Horizontal type drawing press

A press, horizontal technology, applied in the field of horizontal drawing and stretching press, can solve the problems of bending, inability to form directly, poor forming accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

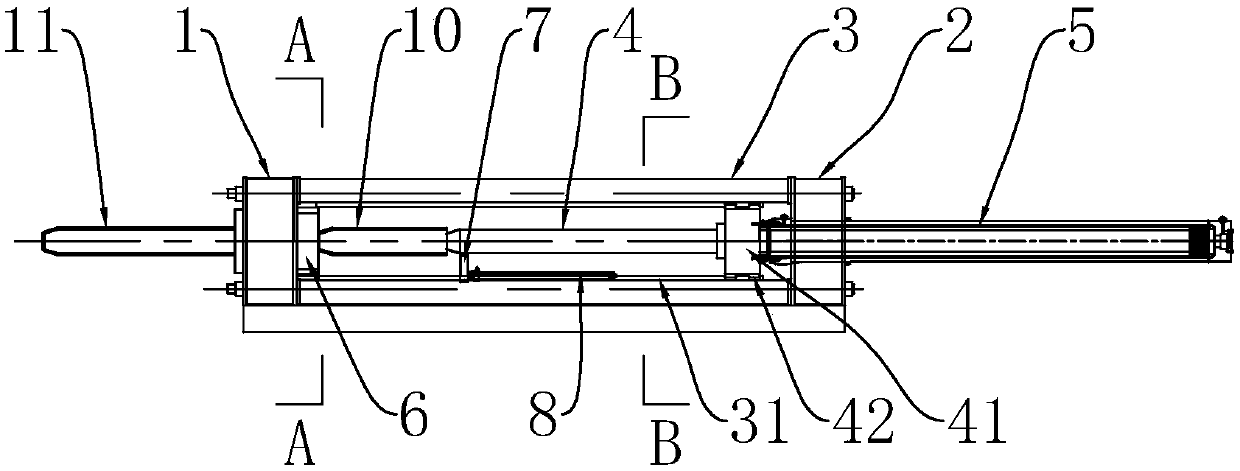

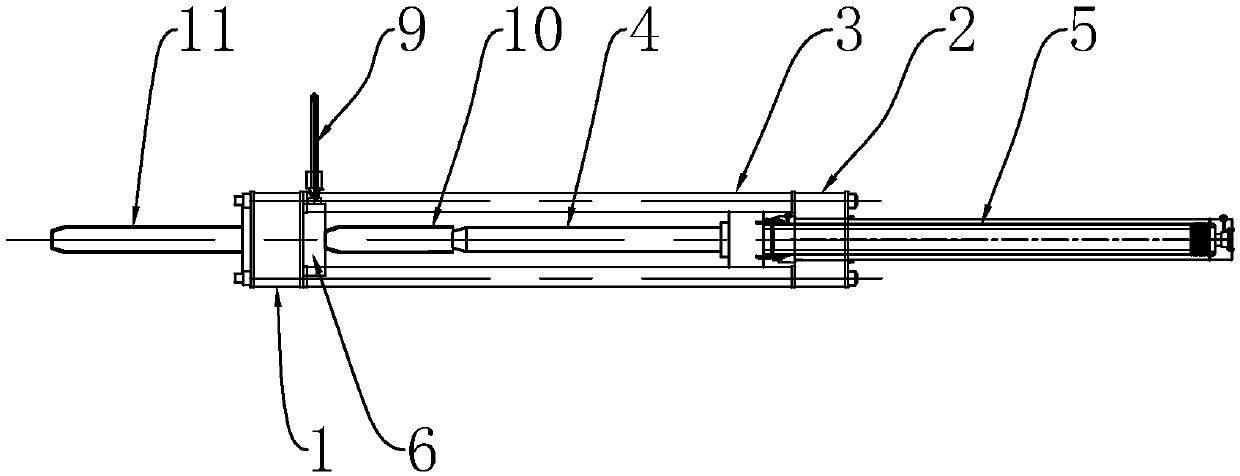

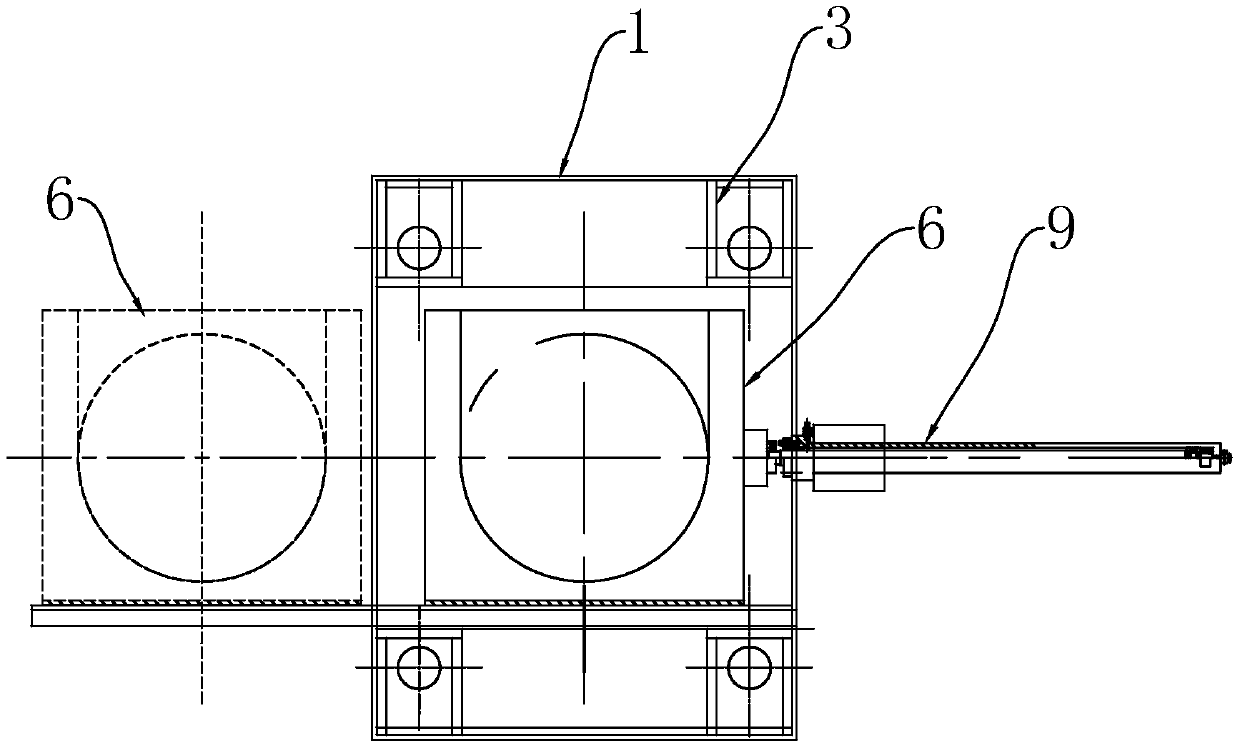

[0032] Such as figure 1 and 2 Shown: a horizontal drawing and stretching press, consisting of a front beam 1, a rear beam 2, a plurality of square columns 3, a punch 4 and a cylinder body 5, the front beam 1 and the rear beam 2 are respectively fixed on the square columns 3 both ends, the rear beam 2 fixes the cylinder body 5, the punch 4 is arranged between the square columns 3, the punch 4 is connected to the output end of the cylinder body 5, and the front beam 1 is installed There is a drawing die 6, a support beam 7 is provided directly below the punch 4, and a drive mechanism 8 for driving the support beam 7 to move back and forth along the axial direction of the punch 4 is provided at the bottom of the support beam 7. The driving mechanism 8 is an axial push cylinder arranged axially along the punch 4 , and the telescopic rod of the axial push cylinder is fixedly connected with the lower part of the support beam 7 . The top surface of the support beam 7 contacts and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com