PVC floor winding equipment with hoisting function

A ground rubber and functional technology, which is applied in the direction of cranes, trolley cranes, load suspension components, etc., can solve the problems of difficult separation of ground rubber from the ground, time-consuming and laborious operation, and inability to adjust the height of the bottom plate from the ground, etc., to increase the gap adjustment Function, the effect of liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

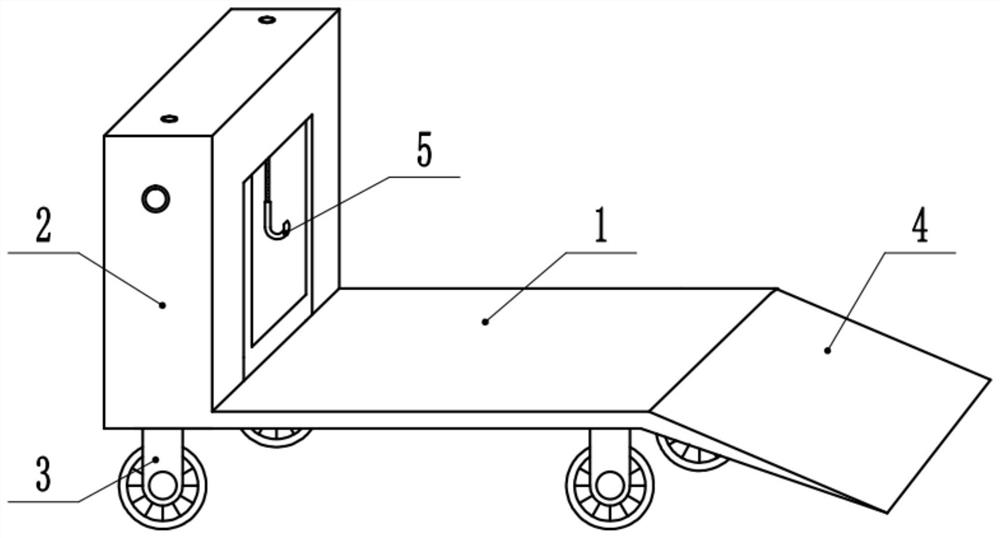

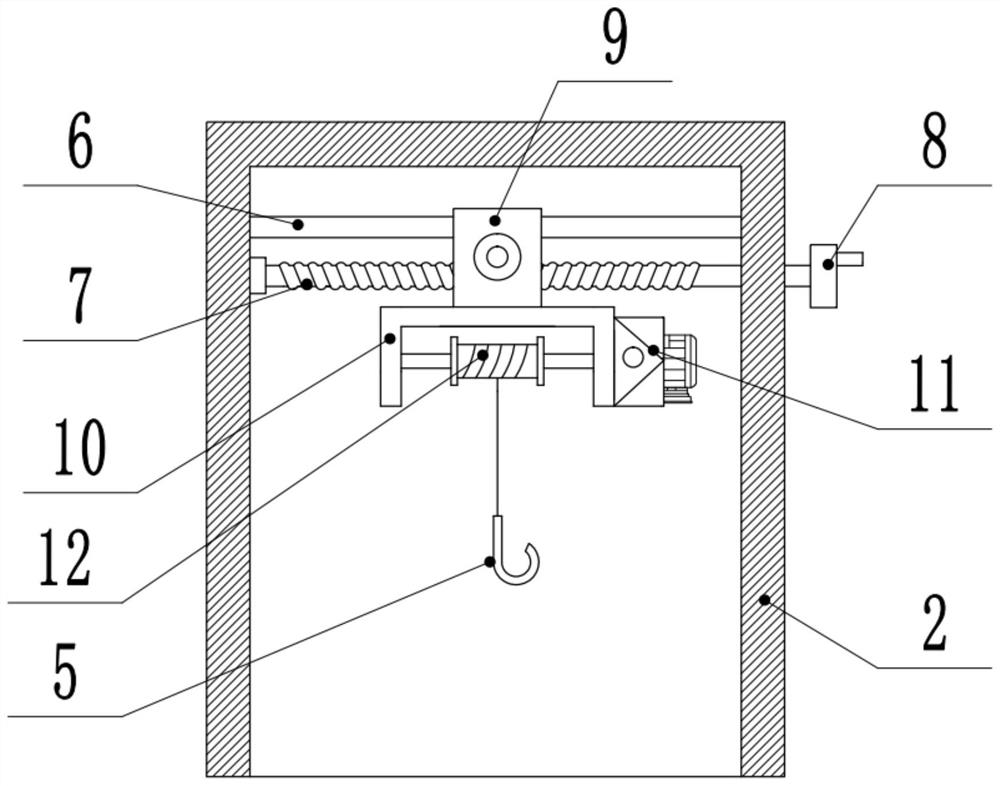

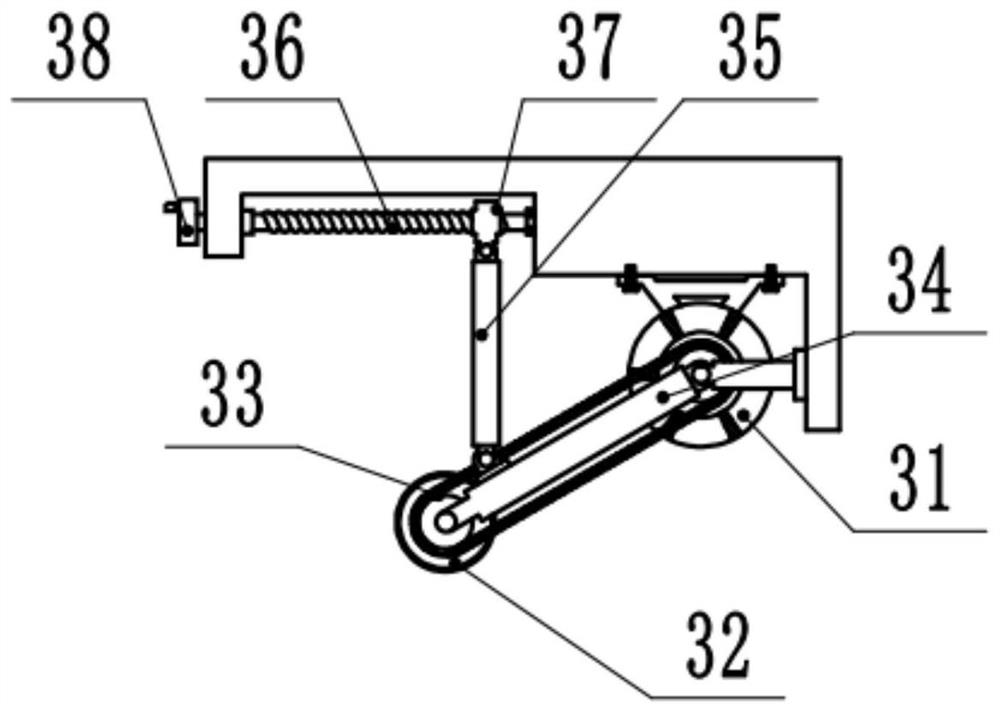

[0020] see Figure 1-3 , a ground rubber rolling device with a lifting function, comprising a base plate 1, a roller assembly 3 is installed at the four corners of the lower side of the base plate 1, and the roller assembly 3 includes a driving wheel 31, a driven wheel 32, and a driving chain 33 , connecting rod 34, adjusting rod 35, the second screw rod 36, the second slide block 37 and the second rocking wheel 38, the driving wheel 31 is installed on the bottom of the base plate 1 and driven by the driving motor, the driving wheel 32 is connected with the driving chain 33 Driven wheel 32, driven wheel 32 is also hingedly installed on the underside of base plate 1 by connecting rod 34, drives driving wheel 31 to rotate by driving motor, drives chain 33 transmissions between driving wheel 31 and driven wheel 32, thereby drives driven wheel 32 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com