A ceramic plug valve

A cock valve and ceramic technology, which is applied in the field of ceramic cock valves, can solve the problems of short service life of metal cock valves, wear gap between valve core and middle body, and high cost of use, and achieve good sealing performance, smooth switching and low cost of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

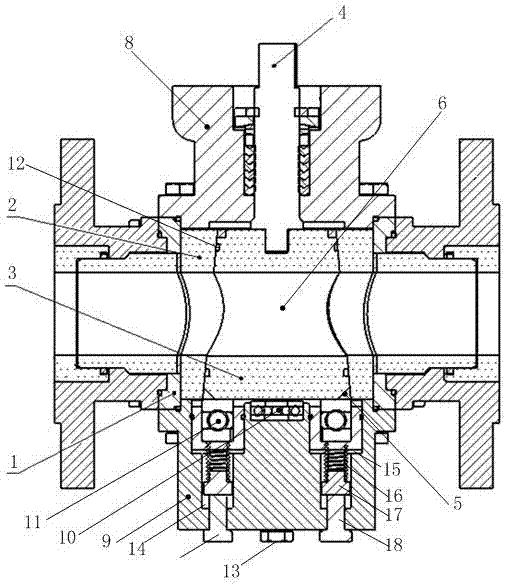

[0021] Embodiment 1, the ceramic plug valve of this embodiment, refer to figure 1 , including a metal shell 1, an upper end cap 8 is screwed on the top of the shell 1, a lower end cap 9 is screwed on the bottom of the shell 1, a middle body 2 of ceramics or other non-metallic materials is arranged inside the shell 1, and the inner body 2 Tightly match the ceramic valve core 3, the center of the upper end surface of the valve core 3 is provided with a valve stem hole, the valve stem 4 passes through the upper end cover 8 to cooperate with the valve stem hole; the middle part of the valve core 3 is provided with a circular or V-shaped through hole 6, if The spool is divided into upper and lower parts on the basis of the through hole 6, and the spool 3 is in the shape of an upper taper with a thick top and a thin bottom or a lower taper with a thin top and a thick bottom, and the taper is 0-20 degrees. It is characterized in that: the spool 3. Inverted bevel or circular arc at th...

Embodiment 2

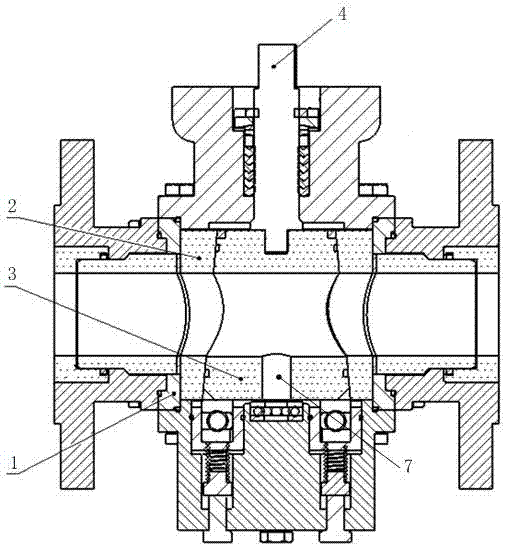

[0022] Embodiment 2, the ceramic plug valve of this embodiment, refer to figure 2 , the others are the same as in Embodiment 1, the difference is: the center of the thick end surface of the spool 3 is provided with a pressure relief hole 7 communicating with the through hole 6, and the pressure relief hole 7 is a straight hole, which is connected to the groove or arc. The combined effect of the size and the angle makes the tapered end area of the upper and lower parts of the spool equal to the area of the upper and lower parts inside the through hole 6 of the spool.

Embodiment 3

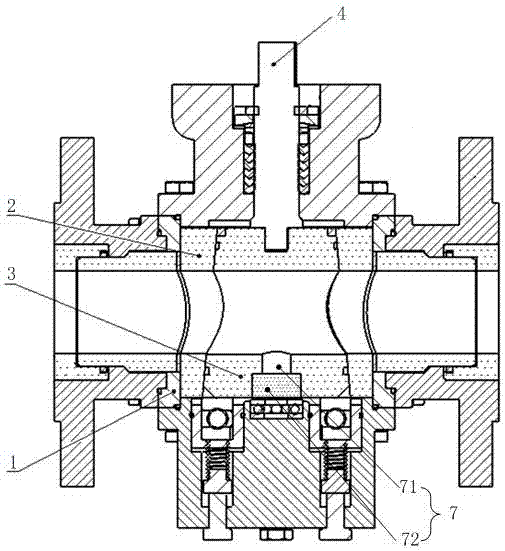

[0023] Embodiment 3, the ceramic plug valve of this embodiment, refer to image 3 , the others are the same as in Embodiment 2, the difference is that the pressure relief hole 7 is a stepped hole, including a thin section pressure relief hole 71 close to the thin end surface of the valve core and a thick section pressure relief hole 72 close to the thick end surface of the valve core, and the thick section pressure relief hole 72 is close to the thick end surface of the valve core. The pressure hole 72 is filled with a decompression plunger. The joint effect of the thin section pressure relief hole 71, the thick section pressure relief hole 72 and the size and angle of the groove or arc makes the upper and lower areas of the upper and lower parts of the valve core in the conical end area of the valve core through hole 6 equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com