Fuel spraying valve and method for regulating its spraying volumn

A fuel injection valve, fuel injection technology, applied in the direction of fuel injection device, charging system, engine components, etc., can solve the problems of long adjustment time, high production cost, etc., to reduce residues and debris, low pressure, easy to manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

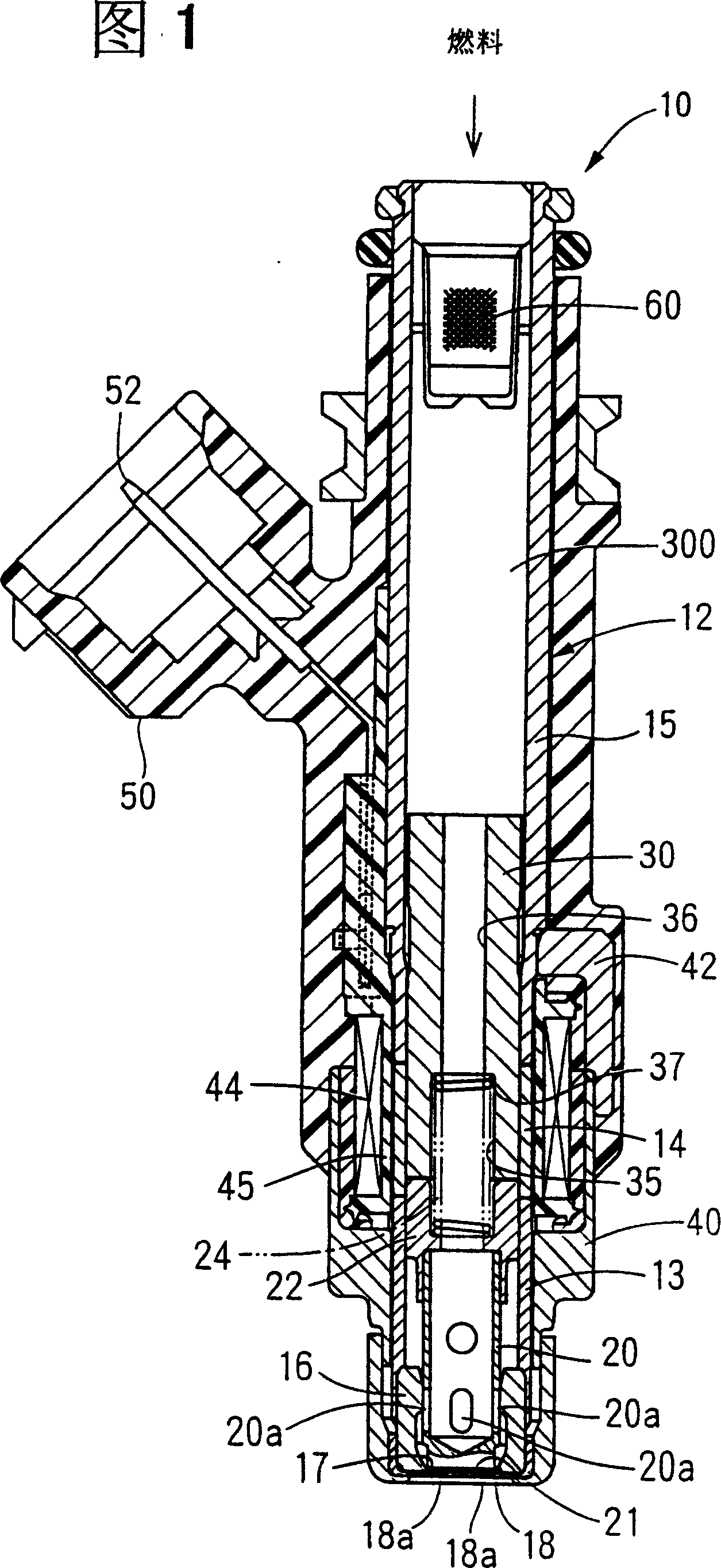

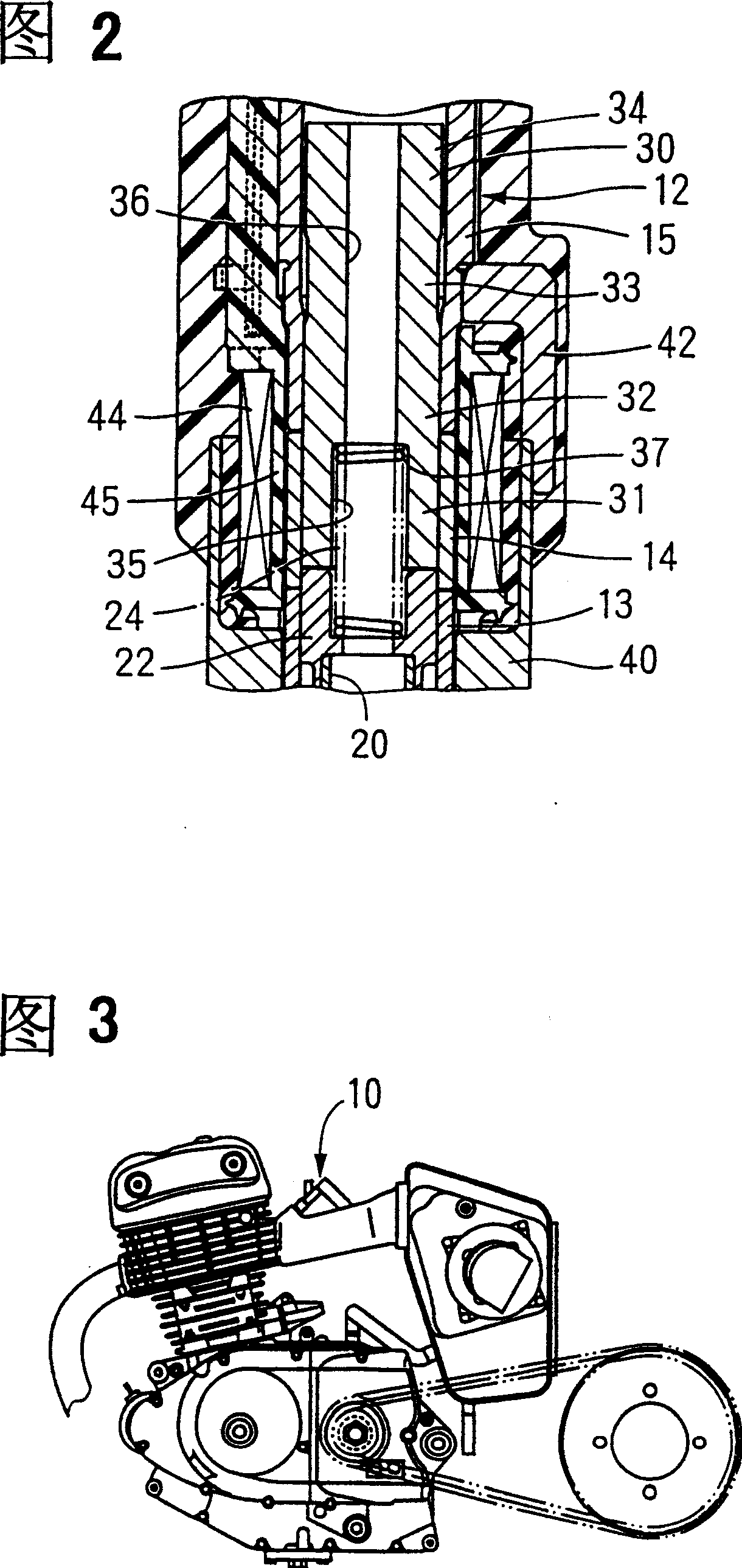

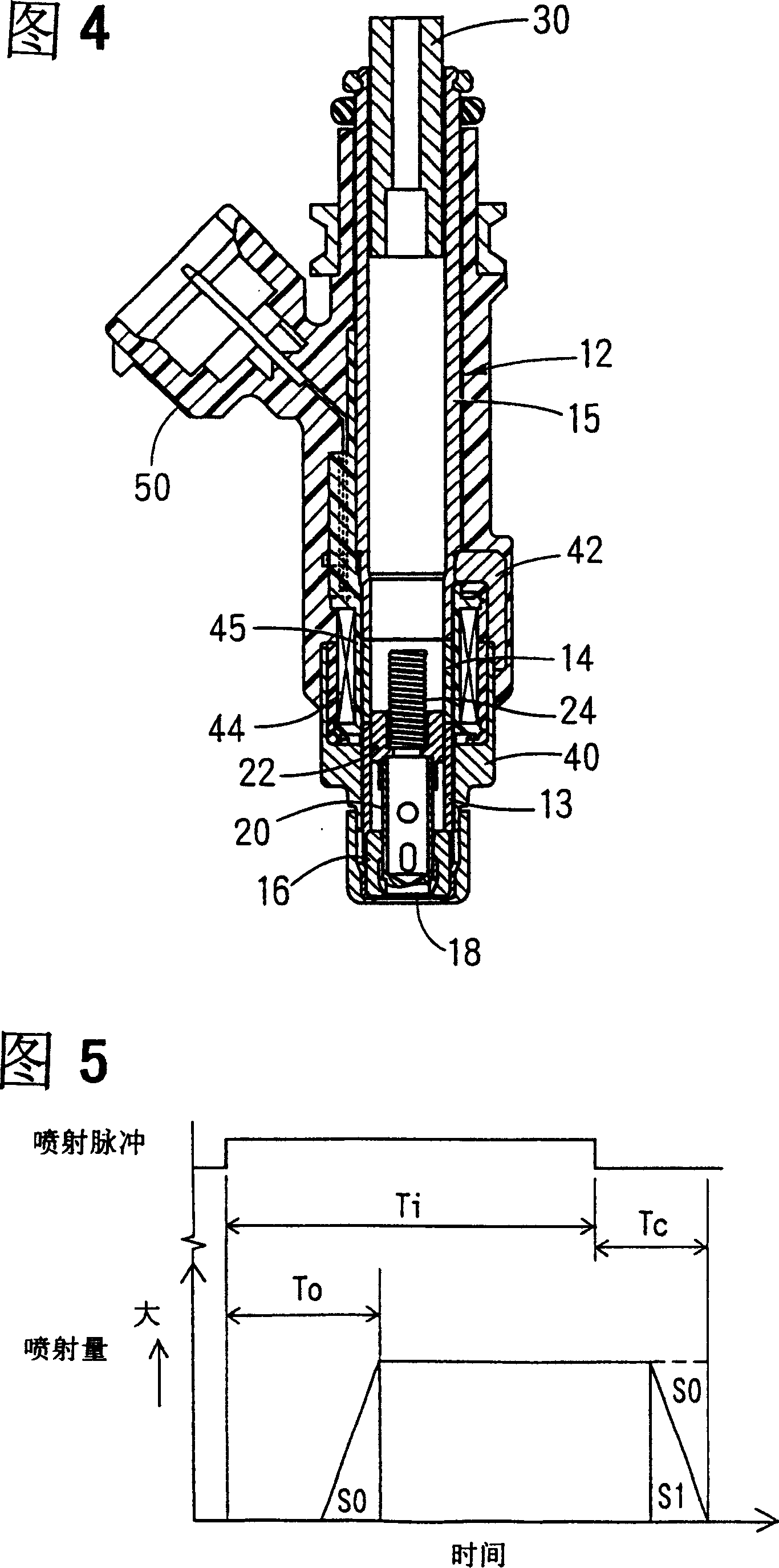

[0038] In FIG. 1 , a fuel injection valve 10 according to the first embodiment of the present invention is shown, which is installed in a single-cylinder engine of a two-wheeled motor vehicle shown in FIG. 3 . As shown in FIG. 1 , a tube 12 is composed of a magnetic element and a magnetoresistive element, and its shape is a cylinder. The inside of the pipe member 12 is provided with a fuel passage 300 . Inside the fuel passage 300 are housed the valve body 16 , the valve member 20 and the moving core 22 , the spring 24 serving as an urging member, and the fixed core 30 .

[0039] The pipe piece 12 has a first magnetic element 13 , a reluctance element 14 as a diamagnetic element and a second magnetic element 15 , which are sequentially arranged upward from the vicinity of the valve body 16 at the lower part in FIG. 1 . The connection between the first magnetic element 13 and the magneto-resistive element 14 and the connection between the magneto-resistive element 14 and the s...

no. 2 example

[0062] The method of adjusting the dynamic injection quantity according to the second embodiment will be described below with reference to FIGS. 10 to 13 . The method of adjusting the dynamic injection quantity according to the second embodiment is applicable to the structure of the fuel injection valve, which is basically the same as that of the first embodiment. Fig. 13 is a flowchart showing a method of adjusting the dynamic injection quantity according to the second embodiment.

[0063] As shown in FIG. 10A, the case member 200 is made of a resin material by connecting the magnetic elements 40 and 42 and the coil 44 (step 400 in FIG. 13). The magnetic elements 40 and 42 and the coil 44 are members provided on the periphery of the tube 12 . Further, as shown in FIG. 10B , the tube 12 is formed by welding the first magnetic member 13 , the magnetoresistive element 14 and the second magnetic member 15 to each other.

[0064] As shown in FIG. 11A, the pipe member 12 is press...

no. 3 example

[0072] A third embodiment of the present invention will be described with reference to FIG. 14 . The same reference numerals as in the first embodiment denote elements with substantially similar functions.

[0073] A fixed core 70 is press fit into the tube 12 . On the inner periphery of the fixed core 70, a plurality of protrusions or an annular protrusion 72 are arranged at circumferential intervals, which are radially protruded inwardly by cold forging or stamping. A single or a plurality of protrusions 72 constitute a protrusion portion. The inner diameter of the fixed core 30 becomes smaller at the protrusion 72 by which the spring 24 is restrained.

[0074] In the fuel injection valve according to the third embodiment, the static and dynamic injection quantities are simultaneously determined by adjusting the gap between the movable core 22 and the fixed core 30 to a predetermined value.

[0075] Furthermore, when the fixed core 70 is press-fitted into the pipe member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com