A geotechnical piling machine box for driving simulated piles into landslides under high geotechnical acceleration

A high-acceleration, simulating pile technology, applied in infrastructure engineering, infrastructure testing, construction, etc., can solve problems such as time-consuming, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

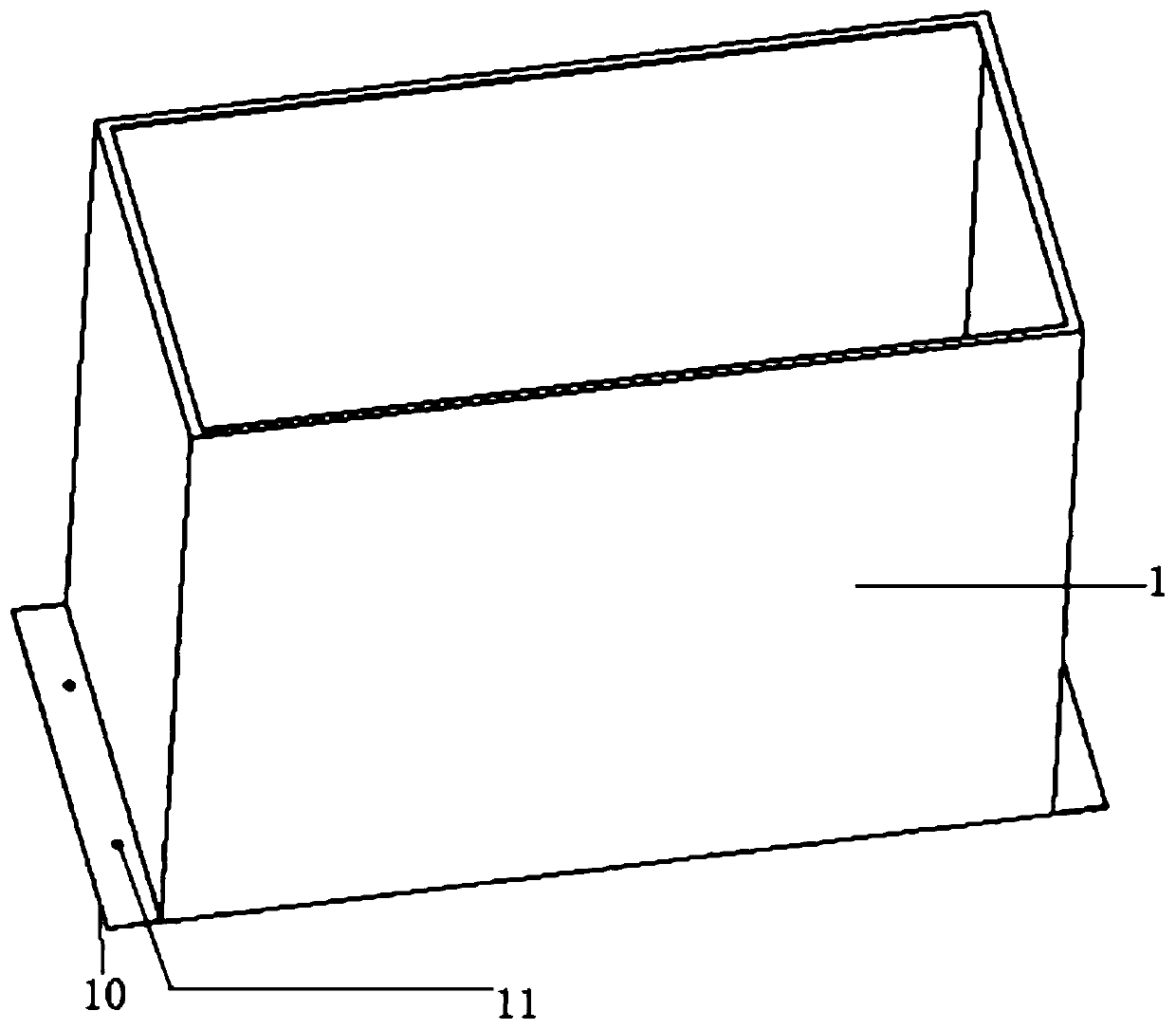

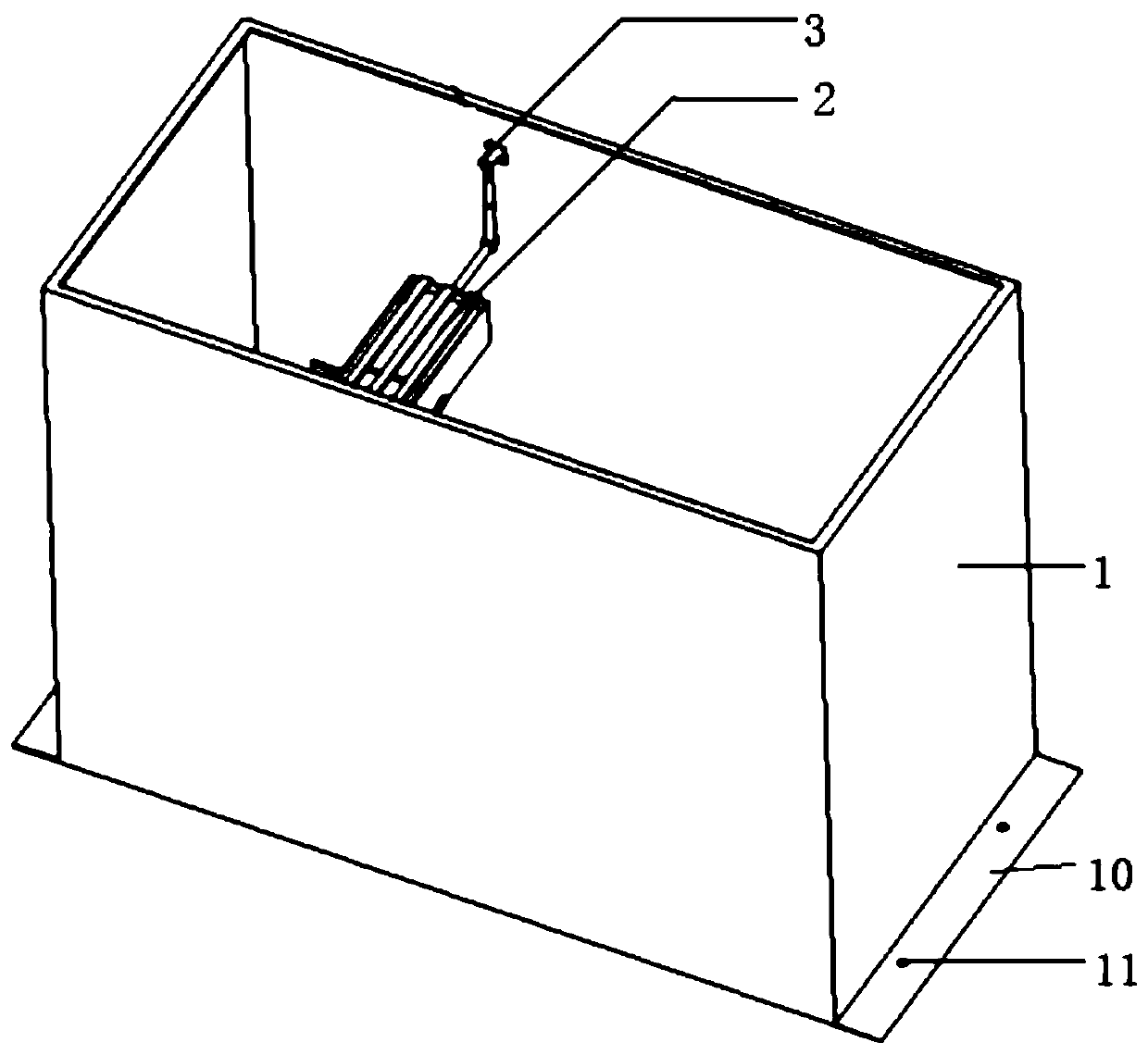

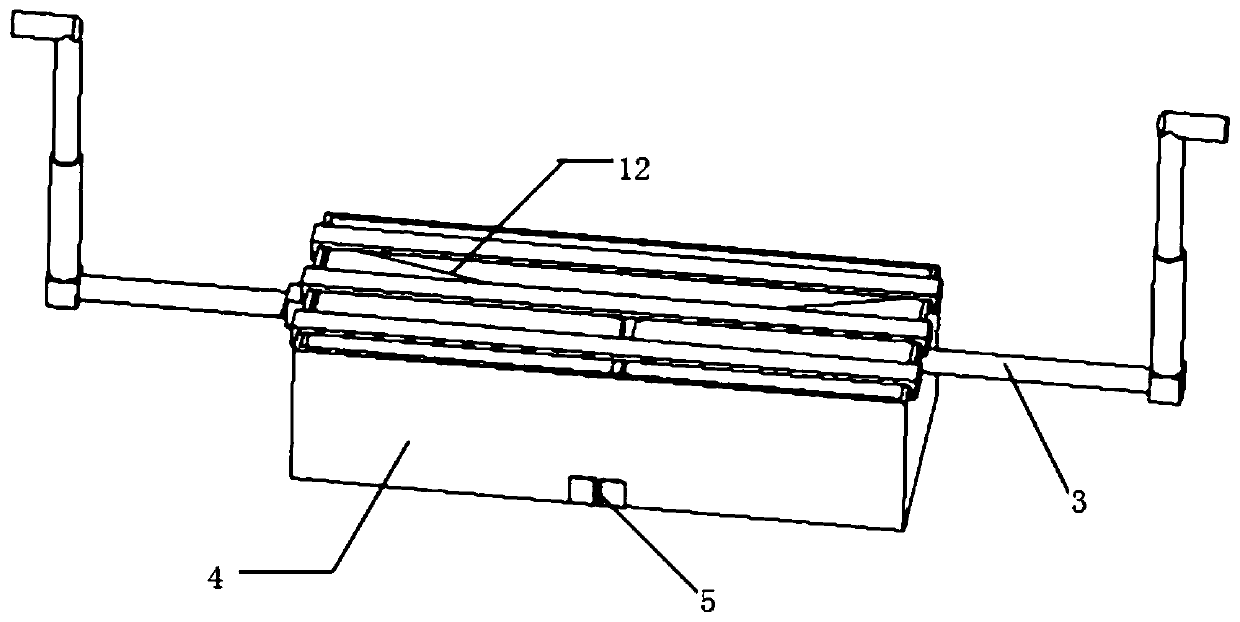

[0024] Such as figure 1 , 2 , shown in 3, 4, 5, a kind of geotechnical piling box that drives into simulation pile to landslide under high geotechnical acceleration, comprises piling box 1, is equipped with internal piling machine 2 inside piling box 1, described internal piling The machine 2 is fixed in the pile driver box 1 through the angle position adjustment rod 3. The internal pile driver 2 includes a simulation pile placement box 4, and a simulation pile driving outlet 5 is provided on the front of the simulation pile placement box 4. The back side of the pile placement box 4 is equipped with a driver 6, and the driver 6 is facing the simulation pile driving outlet 5, and the inside of the simulation pile placement box 4 is provided with two relative rolling slopes 7, and the two rolling slopes A simulated pile drop opening 8 is reserved between the lower ends of the 7, and the simulated pile rolls down from the rolling slope 7 and falls from the simulated pile drop op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com