Electromagnetic heating static shaft shoulder friction stir welding mechanism and method

A friction stir welding and electromagnetic heating coil technology, applied in non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of current dispersion, difficulty in meeting the requirements of consistent weld performance, and uneven heat distribution of weld workpieces. , to achieve consistent performance, obvious heating effect, and avoid uneven heating of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

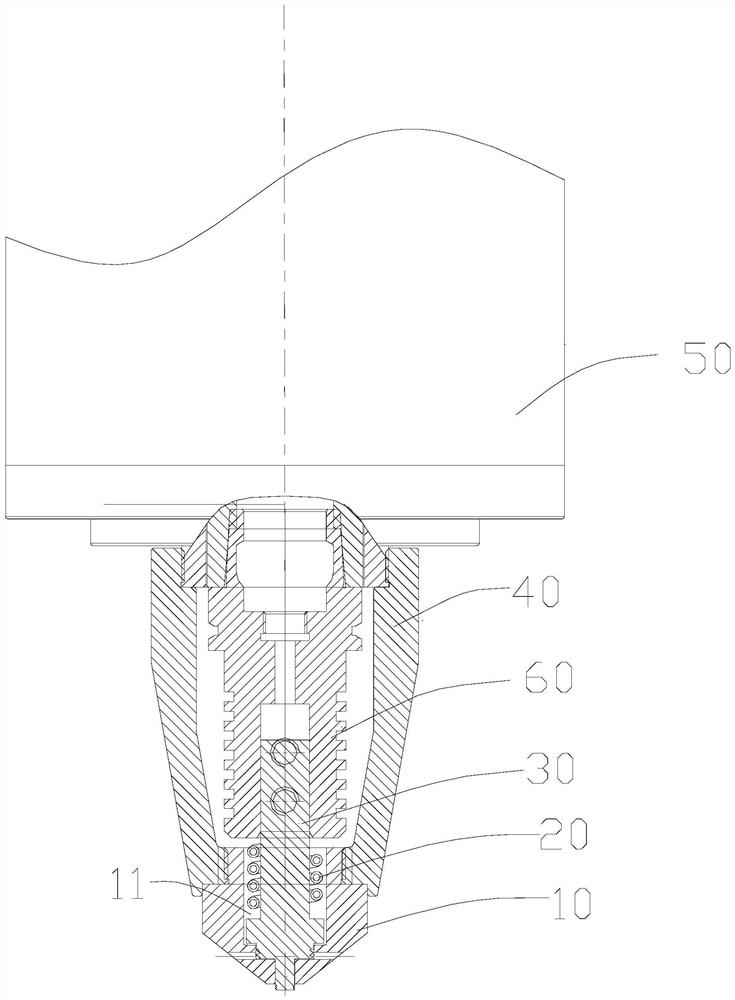

[0024] like figure 1 As shown, the electromagnetic heating static shaft shoulder friction stir welding mechanism includes a static shaft shoulder 10, an electromagnetic heating coil 20 and a thermally conductive stirring needle 30; the static shaft shoulder 10 has a accommodating cavity 11; inside, and the lower end of the stirring needle 30 protrudes out of the lower end of the static shaft shoulder 10; the electromagnetic heating coil 20 is arranged in the accommodating cavity 11 and is fixedly connected with the static shaft shoulder 10; the electromagnetic heating coil 20 is wound around the stirring needle 30, and the electromagnetic heating coil After the heating coil 20 is energized, the stirring needle 30 can be heated.

[0025] On the basis of the above structure, when the electromagnetic heating static shoulder friction stir welding mechanism is used, the parts to be welded of the first welding workpiece and the second welding workpiece are attached to each other, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com