Polytetrafluoroethylene contact type sealing device

A technology of polytetrafluoroethylene and contact sealing, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as metal brush wire melting, damage to high-precision testing instruments, graphite ring fracture, etc., to reduce friction and friction loss, reduce test accidents and errors, and facilitate installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

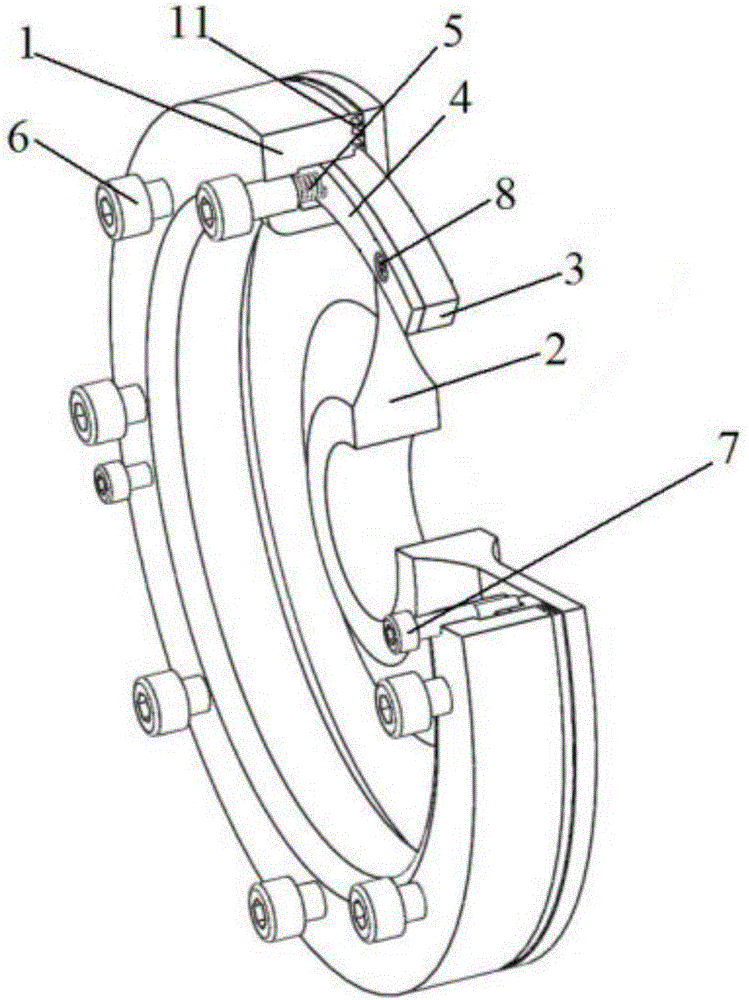

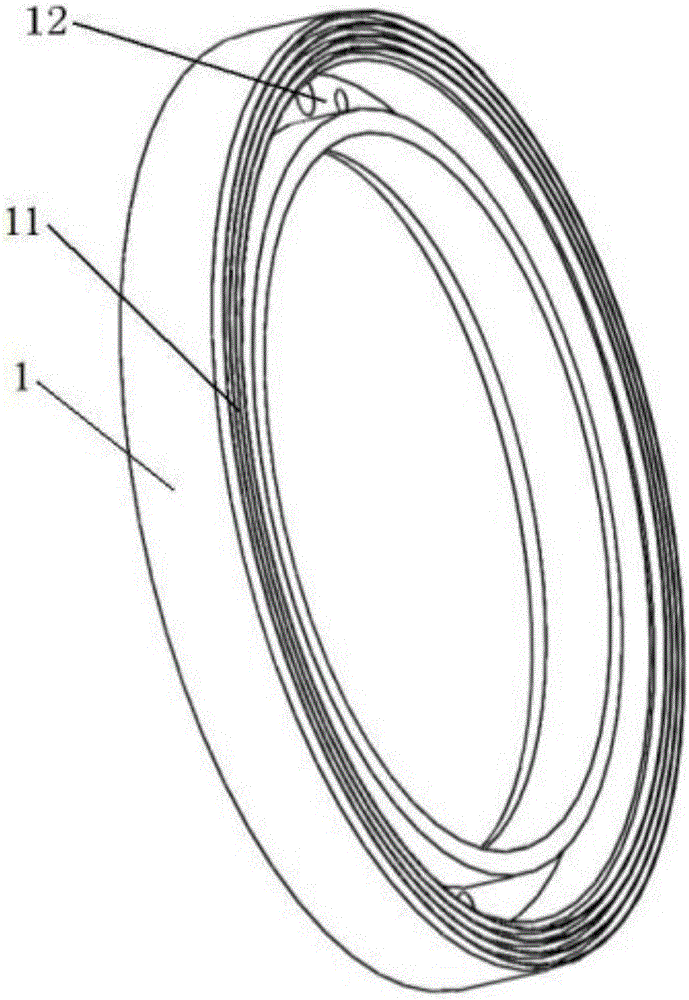

[0031] Embodiment one: if figure 1 , 5 As shown, the fastening screw is a countersunk screw 8 , and the bearing spring 5 is only sleeved on the cylinder 61 at the tail of the spring compression screw 6 .

Embodiment 2

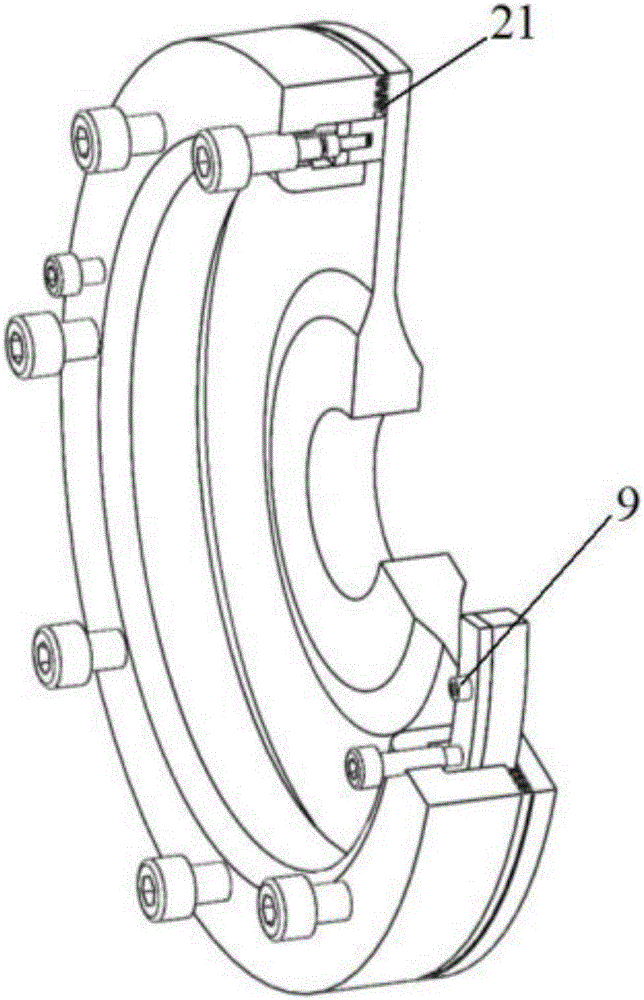

[0032] Embodiment two: if figure 2 , 6 As shown, the fastening screw is a hexagon socket head screw 9 , and the upper end of the bearing spring 5 is sleeved on the cylinder 61 , and its lower end is sleeved on the cylinder head of the hexagon socket head screw 9 .

[0033] Such as Figure 8As shown, after the sealing of the stationary wheel 1 and the rotating wheel 2 is realized by this sealing device, the air flow will first pass through the straight-through grate sealing ring before flowing to the PTFE sealing ring 3, and first pass through several stages of straight-through grate The primary sealing function of the sealing ring reduces the pressure of the incoming flow; afterward, the air flow hits the outer surface of the PTFE sealing ring 3 and is divided into two paths: the right path is due to the PTFE sealing ring 3 and the rotating wheel 2 The tight fit of the sealing surface prevents the airflow from leaking here; the way to the left is due to the contact between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com