Material transportation and weighing integrated inspection system

A technology for inspection systems and materials, used in transportation and packaging, weighing, conveyors, etc., can solve the problems of cumbersome blanking operations and affect production efficiency, achieve light weight overall, improve production efficiency, and reduce left and right shaking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-7 The application is described in further detail.

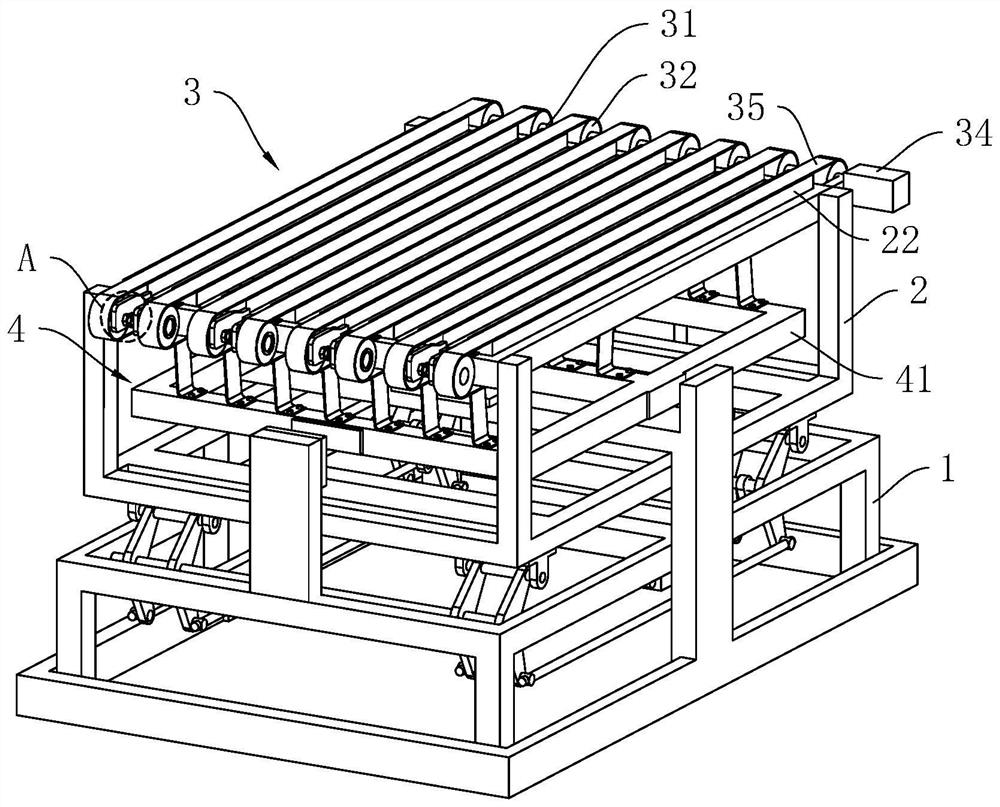

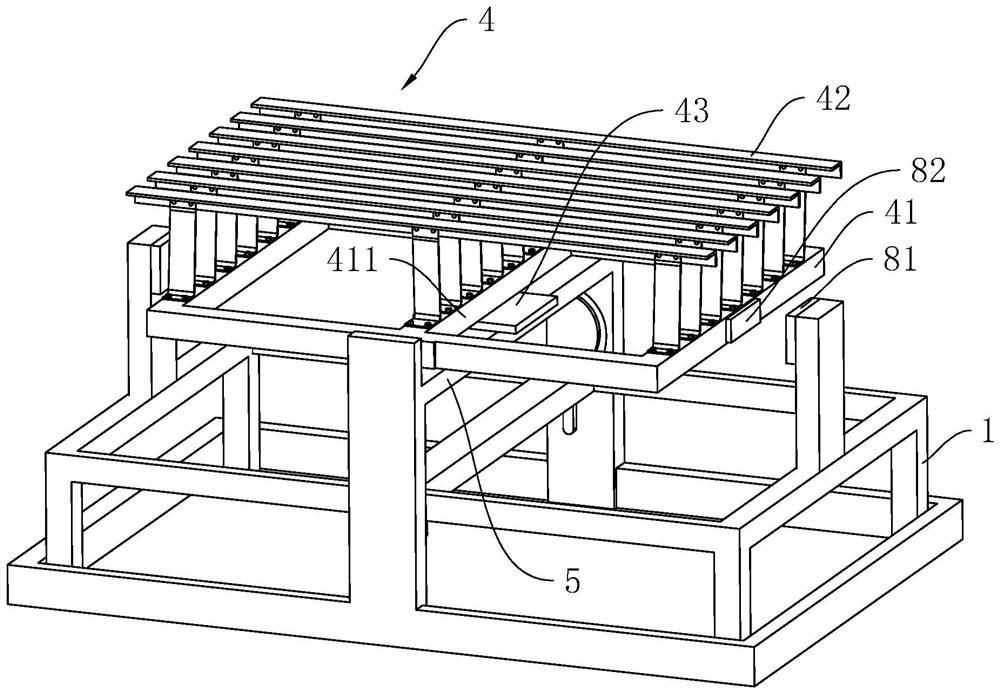

[0037] The embodiment of this application discloses an integrated inspection system for material transportation and weighing. figure 1 , the material transportation and weighing integrated inspection system includes a frame body 1 , an installation frame 2 , a transport mechanism 3 and a weighing mechanism 4 .

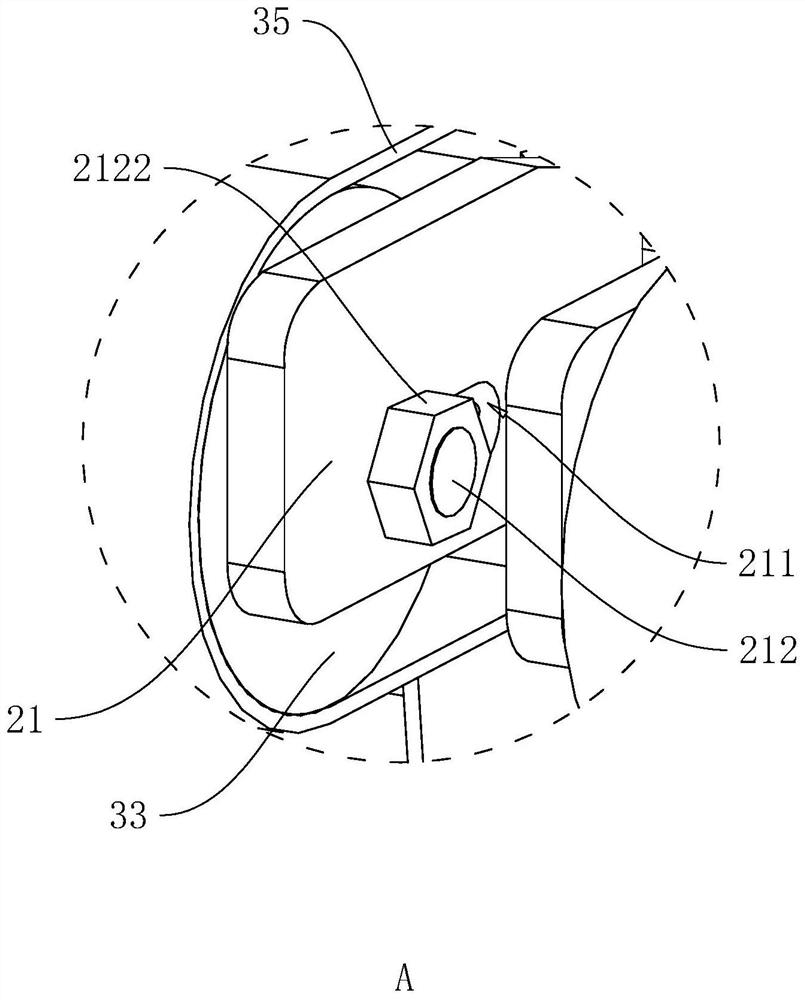

[0038] The installation frame 2 is arranged on the frame body 1 , and the transport mechanism 3 is arranged on the top of the installation frame 2 . The transport mechanism 3 includes several conveyor belts 35 arranged at intervals along the width direction of the installation frame 2 and a drive assembly for driving the conveyor belt 35 to run. The drive assembly includes a driving shaft 31 , a driving roller 32 , a driven roller 33 and a driving member. The driving shaft 31 is located at one end of the top of the mounting frame 2 along the length direction. The driving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com