Working defrosting method of variable-frequency air-conditioner

A frequency conversion air conditioner, working technology, applied in the direction of heating and ventilation control system, damage protection, refrigeration components, etc., can solve the problems of uncomfortable experience, user uncomfortable experience, affecting service life, etc., to reduce the number of maintenance personnel, heating Better effect, better experience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation Way.

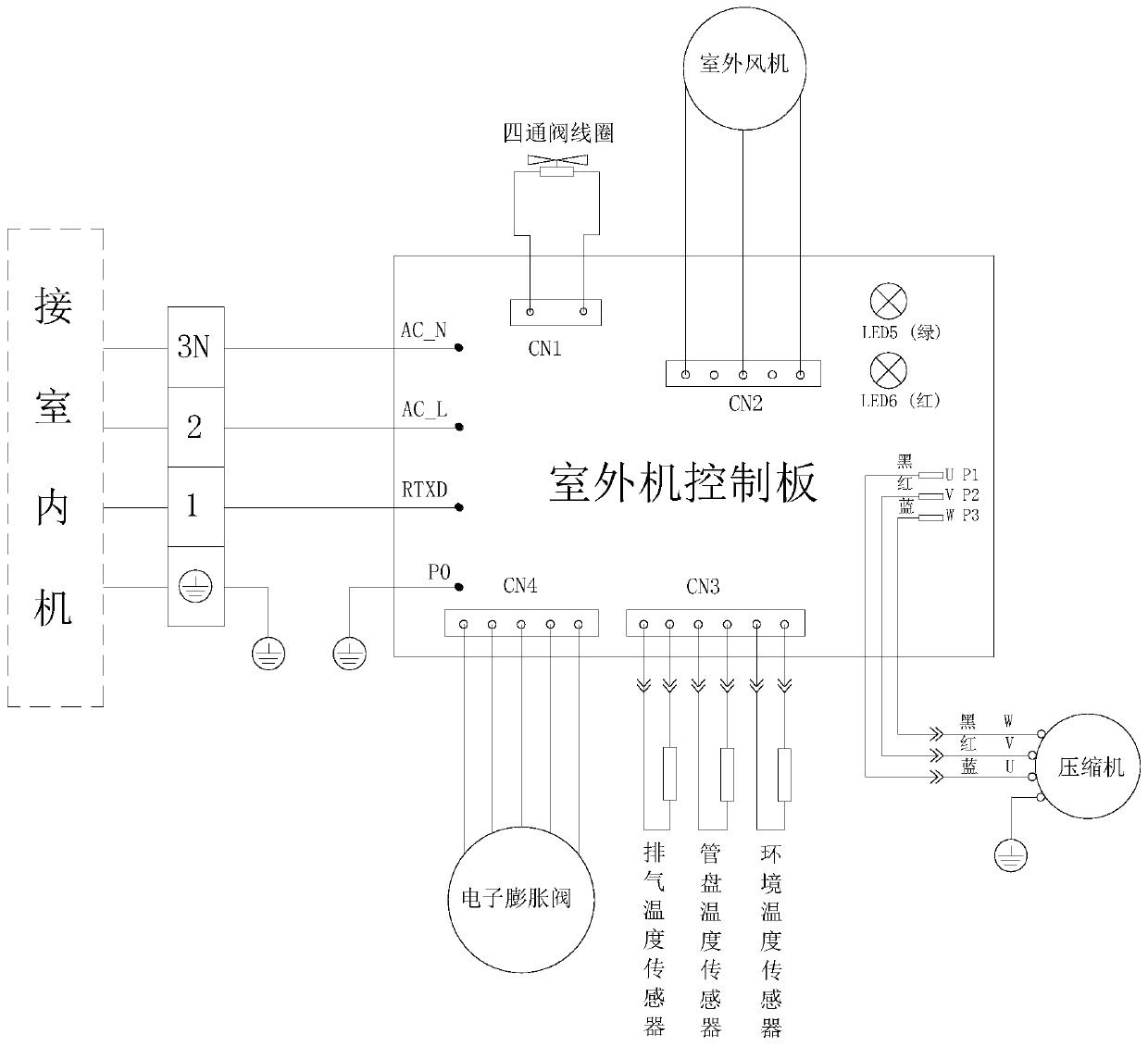

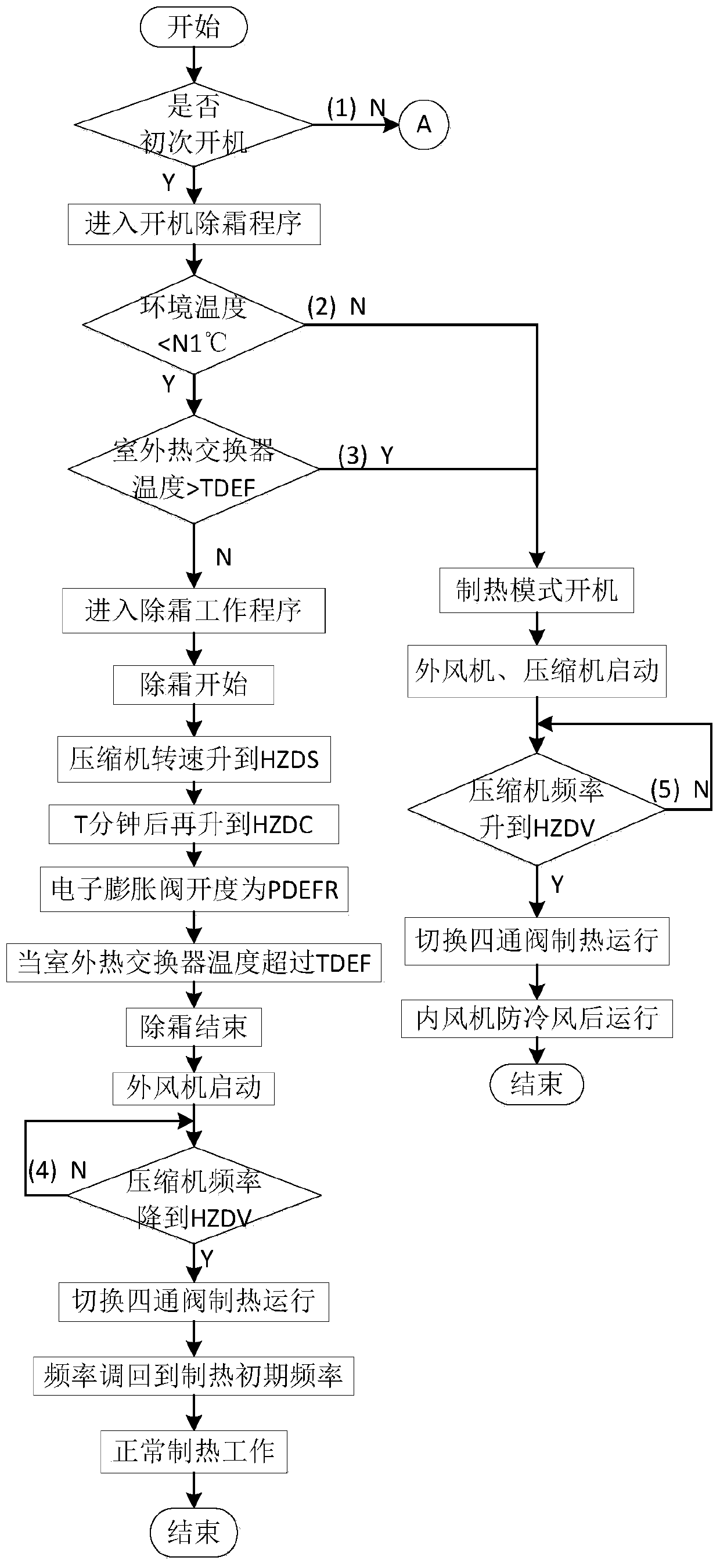

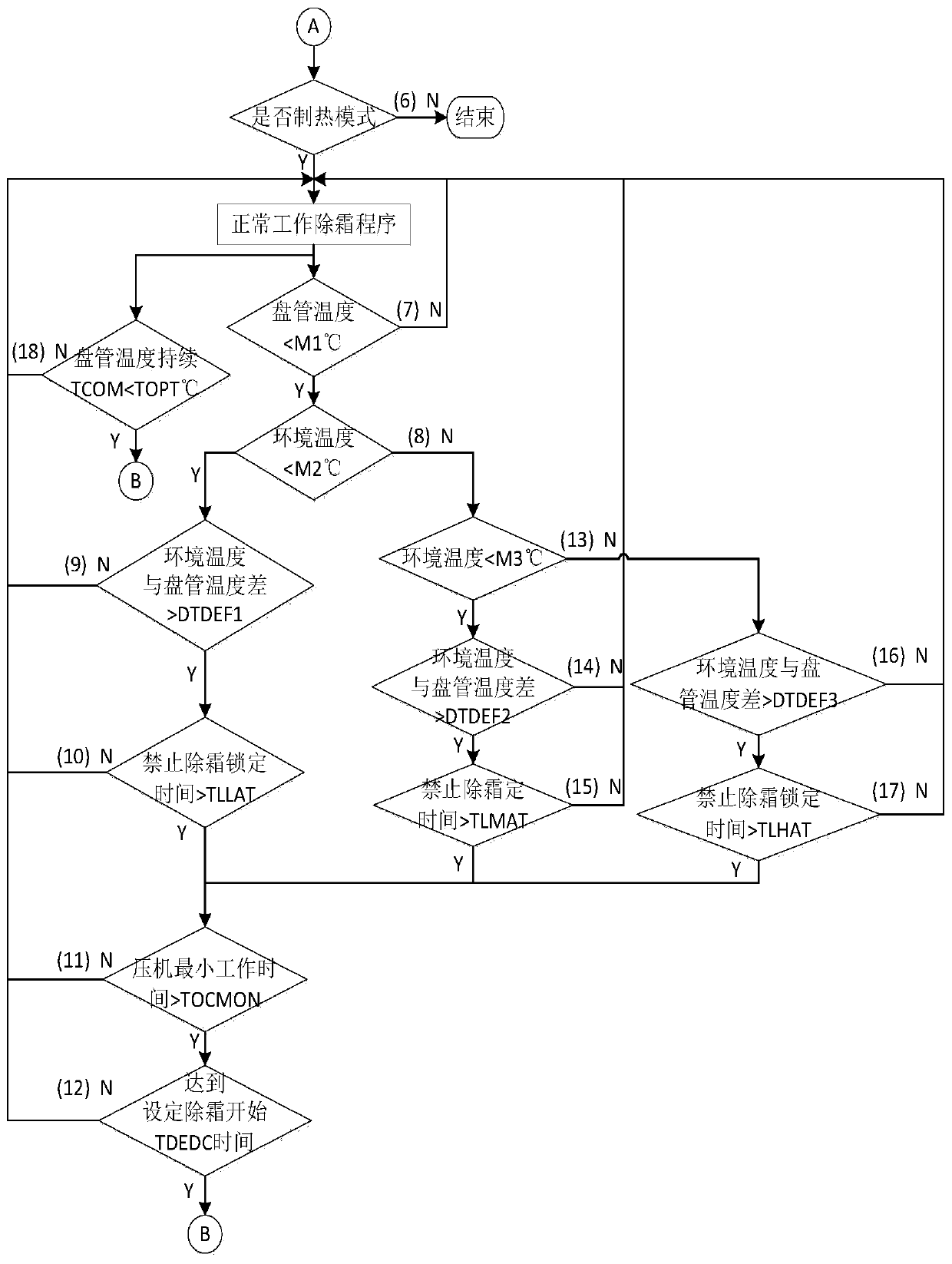

[0032] Air conditioner outdoor panels such as figure 1 mode wiring, the program starts, see figure 2, First judge (1) Is the air conditioner turned on for the first time? If it is the first start-up, enter the start-up defrosting procedure; if the result is no, it means that the air conditioner has been running for a period of time, then transfer to A to execute the judgment (6); judgment (1) is the precondition for the start-up defrosting process, if it is not the first start-up , it is not necessary to perform power-on defrosting detection. (2) Whether the outdoor ambient temperature is lower than N1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com