A ceramic cone valve

A technology of cone valve and ceramic valve core, which is applied in the direction of valve device, cock including cut-off device, engine components, etc. It can solve the problems of short service life of metal cone valve, wear gap between valve core and middle body, high cost of use, etc. , to achieve the effects of good sealing performance, smooth switching and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

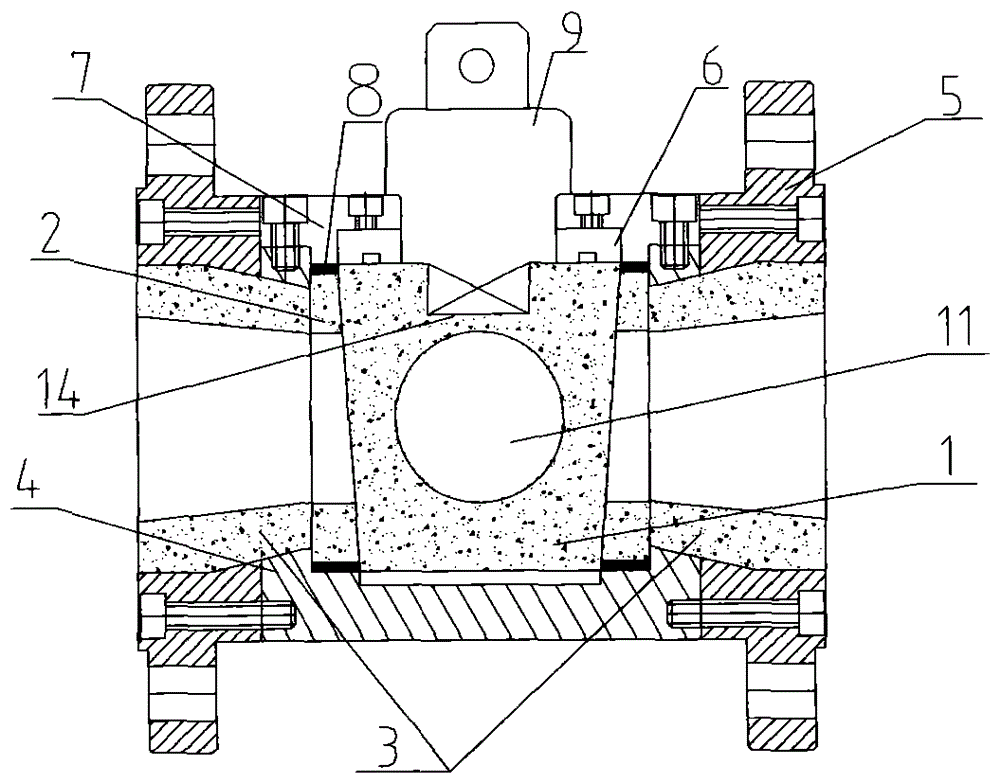

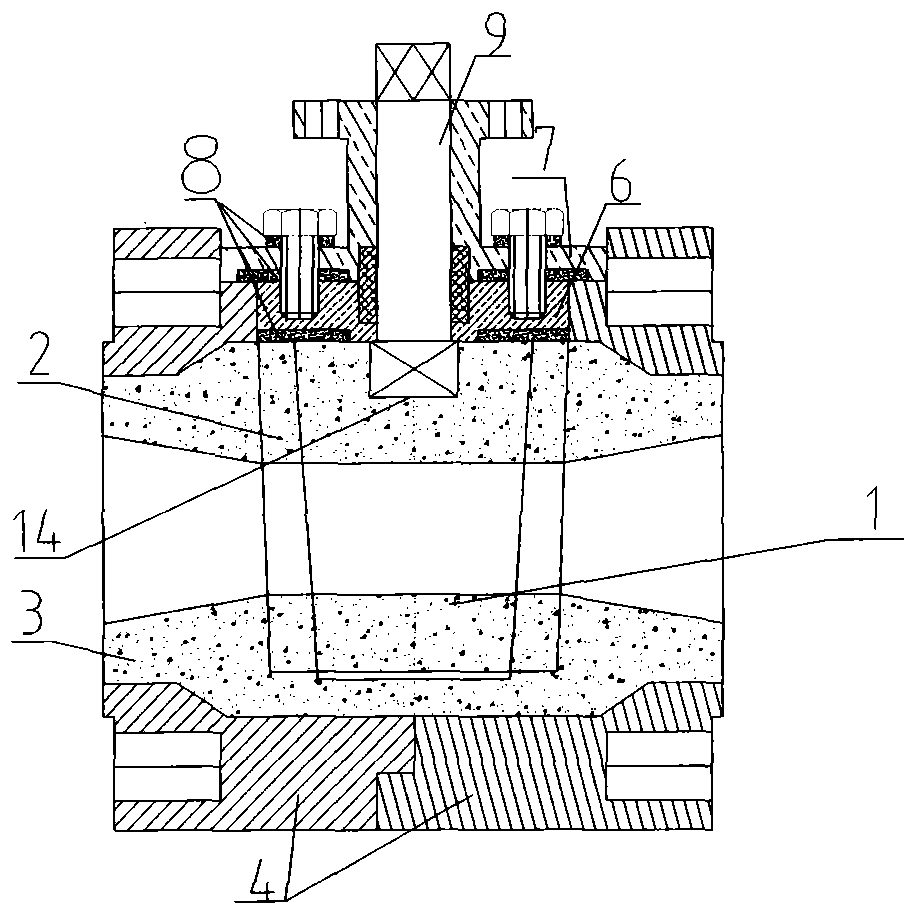

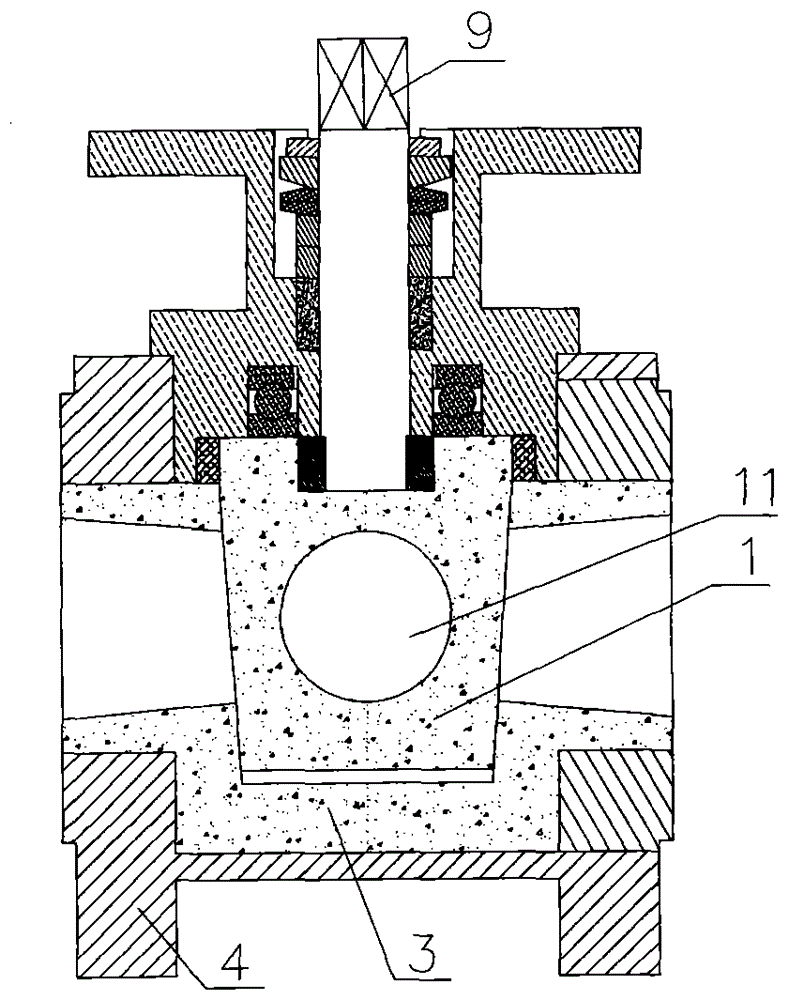

[0042] The ceramic cone valve of the present embodiment, refer to figure 1 , Figure 11-14 , including a shell 4, the shell 4 is a metal shell, the shell 4 is a split structure, the shell 4 is screwed to the flange 5, the shell 4 is provided with a middle body 2, and the middle body 2 is made of ceramics, The inner body 2 is tightly fitted with a ceramic valve core 1. The ceramic valve core 1 is in an upper conical shape with a thick top and a thin bottom. The taper of the ceramic valve core 1 is 4 degrees. The outer periphery of the middle body 2 is provided with a ceramic flange lining 3. The top of the ceramic valve core 1 is provided with an adjustment pressure ring 6, and the top of the adjustment pressure ring 6 is connected with an adjustment pressure plate 7, and the adjustment pressure plate 7 is threadedly connected with the housing 4. A stem hole 14 is provided at the top, and a through hole 11 is provided in the middle of the ceramic valve core 1, and the through ...

Embodiment 2

[0044] The ceramic cone valve of the present embodiment, refer to Figure 2-A , Figure 2-B , Figure 9 , Figure 10 , Figure 13 , Figure 15 , including a shell 4, the shell 4 is welded or screwed together by two metal shells occluded, the shell 4 is provided with a middle body 2, the middle body 2 is made of ceramics, and the middle body 2 is closely fitted with a sleeve There is a ceramic spool 1, the ceramic spool 1 is an upper conical shape with a thick top and a thin bottom, the taper of the ceramic spool 1 is 4 degrees, the outer periphery of the middle body 2 is provided with a ceramic flange lining 3, and the top of the ceramic spool 1 is set There is an adjustment pressure ring 6, and an adjustment pressure plate 7 is connected above the adjustment pressure ring 6, and the adjustment pressure plate 7 is threadedly connected with the housing 4, and the valve stem 9 is installed on the ceramic valve core 1, and the outer circumference of the valve stem 9 is sealed...

Embodiment 3

[0046] The ceramic cone valve of the present embodiment, refer to Figure 2-C , Figure 2-D , Figure 11 , Figure 12 , Figure 13 , Figure 16 , including a shell 4, the shell 4 is a metal shell, the shell 4 is a split structure, the shell 4 is screwed to the flange pressure ring 10, the shell 4 is provided with a middle body 2, and the middle body 2 is made of ceramics The middle body 2 is tightly fitted with a ceramic valve core 1. The ceramic valve core 1 is in the shape of an upper cone with a thick top and a thin bottom. The taper of the ceramic valve core 1 is 4 degrees. The outer periphery of the middle body 2 is provided with a ceramic flange lining. 3. There is a step 12 on the ceramic flange lining 3, an adjustment pressure ring 6 is provided above the ceramic valve core 1, and an adjustment pressure plate 7 is connected above the adjustment pressure ring 6, and the adjustment pressure plate 7 is threadedly connected with the housing 4, and the ceramic A valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com