Device and method for detecting and evaluating defects of elevator composite steel belt

A defect detection and evaluation device technology, applied in transportation and packaging, material magnetic variables, elevators, etc., can solve the lack of portable equipment for composite steel strips, lack of operability for composite steel strip inspection, and specific requirements for composite steel strip inspection. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

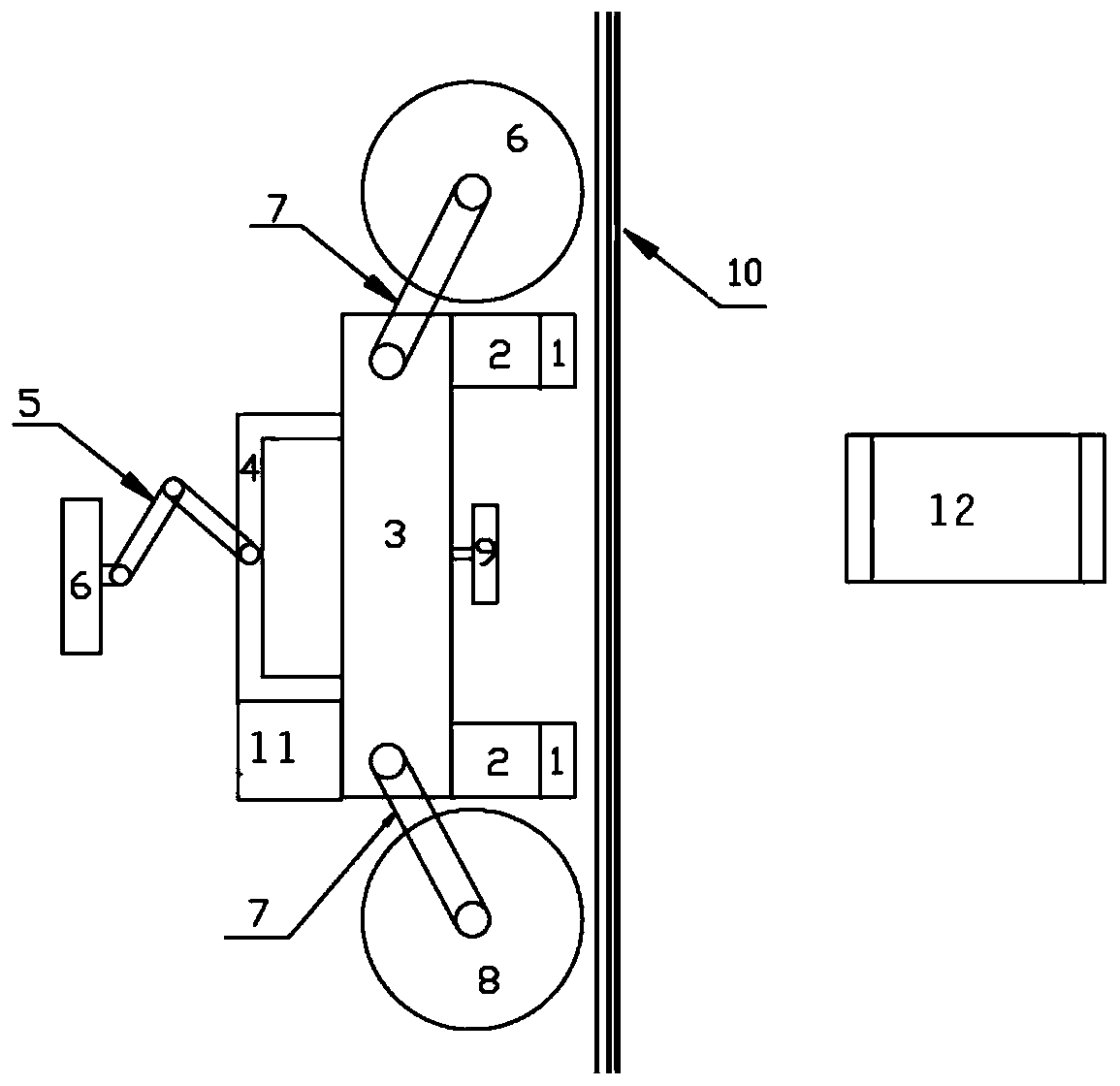

[0037] Such as figure 1 As shown, a magnetic flux leakage detection device for an elevator traction steel belt, which performs magnetic flux leakage detection on an elevator traction steel belt 10, includes:

[0038] The armature 3 connected with the handle 4, carry the detection device by the handle and hold it for detection;

[0039] Two permanent magnets 2 are respectively connected with the two ends of the armature close to the side of the traction steel belt of the detected elevator to form a closed loop of the magnetic field, and the permanent magnets are connected with pole shoes 1;

[0040] The guide wheel 8 is connected with the armature 3, and the guide wheel 8 has a guide groove that cooperates with the traction steel belt of the detected elevator, and the left and right side walls of the guide groove form a limit with both sides of the traction steel belt of the detected elevator;

[0041] Clamping tool 6, connected with the armature, and fixed to the surrounding fence whe...

Embodiment 2

[0050] The method for detecting and evaluating elevator composite steel belt defects, using the elevator composite steel belt defect detection and evaluation device described in Example 1 to detect and evaluate elevator traction steel belts, includes the following steps:

[0051] S1, fix the device to the fence around the elevator by clamping tools;

[0052] S2, the permanent magnet generates a magnetic field to make the steel wire in the traction steel belt of the detected elevator close to magnetic saturation;

[0053] S3: Receive the leakage magnetic field generated by the missing or broken wire of the steel wire in the traction steel belt of the detected elevator through the magnetic flux leakage detection sensor, and transmit it to the data receiving and display module through the data acquisition and transmission module;

[0054] S4. The data receiving and display module analyzes the data collected by the magnetic flux leakage detection sensor, and displays the defect status of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com