A remote control nearly constant water flow height centrifugal box

A technology of remote control and centrifugal box, applied in the direction of liquid level control, control/regulation system, non-electric variable control, etc., can solve the problems of reducing rainfall height and affecting test accuracy, etc., with high possibility of realization, simple installation and disassembly Time-saving, simple and easy-to-understand operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

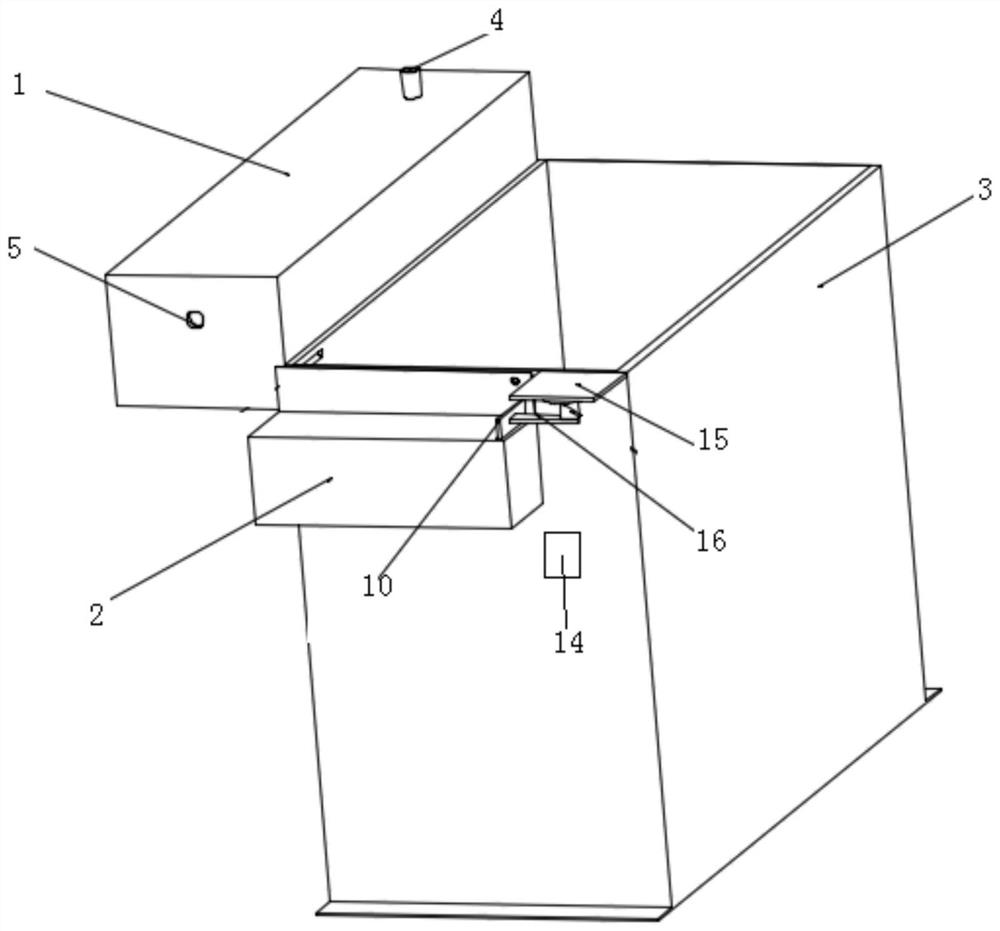

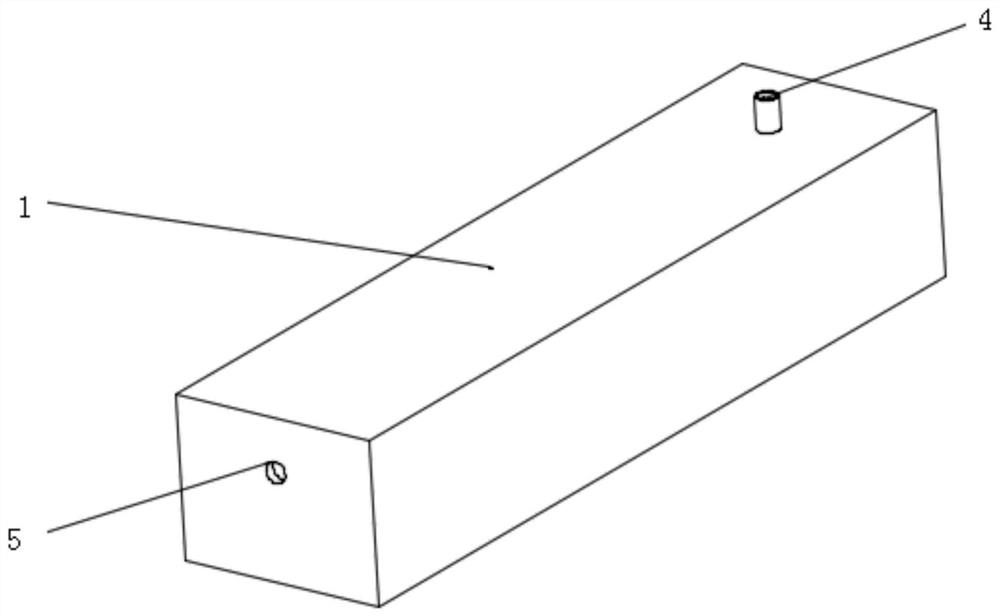

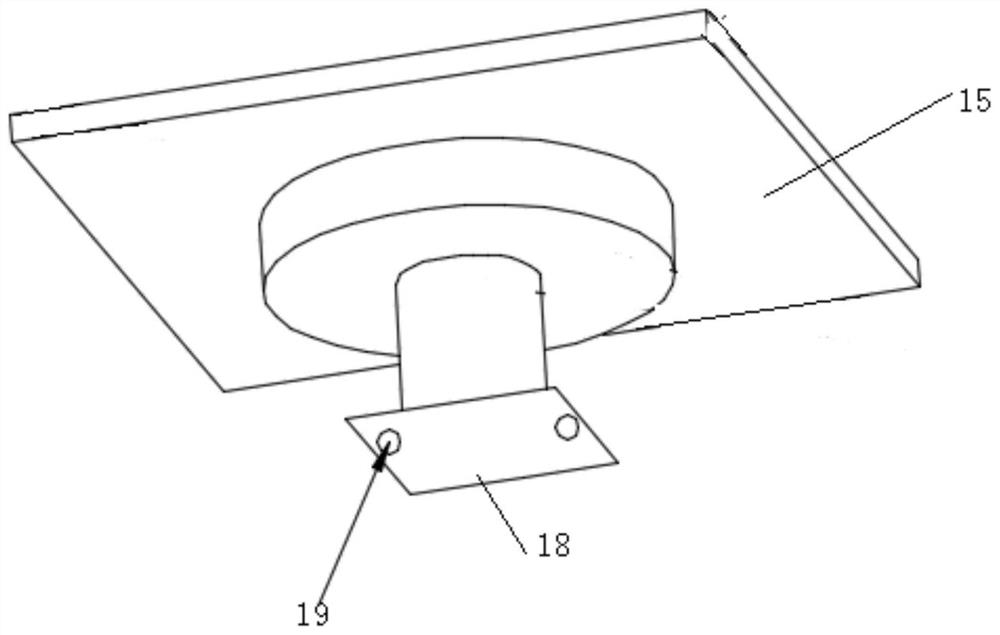

[0024] Such as figure 1 As shown, a centrifugal box with a remote control near-constant water flow height includes a main water tank 1, a control near-constant water tank 2 and an outer box 3, and the described main water tank 1 and the control near-constant water tank 2 are installed in two parts of the outer box 3 respectively. On the outer side, the installation height of the main water tank 1 is higher than that of the outer box 3, and the upper end of the control nearly constant water tank 2 is flush with the upper end of the outer box 3, and the main water tank 1 is provided with a water injection port 4 of the main water tank and a water pipe connection port of the main water tank 5. The near-constant control water tank 2 is provided with a control near-constant water tank water injection port 6 and a plurality of water outlets. A solenoid valve 7 is provided at 6, and a plurality of outer box water injection ports 8 corresponding to the water outlets are opened on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com