A waste asphalt mixture crusher and its crushing method

A technology of waste asphalt and mixture, applied in the direction of grain processing, etc., can solve the problems of limited viscosity of asphalt, low degree of crushing, damage to RAP gradation, etc., to improve the crushing effect, improve the crushing efficiency, and ensure smooth transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

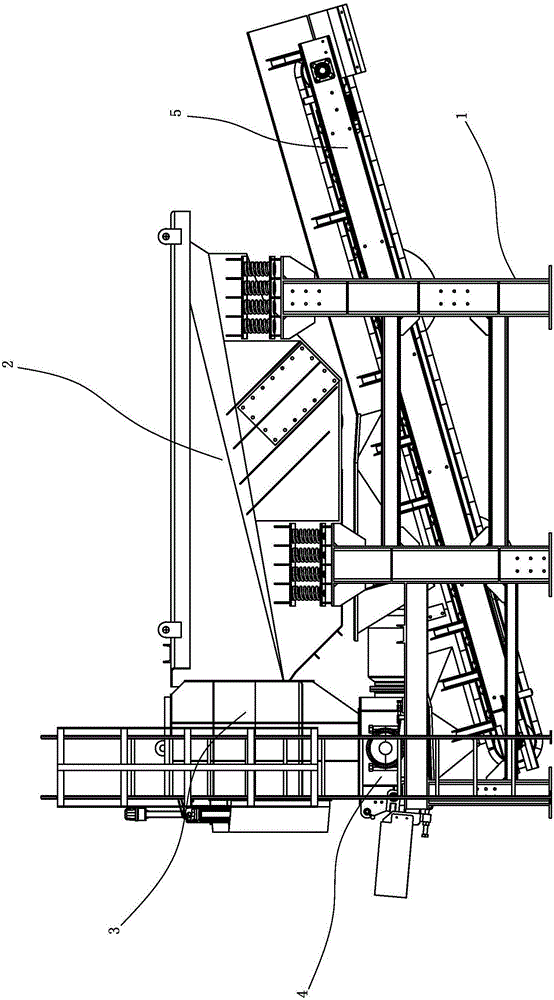

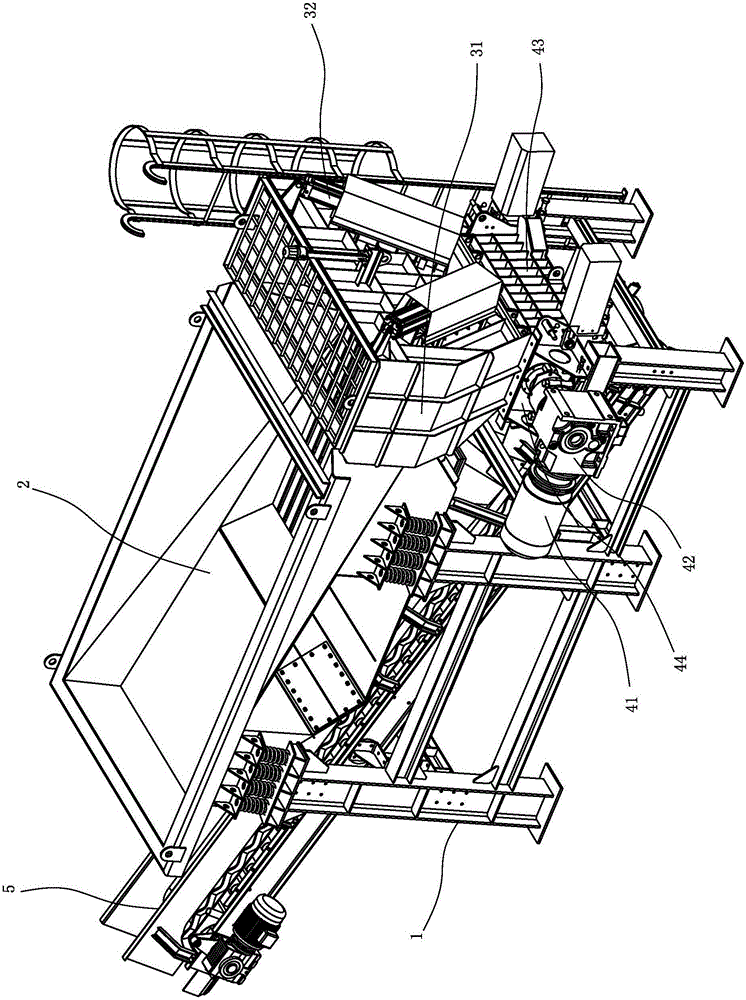

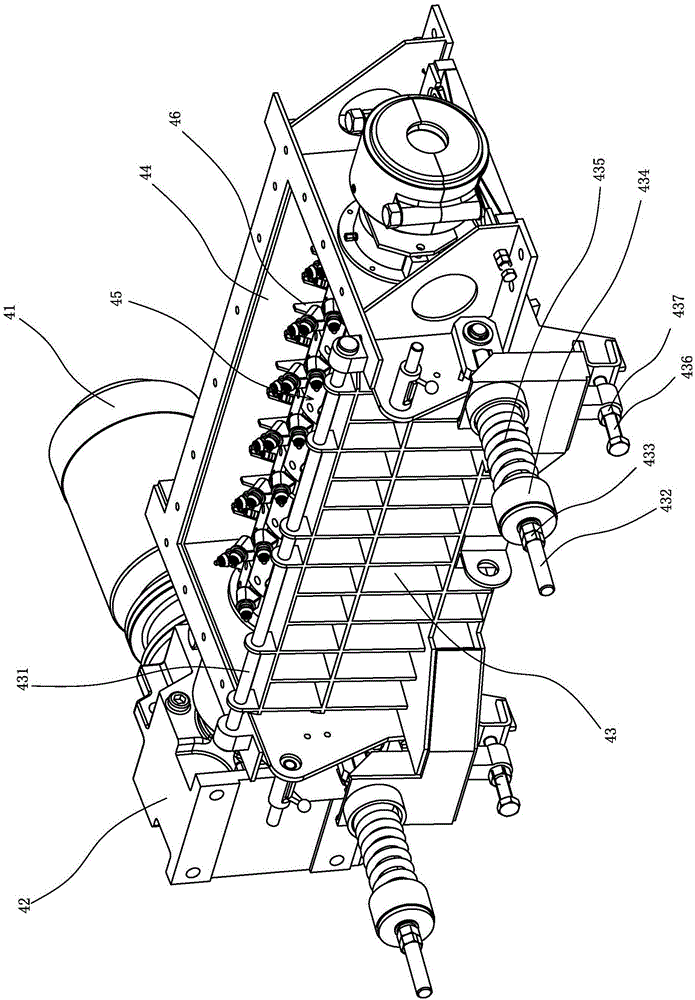

[0035] refer to Figure 1 to Figure 10 As shown, a waste asphalt mixture crusher includes a frame 1, a control device (not shown in the figure), a vibrating screening device 2 respectively arranged on the frame, a collecting device 3, a crushing device 4 and a belt Conveyor 5.

[0036] The vibrating screening device 2 mainly includes a screening frame provided with a screen and a vibrating motor arranged on the screening frame. The screening frame is supported on the frame by a spring, and the mesh aperture of the screen is 40mm; the vibrating screening device The structure of 2 is a known prior art, and will not be described in detail here. Its function is: the waste asphalt mixture is screened into coarse material and fine material, and the coarse material is sent into the collection device 3, and the fine material is sent into Belt conveyor 5.

[0037] The collecting device 3 includes a collecting hopper 31 provided with a material inlet and a discharge port, a material s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com