Contact member supporting hot plug and electric connector using same

A technology of electrical connectors and contacts, which is applied in the direction of contact parts, connections, parts of connection devices, etc., and can solve problems such as burning out contact reeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

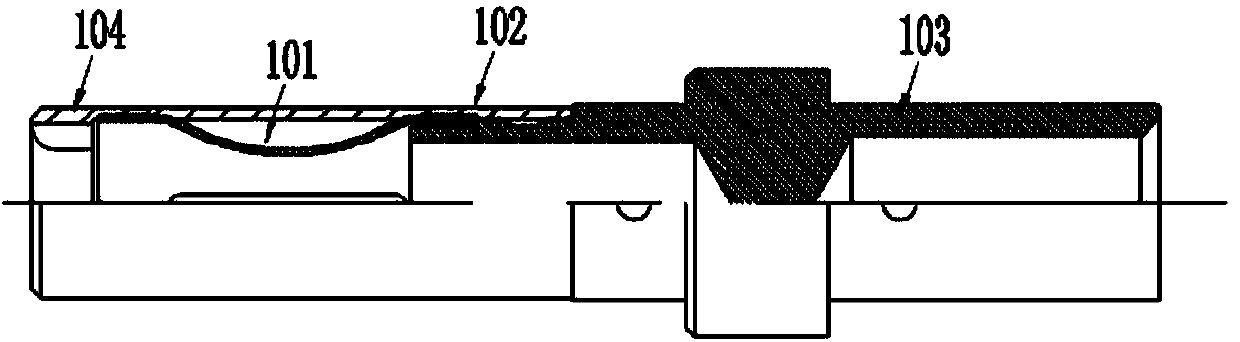

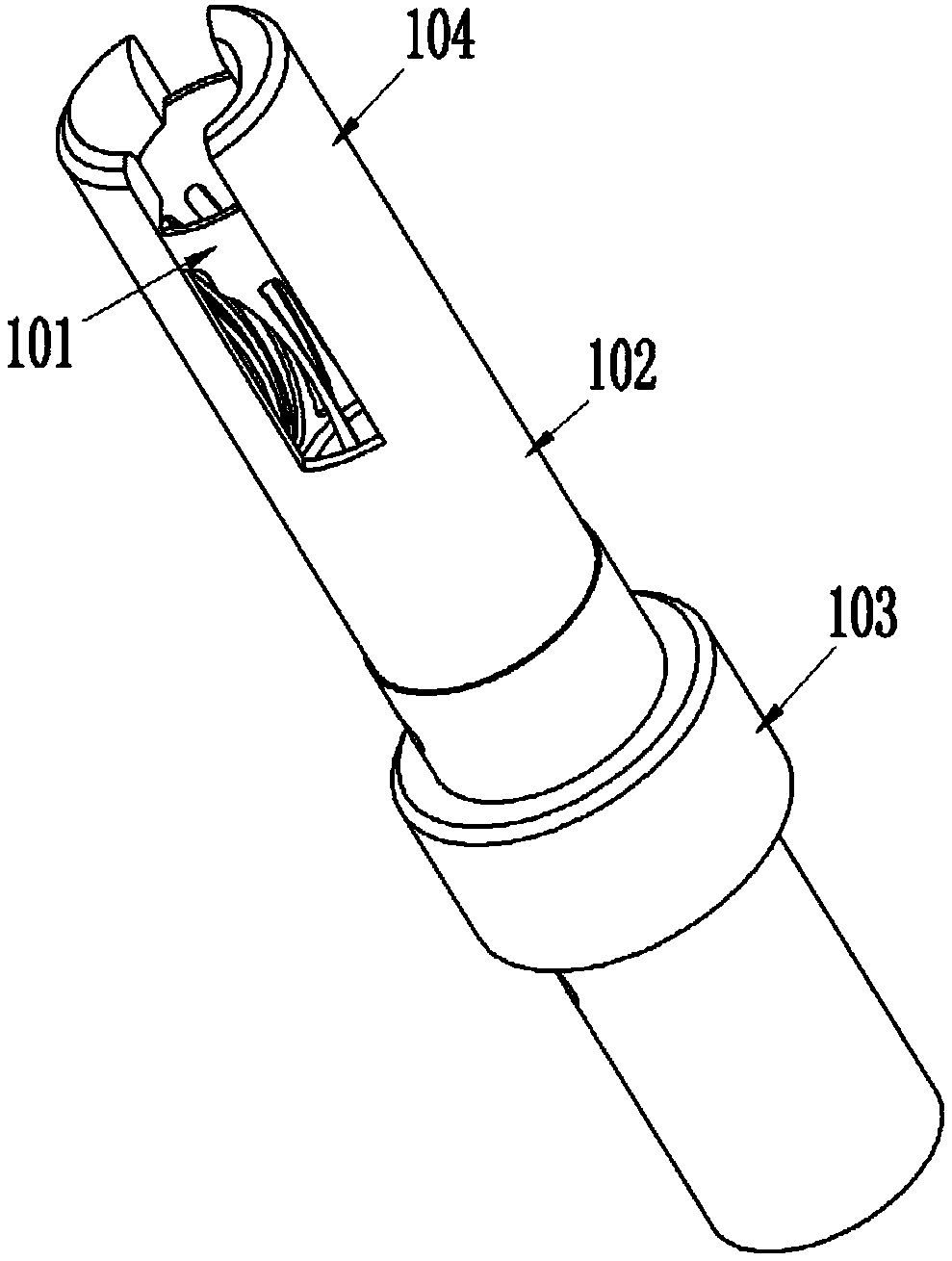

[0020] Embodiments of contacts that support hot swapping, such as Figure 1-2 As shown, the front end of the contact piece is the plug-in end, which includes a female sleeve and a contact spring 101 disposed in the female sleeve.

[0021] The female sleeve includes a front sleeve 102 and a rear sleeve 103 which are fixedly connected together. The front sleeve 102 is made of an arc-extinguishing material, specifically Be material, and its front part is provided with a contact structure for electrical contact with an adapter contact. The structure is located in front of the contact spring 101. In this embodiment, the contact structure is specifically composed of two cantilever-type elastic contact fingers 104 arranged at the front end of the front cover 102, wherein the elastic contact fingers 104 are formed through the front cover 102. The front end of each elastic contact finger 104 is formed after splitting grooves, and each elastic contact finger 104 is provided with a conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com