On-line synchronous continuous feeding decoiling and straightening equipment for bearing rolling element cold heading machine

A technology of cold heading machine and rolling body, which is applied in the field of online synchronous continuous feeding uncoiling and straightening equipment, which can solve the problems of wasting time, materials, and wasting time, and achieve the effects of time saving, continuous transmission, and good straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

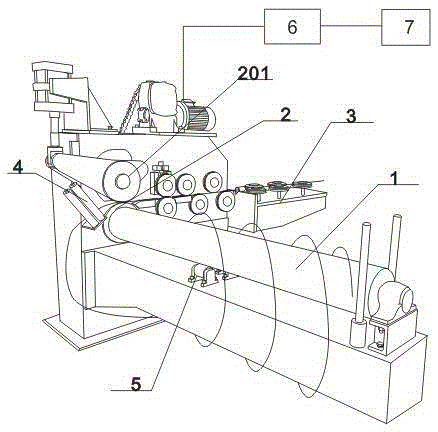

Image

Examples

Embodiment 1

[0026] Install a trigger switch on the cold heading machine / punch machine. The trigger switch can be one of optical sensors, displacement sensors, and rotary encoders. When the cold heading machine / punch machine is working, the optical sensor, displacement sensor or rotary encoder is Sensing the work of the cold heading machine / punch machine, it will collect a work signal and transmit the work signal to the controller. The controller controls the variable speed motor to drive the hanging shaft and pull the opposite wheel to rotate and feed material synchronously. When the trigger switch does not sense the signal, the variable speed motor does not work, ensuring that the feeding speed of the cold heading machine / punching machine is consistent with the feeding speed of the equipment, and the work is synchronized.

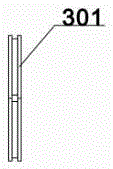

[0027] The straightening device is arranged vertically and is composed of a plurality of extrusion wheels 301. Grooves are provided on the outer peripheral surface of ...

Embodiment 2

[0029] A trigger switch is installed on the cold heading machine / punch machine. The trigger switch can be a travel switch. When the cold heading machine / punch machine is running, a travel switch is set at the swing arm. The swing arm touches the travel switch when it swings, and the travel switch The working signal of the cold heading machine / punching machine is collected, and the working signal is transmitted to the controller. The controller controls the movement of the variable speed motor, so that the variable speed motor drives the hanging shaft and pulls the counter wheel to rotate and feed materials synchronously. When the swing arm is not moving, the travel switch cannot collect signals, and the variable speed motor does not work, so as to ensure that the feeding speed of the cold heading machine / punching machine is consistent with the feeding speed of the equipment, and the work is synchronized.

[0030] The straightening device is vertically arranged and consists of a...

Embodiment 3

[0032] A trigger switch is installed on the cold heading machine / punch machine. The trigger switch can be a travel switch. When the cold heading machine / punch machine is running, a travel switch is set at the swing arm. The swing arm touches the travel switch when it swings, and the travel switch The working signal of the cold heading machine / punching machine is collected, and the working signal is transmitted to the controller. The controller controls the movement of the variable speed motor, so that the variable speed motor drives the hanging shaft and pulls the counter wheel to rotate and feed materials synchronously. When the swing arm is not moving, the travel switch cannot collect signals, and the variable speed motor does not work, so as to ensure that the feeding speed of the cold heading machine / punching machine is consistent with the feeding speed of the equipment, and the work is synchronized.

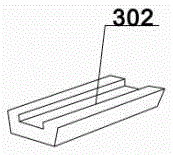

[0033] The straightening device is arranged horizontally and consists of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com