Ceramic rotary cone valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

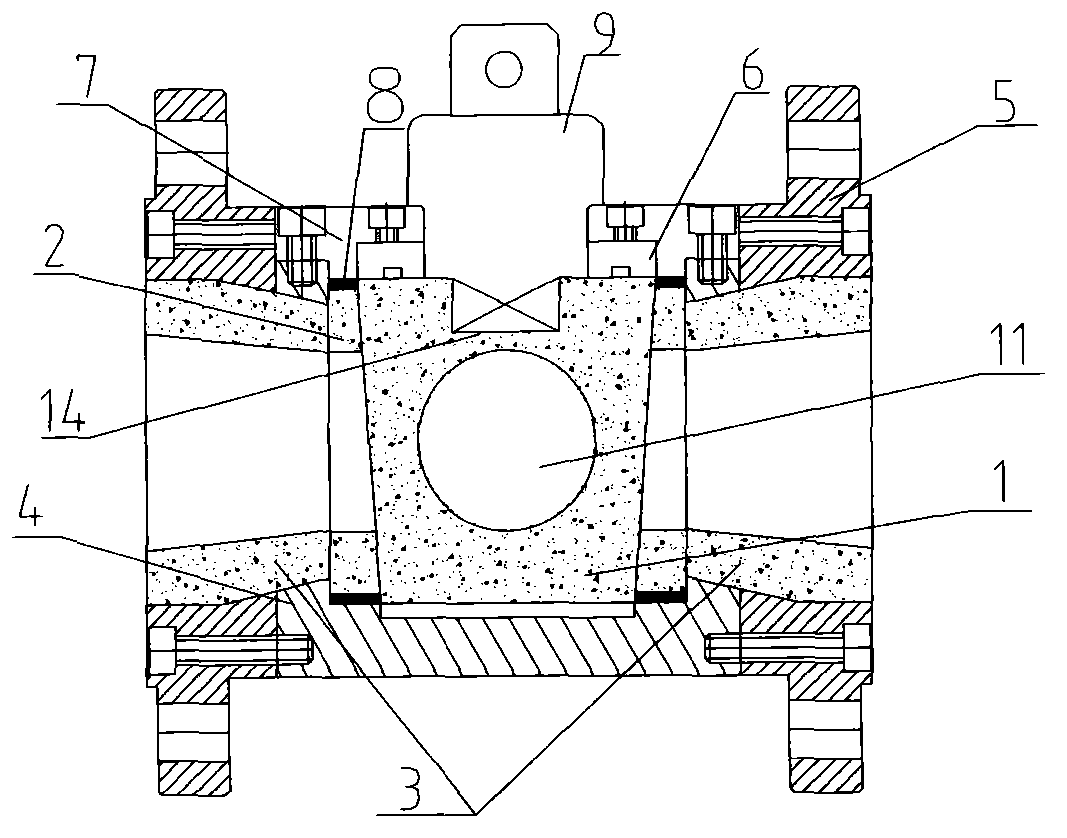

[0042] The ceramic cone valve of this embodiment, refer to figure 1 , Figure 11-14 , Including the shell 4, the shell 4 is a metal shell, the shell 4 is a split structure, the shell 4 is threaded with the flange 5, and the shell 4 is provided with a middle body 2, which is made of ceramic, The middle body 2 is tightly sleeved with a ceramic valve core 1, which has a thick upper cone and a thin upper cone. The cone of the ceramic valve core 1 is 4 degrees. The outer periphery of the middle body 2 is provided with a ceramic flange lining 3. The ceramic valve core 1 is provided with a regulating pressure ring 6 above the regulating pressure ring 6 is connected with a regulating pressure plate 7, and the regulating pressure plate 7 is threadedly connected with the housing 4, a valve stem 9 is installed on the ceramic valve core 1, and a ceramic valve core 1 A stem hole 14 is provided at the top, a through hole 11 is provided in the middle of the ceramic valve core 1, and the throu...

Embodiment 2

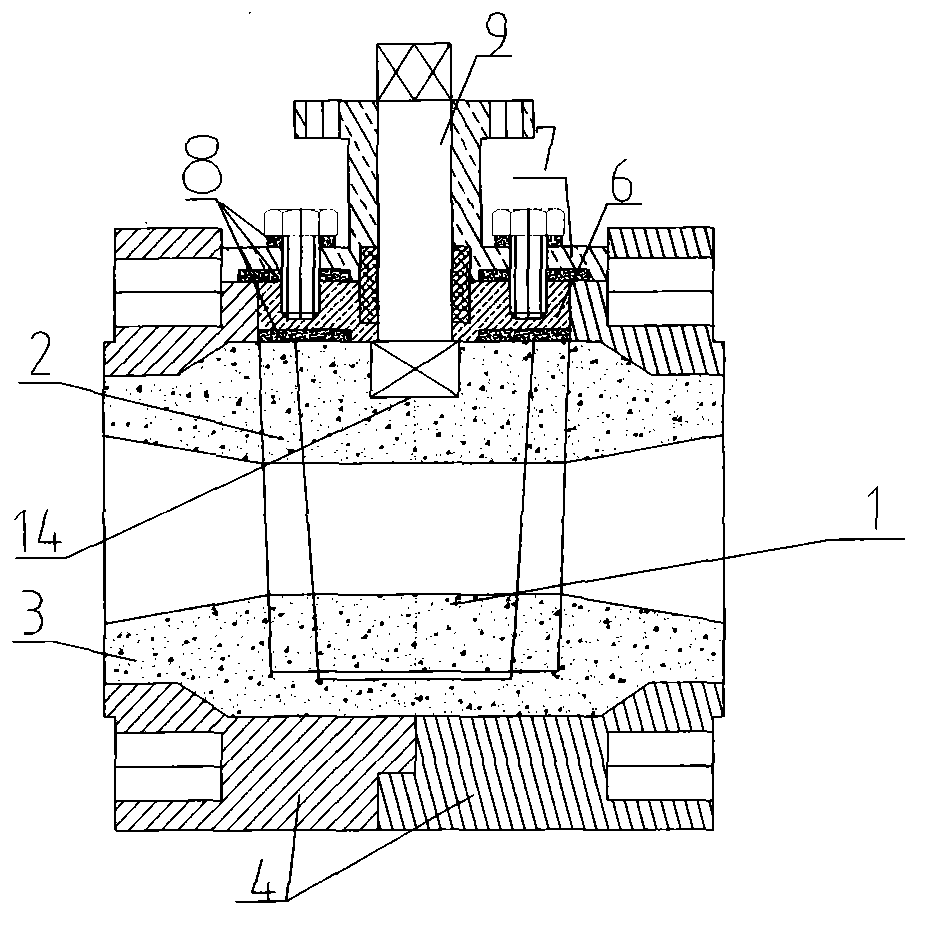

[0044] The ceramic cone valve of this embodiment, refer to Figure 2-A , Figure 2-B , Picture 9 , Picture 10 , Figure 13 , Figure 15 , Including the shell 4, the shell 4 is formed by welding or threaded connection of two metal shells. The shell 4 is provided with a middle body 2, which is made of ceramic, and the inner body 2 is tightly fitted with a sleeve There is a ceramic valve core 1. The ceramic valve core 1 has a thick upper cone and a thin upper cone. The cone of the ceramic valve core 1 is 4 degrees. The outer periphery of the middle body 2 is provided with a ceramic flange lining 3, and the ceramic valve core 1 is provided above There is a regulating pressure ring 6, a regulating pressure plate 7 is connected above the regulating pressure ring 6, and the regulating pressure plate 7 is threadedly connected with the housing 4. The ceramic valve core 1 is equipped with a valve stem 9 whose outer circumference is sealed by graphite. The ceramic valve core 1. A valve s...

Embodiment 3

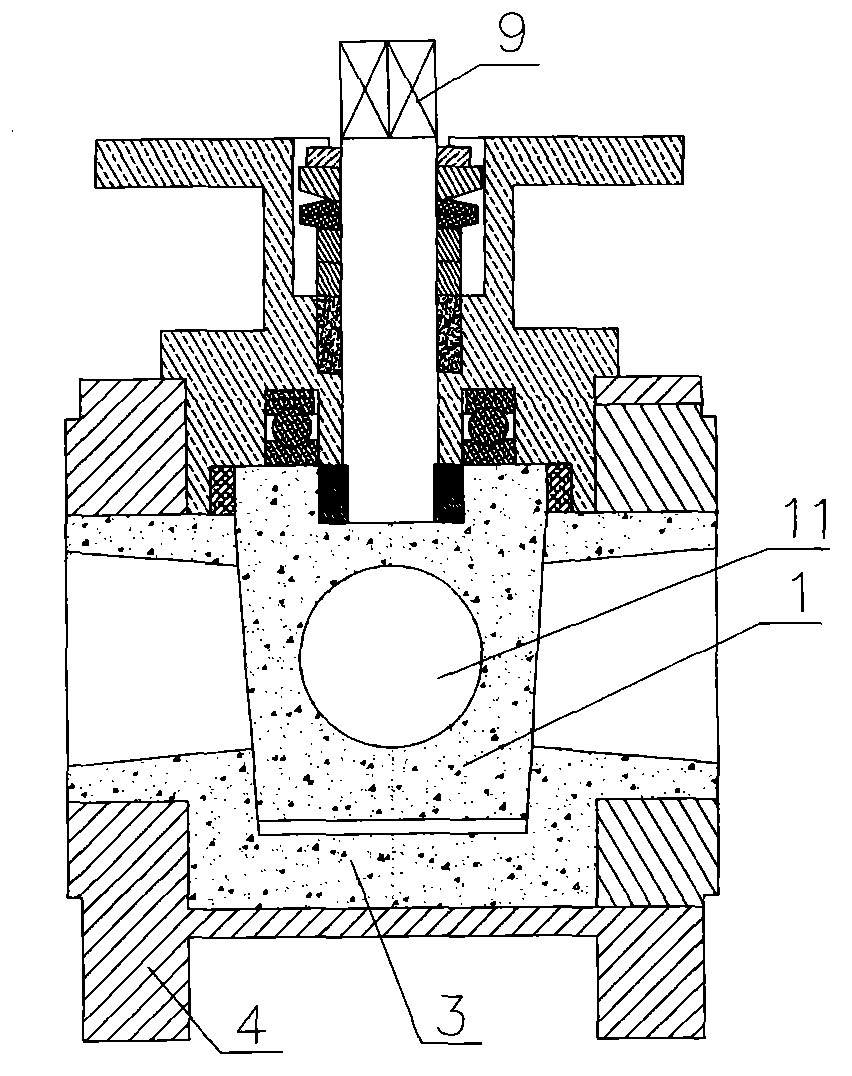

[0046] The ceramic cone valve of this embodiment, refer to Figure 2-C , Figure 2-D , Picture 11 , Picture 12 , Figure 13 , Figure 16 , Including the shell 4, the shell 4 is a metal shell, the shell 4 is a split structure, the shell 4 is screwed with the flange pressure ring 10, the shell 4 is provided with a middle body 2 which is made of ceramic The middle body 2 is fitted with a ceramic valve core 1 in a tight fit. The ceramic valve core 1 has a thick top and a thin upper cone. The taper of the ceramic valve core 1 is 4 degrees. The center body 2 is provided with a ceramic flange lining. 3. The ceramic flange lining 3 is provided with a step 12, the ceramic valve core 1 is provided with a regulating pressure ring 6 above the regulating pressure ring 6 is connected with a regulating pressure plate 7, and the regulating pressure plate 7 is threadedly connected with the shell 4. A valve stem 9 is installed on the valve core 1, the top of the ceramic valve core 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com