Adjustable universal rolling device

A universal roller and adjustable technology, applied in the field of mechanical processing, can solve the problems of incomplete bending of door sheet metal parts, low yield and large occupied area, and achieve the effect of improving processing precision, improving accuracy and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

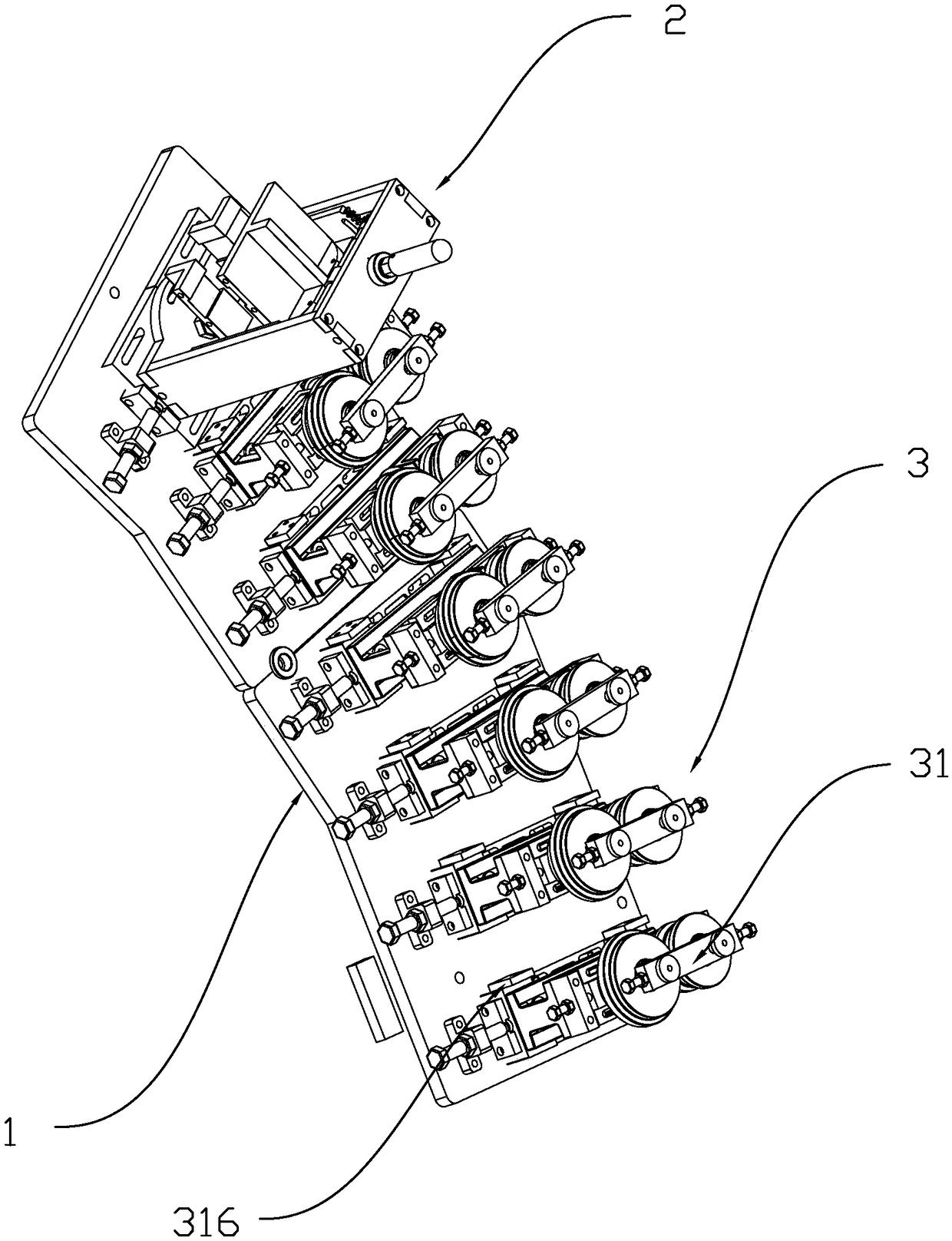

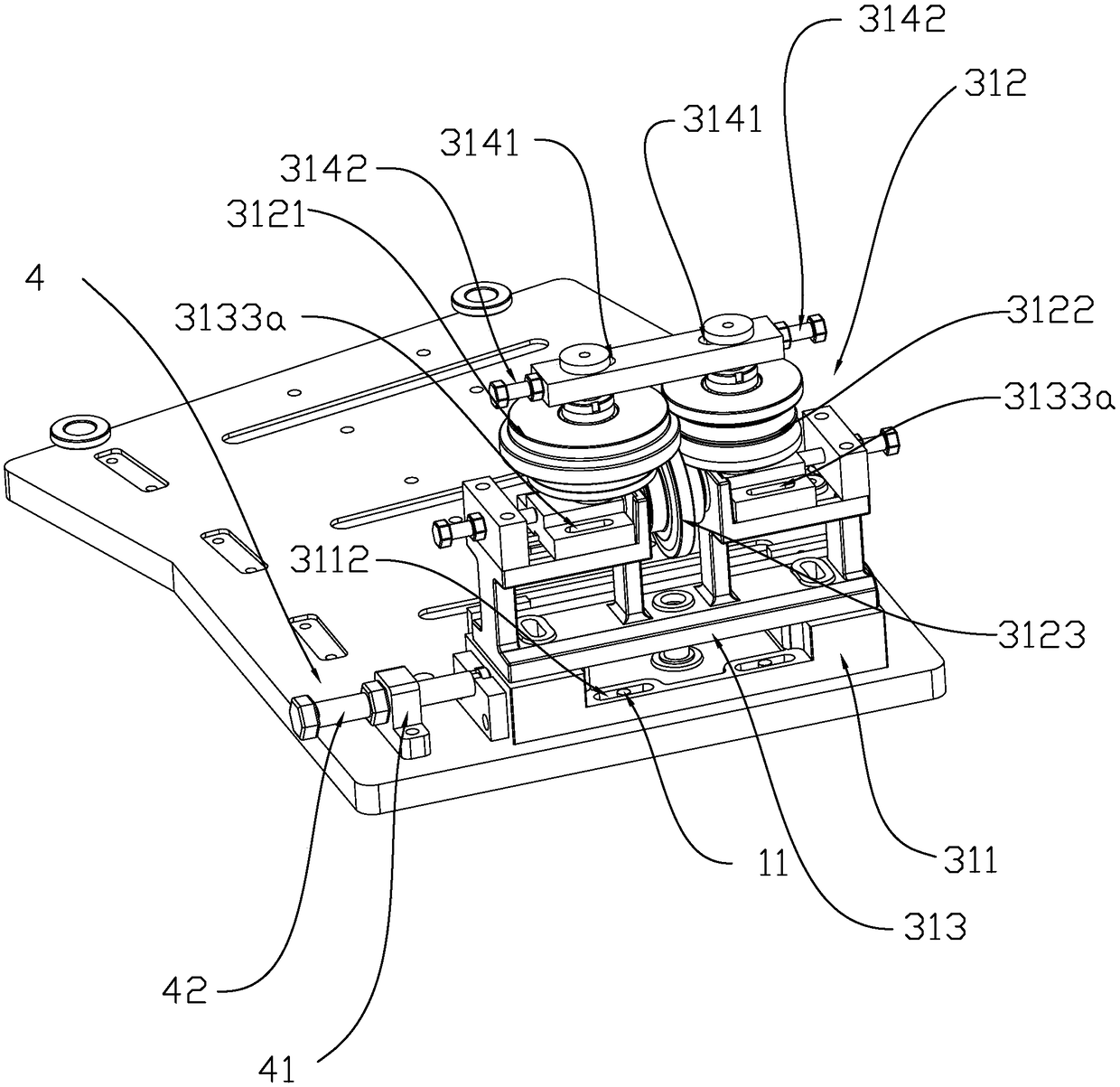

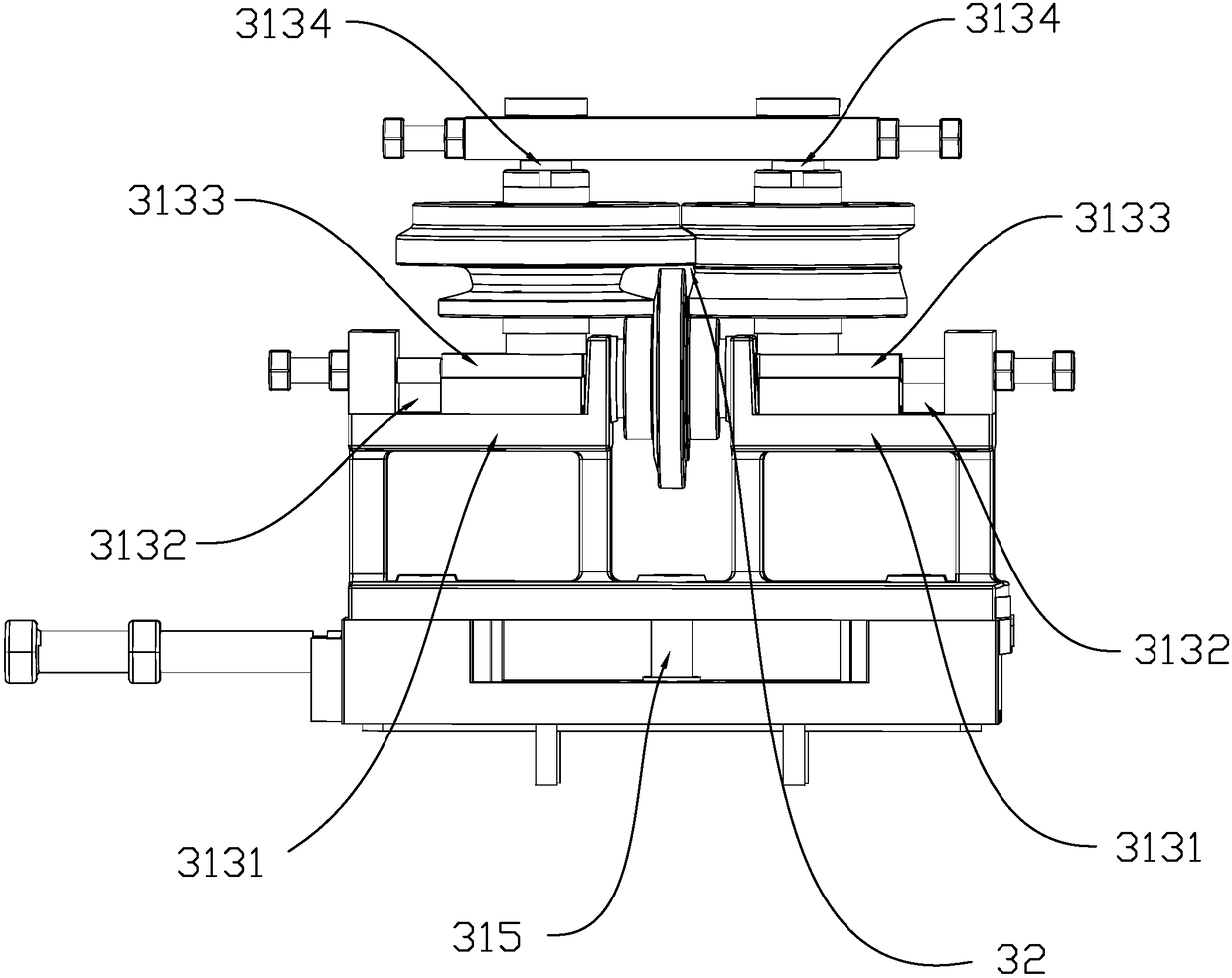

[0036] Specific embodiments of the present invention such as Figure 1-11 As shown, an adjustable universal rolling device includes a console 1 on which a feeding mechanism 2 and a radian mechanism 3 are arranged, and the radian mechanism 3 includes several roller assemblies arranged in an arc 31. The roller assembly 31 includes an adjustment seat 311 arranged on the console 1, an adjustment member 4 that drives the adjustment seat 311 to move, and a roller member 312 arranged on the adjustment seat 311. The roller member 312 includes The first roller 3121 and the second roller 3122, the third roller 3123 is arranged below the first roller 3121 and the second roller 3122, and the third roller 3123 is located at the first roller 3121 and the second roller 3122 The gap between the first roller 3121, the second roller 3122 and the third roller 3223 forms a clamping area 32, and the feeding mechanism 2 includes a slide provided on the console 1 Seat 21, the sliding seat 21 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com