Proton exchange membrane fuel cell low-temperature cold start box capable of realizing uniform heating and control method thereof

A proton exchange membrane and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problem of unimproved stack temperature uniformity, inability of reactants to fully react, and long time required for cold start To achieve the effect of improving battery temperature consistency, shortening cold start time, and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

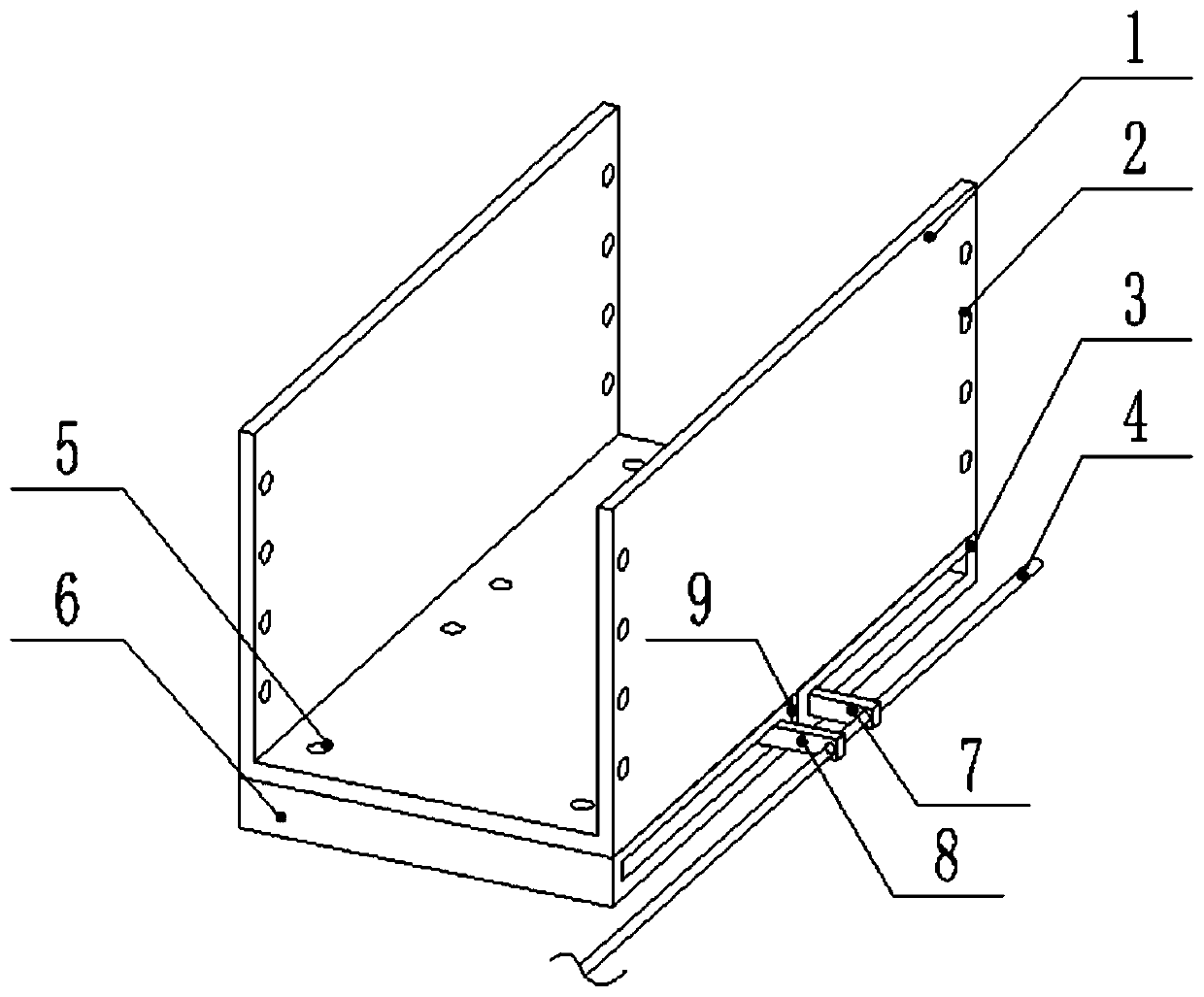

[0035] The embodiment of the present invention discloses a low-temperature cold-start box of a proton exchange membrane fuel cell that realizes uniform heating and a control method thereof, which is used for low-temperature start-up of a proton exchange membrane fuel cell, and can ensure that the fuel cell starts quickly in a low-temperature environment, and To achieve uniform heating of the stack.

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

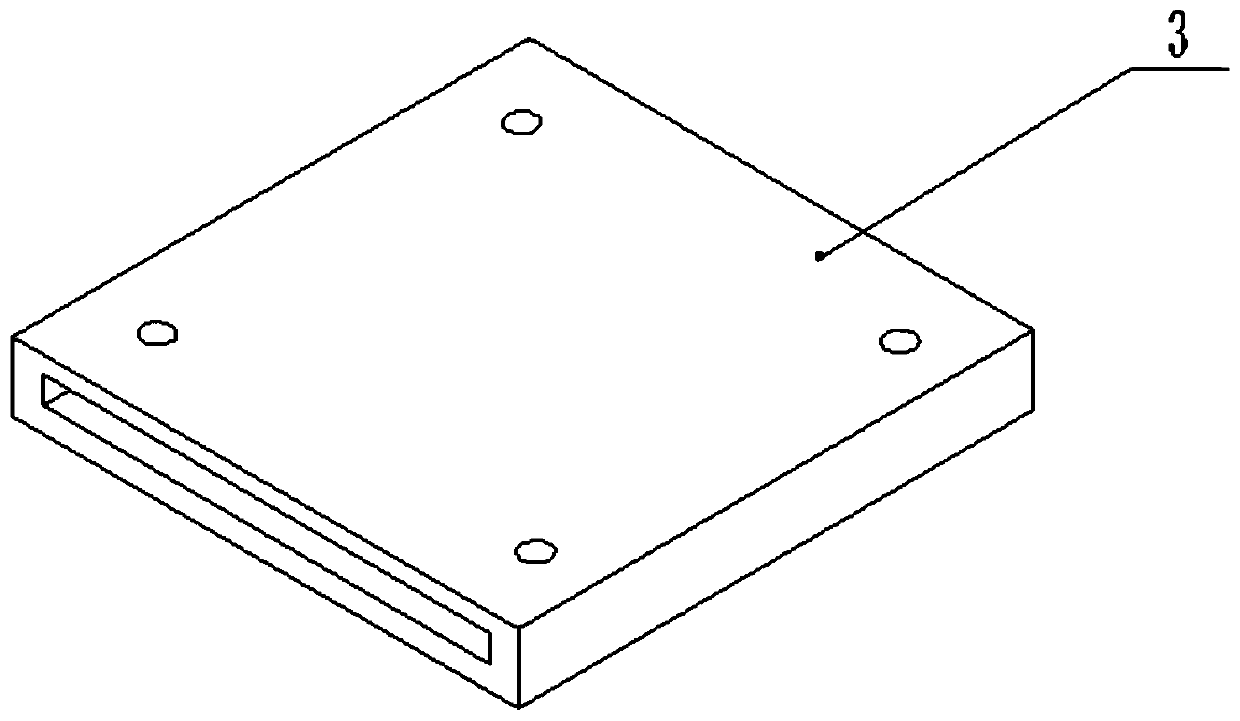

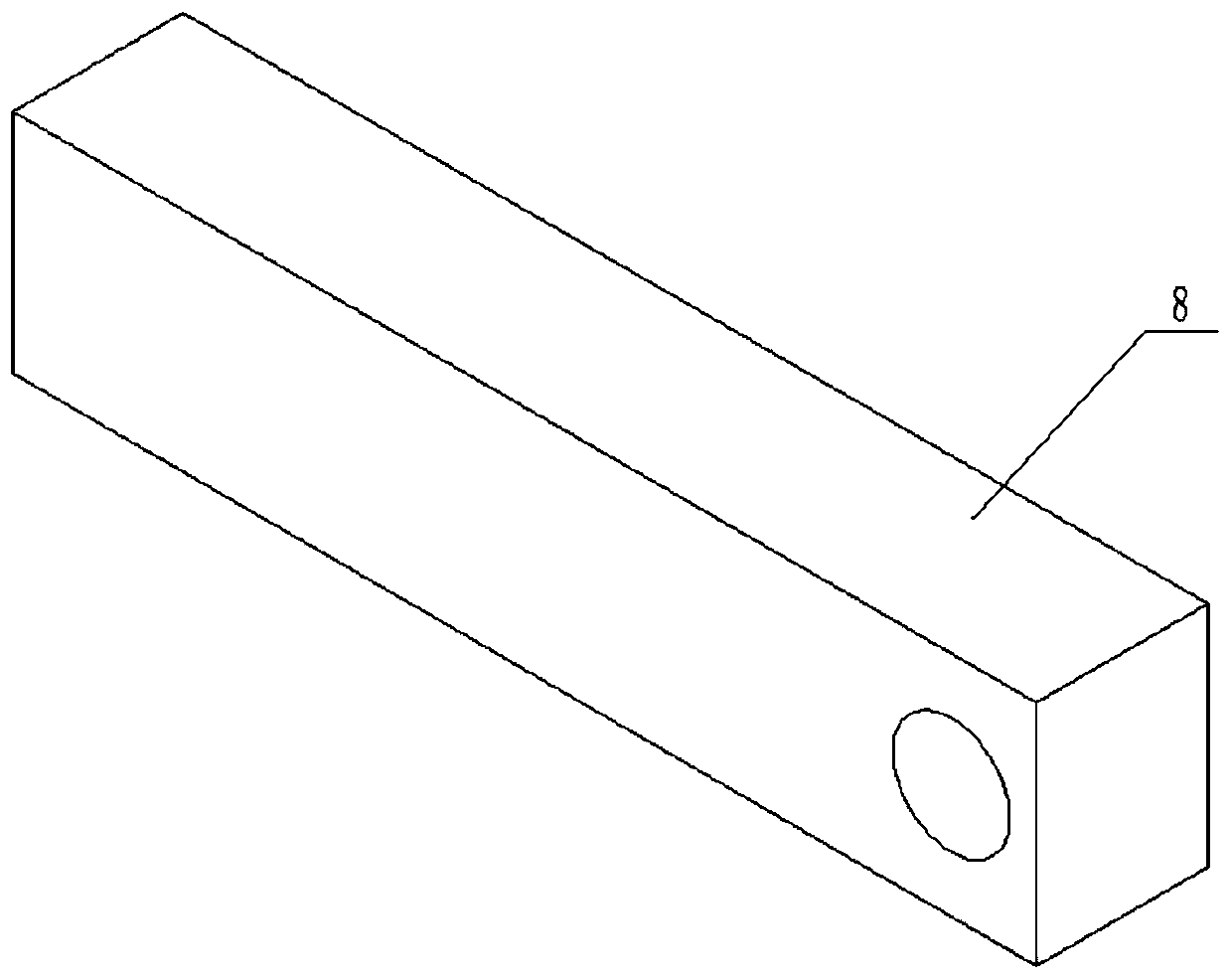

[0037] Such as figure 1 , figure 2 , image 3 As shown, a proton exchange membrane fuel cell low-temperature cold-start box capable of uniform heating and a control method thereof according to the present invention include: stack support box 1, heating resistance board A3, heating resistance board B6, movable Electrode A7, movable electrode B8, threaded rod 4, silicone ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com