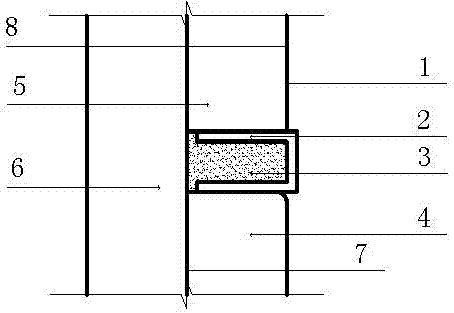

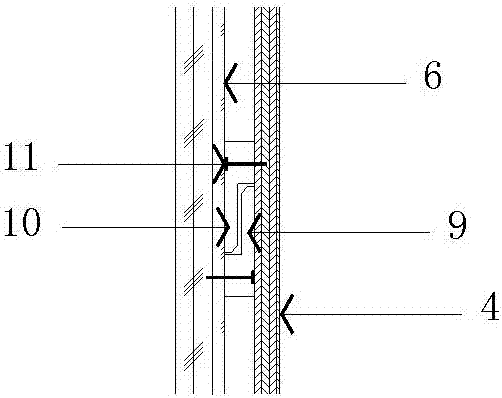

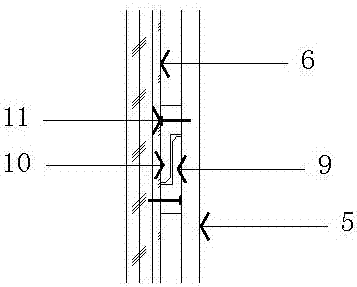

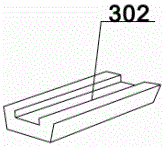

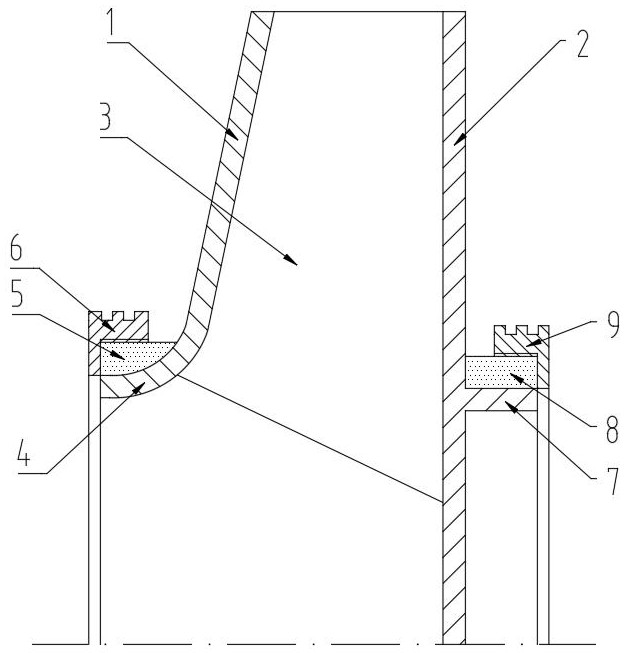

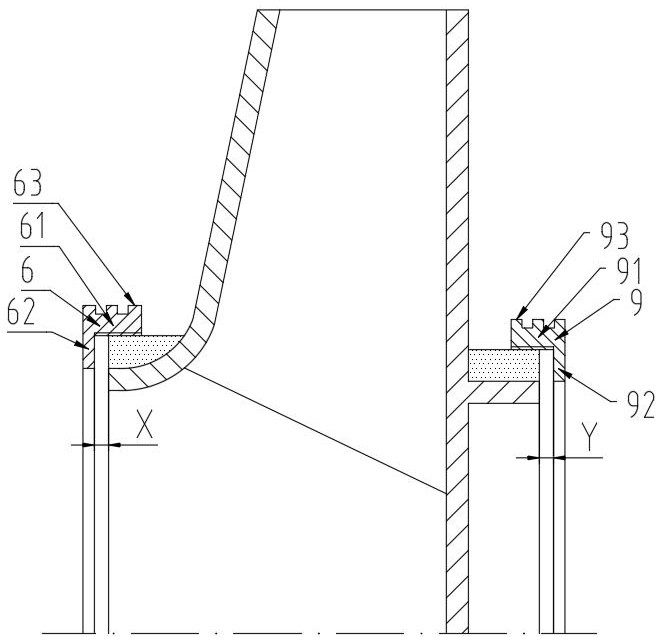

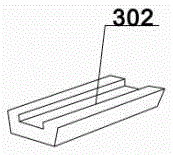

Wall wood veneer close-up method

The invention discloses a wall wood veneer close-up method. The wall wood veneer close-up method comprises the following steps that a, wood veneer basal plate (6) construction is finished, a wood veneer (4) and a wall cloth basal plate (5) are fixed on a wood veneer basal plate by using a dry hanging component (7); b, a gap is reserved in the connecting position between the wood veneer and the wall cloth basal plate, the height of the gap is the same as the height of a U-shaped stainless steel close-up strip (2), and the opening end of the U-shaped stainless steel close-up strip faces towards the wood veneer basal plate (6); c, after mounting of the wood veneer (4) is finished, a silicone weather-resistant sealant (3) is injected into the inner side of the U-shaped stainless steel close-up strip, so that the U-shaped stainless steel close-up strip is fixed in a groove reserved between the wood veneer and a wall cloth basal wall, after the silicone weather-resistant sealant is naturally air-dried, wall cloth pasting and mounting of the wall cloth basal plate are conducted, and the wall wood veneer close-up is finished. The wall wood veneer close-up method has the advantages that edge warping and folding do not occur in the wall cloth at the connecting position through the wood veneer, the U-shaped stainless steel close-up strip serves as decorative line, and quality of appearance of the connecting position is promoted.

Owner:MCC5 GROUP CORP SHANGHAI

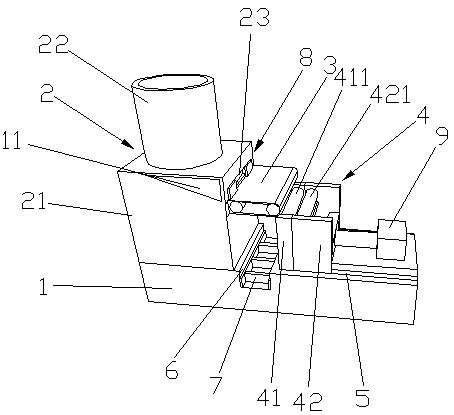

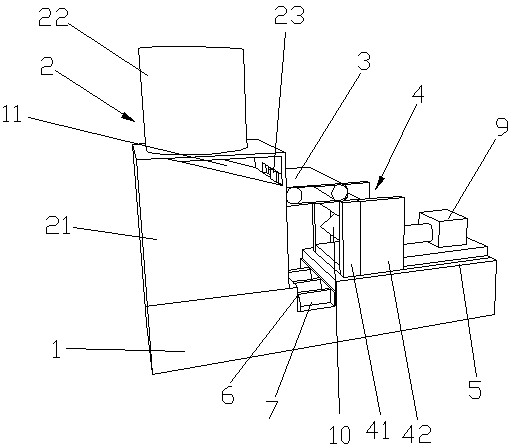

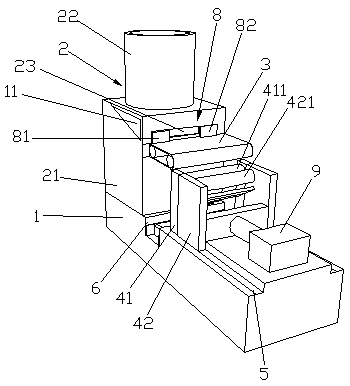

Powder particle quantitative packaging machine

The invention provides a powder particle quantitative packaging machine, and particularly relates to the technical field of packaging equipment. The quantitative packaging machine comprises a packaging machine base, wherein the packaging machine base is sequentially provided with a feeding device, a material conveying belt and a material distribution device; the feeding device comprises a feedingbarrel seat, a feeding barrel is arranged on the feeding barrel seat, the bottom of the feeding barrel communicates with the feeding barrel seat, and a discharging opening is formed in one side of thefeeding barrel seat; the material conveying belt is arranged on the outer wall of the feeding barrel seat; the material distribution device comprises a first material distribution roller frame and asecond material distribution roller frame, a push rod groove is further formed in the packing machine base, and the second material distribution roller frame is movably arranged in the push rod groove, and a first material distribution roller and a second material distribution roller are arranged on the first material distribution roller frame and the second material distribution roller frame respectively; and a material receiving groove is further formed in the position, at the lower end of the material conveying belt, of the packaging machine base, and a plurality of material receiving frames are movably arranged in the material receiving groove. The quantitative packaging machine has the advantages that powder granular products can be quantified during packaging, and the precision of packaging can be controlled.

Owner:合肥普发谐利信息科技有限公司

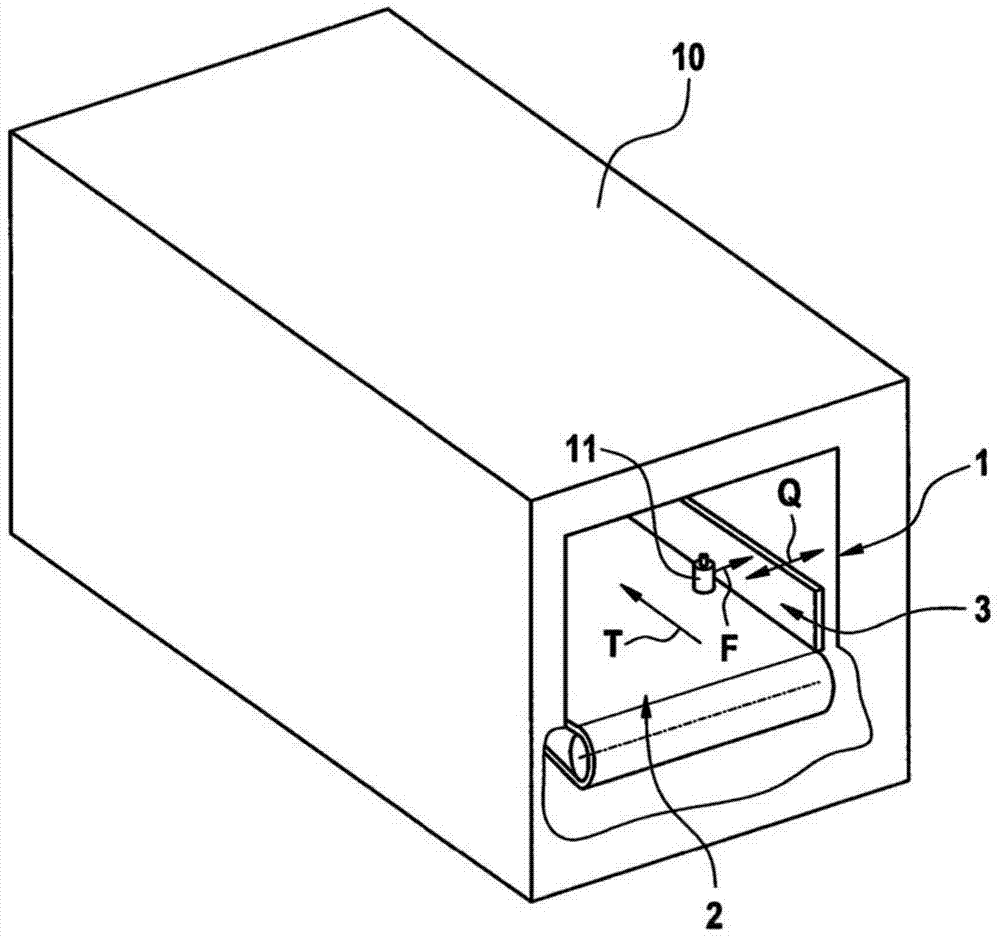

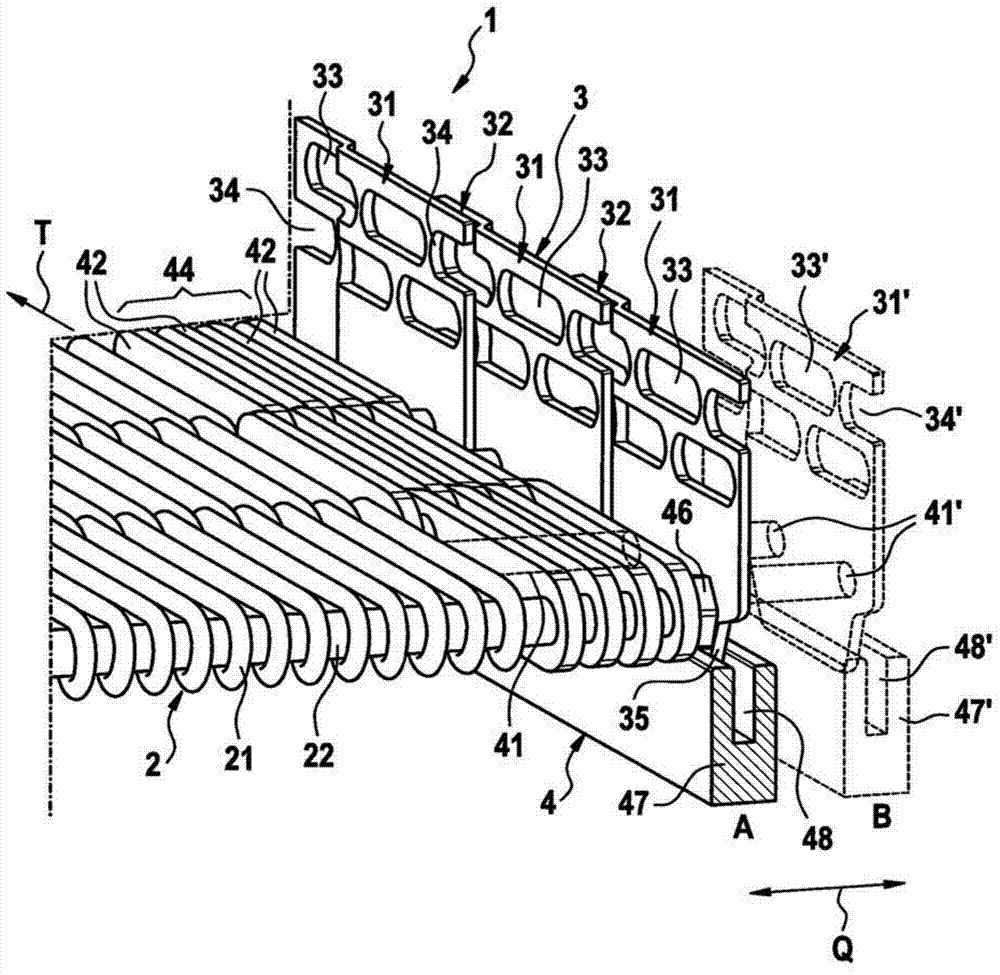

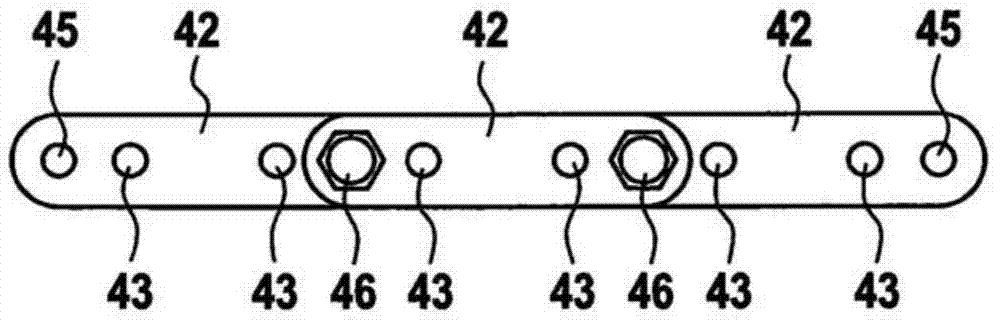

Conveying device used for conveying containers and provided with improved lateral guiding device

Owner:ROBERT BOSCH GMBH

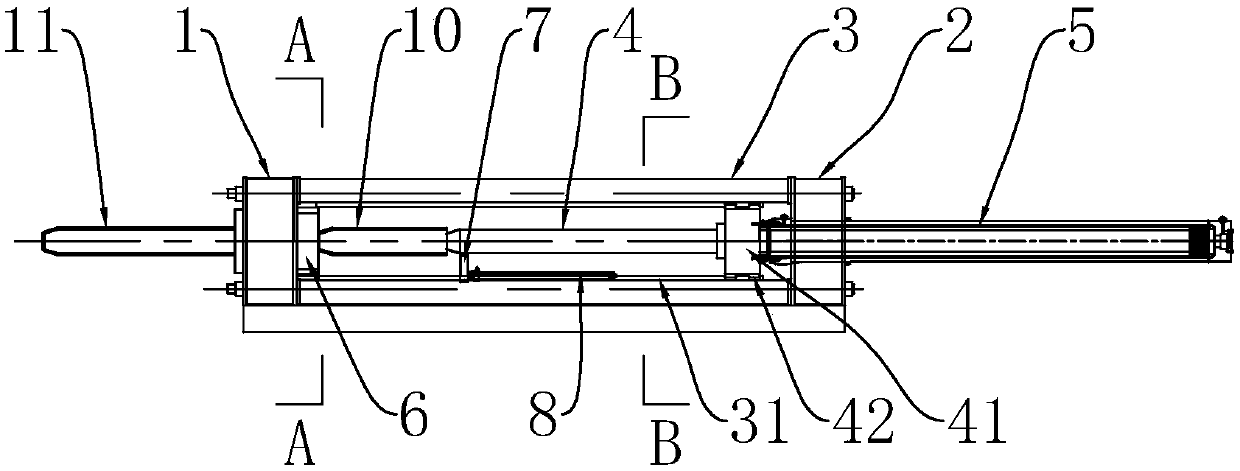

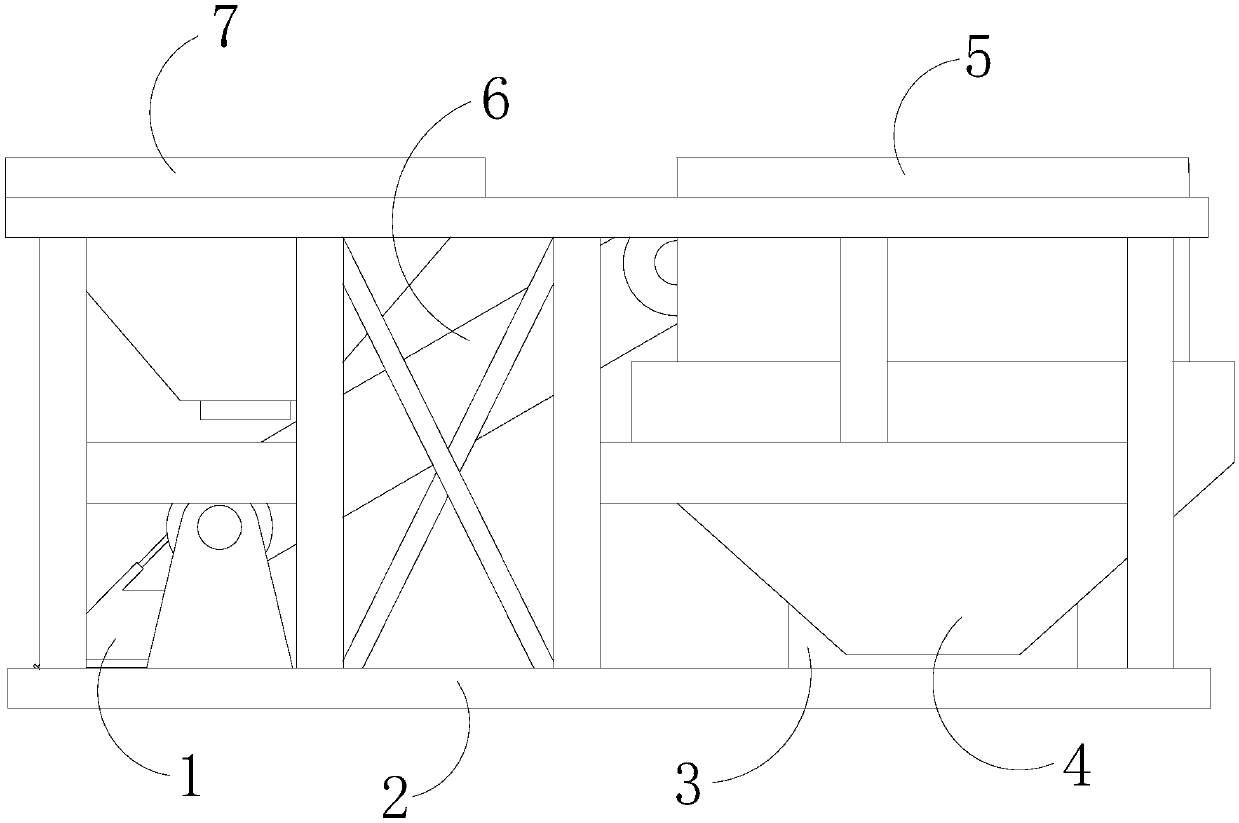

Horizontal type drawing press

The invention discloses a horizontal type drawing press. The horizontal type drawing press comprises a front beam, a rear beam, a plurality of square columns, a punch and a cylinder body, wherein thefront beam and the rear beam are respectively fixed at the two ends of the square columns, the rear beam is used for fixing the cylinder body, and the punch is arranged between the square columns; thepunch is connected with the output end of the cylinder body, a drawing mold is installed on the front beam, a supporting beam is arranged right below the punch, a driving mechanism for driving the supporting beam to move back and forth in the axial direction of the punch is arranged at the lower part of the supporting beam, and the top surface of the supporting beam makes contact with and supports the lower side surface of the front part of the punch; and cushion blocks with adjustable thickness are arranged between the square columns and the sliding block of the punch. The horizontal type drawing press is matched with the supporting beam for supporting the long punch, so that the punch is prevented from falling, and the supporting beam can move along with the sliding block of the mounting punch, gaps between the sliding block of the punch and the square columns can be adjusted at the same time so as to ensure that the punch moves along the center of the press.

Owner:CHONGQING JIANGDONG MACHINERY

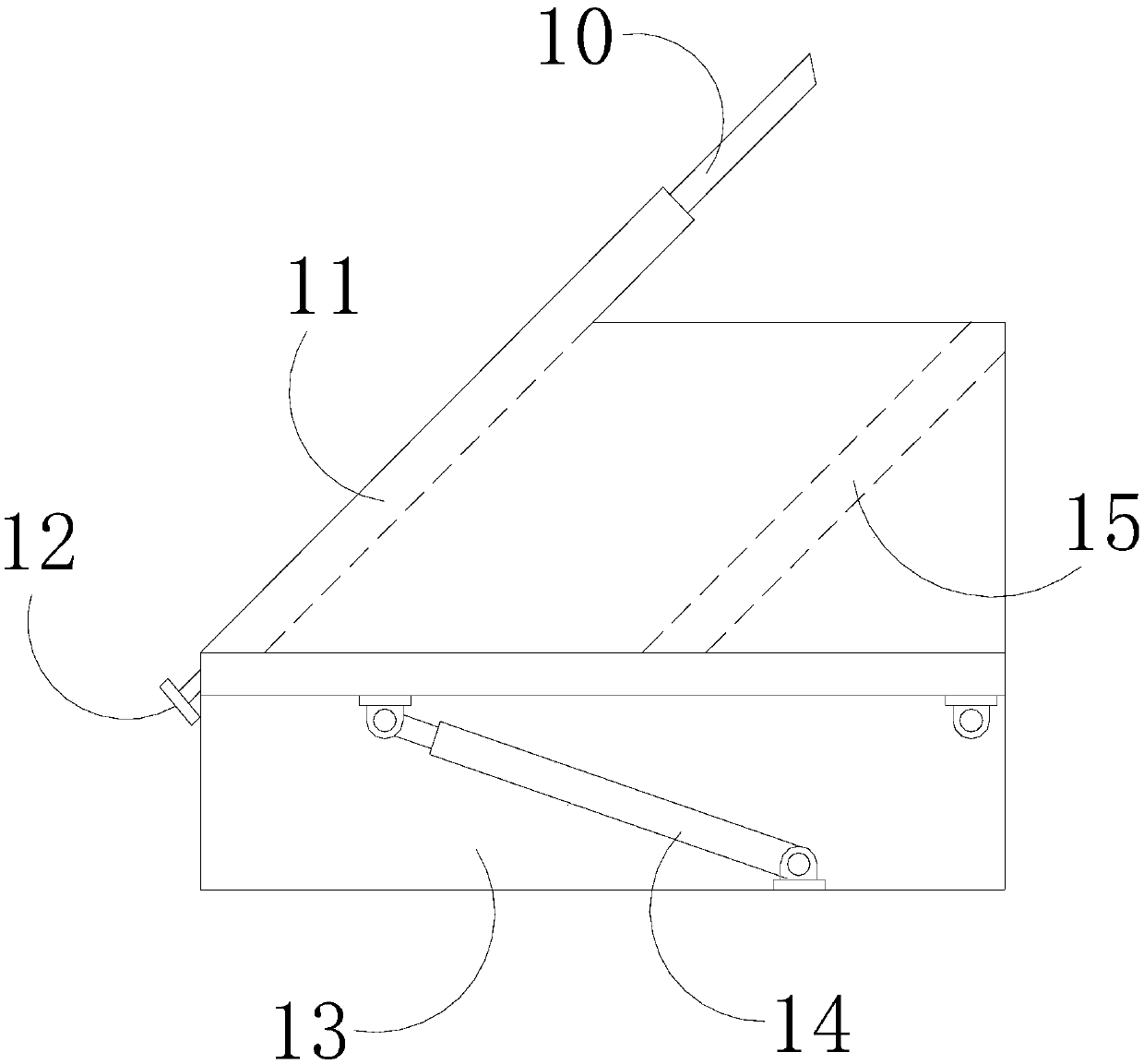

Sand screening facility capable of scraping sand on belt and characterized by being adjustable in separation distance between scraping plate and belt

InactiveCN109625850AAdjustable spacingDoes not affect construction progressConveyorsCleaningEngineeringBelt conveyor

The invention discloses a sand screening facility capable of scraping sand on a belt and characterized by being adjustable in the separation distance between a scraping plate and the belt. The sand screening facility structurally comprises a sand scraping device, a supporting frame, a finished product sand conveying device, a discharging drum, a drum screen, a raw material feeding belt conveyor and a raw material storage hopper. The drum screen is arranged on one side of the supporting frame. Compared with the prior art, the sand screening facility has the beneficial effects that the sand which is kept on the belt can be timely scraped, the phenomenon of accumulation of the sand is effectively avoided, and therefore the sand conveying speed cannot be affected; the normal amount of sand canbe held in a screen drum, and therefore the electric energy is saved advantageously as the screening efficiency is improved, and then the screening cost is reduced; meanwhile, the phenomenon that dueto accumulation of the sand, the flowing sand slides to a rotating shaft can be avoided, the phenomenon that the rotating shaft gets stuck is avoided, the belt can normally supply materials, and theconstruction progress is not affected; and the gap between the sand scraping plate and the belt is adjustable, sand scraping operation is more facilitated, the sand scraping plate is convenient to replace and install, and sand discharging operation is also thorough.

Owner:黄崇生

Steel plate cutting equipment

ActiveCN111992802AImprove stabilityAffect stabilityMetal sawing devicesMaintainance and safety accessoriesClassical mechanicsEngineering

The invention provides steel plate cutting equipment which comprises an operating table provided with supporting rods at the lower end. The steel plate cutting equipment is characterized in that a cutting device is arranged on the operating table, mounting bars are symmetrically mounted on two sides of the cutting device, one sides of the mounting bars are movably connected to one side of a protecting hood in a fit manner, a steel plate clamping device is arranged on the mounting bars, the steel plate clamping device is connected to a steel plate treatment device through a pressure bar, and one side of the steel plate clamping device is further connected to a cooling device through a push rod. The invention provides the steel plate cutting equipment. By adopting the pressure bar to connectthe steel plate clamping device and the steel plate treatment device and adopting the push rod to connect the steel plate clamping device and the cooling device, the steel plate clamping device, thesteel plate treatment device and the cooling device are linked, so that the devices are matched in use when the cutting device cuts a steel plate to cool the steel plate and clean scraps, and therefore, the steel plate is cleaned and planished.

Owner:泰兴市蚁克搬运设备有限公司

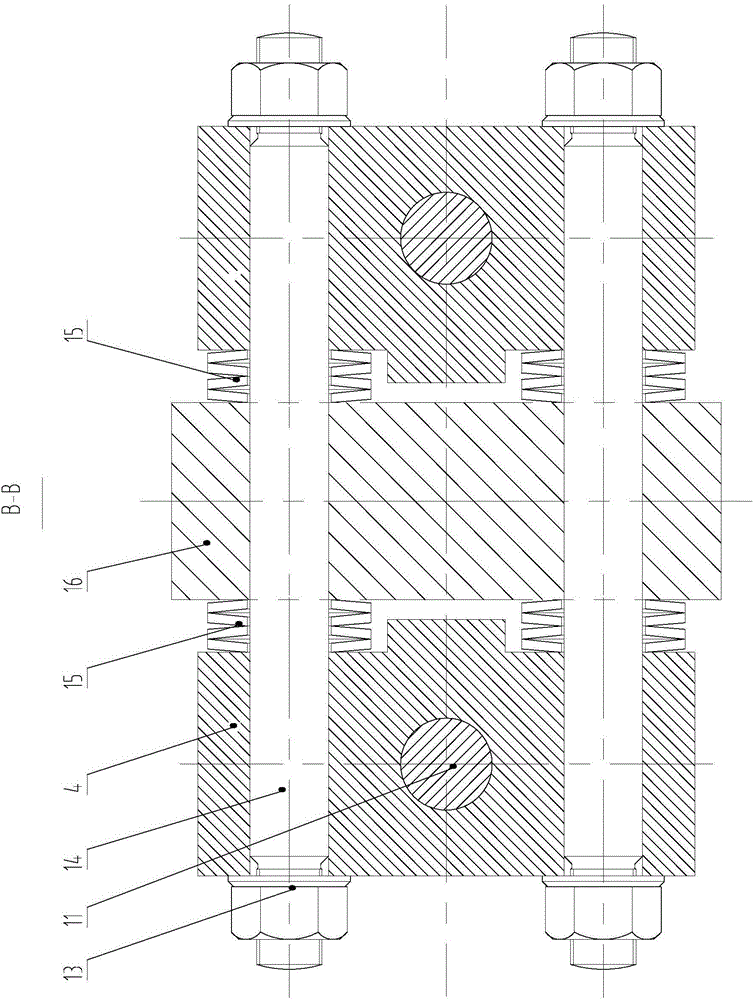

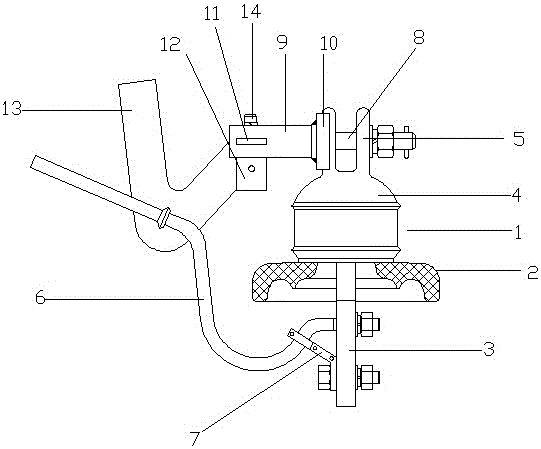

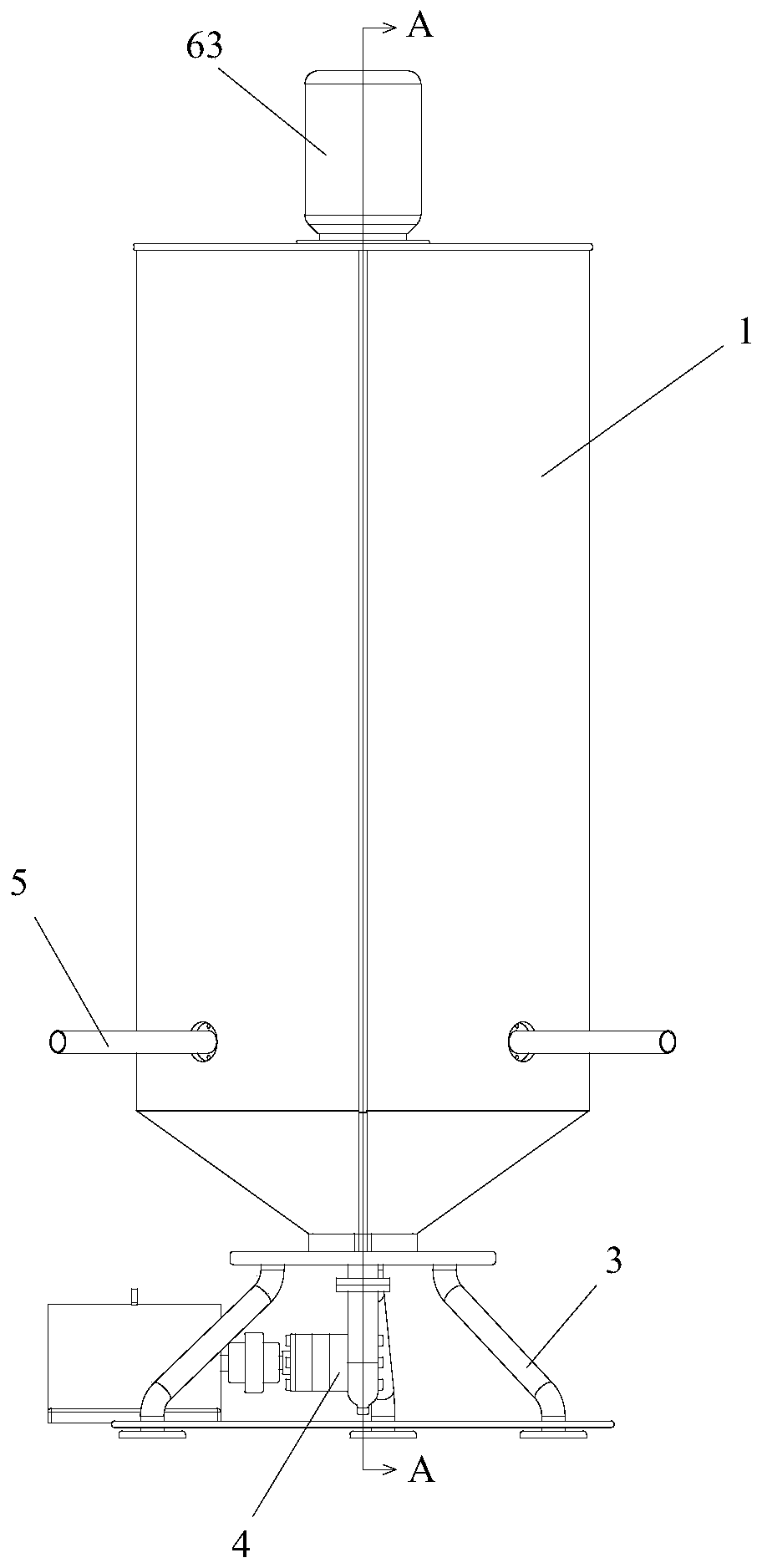

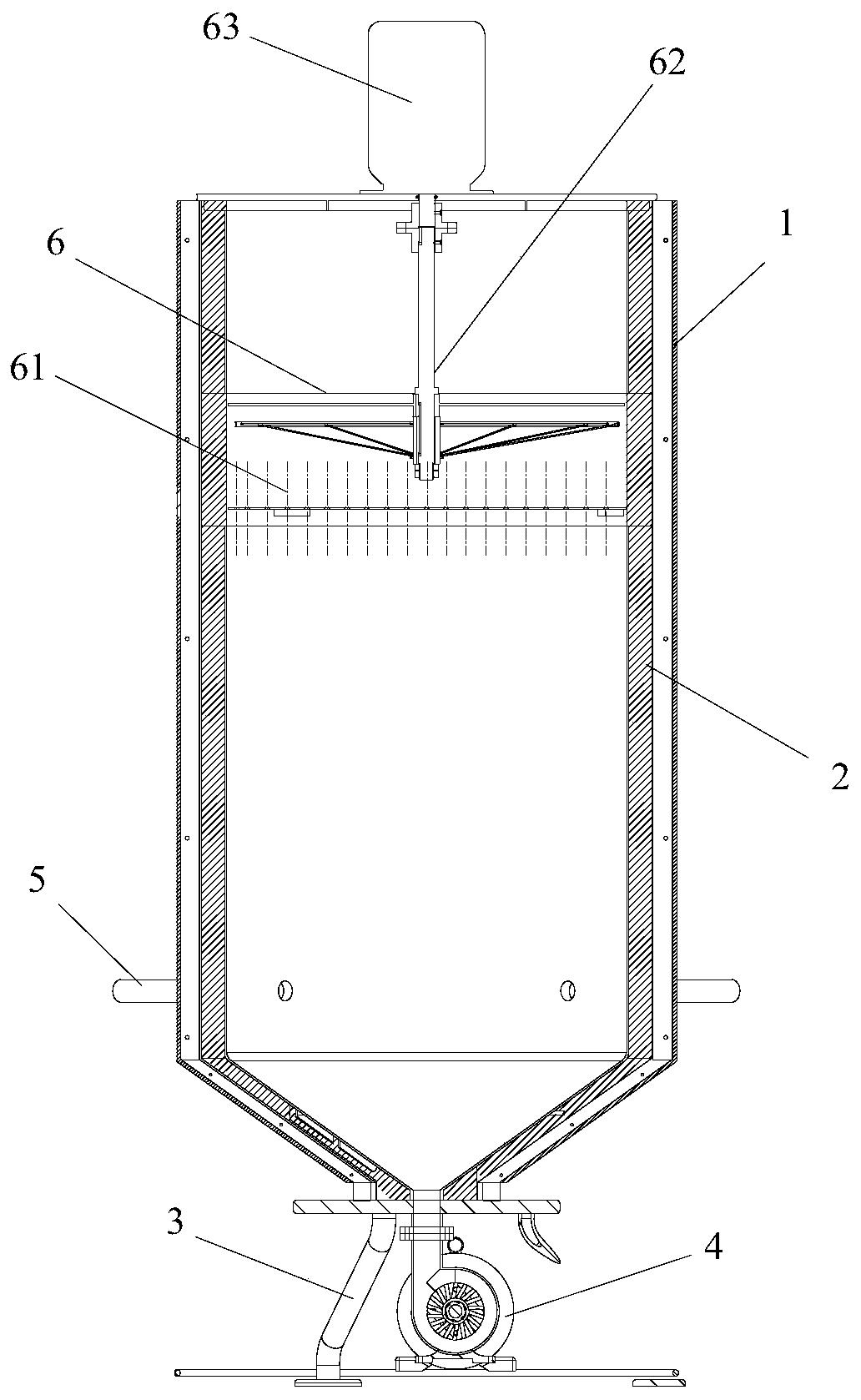

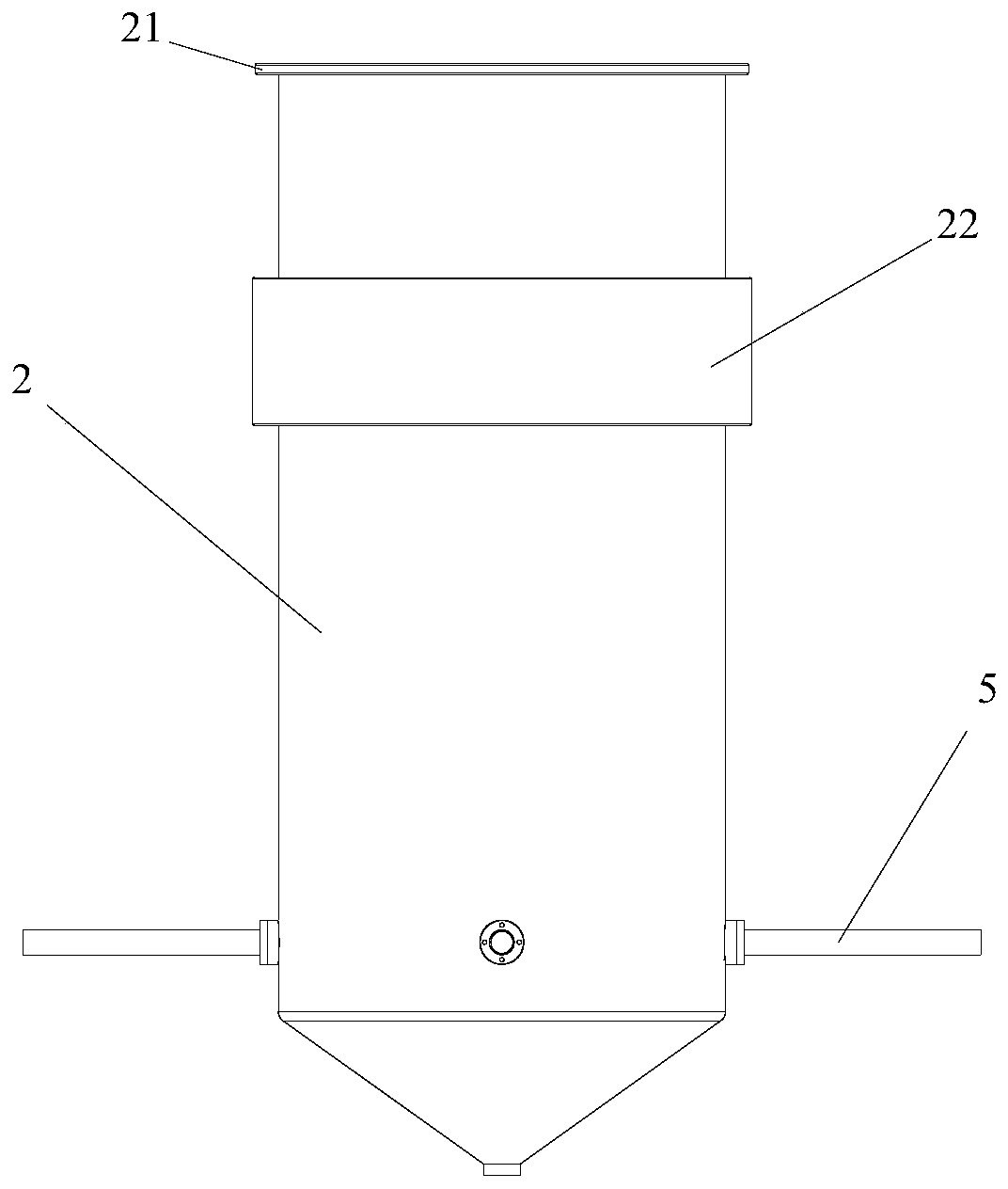

Mixing melting device for preparing modified emulsified asphalt, and use method thereof

InactiveCN110639413AAdjustable clearanceCompact structureTransportation and packagingMixersThermodynamicsBitumen emulsion

The invention discloses a mixing melting device for preparing modified emulsified asphalt. The mixing melting device comprises a base, an outer cylinder arranged on the base, an inner cylinder arranged in the outer cylinder, a stirring device and a group of material inlet pipes penetrating through the outer cylinder and connected to the inner cylinder, wherein the stirring device comprises a suction type rotational flow volute and a first motor for driving a rotational flow core in the rotational flow volute to work, the top end interface of the rotational flow volute is connected to the outlet in the lower end of the inner cylinder, a cage type rotational flow core is arranged in the rotational flow volute, an internal pressure disperser is arranged in the rotational flow core, a colloidmill is installed behind the rotational flow core, and the mixing melting device further comprises a defoaming device. The invention further discloses a method for preparing modified emulsified asphalt. According to the invention, the problem that asphalt modification and emulsification are completed at a time is solved while the temperature of the asphalt is kept at the normal storage temperature, the extra heating is not needed, and in the whole preparation process, the temperature is within 100 DEG C, such that the raw materials are not affected by high-temperature aging, the product performance is high, and the storage is stable.

Owner:北京丰泽华夏生态环境科技有限公司

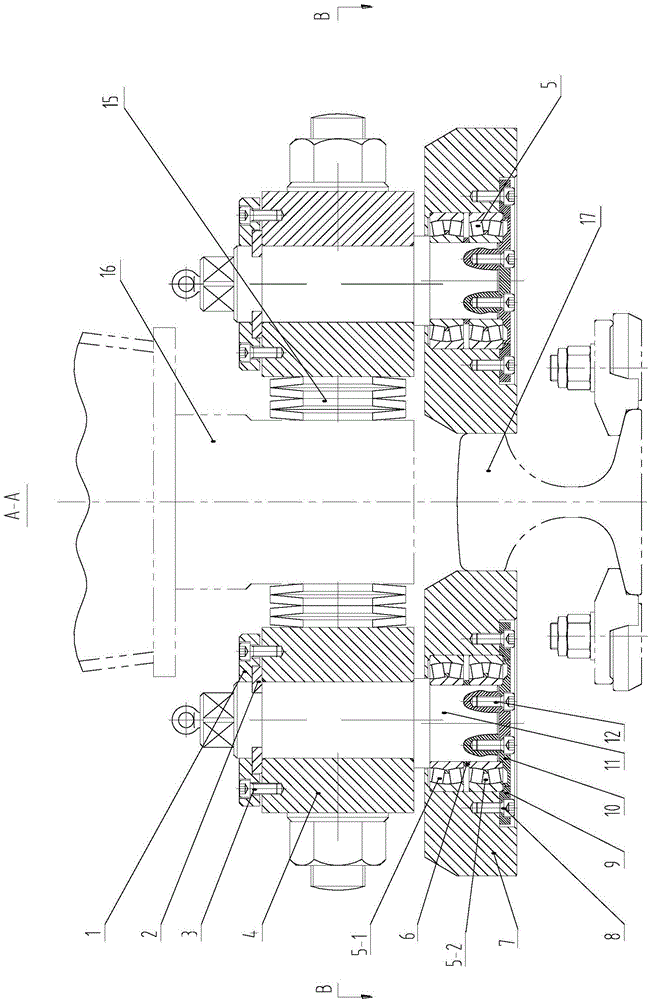

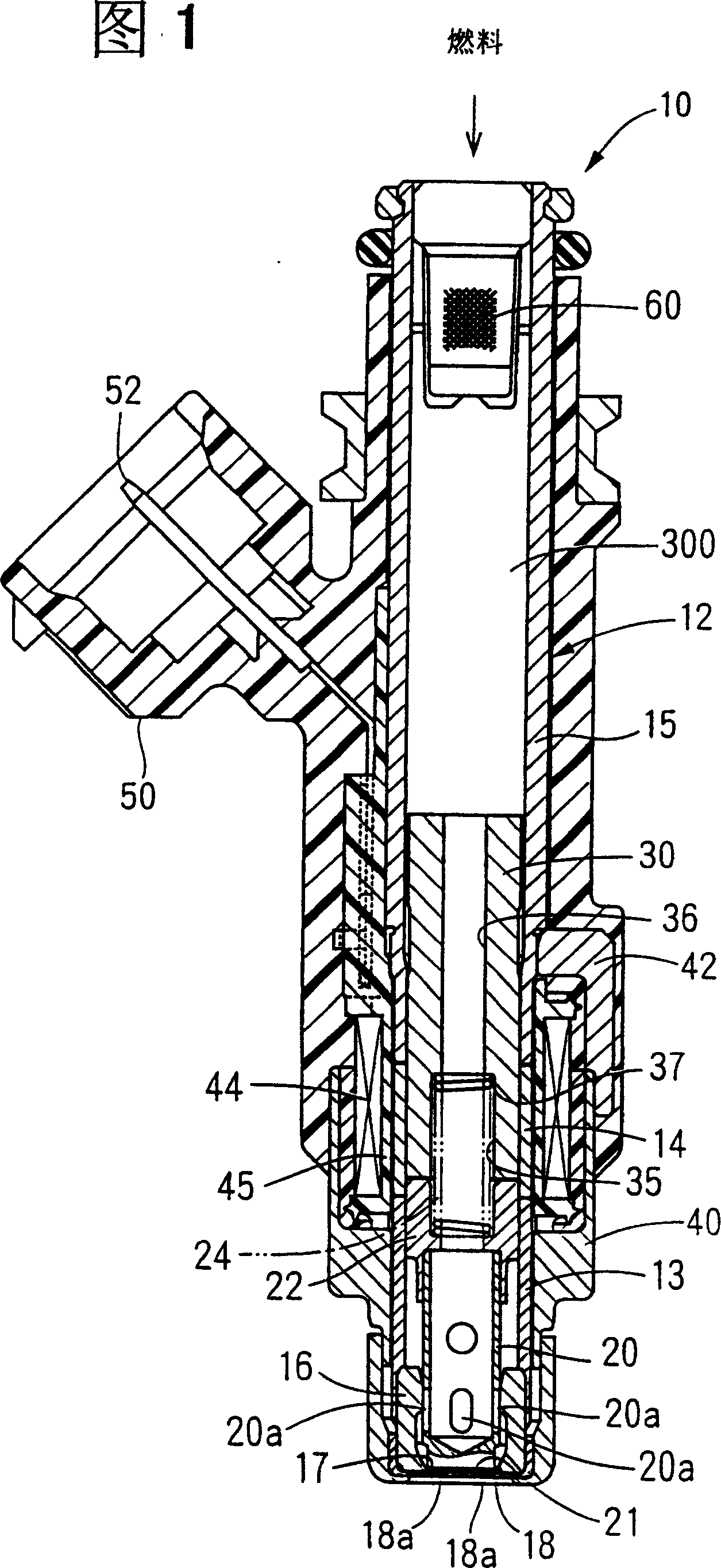

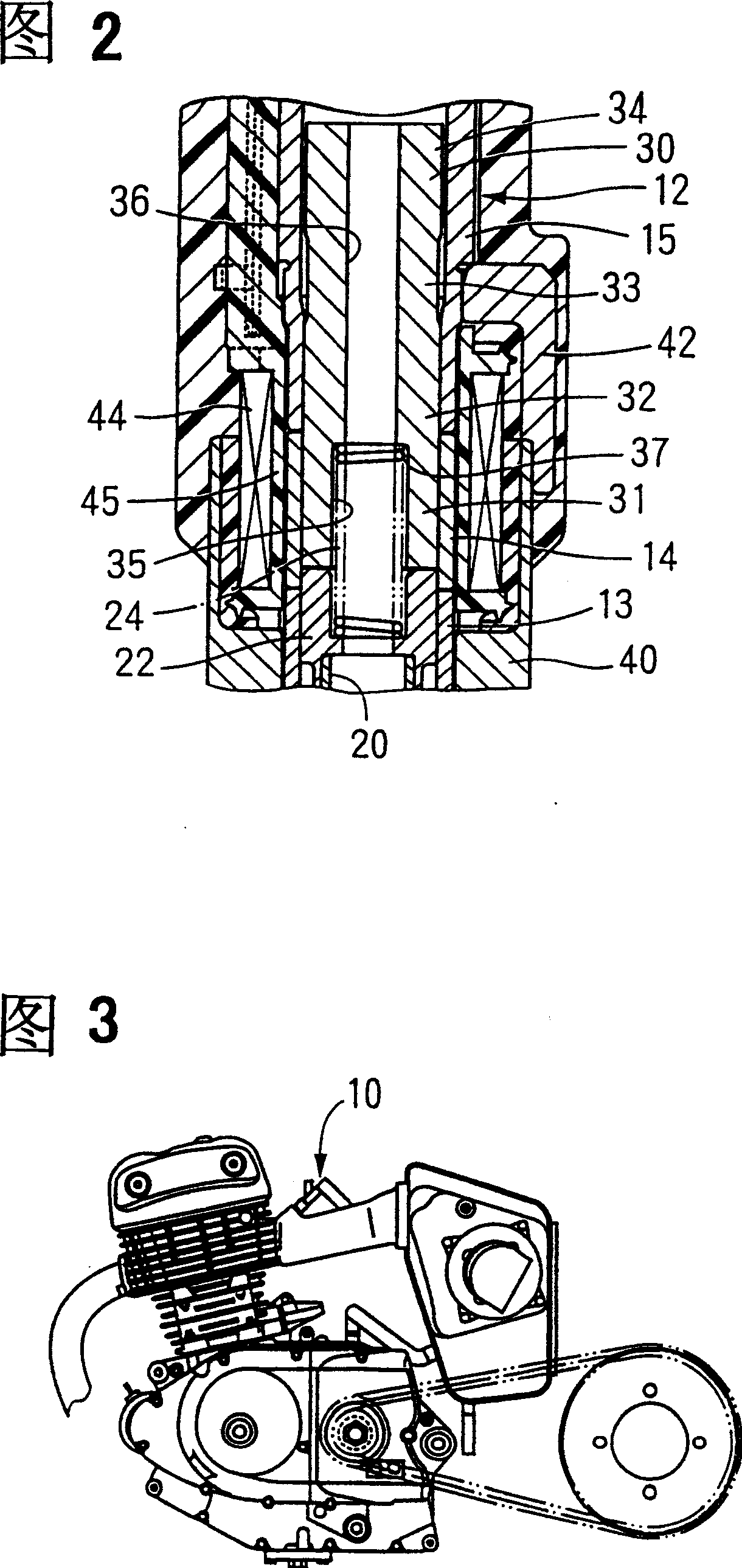

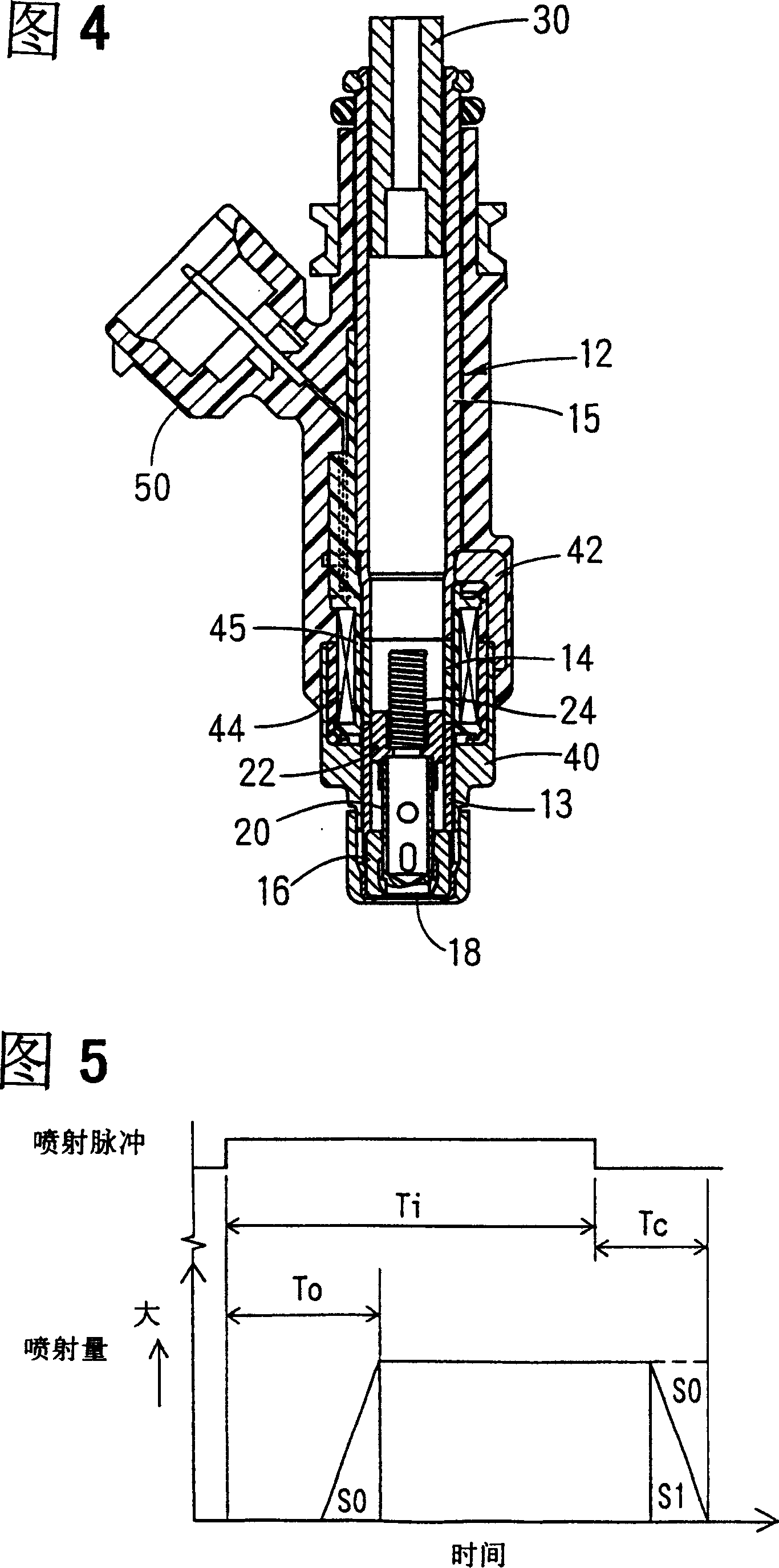

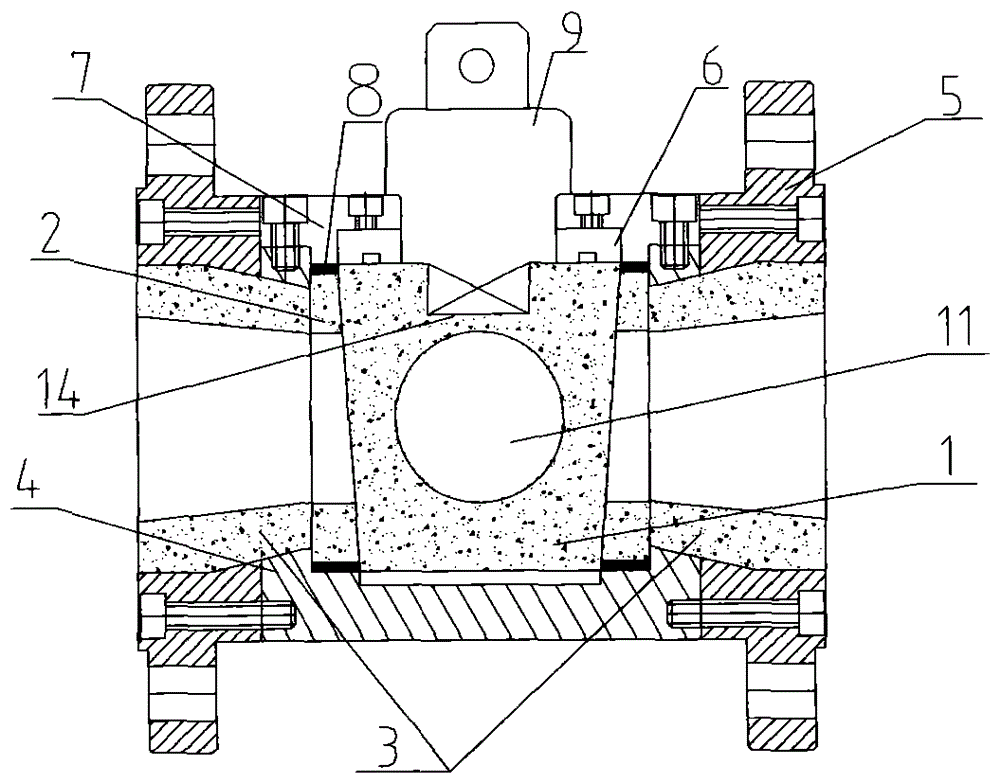

Fuel spraying valve and method for regulating its spraying volumn

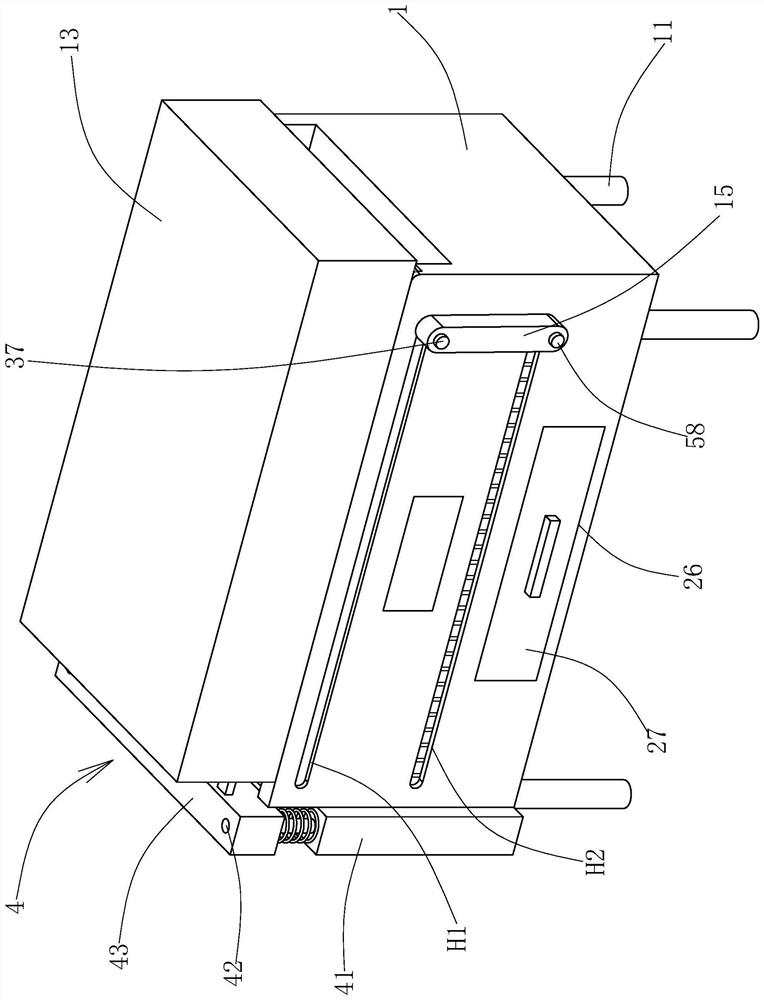

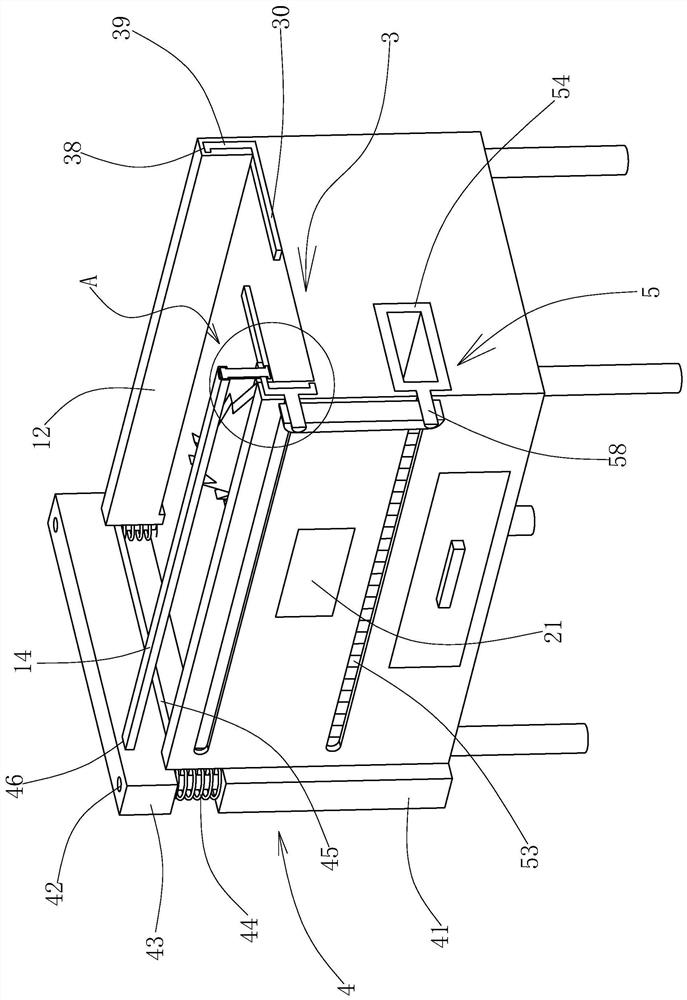

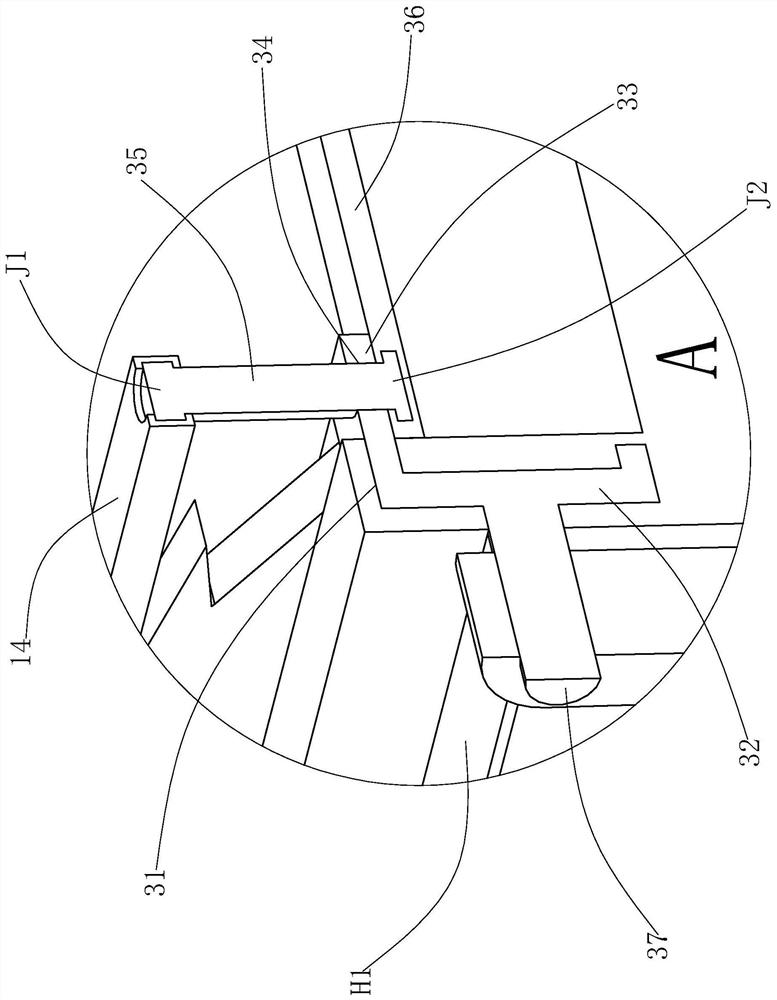

InactiveCN1329653CAdjustable clearanceAdjustable pushing forceFuel injection apparatusMachines/enginesEngineeringInternal combustion engine

A fixed core 30 is fixed to a cylindrical member 12 by being pressed and inserted to a nonmagnetic member 14 of the cylindrical member 12, and inside of a secondary magnetic member 15. An inner diameter wall of the fixed core 30 has a larger diameter part 35 and a smaller diameter part 36. A step 37 is formed on the border between the larger diameter part 35 and the smaller diameter part 36. One end of a spring 24 is engaged with the step 37 and the other end is engaged with the movable core 22. The spring 24 energizes the movable core 22 and a valve member 20 in the direction which the valve member 20 is seated at a valve seat 17. When energization to a coil 44 is on, the valve member 20 along with the movable core 22 is moved to the fixed core 30 against the energization of the spring 24, and a contact 21 is separated from the valve seat 17. Thus, the fuel is injected from an injection hole 18a.

Owner:DENSO CORP

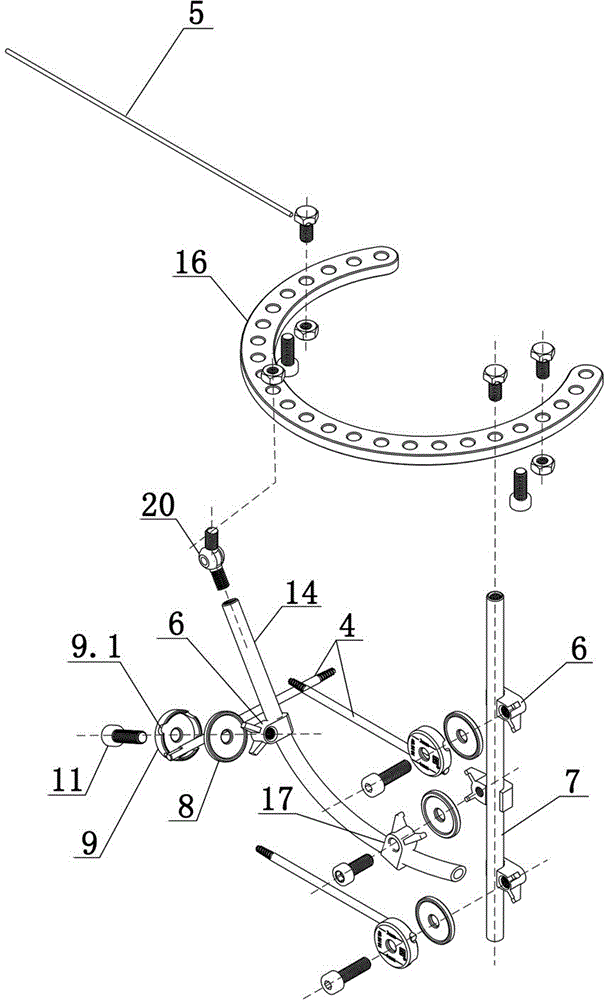

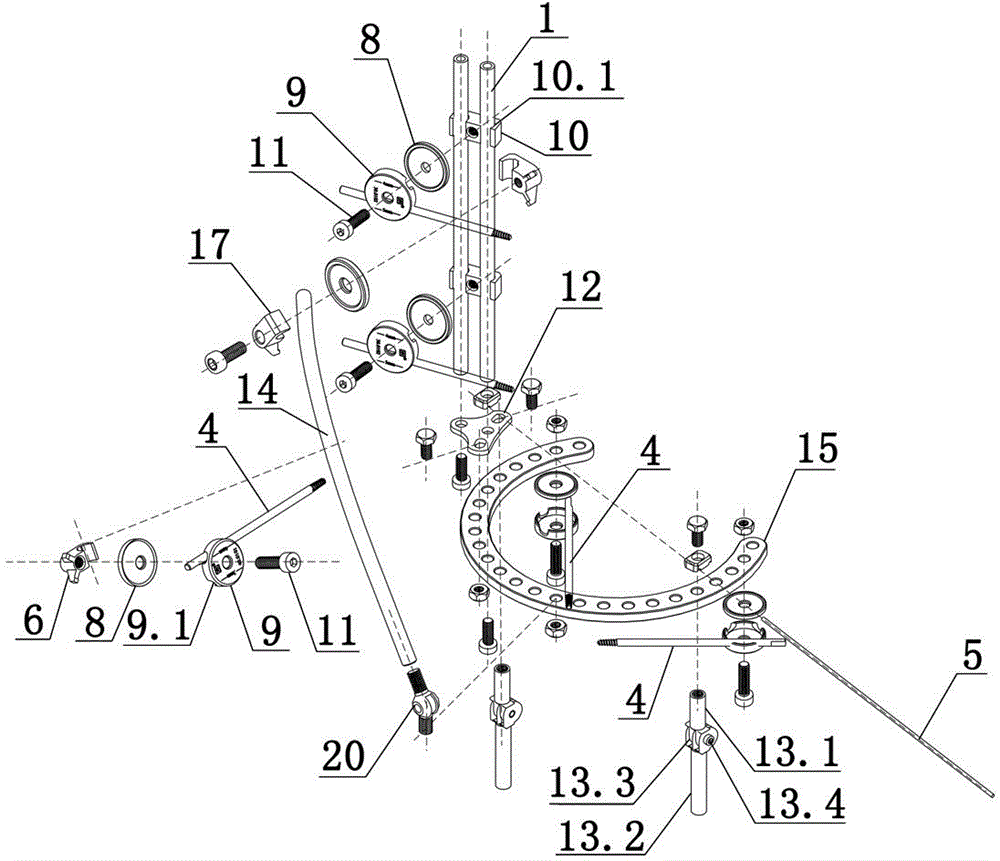

Knee-joint activity and inertia-combined adjusting control outer fixer

A knee-joint activity and inertia-combined adjusting control outer fixer comprises an upper C-shaped hole ring arranged at a thighbone far end, and a lower C-shaped hole ring arranged at a tibia near end; the upper C-shaped hole ring is upwards connected with two upper tubular connection rods by a T-shaped connection plate; two dual-groove steel needle fixing clamps are fixed on the two upper tubular connection rods; point ends of two thread semi-needles are fixed on a femoral shaft; an arc arch is connected between the upper C-shaped hole ring and the upper tubular connection rods; the tail ends of the thread semi-needles are fixed with a single-groove steel needle fixing clamp on the arc arch; the point ends of the thread semi-needles are fixed on the femoral shaft. The upper C-shaped hole ring and the lower C-shaped hole ring are connected by a knee elbow joint device. The knee-joint activity and inertia-combined adjusting control outer fixer is firm in static fixing and balanced in dynamic fixing, can adjust and control the kneel joint gap, can promote the fracture healing and reduce or avoid the stiffness of the knee joint and is an advanced and excellent treatment method for the knee joint fracture, particularly the severe comminuted fracture.

Owner:JIANGSU GUANGJI MEDICAL TECH

An insulator lightning protection device with adjustable discharge gap

ActiveCN107180689BAdjustable clearanceLightning protection is stableInsulatorsOvervoltage arrestors using spark gapsEngineeringElectric power

The invention relates to the electric power aerial line lightning protection technical field, and discloses an insulator lightning protection device capable of adjusting a discharging gap; the insulator lightning protection device comprises an insulator; the insulator comprises a porcelain body, a core bar, and a steel cap; the steel cap has a connecting lug with a connecting hole; the core bar is provided with a rod electrode; one end of the rod electrode is provided with threads; the core bar is provided with an electrode positioning hole; the rod electrode penetrates the electrode positioning hole and is locked by a nut; a stud is arranged in the steel cap connecting hole; one end of the stud is welded with a connecting rod; the other end of the stud is locked by a nut; a rectangular hole penetrating two sides of the connecting rod is arranged outside the connecting rod; a slide piece is arranged in the rectangular hole; the slide piece outer end bends and extends to form a connecting piece; the connecting piece is provided with a plate electrode; the side face of the connecting rod is provided with a locking bolt used for fixing the slide piece. The insulator lightning protection device can adjust the gap, and is stable in lightning protection effect.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JINHUA POWER SUPPLY CO +1

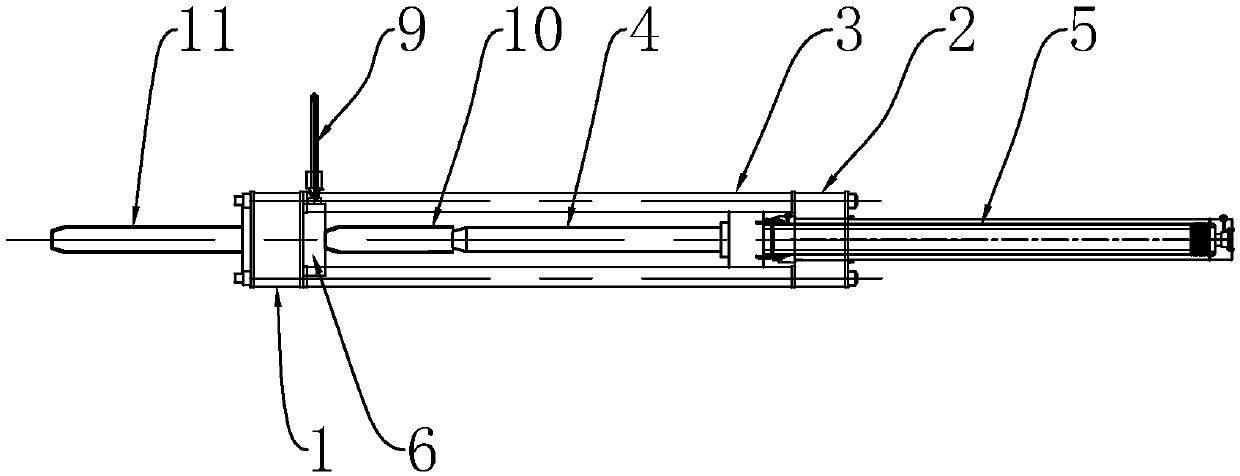

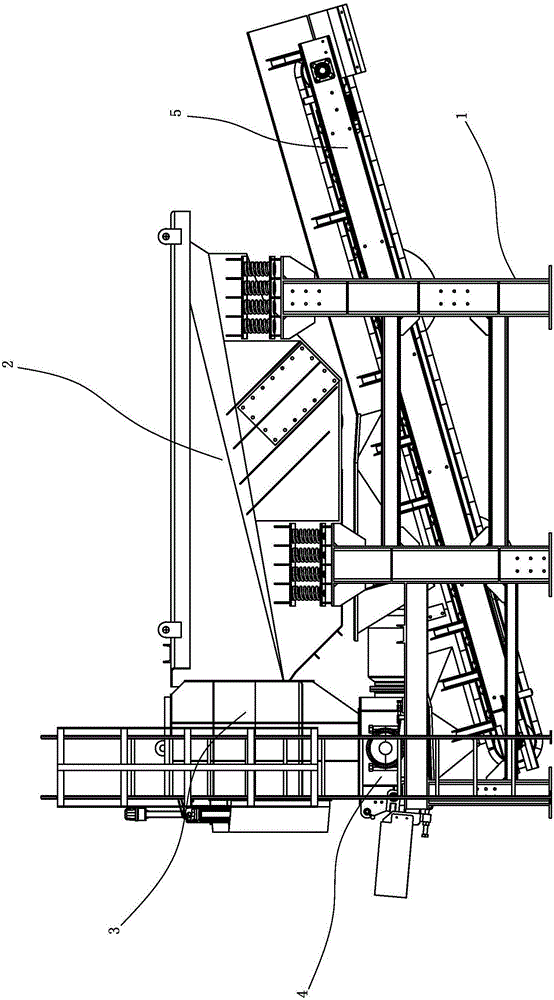

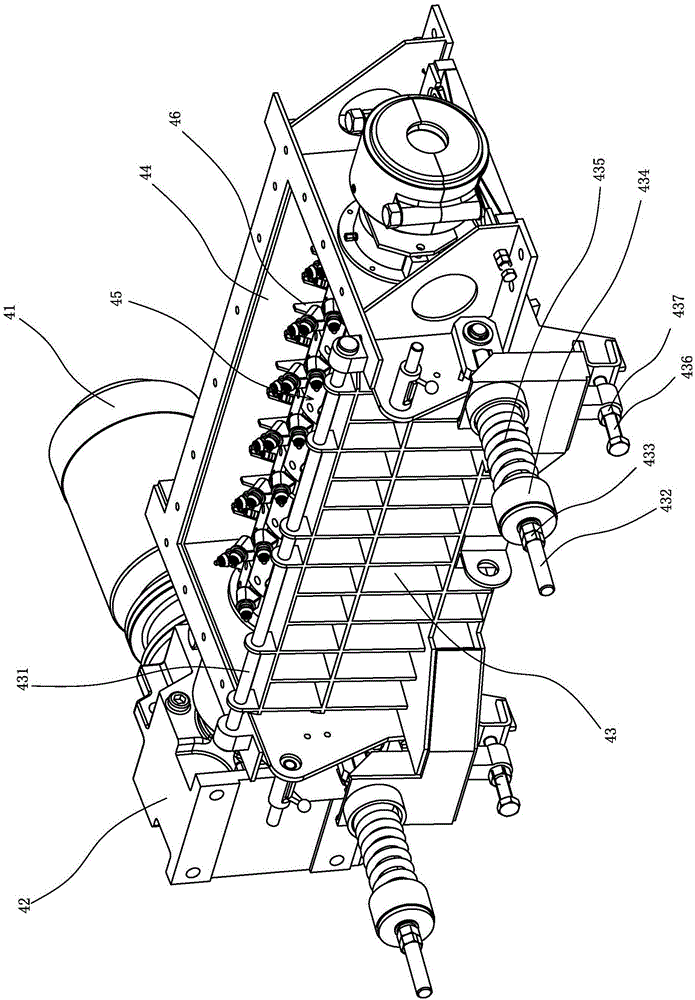

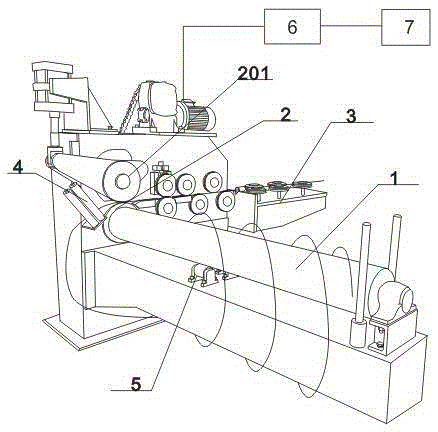

Bearing rolling body cold heading machine online synchronous feeding uncoiling straightening equipment

ActiveCN104028592BRealize continuous straightening and feedingFeeding speed is adjustableEngineeringWheel drive

Online synchronous continuous feeding, uncoiling and straightening equipment of a bearing roller header comprises a hanging shaft used for laying a bearing steel material, a pulling pair wheel driven by a speed-variable motor, and a straightening device used for straightening the bearing steel material. Continuous power is provided to the bearing steel material, pulling speed can be adjusted according to the bearing steel material, and straightening work is completed in the process of conveying.

Owner:LUOYANG WEICHUANG BEARING MOLD

A waste asphalt mixture crusher and its crushing method

A waste asphalt mixture crusher and its crushing method, the crusher includes a frame, a control device, a vibration screening device respectively arranged on the frame, a collecting device, a crushing device and a finished product conveying device, the crushing device includes A crushing bin with a feed inlet and a discharge port, a crushing roller arranged in the crushing bin, a driving motor for driving the crushing roller to rotate, and a jaw plate arranged on the crushing bin opposite to the crushing roller. The outer peripheral surface of the crushing roller is distributed There are several milling knives, and several milling slots for the milling knives are arranged on the opposite surface of the jaw plate and the crushing roller, and a gap is formed between the milling knives and the milling slots to accommodate the coarse aggregate in the coarse material, To prevent the crushing of the coarse aggregate from damaging the original gradation of the waste asphalt mixture, the invention performs crushing by means of alternate crushing, which can effectively improve the crushing efficiency and crushing effect.

Owner:FUJIAN TIETUO MACHINERY

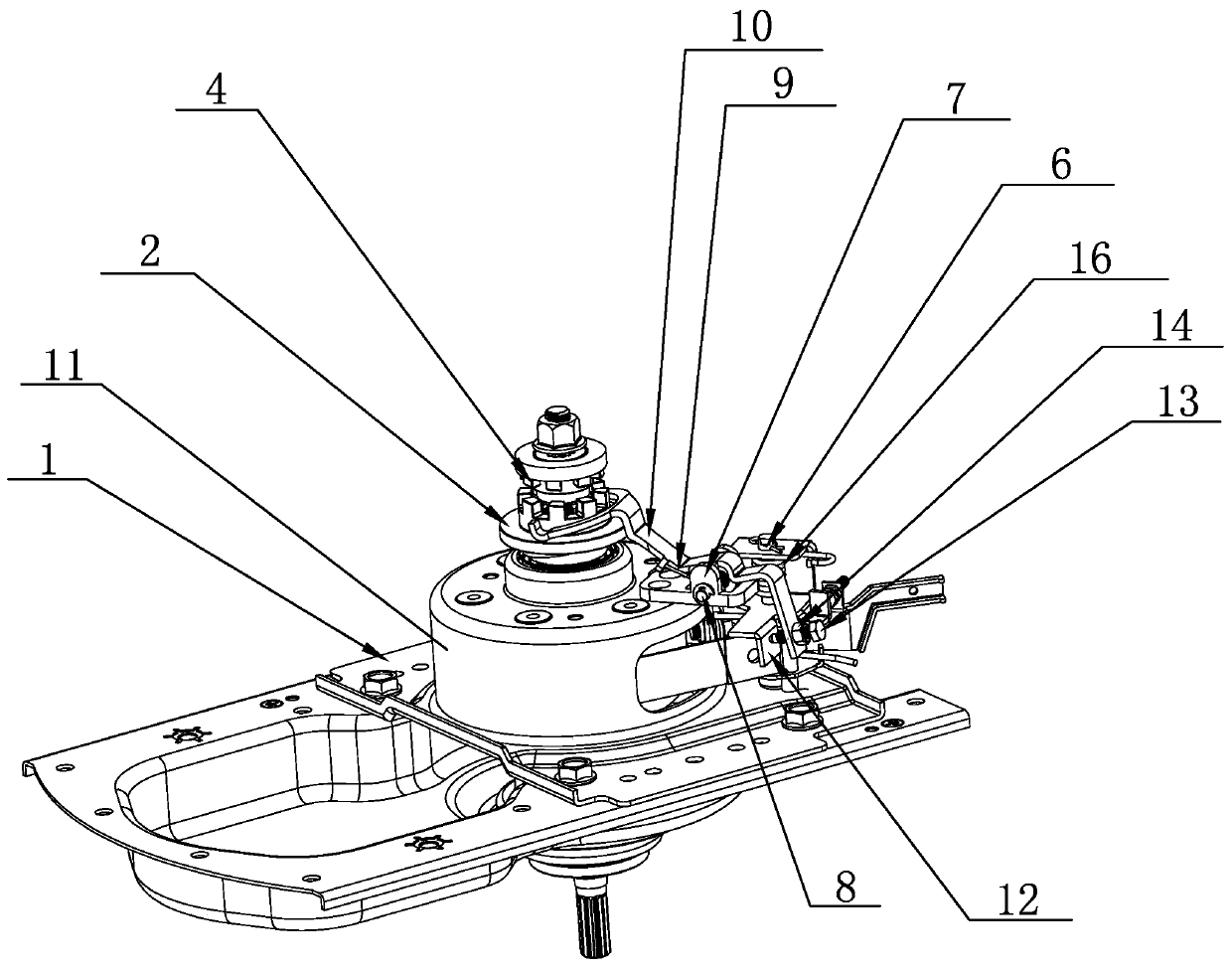

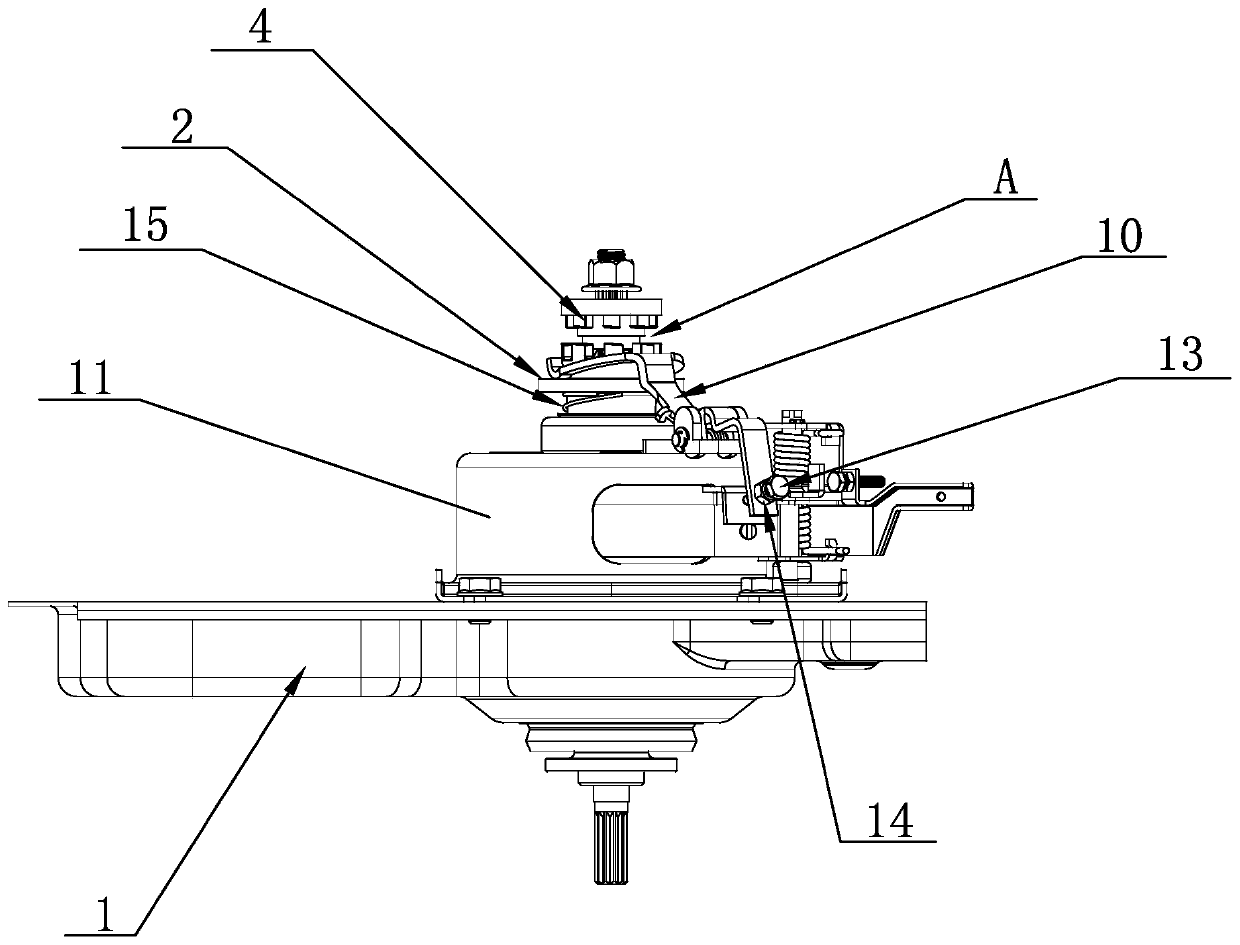

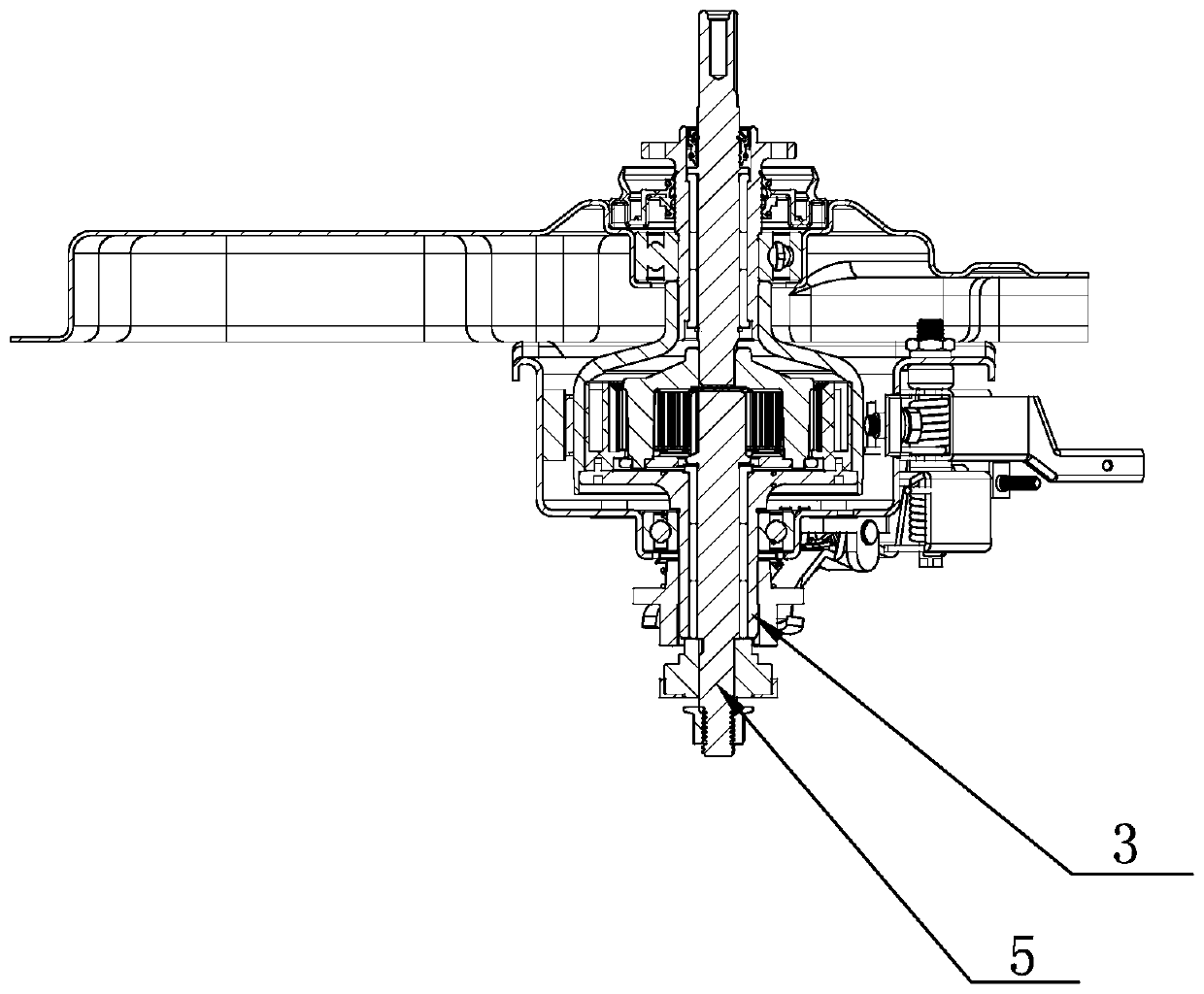

Clutch device of speed reduction clutch

PendingCN111120537AReasonable structural designAdjustable clearanceMechanical actuated clutchesOther washing machinesControl engineeringTorque transmission

The invention discloses a clutch device of a speed reduction clutch. The device comprises a lower shell, a linkage disc, a brake axle, a torque transmission shaft sleeve, an input shaft and brake armpins. A shifting fork positioning block is fixedly arranged on the lower shell and provided with multiple pin holes, shifting fork linkage pins penetrate through the pin holes, shifting fork springs sleeve the shifting fork linkage pins, and a shifting fork is connected to each shifting fork spring. One end of the shifting fork is provided with a shifting fork push arm, the shifting fork push armssleeve the brake arm pins, and the shifting fork push arms are provided with shifting fork push arm torsional springs. One end of each shifting fork push arm is provided with a positioning face, theother end of each shifting fork push arm is provided with a contact plane, the portion, aligned with the corresponding contact plane, of each shifting fork is provided with a screw hole, a limit screwis in threaded connection with the interior of each screw hole, and the head of each limit screw abuts against the corresponding contact plane. According to the technical scheme, the clutch device isreasonable in structural design and simple in structure, the shifting forks and positioning discs do not easily deform, assembly is easy, the reject ratio of production can be lowered, the productionefficiency can be improved, and the practicability is good.

Owner:ZHEJIANG SANXING MECHANICAL & ELECTRONICSAL STOCK

Blow-drying device for ceramic production process

ActiveCN113446246AReduce noiseGood noise reductionPump componentsPump installationsComposite materialImpeller

The invention discloses a blow-drying device for a ceramic production process. The blow-drying device for the ceramic production process comprises a centrifugal fan, an impeller comprises a front disc, a rear disc and blades, the multiple blades are evenly distributed between the front disc and the rear disc in the circumferential direction, the inlet end of the front disc is provided with an arc-shaped inlet ring part, and the side, away from the blades, of the rear disc is provided with a back ring; and the blow-drying device is characterized in that the radial periphery of the arc-shaped inlet ring part is tightly connected with a first noise reduction ring, and the first noise reduction ring is a first metal foaming porous body. The noise reduction ring / metal foaming porous body is arranged at the inlet ring and / or the back ring of the impeller, the noise of the fan can be effectively reduced, the metal foaming porous body is arranged at the inlet ring and the back ring of the impeller, compared with other noise reduction structures, the better noise reduction effect is achieved, the better heat dissipation / heat transfer effect is achieved, and therefore, the blow-drying effect is improved.

Owner:JINGDEZHEN CERAMIC INSTITUTE

On-line synchronous continuous feeding decoiling and straightening equipment for bearing rolling element cold heading machine

ActiveCN104028591BRealize continuous straightening and feedingFeeding speed is adjustablePunch pressRolling-element bearing

Online synchronous continuous feeding, uncoiling and straightening equipment of a bearing roller cold header comprises a hanging shaft used for laying a bearing steel material, a pulling pair wheel driven by a motor, a trigger switch, a controller for controlling rotation of the motor, and a straightening device used for straightening the bearing steel material. Power is continuously provided to the bearing steel material, conveying speed of the bearing steel material is adjusted by adjusting working speed of the cold header or a punching machine to ensure the conveying speed to be uniform with using speed, synchronous working is realized, and straightening work is completed in the process of conveying.

Owner:LUOYANG WEICHUANG BEARING MOLD

High-strength carbon fiber easy-to-install printing cylinder support body

The invention relates to a component of an offset printing machine, in particular to an easy-installation and high-strength carbon fiber printing cylinder support comprising a printing cylinder and a central solid shaft, wherein a support body is arranged between the printing cylinder and the solid shaft. The support is characterized by compositing a carbon fiber layer, an EVA elastic body layer and a glass fiber layer to be cylindrical. The support is high in strength and adjustable in strength by adjusting the thickness of the carbon fiber layer and the thickness of the glass fiber layer. In addition, the support has certain elasticity and is convenient to install, and the play of the cylinder can be adjusted by adjusting the thickness of the EVA elastic body layer.

Owner:ZIBO LANGDA COMPOSITE TECH

A ceramic cone valve

The invention relates to a rotary cone valve, in particular relates to a ceramic rotary cone valve, and belongs to the technical field of rotary cone valves. The ceramic rotary cone valve comprises a shell, wherein the shell is a metal shell or a ceramic shell, has a split structure or an integrated structure, and is in threaded connection with a flange or a flange pressing ring; an intermediate is arranged in the shell and is made of ceramics or polytetrafluoroethylene; and a ceramic valve core is sleeved in the intermediate in a close fit manner. According to the ceramic rotary cone valve, a clearance between the ceramic valve core and the intermediate can be adjusted, so that an optimal sealing effect is achieved; a ceramic flange liner is in close fit with the flange pressing ring through an additionally arranged step, so that the problem that the ceramic flange liner easily drops off at high temperature in the prior art is solved; the intermediate can be made of a polytetrafluoroethylene material, so that the ceramic rotary cone valve is high in sealing performance, cannot be scratched, is small in torque, and is smoothly turned on and turned off; and with the structure, the ceramic rotary cone valve is long in service life and low in using cost.

Owner:烟台明珠陶瓷科技有限公司

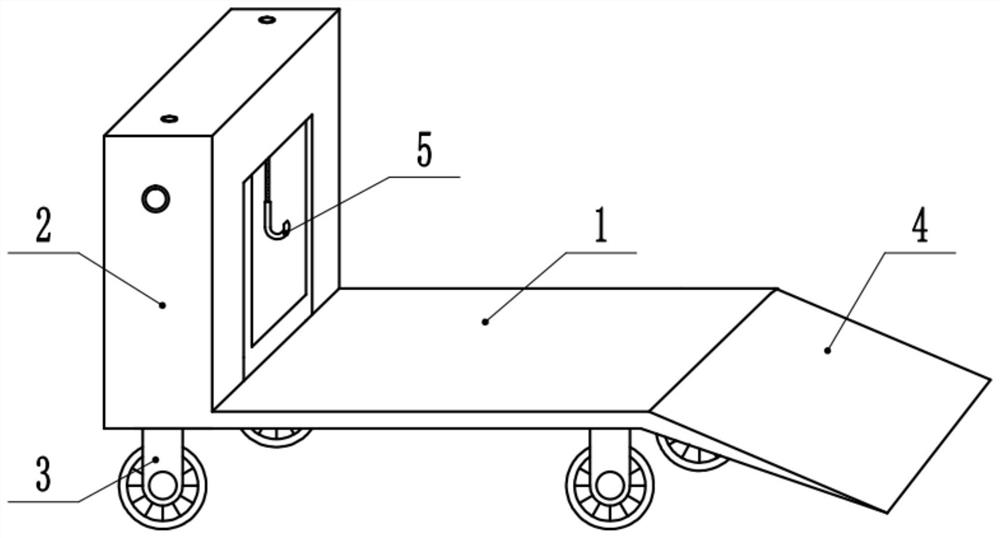

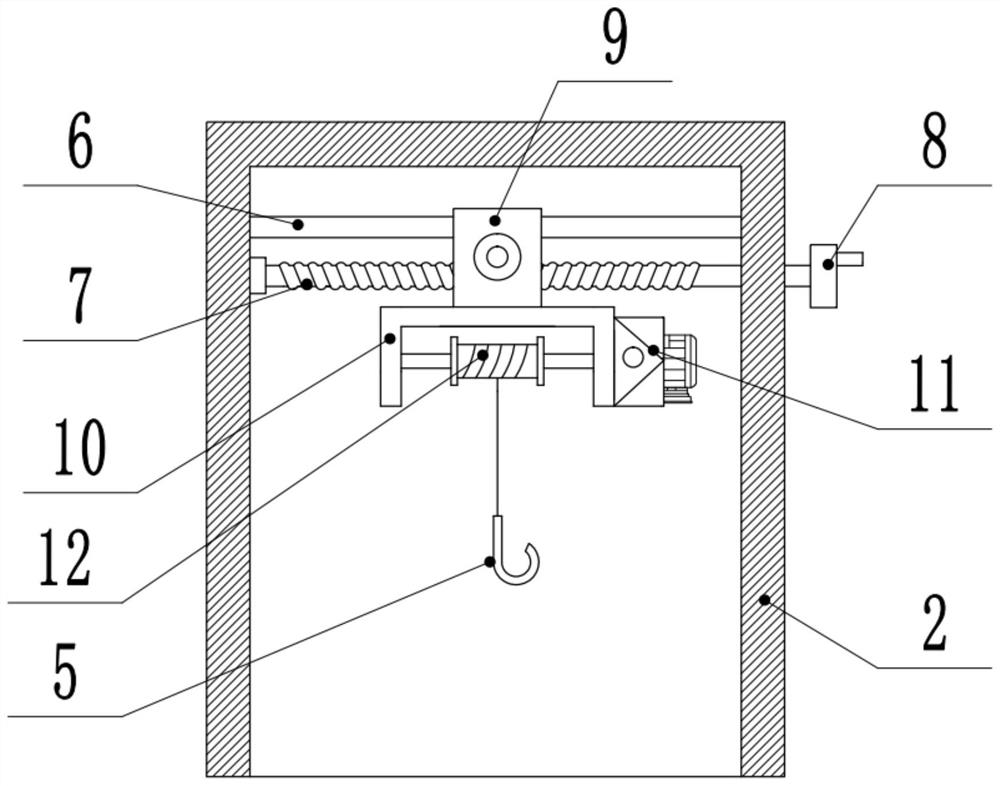

PVC floor winding equipment with hoisting function

PendingCN111908345AAdjustable clearanceEasy to separateTrolley cranesTravelling gearElectric machineControl theory

The invention discloses PVC floor winding equipment with a hoisting function. The PVC floor winding equipment comprises a bottom plate, and roller assemblies are mounted at four corners of the lower side of the bottom plate; a hoisting assembly is arranged on the left side of the upper surface of the bottom plate, a first sliding block is installed on a first screw through threads, an installationframe is welded to the lower side of the first sliding block, a hoisting motor is fixedly installed on the outer wall of the right side of the installation frame through a support, a winding roller is fixedly installed on an output shaft of the hoisting motor, and a hook is installed at the lower end of a pull rope on the winding roller. By adjusting the ground clearance of the bottom plate, thegap between a push plate and the ground can be adjusted. Compared with existing winding equipment, the PVC floor winding equipment has a function of adjusting the gap between the push plate and the ground , so that the push plate is more convenient, simpler and more effective when separating a PVC floor from the ground. Compared with an existing mode of hoisting the PVC floor manually, a mode of agantry crane principle is adopted, manual labor-consuming operation is not needed, manpower is greatly liberated, and time and labor are saved.

Owner:河北皋端建材科技有限公司

A ceramic plug valve

ActiveCN105276218BReasonable structural designExtended service lifePlug valvesStopcockMetallic materials

The invention relates to a ceramic plug valve, which comprises a metal shell, wherein an upper end cover is screwed above the shell; a lower end cover is screwed below the shell; a ceramic or other nonmetal material middle body is arranged in the shell; a ceramic valve element is tightly matched in the middle body; a valve rod hole is formed in the center of the upper end face of the valve element; a valve rod penetrates through the upper end cover and is matched with the valve rod hole; a circular or V-shaped through hole is formed in the middle of the valve element; the valve element is divided into an upper part and a lower part by taking the through hole as a basis, the valve element is an upper cone with thick upper part and thin lower part or a lower cone with thin upper part and thick lower part, and the taper is 0-20 degrees. The ceramic plug valve is characterized in that the joint between the thick end face of the valve element and the side face is provided with a groove or arc. Compared with the prior art, the ceramic plug valve has the advantages that the structural design is reasonable; the service life is long; the cost is low; no torque is produced by the valve under any pressure and only area friction force is produced; and the ceramic plug valve has the advantages of wear resistance, erosion resistance, corrosion resistance, high temperature resistance and the like.

Owner:烟台明珠陶瓷科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com